How does through-hole technology differ from surface mount technology in PCB assembly?

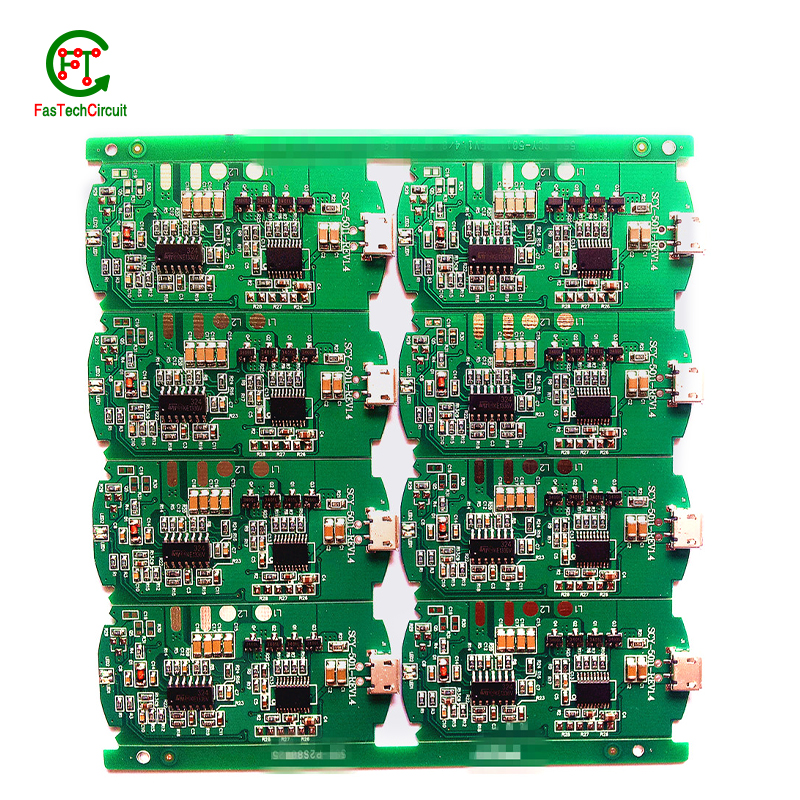

The assembly process can be done manually by skilled technicians or through automated machinery. Modern PCB assembly techniques use surface mount components, where the components are placed on the surface of the PCB instead of being inserted through holes. This technique allows for smaller, lighter, and more complex circuit boards to be produced, making it more suitable for today's advanced technology.

PCB assembly is a critical step in the production of various electronic devices, including computers, smartphones, medical devices, and many more. With the increasing demand for electronic products, the PCB assembly industry continues to evolve and innovate, ensuring the efficient and effective production of high-quality electronic devices.

We understand the importance of achieving a high ROI for your project, which is why we offer cost-effective PCB assembly solutions. Our streamlined processes, efficient manufacturing, and strategic sourcing of materials help us to keep our costs affordable without compromising on quality. This way, you can rest assured that you are getting the best value for your investment with our assembly services.

Whether you need a small batch or a large-scale production run, our flexible PCB assembly services have got you covered. We have the capability to handle both small and large volume orders efficiently and effectively. Our flexible assembly process allows us to adjust to your production needs, ensuring consistency, quality, and cost-effectiveness regardless of the order size.

PCB assembly is the process of preparing, placing, and soldering various electronic components onto a printed circuit board (PCB). This involves creating a complete and functional electronic system by interconnecting different components such as capacitors, resistors, integrated circuits, and connectors on a PCB. The assembly process requires precise and accurate placement of components, careful soldering techniques, and thorough quality control measures to ensure proper functioning of the final product. In this introduction, we will discuss the various stages of PCB assembly and the importance of each step in creating a reliable and efficient electronic system.

2.Can a PCB assembly be repaired if it gets damaged?

3.How does through-hole technology differ from surface mount technology in PCB assembly?

4.What are the main challenges faced in PCB assembly process?

5.What steps are taken to ensure compatibility between the PCB assembly and other components?

6.What materials are typically used in a PCB assembly?

7.How are PCB assemblies manufactured and assembled?

8.What is the role of surface mount technology in PCB assembly?

9.What is a PCB assembly and how does it differ from traditional circuit assembly?

10.How important is quality control in the production of PCB assemblies?

1.How has automation and robotics impacted the PCB assembly industry?

1. Increased Efficiency and Productivity: Automation and robotics have greatly increased the speed and accuracy of PCB assembly processes. This has led to a significant increase in efficiency and productivity, as machines can work faster and longer without breaks or errors.

2. Improved Quality Control: With automation and robotics, the chances of human error in PCB assembly are greatly reduced. This results in higher quality products and fewer defects, leading to improved customer satisfaction and reduced costs for rework or repairs.

3. Cost Savings: Automation and robotics have reduced the need for manual labor in PCB assembly, resulting in cost savings for manufacturers. This is especially beneficial for high-volume production, as machines can work continuously without the need for breaks or overtime pay.

4. Flexibility and Customization: Automated PCB assembly machines can be programmed to handle a wide range of components and PCB designs, making it easier to produce customized or complex PCBs. This flexibility allows manufacturers to meet the demands of a diverse customer base.

5. Reduced Lead Times: With automation and robotics, the time required for PCB assembly is significantly reduced. This allows manufacturers to meet tight deadlines and deliver products to customers faster, improving their competitiveness in the market.

6. Safer Working Environment: PCB assembly involves handling hazardous materials and working with high temperatures and precision tools. Automation and robotics have reduced the need for human involvement in these processes, making the working environment safer for employees.

7. Integration with Industry 4.0: Automation and robotics have enabled the integration of PCB assembly processes with Industry 4.0 technologies such as data analytics, artificial intelligence, and the Internet of Things. This allows for real-time monitoring and optimization of production processes, leading to further improvements in efficiency and quality.

2.Can a PCB assembly be repaired if it gets damaged?

Yes, a PCB assembly can be repaired if it gets damaged. The extent of the damage and the availability of replacement components will determine the feasibility and cost of the repair. In some cases, it may be more cost-effective to replace the entire PCB assembly rather than attempting to repair it. However, if the damage is minor and the necessary components are readily available, a skilled technician can repair the PCB assembly.

3.How does through-hole technology differ from surface mount technology in PCB assembly?

Through-hole technology and surface mount technology are two different methods of assembling electronic components onto a printed circuit board (PCB). The main difference between the two is the way in which the components are mounted onto the board.

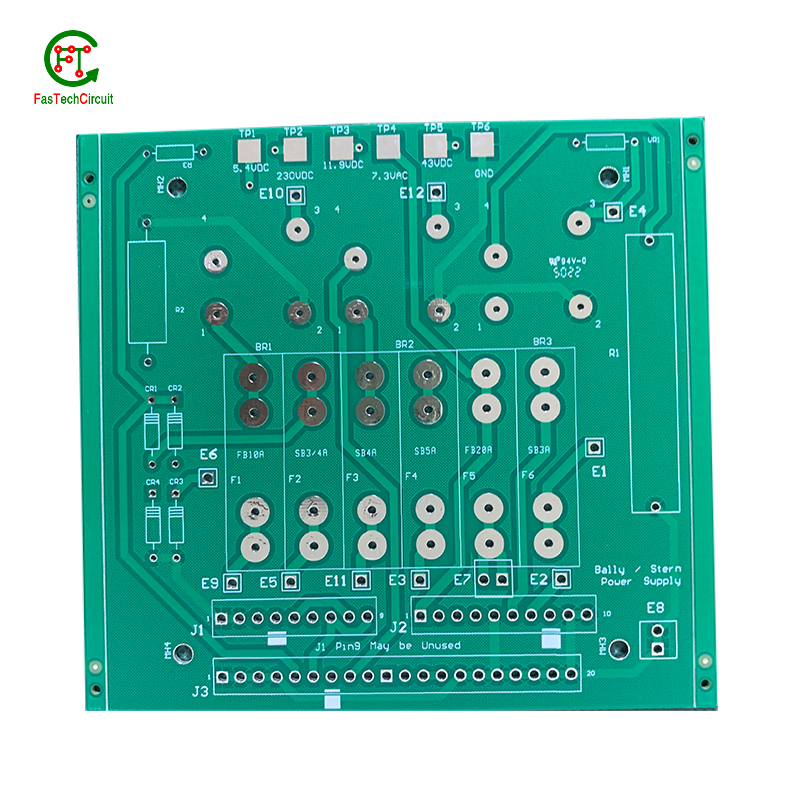

Through-hole technology involves drilling holes into the PCB and inserting the leads of the components through the holes. The leads are then soldered onto the opposite side of the board to create a strong mechanical and electrical connection. This method is typically used for larger, heavier components such as resistors, capacitors, and connectors.

Surface mount technology, on the other hand, does not require holes to be drilled into the PCB. Instead, the components are mounted directly onto the surface of the board using solder paste and a reflow oven. This method is more suitable for smaller, lighter components such as integrated circuits, transistors, and diodes.

Some other key differences between through-hole and surface mount technology include:

1. Size and Space: Through-hole components take up more space on the PCB due to the need for holes and leads, while surface mount components are smaller and can be placed closer together, allowing for more compact designs.

2. Cost: Through-hole components are generally less expensive than surface mount components, but the cost of drilling holes and the additional labor involved in through-hole assembly can make it more expensive overall.

3. Speed: Surface mount technology is faster and more efficient than through-hole technology, as it does not require manual insertion and soldering of components.

4. Reliability: Through-hole components have a stronger mechanical connection to the PCB, making them more reliable in high-stress environments. However, surface mount components are less prone to damage during handling and shipping.

In summary, through-hole technology is better suited for larger, heavier components and applications where reliability is crucial, while surface mount technology is more suitable for smaller, lighter components and applications where speed and efficiency are important. Many modern PCBs use a combination of both through-hole and surface mount technology to take advantage of the benefits of each method.

4.What are the main challenges faced in PCB assembly process?

1. Component Placement: One of the main challenges in PCB assembly is accurately placing the components on the board. This requires precision and can be time-consuming, especially for complex designs with a large number of components.

2. Soldering: Soldering is a critical step in the PCB assembly process and requires skilled technicians to ensure proper connections and avoid defects such as cold joints or solder bridges.

3. Component Compatibility: Ensuring that all components are compatible with each other and the PCB design is crucial. Any mismatch can lead to malfunctioning or failure of the circuit.

4. Quality Control: Maintaining quality control throughout the assembly process is essential to ensure the final product meets the required standards. This includes checking for defects, proper component placement, and soldering.

5. Miniaturization: With the increasing demand for smaller and more compact electronic devices, PCB assembly is becoming more challenging due to the need for smaller components and tighter spacing between them.

6. Thermal Management: As electronic devices become more powerful, managing heat dissipation becomes a significant challenge in PCB assembly. Improper thermal management can lead to component failure and reduced lifespan of the device.

7. Design Changes: Changes in the PCB design during the assembly process can cause delays and increase costs. It is essential to have a well-defined and finalized design before starting the assembly process.

8. Lead-Free Soldering: The use of lead-free soldering has become a standard in many countries due to environmental concerns. However, lead-free soldering requires higher temperatures and can be more challenging to work with, leading to increased defects.

9. Component Counterfeiting: The rise of counterfeit electronic components in the market poses a significant challenge in PCB assembly. These components can be of poor quality and lead to product failure, making it crucial to source components from reliable suppliers.

10. Cost and Time Constraints: PCB assembly can be a time-consuming and costly process, especially for complex designs. Meeting tight deadlines and keeping costs under control can be a significant challenge for manufacturers.

5.What steps are taken to ensure compatibility between the PCB assembly and other components?

1. Design review: The first step is to conduct a thorough design review of the PCB assembly and other components to identify any potential compatibility issues. This involves checking the specifications, dimensions, and electrical requirements of each component.

2. Component selection: During the design phase, components are carefully selected based on their compatibility with the PCB assembly. This includes considering factors such as voltage, current, temperature range, and physical dimensions.

3. Prototyping: Before mass production, a prototype of the PCB assembly is usually created to test its compatibility with other components. This allows any issues to be identified and resolved before production begins.

4. Simulation and testing: Simulation software can be used to simulate the behavior of the PCB assembly and other components in a virtual environment. This helps to identify any potential issues and allows for adjustments to be made before production.

5. Compliance with standards: The PCB assembly and other components must comply with industry standards and regulations to ensure compatibility. This includes standards for electrical, mechanical, and environmental requirements.

6. Communication with suppliers: It is important to communicate with the suppliers of the PCB assembly and other components to ensure that they are aware of the compatibility requirements. This allows for any potential issues to be addressed before production.

7. Quality control: During the production process, quality control measures are implemented to ensure that the PCB assembly and other components are manufactured to the required specifications. This includes testing for compatibility and functionality.

8. Assembly process: The assembly process must be carefully planned and executed to ensure that the PCB assembly and other components are assembled correctly and in a way that ensures compatibility.

9. Post-assembly testing: After the PCB assembly and other components are assembled, they undergo thorough testing to ensure that they are functioning correctly and are compatible with each other.

10. Ongoing monitoring: Even after the PCB assembly and other components are assembled and tested, ongoing monitoring is important to ensure that they continue to function correctly and remain compatible with each other.

6.What materials are typically used in a PCB assembly?

1. Printed Circuit Board (PCB): This is the base material on which all the components are mounted. It is usually made of fiberglass or composite epoxy materials.

2. Copper Foil: This is used to create the conductive traces on the PCB. It is usually laminated onto the surface of the PCB.

3. Solder Mask: This is a layer of polymer that is applied over the copper traces to protect them from oxidation and to prevent short circuits.

4. Solder Paste: This is a mixture of flux and solder particles that is used to attach the components to the PCB.

5. Electronic Components: These include resistors, capacitors, diodes, transistors, integrated circuits, and other electronic devices that are mounted on the PCB.

6. Solder: This is used to create a permanent connection between the components and the PCB.

7. Adhesives: These are used to secure components that cannot be soldered, such as surface mount components.

8. Flux: This is a chemical substance that is used to clean and prepare the surfaces of the PCB and components for soldering.

9. Insulating Materials: These are used to insulate and protect the PCB from external factors such as moisture, heat, and mechanical stress.

10. Connectors: These are used to connect the PCB to other electronic devices or systems.

11. Test Points: These are small metal pads on the PCB that are used for testing and troubleshooting during the assembly process.

12. Thermal Management Materials: These include heat sinks, thermal pads, and thermal paste, which are used to dissipate heat from components that generate a lot of heat.

13. Enclosures: These are used to protect the PCB and its components from external factors and to provide a physical barrier for safety purposes.

14. Labels and Markings: These are used to identify components, trace connections, and provide instructions for assembly and maintenance.

7.How are PCB assemblies manufactured and assembled?

1. Design and Layout: The first step in manufacturing a PCB assembly is to design and layout the circuit board. This involves creating a schematic diagram of the circuit and then using specialized software to design the layout of the components on the board.

2. PCB Fabrication: Once the design is finalized, the PCB is fabricated. This involves printing the circuit pattern onto a copper-clad board using a photosensitive process. The board is then etched to remove the unwanted copper and create the circuit traces.

3. Component Procurement: The next step is to procure all the necessary components for the assembly. This includes electronic components such as resistors, capacitors, integrated circuits, and connectors.

4. Solder Paste Application: Solder paste is a mixture of tiny solder particles and flux. It is applied to the PCB using a stencil, which ensures precise placement of the paste on the board.

5. Pick and Place: Once the solder paste is applied, the components are placed on the board using a pick and place machine. This machine uses a vacuum nozzle to pick up the components and place them on the correct location on the board.

6. Reflow Soldering: After the components are placed, the board is passed through a reflow oven. The oven heats the board to a specific temperature, causing the solder paste to melt and create a strong bond between the components and the board.

7. Inspection: Once the board has been soldered, it goes through a visual inspection to check for any defects or missing components. Automated optical inspection (AOI) machines are often used for this process.

8. Testing: After inspection, the board is tested to ensure that it functions correctly. This can include functional testing, in-circuit testing, and boundary scan testing.

9. Final Assembly: Once the PCB assembly is tested and approved, it is ready for final assembly. This can include adding any additional components, such as connectors or heat sinks, and mounting the board into its final enclosure.

10. Quality Control: The final step is quality control, where the assembled PCB is checked for any defects or issues. This ensures that the final product meets the required specifications and is ready for use.

8.What is the role of surface mount technology in PCB assembly?

Surface mount technology (SMT) is a method of electronic component placement on a printed circuit board (PCB) that involves directly mounting components onto the surface of the board. This is in contrast to through-hole technology, where components are inserted into holes drilled into the board.

The role of SMT in PCB assembly is to provide a more efficient and cost-effective method of assembling electronic circuits. Some of the key benefits of SMT include:

1. Higher component density: SMT allows for smaller and more compact designs, as components can be placed closer together on the surface of the board.

2. Faster assembly: SMT components can be placed and soldered onto the board using automated machines, which speeds up the assembly process and reduces the need for manual labor.

3. Cost-effective: SMT reduces the amount of material and labor required for PCB assembly, making it a more cost-effective option for high-volume production.

4. Improved performance: SMT components have shorter lead lengths, which reduces the parasitic effects and improves the overall performance of the circuit.

5. Compatibility with modern components: Many modern electronic components are only available in surface mount packages, making SMT essential for incorporating these components into PCB designs.

Overall, the role of SMT in PCB assembly is to provide a more efficient, cost-effective, and reliable method of assembling electronic circuits. It has become the standard method of PCB assembly in the electronics industry and continues to evolve with advancements in technology.

9.What is a PCB assembly and how does it differ from traditional circuit assembly?

A PCB (Printed Circuit Board) assembly is the process of attaching electronic components to a printed circuit board in order to create a functional electronic circuit. This process involves soldering or other methods of attaching the components to the board, as well as testing and inspection to ensure proper functionality.

The main difference between PCB assembly and traditional circuit assembly is the use of a printed circuit board. In traditional circuit assembly, the components are typically connected by wires or other means on a non-conductive surface, such as a breadboard. This method is often used for prototyping and testing purposes, but is not suitable for mass production.

PCB assembly, on the other hand, allows for a more efficient and reliable production process. The components are mounted directly onto the board, which is designed with specific traces and pads to connect the components and create a complete circuit. This method is commonly used in the manufacturing of electronic devices, as it allows for faster production and higher quality control.

Overall, PCB assembly offers a more streamlined and cost-effective approach to circuit assembly, making it the preferred method for mass production of electronic devices.

10.How important is quality control in the production of PCB assemblies?

Quality control is extremely important in the production of PCB assemblies. PCB assemblies are used in a wide range of electronic devices, from simple household appliances to complex medical equipment. These devices often have critical functions and any defects in the PCB assembly can lead to malfunctions or failures, which can have serious consequences.

Quality control ensures that the PCB assemblies meet the required specifications and standards, and are free from defects. This involves rigorous testing and inspection at various stages of the production process, from the initial design to the final assembly. Quality control also involves identifying and addressing any issues or defects that may arise during production, to ensure that the final product is of the highest quality.

In addition, quality control helps to prevent costly rework or recalls, which can have a significant impact on the production schedule and budget. It also helps to maintain the reputation of the manufacturer and build trust with customers, as they can be confident in the reliability and performance of the PCB assemblies.

Overall, quality control is crucial in the production of PCB assemblies to ensure that they meet the required standards and function properly, which ultimately leads to customer satisfaction and the success of the product.

RELATED NEWS

pcb board manufacturing How To Contact US

PCB from 1 to 30 layers, HDI, Heavy Copper, Rigid-flex board with "pcb board manufacturing One-Stop" service.