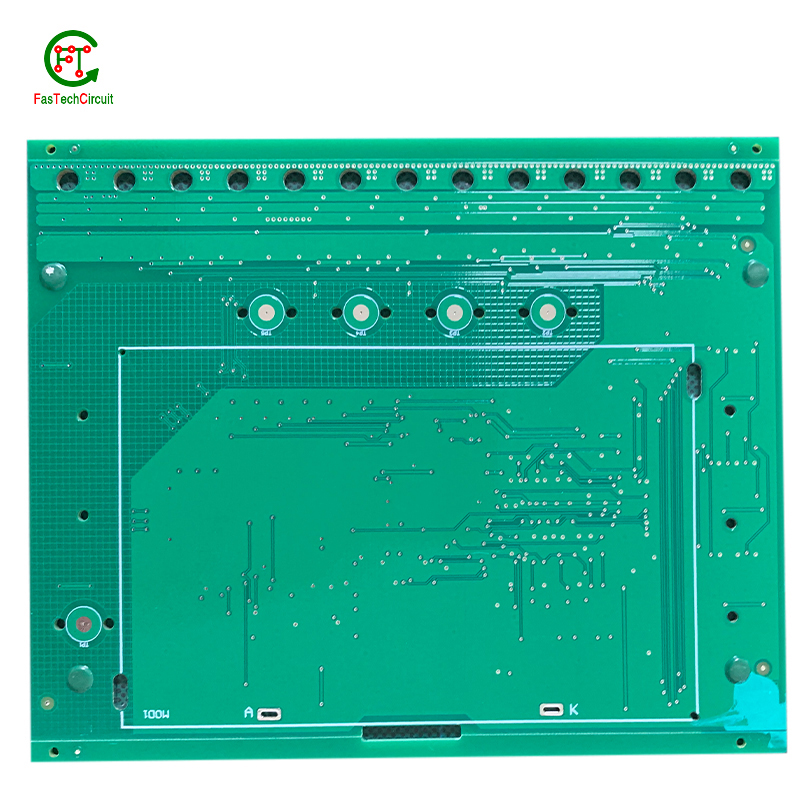

pcb board manufacturing

Which type of pcb board manufacturing is the most popular

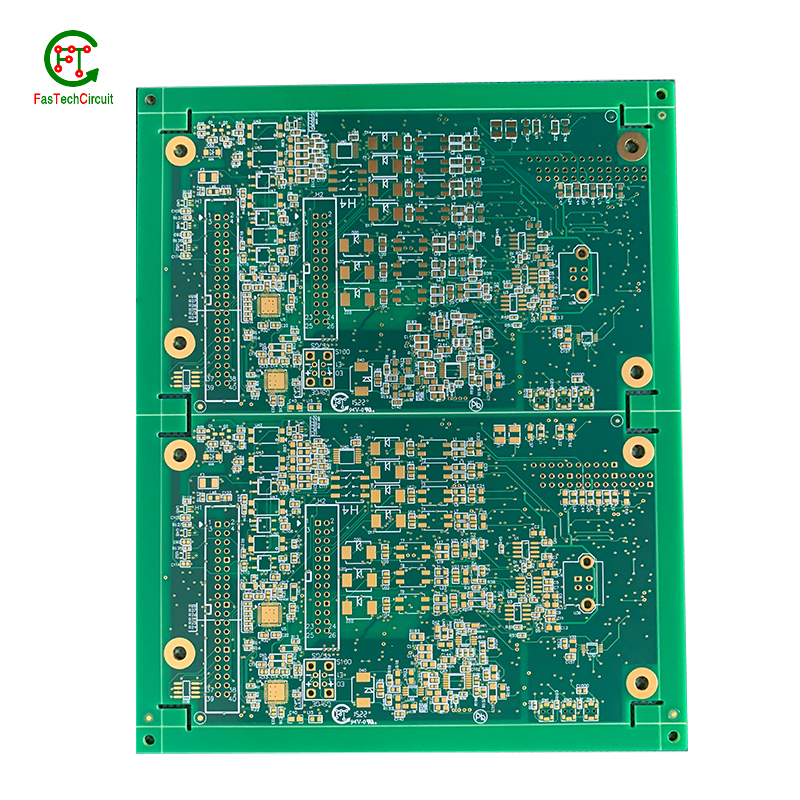

The most popular type of PCB board manufacturing is surface mount technology (SMT). SMT is a process in which components are placed directly onto the surface of a printed circuit board (PCB) and soldered in place. This type of manufacturing is popular because it is cost-effective, efficient, and allows for the production of high-density boards with a high degree of accuracy.PCB assembly

What kind of help does the pcb board manufacturing bring to human beings?

PCB board manufacturing helps to make the production of electronic devices more efficient and cost-effective. It also helps to reduce the amount of time and resources needed to create complex electronic components. PCB boards are used in a wide range of products, from computers and cell phones to medical devices and industrial equipment. By streamlining the production process, PCB board manufacturing helps to reduce the cost of these products and make them more accessible to consumers.

Where are the pcb board manufacturing concentrated in China?

The majority of PCB board manufacturing is concentrated in the Pearl River Delta region of China, which includes the cities of Shenzhen, Guangzhou, and Dongguan. Other major PCB manufacturing hubs in China include Shanghai, Suzhou, and Chengdu.

What materials are needed for pcb board manufacturing production

1. Copper Clad Laminate (CCL): This is the base material used to make a PCB. It is a thin sheet of copper foil bonded to an insulating substrate material such as fiberglass or paper-phenolic.

2. Solder Mask: This is a protective coating applied to the copper traces of a PCB to prevent short circuits and corrosion.

3. Silkscreen: This is a thin layer of ink printed on the PCB to indicate component placement and other information.

4. Drilling: This is the process of creating holes in the PCB for mounting components.

5. Plating: This is the process of coating the copper traces with a thin layer of metal such as tin or gold to improve electrical conductivity.

6. Etching: This is the process of removing unwanted copper from the PCB using a chemical solution.

7. Soldering: This is the process of attaching components to the PCB using a soldering iron.

Why do we need pcb board manufacturing?

PCB board manufacturing is essential for the production of electronic devices. PCBs, or printed circuit boards, are the backbone of any electronic device, providing the physical support and electrical connections necessary for the device to function. PCBs are made up of a number of layers of copper, plastic, and other materials, which are etched with a pattern of electrical pathways. This pattern is designed to provide the necessary electrical connections between the components of the device.

PCB board manufacturing is a complex process that requires precision and accuracy. The process begins with the design of the PCB, which is typically done using computer-aided design (CAD) software. Once the design is complete, the PCB is manufactured using a variety of processes, such as etching, drilling, and soldering. The components of the device are then mounted onto the PCB, and the device is tested to ensure that it is functioning properly.

PCB board manufacturing is an essential part of the production of electronic devices, as it provides the physical and electrical support necessary for the device to function. Without PCBs, electronic devices would not be able to function properly.

Overview of the historical development of pcb board manufacturing

The history of PCB board manufacturing dates back to the early 20th century. The first printed circuit boards were developed in the 1920s, when the first printed circuit boards were used in radios. In the 1930s, the first printed circuit boards were used in computers. In the 1940s, the first printed circuit boards were used in military applications. In the 1950s, the first printed circuit boards were used in consumer electronics. In the 1960s, the first printed circuit boards were used in industrial applications. In the 1970s, the first printed circuit boards were used in medical applications. In the 1980s, the first printed circuit boards were used in telecommunications. In the 1990s, the first printed circuit boards were used in automotive applications. In the 2000s, the first printed circuit boards were used in aerospace applications. Today, printed circuit boards are used in a wide variety of applications, from consumer electronics to industrial applications.

In which city was the earliest pcb board manufacturing manufacturer in China established?

The earliest PCB board manufacturing manufacturer in China was established in Shenzhen, Guangdong Province.

How to choose a pcb board manufacturing manufacturers with good quality for purchasing?

1. Research the company’s reputation: Check online reviews and customer feedback to get an idea of the company’s reputation.

2. Ask for samples: Ask the company to provide samples of their work so you can evaluate the quality of their products.

3. Check certifications: Make sure the company is certified by the relevant industry standards.

4. Compare prices: Compare the prices of different manufacturers to get the best deal.

5. Ask for references: Ask the company for references from previous customers to get an idea of their customer service.

6. Check turnaround time: Make sure the company can meet your deadlines.

7. Consider the location: Consider the location of the manufacturer to ensure timely delivery.

Share a few influential international pcb board manufacturing exhibitions

1. NEPCON China: This is the largest electronics manufacturing exhibition in Asia, held annually in Shanghai. It showcases the latest in PCB manufacturing technology, materials, and equipment.

2. Productronica: This is the world’s leading trade fair for electronics development and production, held annually in Munich, Germany. It features the latest in PCB manufacturing technology, materials, and equipment.

3. IPC APEX EXPO: This is the largest electronics manufacturing exhibition in the United States, held annually in San Diego, California. It showcases the latest in PCB manufacturing technology, materials, and equipment.

4. SMTA International: This is the world’s largest electronics assembly and packaging exhibition, held annually in Rosemont, Illinois. It features the latest in PCB manufacturing technology, materials, and equipment.

5. Electronica: This is the world’s leading trade fair for electronics development and production, held annually in Munich, Germany. It showcases the latest in PCB manufacturing technology, materials, and equipment.

Comparison of the daily production capacity of the earliest pcb board manufacturing manufacturer and the daily production capacity of modern pcb board manufacturing production technology

The earliest PCB board manufacturing technology was limited by the manual assembly process and the lack of automation. As a result, the daily production capacity was relatively low, typically in the range of a few hundred to a few thousand boards.

Modern PCB board manufacturing production technology, on the other hand, is highly automated and can produce thousands to millions of boards per day. This is due to the use of advanced equipment such as automated pick-and-place machines, surface mount technology, and automated optical inspection systems. Additionally, modern PCB board manufacturing processes are more efficient and cost-effective than ever before.

What impact does the pcb board manufacturing manufacturing industry have on society?

The PCB board manufacturing industry has a significant impact on society. It enables the production of a wide range of products, from consumer electronics to medical devices, that are essential to modern life. It also provides jobs and economic growth, as well as contributing to the development of new technologies. Additionally, the industry is a major contributor to environmental protection, as it is increasingly focused on reducing waste and using sustainable materials.

Detailed analysis of the operation of the pcb board manufacturing manufacturer

The operation of a PCB board manufacturing manufacturer involves a number of steps. The first step is to design the board. This involves creating a schematic diagram of the board, which includes the components and their connections. The schematic is then used to create a printed circuit board (PCB) layout. This layout is then used to create the actual board.

The next step is to fabricate the board. This involves etching the board with a chemical solution to create the desired pattern of copper traces. The board is then drilled with holes for the components to be mounted. The components are then soldered onto the board.

The board is then tested to ensure that it is functioning correctly. This includes testing the electrical connections and ensuring that the components are properly connected. Once the board has passed the tests, it is ready for assembly.

The assembly process involves mounting the components onto the board and soldering them in place. The board is then tested again to ensure that it is functioning correctly. Once the board has passed the tests, it is ready for shipment.

The final step is to package the board for shipment. This involves placing the board in an anti-static bag and then packing it in a box for shipment. The board is then shipped to the customer.

Development status of pcb board manufacturing manufacturing industry

The PCB board manufacturing industry is a rapidly growing industry. In recent years, the industry has seen a surge in demand due to the increasing use of electronics in everyday life. This has led to an increase in the number of PCB board manufacturers, as well as an increase in the number of new technologies and processes being developed.

The industry is highly competitive, with many companies competing for market share. Companies are constantly innovating and developing new technologies to stay ahead of the competition. This has led to a number of advancements in the industry, such as the development of high-density interconnects, advanced materials, and improved manufacturing processes.

The industry is also seeing an increase in the use of automation and robotics, which has helped to reduce costs and improve efficiency. This has allowed companies to produce higher quality products at a lower cost.

Overall, the PCB board manufacturing industry is in a healthy state and is expected to continue to grow in the coming years.

The quality control of the pcb board manufacturing manufacturers needs to do the following:

1. Establish a quality control system: Establish a quality control system that includes quality control procedures, quality control standards, and quality control processes.

2. Inspect incoming materials: Inspect all incoming materials to ensure they meet the required specifications.

3. Test the PCBs: Test the PCBs to ensure they meet the required specifications.

4. Inspect the PCBs: Inspect the PCBs to ensure they meet the required specifications.

5. Perform functional tests: Perform functional tests to ensure the PCBs are functioning correctly.

6. Perform reliability tests: Perform reliability tests to ensure the PCBs are reliable and will last for a long time.

7. Perform environmental tests: Perform environmental tests to ensure the PCBs are safe to use in different environments.

8. Perform final inspections: Perform final inspections to ensure the PCBs meet the required specifications.

9. Document the results: Document the results of all tests and inspections to ensure the quality of the PCBs.

How can pcb board manufacturing manufacturer improve their brand image?

1. Develop a strong online presence: Establish a website and social media accounts to showcase your products and services.

2. Focus on customer service: Make sure your customer service is top-notch and that you respond quickly to customer inquiries.

3. Invest in quality control: Ensure that your products are of the highest quality and that they meet industry standards.

4. Utilize customer feedback: Ask customers for feedback and use it to improve your products and services.

5. Participate in industry events: Attend trade shows and other industry events to network and build relationships with potential customers.

6. Offer discounts and promotions: Offer discounts and promotions to attract new customers and keep existing ones.

7. Invest in marketing: Develop a marketing strategy to promote your brand and products.

8. Develop a strong brand identity: Create a unique logo and brand identity to help customers recognize your company.

5 suggestions for pcb board manufacturing manufacturer to improve production process

1. Invest in Automation: Automation can help reduce costs and improve production efficiency. Automated processes can help reduce labor costs, reduce errors, and increase production speed.

2. Implement Quality Control: Quality control is essential for any PCB board manufacturing process. Implementing quality control measures can help ensure that the boards are manufactured to the highest standards.

3. Invest in Training: Investing in training for employees can help ensure that they are knowledgeable about the latest technologies and processes. This can help reduce errors and improve production efficiency.

4. Utilize Lean Manufacturing: Lean manufacturing is a process that focuses on eliminating waste and improving efficiency. Utilizing lean manufacturing techniques can help reduce costs and improve production speed.

5. Invest in Technology: Investing in the latest technologies can help improve production speed and reduce costs. Investing in the latest technologies can also help ensure that the boards are manufactured to the highest standards.

The marketing ability of pcb board manufacturing manufacturer depends on these 5 points

1. Quality: Quality is the most important factor in determining the success of a PCB board manufacturing manufacturer. Quality products will attract more customers and increase the reputation of the manufacturer.

2. Price: Price is also an important factor in determining the success of a PCB board manufacturing manufacturer. Customers will be more likely to purchase from a manufacturer that offers competitive prices.

3. Delivery: Delivery is an important factor in determining the success of a PCB board manufacturing manufacturer. Customers will be more likely to purchase from a manufacturer that offers fast and reliable delivery.

4. Customer Service: Customer service is an important factor in determining the success of a PCB board manufacturing manufacturer. Customers will be more likely to purchase from a manufacturer that offers excellent customer service.

5. Technology: Technology is an important factor in determining the success of a PCB board manufacturing manufacturer. Customers will be more likely to purchase from a manufacturer that offers the latest technology and innovative solutions.

Reference plan for pcb board manufacturing manufacturer to improve the production level of the manufacturing industry

1. Develop a comprehensive production plan: Develop a comprehensive production plan that outlines the steps and processes involved in the production of PCB boards. This plan should include the materials needed, the production timeline, and the quality control measures that will be implemented.

2. Invest in new technology: Invest in new technology that will help to improve the efficiency and accuracy of the production process. This could include automated machines, 3D printing, and other advanced technologies.

3. Improve quality control: Implement a quality control system that will ensure that all PCB boards produced meet the highest standards. This could include regular inspections, testing, and other measures.

4. Train staff: Train staff on the latest production techniques and technologies. This will help to ensure that the production process is as efficient and accurate as possible.

5. Invest in research and development: Invest in research and development to stay ahead of the competition. This could include researching new materials, processes, and technologies that could be used to improve the production process.

6. Monitor production: Monitor the production process to ensure that it is running smoothly and efficiently. This could include tracking production times, materials used, and other metrics.

7. Improve customer service: Improve customer service by providing timely and accurate information about the production process. This could include providing customers with updates on the progress of their orders and answering any questions they may have.

Difficulties encountered by pcb board manufacturing manufacturer in implementing management innovation

1. Lack of resources: Many PCB board manufacturing companies lack the resources to implement management innovation. This includes financial resources, personnel resources, and technological resources.

2. Lack of knowledge: Many PCB board manufacturing companies lack the knowledge and expertise to implement management innovation. This includes knowledge of the latest management trends, best practices, and technologies.

3. Resistance to change: Many PCB board manufacturing companies may be resistant to change due to the fear of the unknown or the fear of failure.

4. Lack of motivation: Many PCB board manufacturing companies may lack the motivation to implement management innovation due to the lack of immediate rewards or the lack of a clear vision of the future.

5. Poor communication: Many PCB board manufacturing companies may have poor communication between departments or between management and employees, which can lead to a lack of understanding of the need for management innovation.

Modern management mode of pcb board manufacturing manufacturer

1. Quality Control: Quality control is the most important part of PCB board manufacturing. Quality control should be implemented throughout the entire production process, from the selection of raw materials to the final product. Quality control should include testing of the raw materials, inspection of the finished product, and testing of the finished product.

2. Automation: Automation is essential for efficient and cost-effective PCB board manufacturing. Automation can reduce labor costs, improve production efficiency, and reduce errors. Automation can also help to reduce waste and improve product quality.

3. Lean Manufacturing: Lean manufacturing is a process that focuses on eliminating waste and improving efficiency. Lean manufacturing can help to reduce costs, improve quality, and increase productivity.

4. Supply Chain Management: Supply chain management is essential for efficient and cost-effective PCB board manufacturing. Supply chain management should include the selection of suppliers, the management of inventory, and the tracking of orders.

5. Environmental Management: Environmental management is important for PCB board manufacturing. Environmental management should include the selection of materials, the disposal of waste, and the implementation of energy-saving measures.

How can pcb board manufacturing manufacturer improve economic benefits

1. Improve production efficiency: PCB board manufacturers can improve production efficiency by introducing advanced production equipment, optimizing production processes, and improving the quality of production personnel.

2. Strengthen cost control: PCB board manufacturers can strengthen cost control by optimizing the procurement process, reducing the cost of raw materials, and improving the efficiency of production processes.

3. Improve product quality: PCB board manufacturers can improve product quality by introducing advanced testing equipment, improving the quality of production personnel, and strengthening quality control.

4. Strengthen marketing: PCB board manufacturers can strengthen marketing by increasing the visibility of their products, expanding their customer base, and improving customer service.

5. Increase innovation: PCB board manufacturers can increase innovation by investing in research and development, introducing new technologies, and improving product design.

How can pcb board manufacturing manufacturer strengthen cooperation with foreign companies?

1. Establish a strong relationship with foreign companies by attending international trade shows and conferences.

2. Develop a comprehensive understanding of the needs and requirements of foreign companies.

3. Develop a comprehensive understanding of the local market and the needs of foreign companies.

4. Develop a comprehensive understanding of the local regulations and laws related to PCB board manufacturing.

5. Develop a comprehensive understanding of the international standards related to PCB board manufacturing.

6. Develop a comprehensive understanding of the international trends related to PCB board manufacturing.

7. Develop a comprehensive understanding of the international market and the needs of foreign companies.

8. Develop a comprehensive understanding of the international supply chain and the needs of foreign companies.

9. Develop a comprehensive understanding of the international logistics and the needs of foreign companies.

10. Develop a comprehensive understanding of the international quality standards related to PCB board manufacturing.

pcb board manufacturing manufacturer need to take the following environmental protection measures in the production process

1. Adopt advanced environmental protection technology and equipment to reduce air and water pollution.

2. Establish a waste management system to reduce the amount of waste generated.

3. Use non-toxic materials and chemicals in the production process.

4. Install air and water filtration systems to reduce emissions.

5. Implement energy-saving measures to reduce energy consumption.

6. Recycle and reuse materials and components whenever possible.

7. Educate employees on environmental protection and safety.

8. Monitor and control the production process to ensure compliance with environmental regulations.

Analysis of the status quo of the international trade market for pcb board manufacturing manufacturer

The global market for PCB board manufacturing is highly competitive and fragmented. The market is dominated by a few large players, such as Samsung, LG, and Foxconn, who have a significant share of the market. However, there are also many smaller players, such as PCBWay, who are gaining market share.

The global market for PCB board manufacturing is expected to grow at a CAGR of 5.2% from 2020 to 2027. This growth is driven by the increasing demand for electronic products, such as smartphones, tablets, and laptops, as well as the increasing demand for advanced PCBs for industrial applications.

The market is also driven by the increasing demand for miniaturization of electronic components, which is driving the need for more advanced PCBs. Additionally, the increasing demand for high-performance PCBs for automotive and aerospace applications is also driving the market.

The market is also driven by the increasing demand for green PCBs, which are more energy-efficient and environmentally friendly. Additionally, the increasing demand for flexible PCBs is also driving the market.

The market is also driven by the increasing demand for high-quality PCBs, which are more reliable and durable. Additionally, the increasing demand for PCBs with advanced features, such as high-speed transmission, is also driving the market.

Overall, the global market for PCB board manufacturing is expected to continue to grow at a steady pace over the forecast period.

How can pcb board manufacturing manufacturer strengthen the protection of intellectual property rights

1. Establish a comprehensive intellectual property management system.

2. Establish a strict internal control system to prevent the leakage of confidential information.

3. Establish a system of rewards and punishments to encourage employees to protect intellectual property rights.

4. Establish a system of legal protection for intellectual property rights.

5. Establish a system of monitoring and tracking the use of intellectual property rights.

6. Establish a system of training and education for employees on the importance of protecting intellectual property rights.

7. Establish a system of cooperation with other companies to protect intellectual property rights.

8. Establish a system of legal action against any infringement of intellectual property rights.

Do the following points for pcb board manufacturing manufacturers to improve foreign trade performance

1. Develop a comprehensive marketing strategy: Develop a comprehensive marketing strategy that includes both online and offline marketing tactics. This should include a mix of digital marketing, such as SEO, PPC, and social media, as well as traditional marketing tactics, such as trade shows, print advertising, and direct mail.

2. Invest in quality control: Quality control is essential for PCB board manufacturing manufacturers to ensure that their products meet the highest standards. Investing in quality control processes and procedures can help to ensure that the products they produce are of the highest quality and meet the needs of their customers.

3. Establish relationships with foreign buyers: Establishing relationships with foreign buyers can help PCB board manufacturing manufacturers to increase their sales and expand their customer base. This can be done through attending trade shows, participating in industry events, and networking with potential buyers.

4. Utilize e-commerce platforms: Utilizing e-commerce platforms can help PCB board manufacturing manufacturers to reach a wider audience and increase their sales. This can be done by setting up an online store, creating a website, and utilizing social media platforms to promote their products.

5. Offer competitive pricing: Offering competitive pricing can help PCB board manufacturing manufacturers to attract more customers and increase their sales. This can be done by researching the market and understanding the pricing of competitors.

6. Invest in customer service: Investing in customer service can help PCB board manufacturing manufacturers to build relationships with their customers and ensure that they are satisfied with their products. This can be done by providing helpful customer service, responding to customer inquiries quickly, and offering after-sales support.

Foreign trade talent training skills of pcb board manufacturing manufacturer

1. Understand the basic knowledge of international trade: Understand the basic knowledge of international trade, such as international trade terms, international trade documents, international trade finance, international trade law, international trade negotiation, international trade dispute resolution, etc.

2. Understand the international market: Understand the international market, such as the international market environment, the international market demand, the international market competition, the international market strategy, the international market analysis, the international market risk, etc.

3. Understand the international trade process: Understand the international trade process, such as the international trade order, the international trade contract, the international trade payment, the international trade delivery, the international trade inspection, the international trade insurance, the international trade settlement, etc.

4. Understand the international trade regulations: Understand the international trade regulations, such as the international trade laws, the international trade agreements, the international trade sanctions, the international trade embargoes, the international trade customs, the international trade taxes, the international trade quotas, etc.

5. Understand the international trade finance: Understand the international trade finance, such as the international trade financing, the international trade credit, the international trade payment, the international trade collection, the international trade exchange, the international trade hedging, the international trade insurance, etc.

6. Understand the international trade logistics: Understand the international trade logistics, such as the international trade transportation, the international trade warehousing, the international trade packaging, the international trade customs clearance, the international trade documentation, the international trade tracking, etc.

7. Understand the international trade risk management: Understand the international trade risk management, such as the international trade risk assessment, the international trade risk control, the international trade risk mitigation, the international trade risk insurance, the international trade risk management system, etc.

Overview of modern production technology of Chinese pcb board manufacturing manufacturer

Modern production technology of Chinese PCB board manufacturing manufacturer is mainly divided into three categories:

1. Automated production technology: This technology is mainly used in the production of high-end PCB boards. It is characterized by high precision, high efficiency, and low cost. The automated production technology includes automatic drilling, automatic soldering, automatic testing, and automatic assembly.

2. Traditional production technology: This technology is mainly used in the production of low-end PCB boards. It is characterized by low precision, low efficiency, and high cost. The traditional production technology includes manual drilling, manual soldering, manual testing, and manual assembly.

3. Advanced production technology: This technology is mainly used in the production of medium-end PCB boards. It is characterized by medium precision, medium efficiency, and medium cost. The advanced production technology includes semi-automatic drilling, semi-automatic soldering, semi-automatic testing, and semi-automatic assembly.

pcb board manufacturing manufacturer need to make preparations for implementing the new economic model

1. Develop a comprehensive understanding of the new economic model and its implications for the PCB board manufacturing industry.

2. Analyze the current market conditions and identify potential opportunities and risks associated with the new economic model.

3. Develop a strategic plan to capitalize on the opportunities and mitigate the risks associated with the new economic model.

4. Identify and evaluate potential partners and suppliers that can help the PCB board manufacturing manufacturer to implement the new economic model.

5. Develop a comprehensive marketing plan to promote the new economic model and the PCB board manufacturing manufacturer’s products and services.

6. Develop a pricing strategy that is competitive and profitable in the new economic model.

7. Develop a customer service strategy that is tailored to the new economic model.

8. Develop a training program for employees to ensure they are knowledgeable and prepared to implement the new economic model.

9. Develop a system for tracking and monitoring the performance of the new economic model.

10. Develop a system for evaluating the success of the new economic model and making necessary adjustments.

The production capacity of pcb board manufacturing manufacturers depends on the efficiency of these equipment

The production capacity of pcb board manufacturing manufacturers depends on the efficiency of the equipment used in the production process. This includes the machines used to cut, drill, and etch the boards, as well as the machines used to assemble the components onto the boards. The more efficient the machines, the higher the production capacity of the manufacturer. Additionally, the quality of the components used in the production process can also affect the production capacity of the manufacturer.

How can pcb board manufacturing manufacturer improve product quality?

1. Invest in high-quality materials: Investing in high-quality materials is essential for producing high-quality PCBs. Quality materials will ensure that the boards are reliable and durable.

2. Utilize advanced technology: Utilizing advanced technology such as automated testing and inspection systems can help to ensure that the boards are manufactured to the highest standards.

3. Implement quality control measures: Quality control measures such as regular inspections and testing should be implemented to ensure that the boards are manufactured to the highest standards.

4. Invest in training: Investing in training for employees can help to ensure that they are knowledgeable about the latest technologies and techniques for producing high-quality PCBs.

5. Utilize feedback: Utilizing feedback from customers can help to identify areas where improvements can be made to the manufacturing process.

The production capacity of the pcb board manufacturing manufacturer depends on the experience of the following technicians

1. PCB Designers: PCB designers are responsible for creating the layout of the printed circuit board. They must have a thorough understanding of the electrical components and their interactions with each other.

2. PCB Fabricators: PCB fabricators are responsible for the actual production of the printed circuit board. They must have a good understanding of the materials and processes used in the fabrication of the board.

3. PCB Assembly Technicians: PCB assembly technicians are responsible for the assembly of the components onto the printed circuit board. They must have a good understanding of the components and their interactions with each other.

4. Quality Control Technicians: Quality control technicians are responsible for ensuring that the printed circuit board meets the required specifications. They must have a good understanding of the components and their interactions with each other.

There are five methods for pcb board manufacturing manufacturer to build their own dealer channels

1. Develop a Network of Distributors: Developing a network of distributors is one of the most effective ways to build a dealer channel. Distributors can help manufacturers reach a wider audience and increase their sales.

2. Utilize Online Platforms: Utilizing online platforms such as Amazon, eBay, and Alibaba can help manufacturers reach a larger audience and increase their sales.

3. Participate in Trade Shows: Participating in trade shows is a great way to meet potential dealers and build relationships.

4. Offer Incentives: Offering incentives such as discounts, free shipping, and other promotions can help attract dealers to your product.

5. Develop a Referral Program: Developing a referral program can help manufacturers build their dealer channel by encouraging existing dealers to refer new dealers.

What are the services of pcb board manufacturing manufacturer?

1. Design and layout services: PCB board manufacturing manufacturers provide design and layout services to ensure that the board meets the customer's requirements.

2. Fabrication services: PCB board manufacturing manufacturers provide fabrication services to create the board from the customer's design.

3. Assembly services: PCB board manufacturing manufacturers provide assembly services to assemble the components onto the board.

4. Testing services: PCB board manufacturing manufacturers provide testing services to ensure that the board meets the customer's requirements.

5. Repair services: PCB board manufacturing manufacturers provide repair services to fix any issues with the board.

The latest production technology of pcb board manufacturing manufacturer

The latest production technology of pcb board manufacturing manufacturer includes:

1. Automated Optical Inspection (AOI): AOI is a process that uses cameras and software to inspect the quality of the printed circuit board (PCB) and detect any defects.

2. Automated X-Ray Inspection (AXI): AXI is a process that uses X-ray technology to inspect the internal layers of the PCB and detect any defects.

3. Automated Solder Paste Inspection (SPI): SPI is a process that uses cameras and software to inspect the quality of the solder paste on the PCB and detect any defects.

4. Automated Test Fixture (ATF): ATF is a process that uses a test fixture to test the functionality of the PCB and detect any defects.

5. Automated Optical Character Recognition (OCR): OCR is a process that uses cameras and software to read the text on the PCB and detect any errors.

6. Automated Flux Dispensing (AFD): AFD is a process that uses a robotic arm to dispense flux onto the PCB and ensure proper soldering.

Customer group and service level of pcb board manufacturing manufacturer

The customer group for a PCB board manufacturing manufacturer would depend on the type of products they offer. Generally, the customer group would include electronics manufacturers, research and development companies, and other businesses that require PCB boards for their products.

The service level of a PCB board manufacturing manufacturer would depend on the type of services they offer. Generally, the service level would include design and engineering services, prototyping, production, testing, and assembly. The manufacturer may also offer additional services such as custom design, product development, and after-sales support.

What services are included in the pcb board manufacturing manufacturer's after-sales service?

The after-sales service of a PCB board manufacturing manufacturer typically includes technical support, repair services, and warranty services. Technical support may include providing technical advice, troubleshooting, and providing software updates. Repair services may include repairing or replacing defective components, and warranty services may include providing a warranty for the product.

R&D direction of pcb board manufacturing manufacturers industry

1. Automation: Automation is becoming increasingly important in the PCB manufacturing industry. Automation can help reduce costs, improve efficiency, and reduce errors. Automation can also help reduce the need for manual labor, which can help reduce labor costs.

2. Miniaturization: Miniaturization is becoming increasingly important in the PCB manufacturing industry. Miniaturization can help reduce the size and weight of PCBs, which can help reduce costs and improve efficiency.

3. Quality Control: Quality control is becoming increasingly important in the PCB manufacturing industry. Quality control can help ensure that PCBs are manufactured to the highest standards and that they meet customer requirements.

4. Environmental Sustainability: Environmental sustainability is becoming increasingly important in the PCB manufacturing industry. Environmental sustainability can help reduce the environmental impact of PCB manufacturing and help ensure that PCBs are manufactured in an environmentally responsible manner.

5. Cost Reduction: Cost reduction is becoming increasingly important in the PCB manufacturing industry. Cost reduction can help reduce the cost of manufacturing PCBs and help ensure that PCBs are manufactured at a competitive price.

The international production mode adopted by pcb board manufacturing manufacturer

PCB board manufacturing manufacturers typically use an international production mode that involves outsourcing components from different countries. This allows them to take advantage of lower labor costs and access to specialized components. The components are then shipped to the manufacturer’s facility, where they are assembled into the finished product. This production mode allows manufacturers to reduce costs and increase efficiency. Additionally, it allows them to access components from different countries, which can help them to create products with unique features.

pcb board manufacturing manufacturer' skill requirements for production operators

1. Ability to read and understand blueprints, schematics, and other technical documents.

2. Ability to use hand tools, power tools, and other equipment to assemble and test printed circuit boards.

3. Knowledge of safety procedures and the ability to follow them.

4. Ability to use measuring instruments such as calipers, micrometers, and other precision tools.

5. Ability to troubleshoot and diagnose problems with printed circuit boards.

6. Ability to work with a variety of materials, including copper, solder, and other components.

7. Ability to work with a variety of chemicals and solvents.

8. Ability to work in a fast-paced environment and meet deadlines.

9. Ability to work independently and as part of a team.

10. Ability to lift and move heavy objects.

pcb board manufacturing design, what are the shortcomings of Chinese enterprises?

1. Lack of innovation: Chinese enterprises often lack the ability to innovate and develop new products.

2. Poor quality control: Chinese enterprises often lack the necessary quality control measures to ensure the quality of their products.

3. Low cost: Chinese enterprises often focus on low cost production, which can lead to lower quality products.

4. Limited resources: Chinese enterprises often lack the resources to invest in research and development, which can limit their ability to develop new products.

5. Poor customer service: Chinese enterprises often lack the customer service infrastructure to provide timely and effective customer service.

Product quality control of pcb board manufacturing manufacturer

1. Quality Control Plan: The PCB board manufacturing manufacturer should have a quality control plan in place that outlines the steps and processes that will be used to ensure the quality of the product. This plan should include the inspection and testing of raw materials, components, and finished products. It should also include the documentation of any non-conformances and corrective actions taken.

2. Quality Assurance: The PCB board manufacturing manufacturer should have a quality assurance system in place that ensures that all products meet the required specifications. This system should include the use of statistical process control (SPC) to monitor the production process and ensure that all products meet the required standards.

3. Quality Audits: The PCB board manufacturing manufacturer should conduct regular quality audits to ensure that the quality control plan is being followed and that all products meet the required specifications. The audits should include the review of the quality control plan, the inspection and testing of raw materials, components, and finished products, and the documentation of any non-conformances and corrective actions taken.

4. Traceability: The PCB board manufacturing manufacturer should have a traceability system in place that allows them to trace the origin of any component or product back to its source. This system should include the use of serial numbers, barcodes, and other tracking methods.

5. Quality Documentation: The PCB board manufacturing manufacturer should have a system in place that allows them to document all quality control activities. This system should include the documentation of all inspections, tests, and non-conformances. It should also include the documentation of any corrective actions taken.

Skill requirements for pcb board manufacturing designers

1. Knowledge of circuit board design and layout: PCB designers must have a thorough understanding of circuit board design and layout principles, including the ability to read and interpret schematics.

2. Knowledge of CAD software: PCB designers must be proficient in the use of computer-aided design (CAD) software, such as Altium Designer, Cadence Allegro, and Mentor Graphics PADS.

3. Knowledge of manufacturing processes: PCB designers must have a good understanding of the various manufacturing processes used to produce printed circuit boards, such as surface mount technology (SMT) and through-hole technology (THT).

4. Knowledge of materials: PCB designers must have a good understanding of the various materials used in the manufacture of printed circuit boards, such as copper, solder mask, and laminate.

5. Problem-solving skills: PCB designers must be able to identify and solve problems related to circuit board design and layout.

6. Attention to detail: PCB designers must be able to pay close attention to detail in order to ensure that the circuit board design is accurate and meets all specifications.

7. Communication skills: PCB designers must be able to effectively communicate with other members of the design team, as well as with manufacturing personnel.

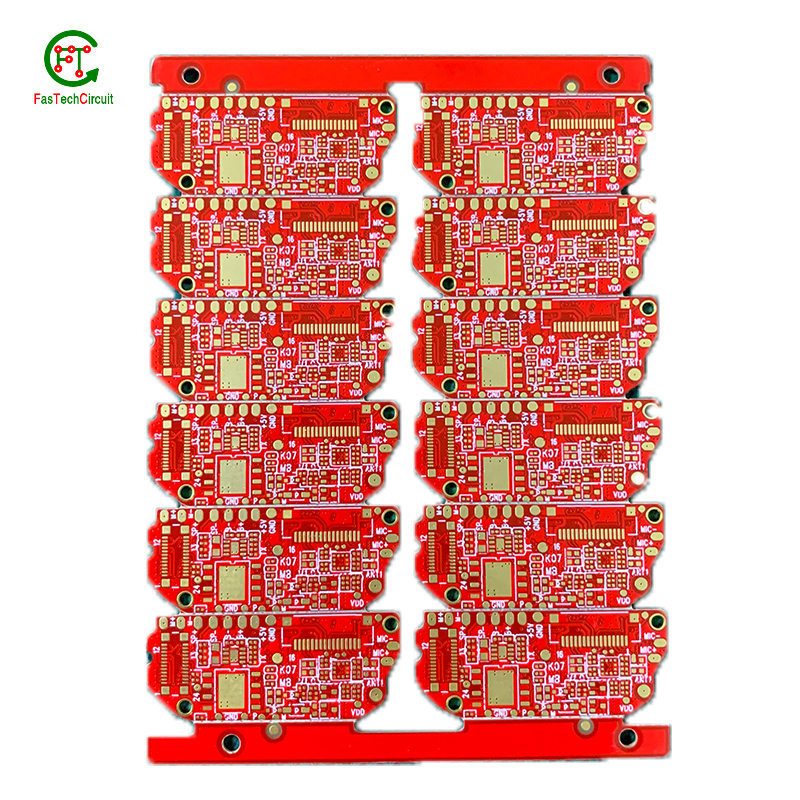

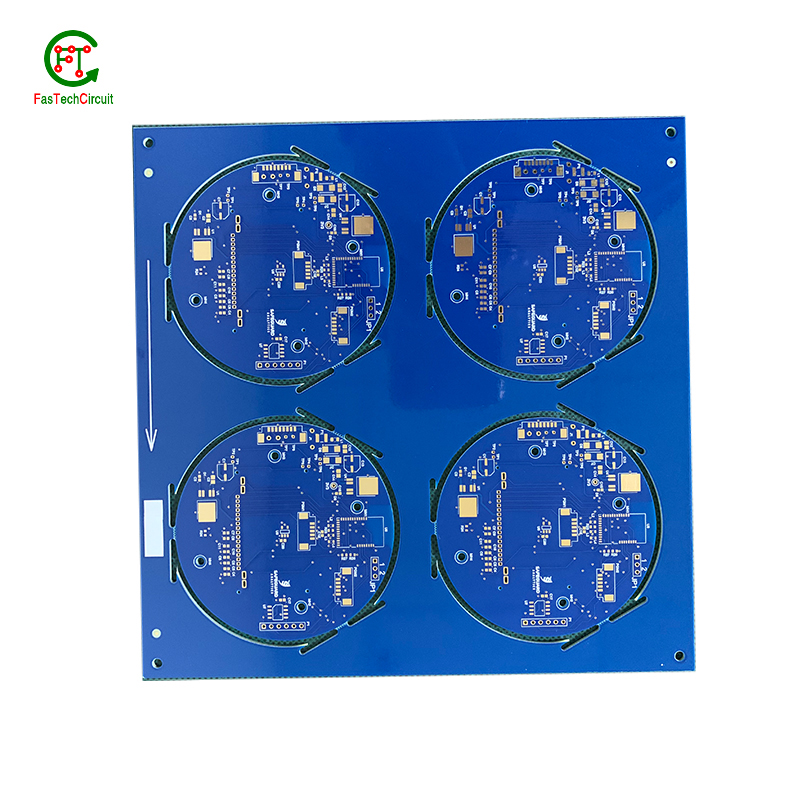

pcb board manufacturing How To Contact US

PCB from 1 to 30 layers, HDI, Heavy Copper, Rigid-flex board with "pcb board manufacturing One-Stop" service.