How to reduce PCB assembly cost?

At Fifth Metal Industrial Co.,LTD., we specialize in high-quality PCB assembly services, catering to a wide range of industries including automotive, aerospace, medical, and consumer electronics. Our advanced assembly facilities house state-of-the-art equipment and cutting-edge technology, allowing us to provide fast and accurate assembly of complex PCBs.

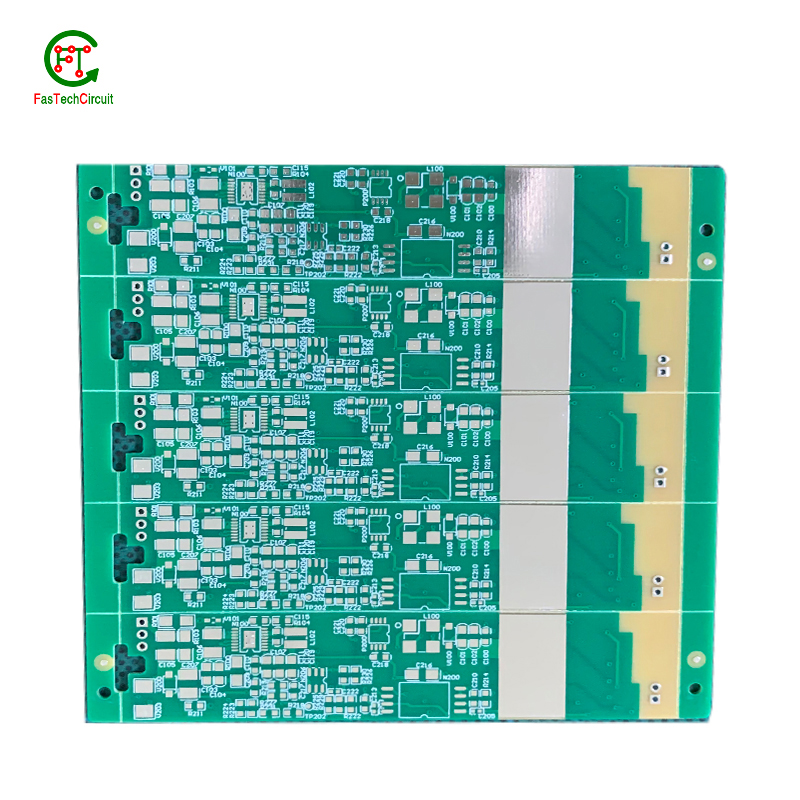

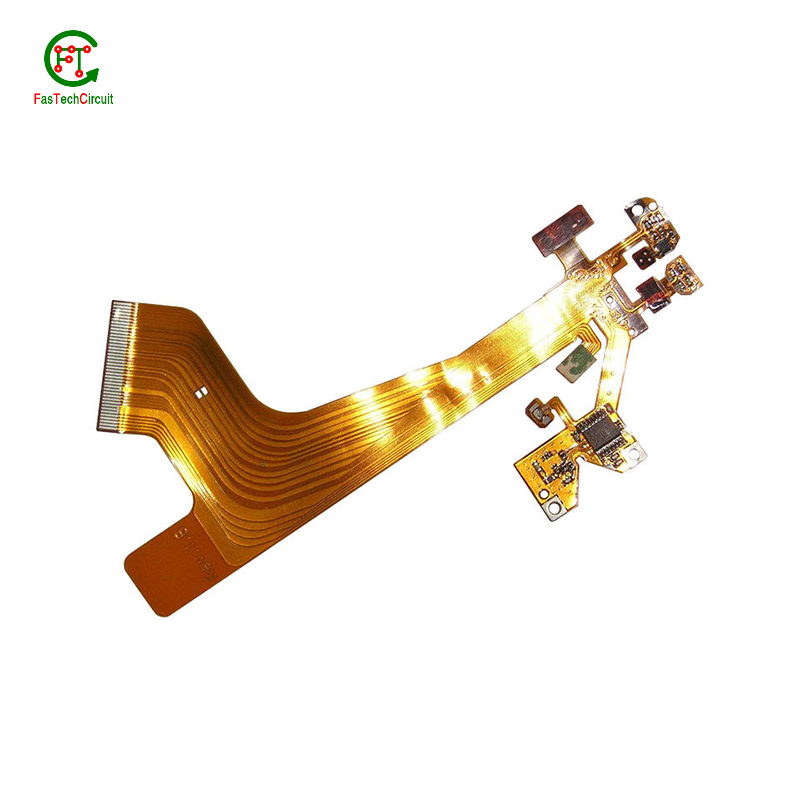

We offer a diverse range of assembly services including surface mount technology (SMT), through-hole technology (THT), and mixed technology. Our team of skilled technicians and engineers are well-versed in handling various types of components such as resistors, capacitors, integrated circuits, and many more. With their expertise and attention to detail, we ensure every component is precisely placed onto the PCB with the highest level of accuracy.

We understand the importance of quality and reliability in electronic products, which is why we implement strict quality control measures at every stage of the assembly process. Our PCB assembly services undergo rigorous testing, including functional and visual inspections, to ensure optimal performance and durability.

In addition to our assembly services, we also offer value-added services such as design for manufacturability (DFM) analysis, prototyping, and turnkey assembly. This allows for a streamlined production process and reduced lead times, ultimately providing our customers with a competitive edge in the market.

At Fifth Metal Industrial Co.,LTD., we pride ourselves on delivering cost-effective and efficient PCB assembly solutions without compromising on quality. We are committed to meeting our customers' specific requirements and providing them with impeccable service and support. Trust us to be your reliable partner for all your PCB assembly needs.

PCB assembly is crucial in the electronics industry as it enables the production of complex and compact electronic devices. This process also allows for easy and efficient repairs and upgrades to electronic products, making them more sustainable and cost-effective.

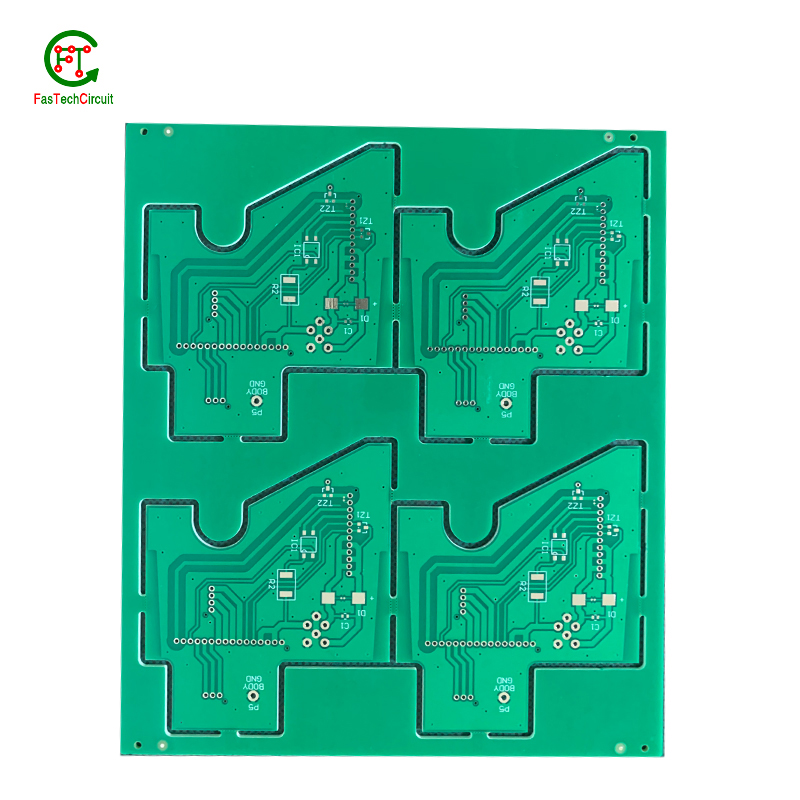

The assembly process begins with the design and layout of the PCB, which dictates the placement and orientation of components. Once the design is finalized, the components are placed using automated equipment or by hand. The PCB is then heated to melt the solder and create permanent connections between the components and the board.

PCB assembly is the process of assembling electronic components onto printed circuit boards (PCBs). It plays a critical role in the production of various electronic devices, from household appliances to advanced industrial equipment. However, as technology advances and the demand for higher quality products increases, there are often concerns and questions regarding the PCB assembly process. In this FQA (Frequently Asked Questions) section, we will address some commonly asked questions to provide a better understanding of PCB assembly.

2.What is PCB standards?

3.What is the quality of PCB assembly?

4.What is main PCB failure?

5.How long does PCB assembly take?

6.How is PCB thickness measured?

7.What is the difference between PCB fabrication and PCB assembly?

1.How to calculate PCB assembly cost?

There are several factors that can affect the cost of PCB assembly, including the complexity of the design, the number of components, and the type of components used. To calculate the cost of PCB assembly, you will need to consider the following factors: 1. PCB Design Complexity: The complexity of the PCB design will have a significant impact on the cost of assembly. A more complex design will require more time and resources to assemble, resulting in a higher cost. 2. Number of Components: The number of components on the PCB will also affect the cost of assembly. The more components there are, the longer it will take to assemble, and the higher the cost will be. 3. Type of Components: The type of components used on the PCB will also impact the cost of assembly. For example, surface mount components are generally more expensive than through-hole components. 4. Labor Costs: The cost of labor will also need to be factored into the overall cost of PCB assembly. This will depend on the location of the assembly facility and the skill level of the technicians. 5. Assembly Method: The method used to assemble the PCB can also affect the cost. Hand assembly is generally more expensive than automated assembly, but it may be necessary for more complex designs. 6. Testing and Quality Control: The cost of testing and quality control should also be considered. This will ensure that the assembled PCB meets the required specifications and functions properly. To calculate the cost of PCB assembly, you can use the following formula: PCB Assembly Cost = (PCB Design Complexity + Number of Components + Type of Components + Labor Costs + Assembly Method + Testing and Quality Control) x Markup Percentage The markup percentage will vary depending on the assembly facility and other factors, but it is typically between 10-20%. It is also important to note that the cost of PCB assembly may vary between different assembly facilities. It is recommended to get quotes from multiple facilities to compare costs and choose the most cost-effective option.

2.What is PCB standards?

PCB standards refer to a set of guidelines and specifications that define the design, manufacturing, and testing requirements for printed circuit boards (PCBs). These standards ensure that PCBs are produced consistently and meet certain quality and performance criteria. They cover various aspects of PCB production, including materials, layout, trace width and spacing, hole sizes, solder mask, and testing methods. Adhering to PCB standards helps to ensure the reliability, functionality, and safety of electronic devices that use PCBs. Some common PCB standards include IPC-2221, IPC-A-600, and UL 796.

3.What is the quality of PCB assembly?

The quality of PCB assembly can vary depending on several factors such as the manufacturing process, materials used, and the expertise of the assembly team. Generally, a high-quality PCB assembly should have the following characteristics: 1. Accurate and precise placement of components: The components should be placed on the PCB accurately and precisely according to the design specifications. 2. Proper soldering: The soldering of components should be done correctly to ensure a strong and reliable connection. 3. Good electrical connections: The PCB assembly should have good electrical connections between components to ensure proper functioning. 4. Adequate testing: The assembled PCB should undergo thorough testing to ensure that all components are functioning correctly. 5. Use of high-quality materials: The use of high-quality materials such as PCBs, components, and soldering materials can greatly impact the overall quality of the assembly. 6. Compliance with industry standards: The assembly should comply with industry standards and regulations to ensure safety and reliability. Overall, a high-quality PCB assembly should have a low defect rate, meet design specifications, and function reliably.

4.What is main PCB failure?

Main PCB failure refers to a malfunction or breakdown of the main printed circuit board (PCB) in an electronic device. The main PCB is responsible for controlling and coordinating the functions of various components in the device, and a failure can result in the device not functioning properly or not functioning at all. This can be caused by various factors such as physical damage, electrical surges, or manufacturing defects. Main PCB failure can be a serious issue and may require professional repair or replacement of the PCB.

5.How long does PCB assembly take?

The time it takes for PCB assembly can vary depending on the complexity of the design, the number of components, and the manufacturing process used. Generally, it can take anywhere from a few hours to several weeks to complete PCB assembly. Here are some factors that can affect the time it takes for PCB assembly: 1. Design complexity: The more complex the design, the longer it will take to assemble the PCB. This is because complex designs require more time for layout, component placement, and soldering. 2. Number of components: The more components that need to be placed on the PCB, the longer it will take to assemble. Each component needs to be carefully placed and soldered, which can be a time-consuming process. 3. Manufacturing process: The type of manufacturing process used can also affect the time it takes for PCB assembly. For example, hand soldering can take longer than automated assembly processes. 4. Availability of components: If all the components needed for the PCB assembly are readily available, the process can be completed faster. However, if some components are out of stock or need to be ordered, it can add to the overall assembly time. 5. Quality control: Quality control checks are an important part of PCB assembly and can add to the overall time it takes to complete the process. These checks ensure that the PCB is assembled correctly and meets the required specifications. Overall, the time it takes for PCB assembly can range from a few hours for simple designs to several weeks for more complex designs. It is important to work closely with your PCB manufacturer to get an accurate estimate of the assembly time for your specific project.

6.How is PCB thickness measured?

PCB thickness is typically measured in millimeters (mm) or mils (1 mil = 0.001 inches). It can be measured using a caliper or a thickness gauge specifically designed for PCBs. The measurement is taken from the top surface of the PCB to the bottom surface, including any copper layers, solder mask, and other coatings. The thickness can vary depending on the number of layers, materials used, and the manufacturing process.

7.What is the difference between PCB fabrication and PCB assembly?

PCB fabrication and PCB assembly are two distinct processes involved in the production of a printed circuit board (PCB). PCB fabrication, also known as PCB manufacturing, is the process of creating the bare PCB board by etching copper traces onto a non-conductive substrate. This involves several steps such as designing the PCB layout, printing the circuit onto the substrate, etching the copper traces, and drilling holes for components. The end result of this process is a bare PCB board with copper traces and holes for components. On the other hand, PCB assembly is the process of attaching electronic components onto the bare PCB board to create a functional electronic circuit. This involves placing the components onto the board, soldering them onto the copper traces, and testing the circuit for functionality. The end result of this process is a fully functional PCB that can be used in electronic devices. In summary, PCB fabrication is the process of creating the bare PCB board, while PCB assembly is the process of adding electronic components to the board to create a functional circuit. Both processes are essential in the production of a PCB and are often carried out by different companies or departments within a company.

RELATED NEWS

pcb board manufacturing How To Contact US

PCB from 1 to 30 layers, HDI, Heavy Copper, Rigid-flex board with "pcb board manufacturing One-Stop" service.