Multilayer PCB comprehensive guide

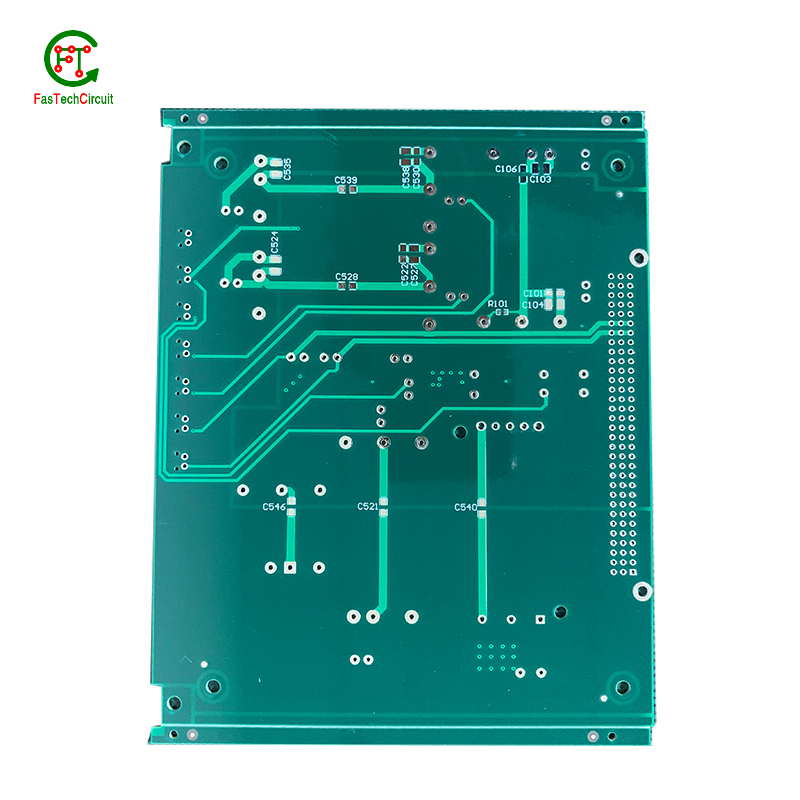

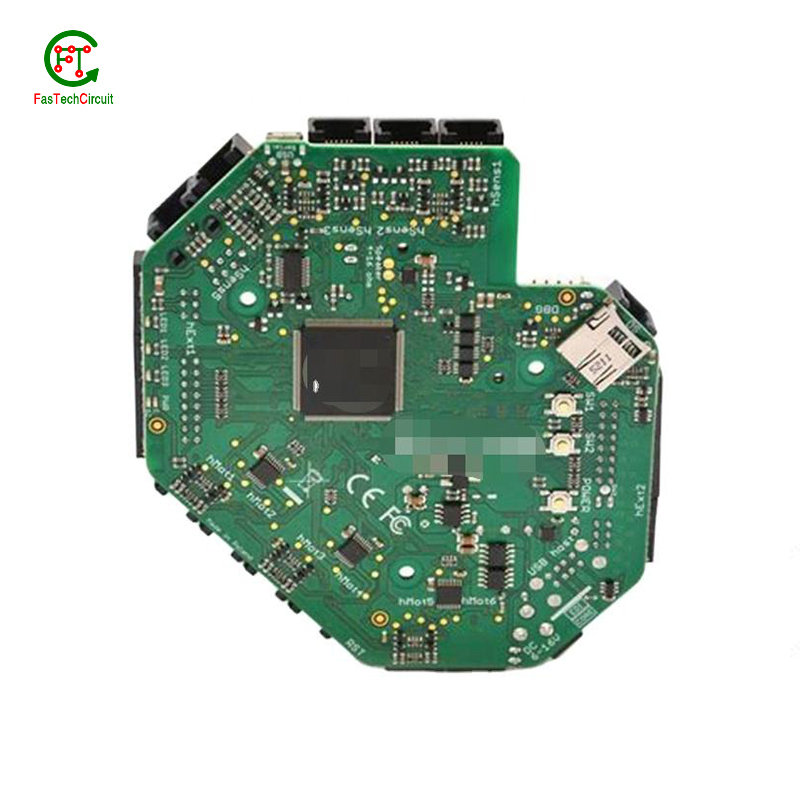

Multilayer Printed Circuit Board (PCB) is a type of circuit board that consists of multiple layers of conductive traces, insulating layers, and other necessary components. This technology offers several advantages compared to traditional single or double-sided PCB, making it a popular choice in various electronic devices such as smartphones, computers, consumer electronics, and automotive systems.

To understand the concept of Multilayer PCB, it is essential to first know about the basic structure of a PCB. A single or double-sided PCB consists of a layer of copper foil attached to a non-conductive substrate, such as fiberglass or epoxy. The copper traces on the surface carry the electrical signals, while the insulating layer between the traces prevents short circuits.

On the other hand, Multilayer PCB have multiple layers of conductive traces and insulating layers sandwiched together. The conductive layers are connected using vias, which are small holes with metal-coated walls that allow the flow of electricity between layers. These vias provide the necessary connections among the different layers, allowing the designers to create complex and compact circuits.

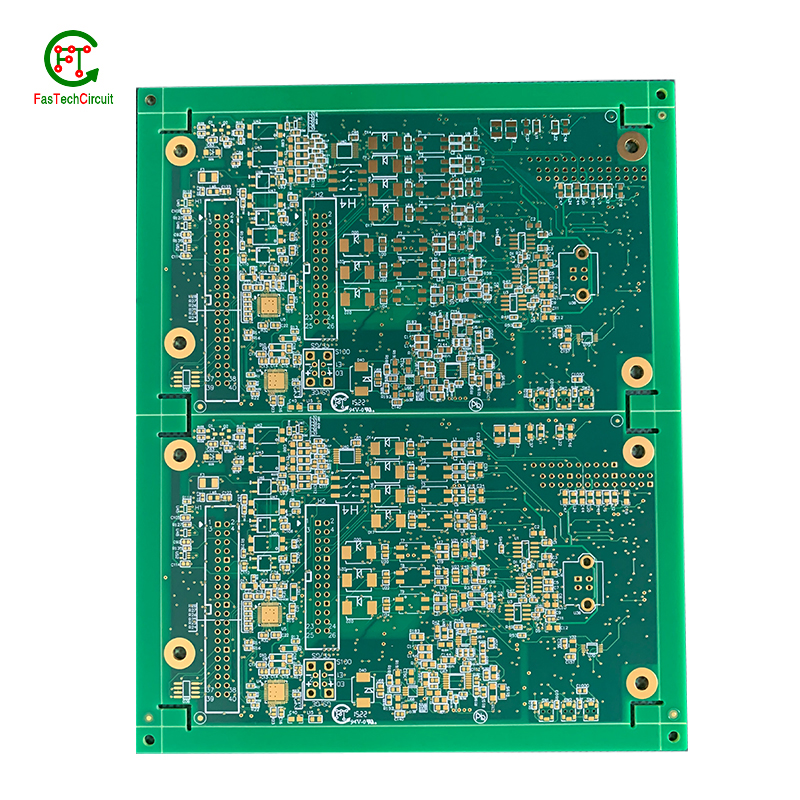

One of the primary advantages of Multilayer PCB is their high density and compactness, making them ideal for high-speed and high-frequency applications. The multiple layers allow designers to add more components and connections in a smaller area, enabling the circuit boards to fit into smaller and thinner devices. Additionally, Multilayer PCBs also offer better signal integrity, as the multiple layers provide more efficient grounding and reduce interference from nearby components.

Another significant advantage of Multilayer PCB is their improved reliability and durability. The layers of insulating material between the conductive layers offer excellent protection against environmental factors such as heat, moisture, and dust. This makes them more resistant to damage and increases their lifespan, making them suitable for use in harsh conditions.

Moreover, Multilayer PCB offer better thermal management compared to single or double-sided PCB. The additional layers provide a better distribution of heat generated by the components, preventing hotspots and ensuring the overall temperature of the PCB remains stable. This makes them suitable for electronic devices that require high power and generate significant heat, such as computers and servers.

Furthermore, Multilayer PCB also offer increased design flexibility, allowing designers to create more complex and high-performance circuits. The multiple layers and vias provide more options for routing, enabling the designers to reduce the length of traces and improve the overall performance of the circuit. This also results in better power distribution and reduces the chances of signal loss.

Multilayer PCB have become an essential component in modern electronic devices, offering significant advantages over traditional single or double-sided PCBs. They provide higher density, improved reliability, better thermal management, and increased design flexibility, making them a popular choice in a wide range of applications. With the continuous advancements in technology, Multilayer PCB are expected to play an even more crucial role in the future of electronic devices.

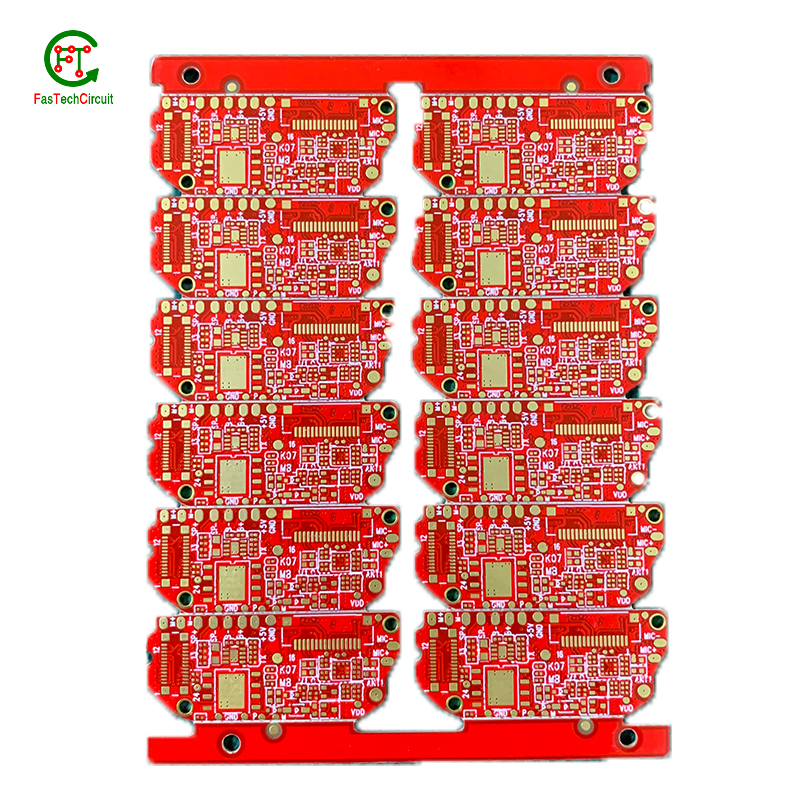

Our high-speed multilayer PCB is specifically engineered for high-frequency applications, delivering exceptional performance and reliability. With advanced materials and specialized manufacturing processes, this PCB can support high-speed signals without interference or loss. Its multilayer design allows for increased flexibility and density, making it ideal for complex and compact electronic designs. From prototype to large-scale production, our high-speed multilayer PCB is the best choice for your high-frequency electronic needs.

2.Are multilayer PCBs more expensive than single-sided PCBs?

3.How is the thickness of a multilayer PCB determined?

4.Can multilayer PCBs be used for high-frequency applications?

5.Can multilayer PCBs support high-power applications?

6.How can I ensure the reliability of my multilayer PCB?

7.How do I specify the stackup of a multilayer PCB?

1.Can multilayer PCBs be used in automotive applications?

Yes, multilayer PCBs are commonly used in automotive applications due to their reliability and compact design.

2.Are multilayer PCBs more expensive than single-sided PCBs?

Yes, multilayer PCBs are generally more expensive than single-sided PCBs due to the complexity and additional layers involved in their manufacturing.

3.How is the thickness of a multilayer PCB determined?

The thickness of a multilayer PCB is determined by the number and thickness of the copper layers, the thickness of the insulating layers, and the overall thickness tolerance specified by the designer.

4.Can multilayer PCBs be used for high-frequency applications?

Yes, multilayer PCBs are suitable for high-frequency applications due to their reduced signal loss and improved signal integrity.

5.Can multilayer PCBs support high-power applications?

Yes, multilayer PCBs can support high-power applications with the use of thicker copper layers and appropriate thermal management techniques.

6.How can I ensure the reliability of my multilayer PCB?

To ensure the reliability of a multilayer PCB, it is important to work with a reputable manufacturer, adhere to industry standards and guidelines, and perform thorough testing before production.

7.How do I specify the stackup of a multilayer PCB?

The stackup of a multilayer PCB is specified by indicating the number and thickness of the conductive and insulating layers, as well as the type of material to be used for each layer.

RELATED NEWS

pcb board manufacturing How To Contact US

PCB from 1 to 30 layers, HDI, Heavy Copper, Rigid-flex board with "pcb board manufacturing One-Stop" service.