What Can We Do?

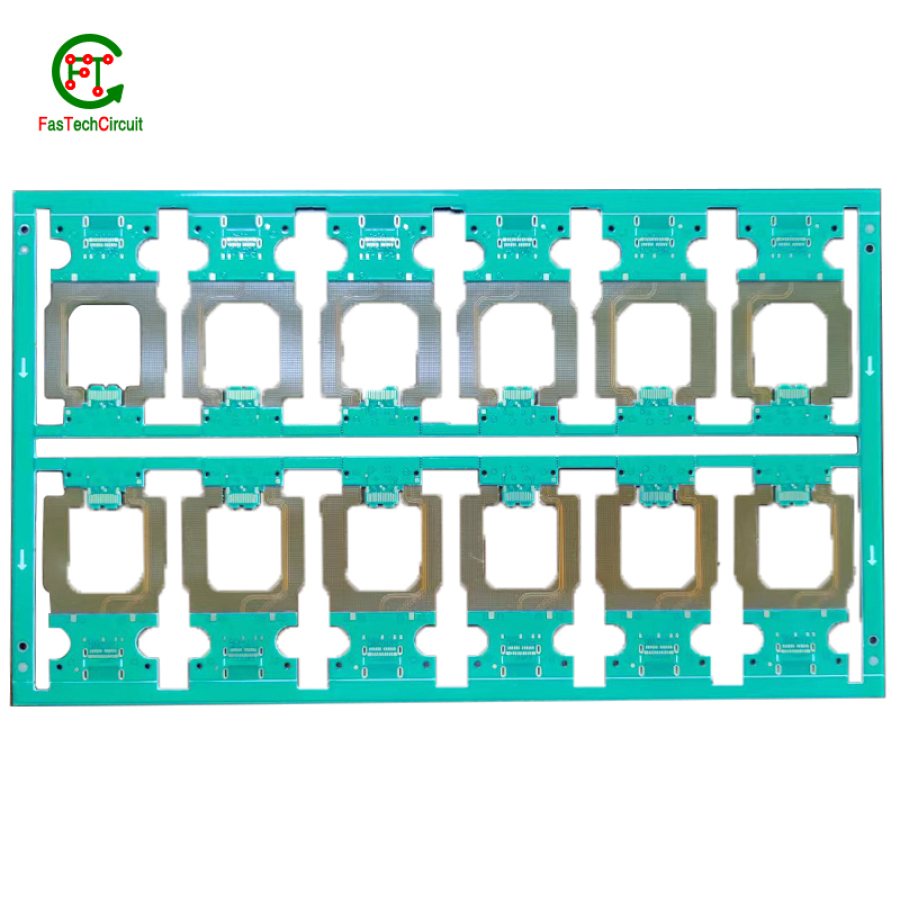

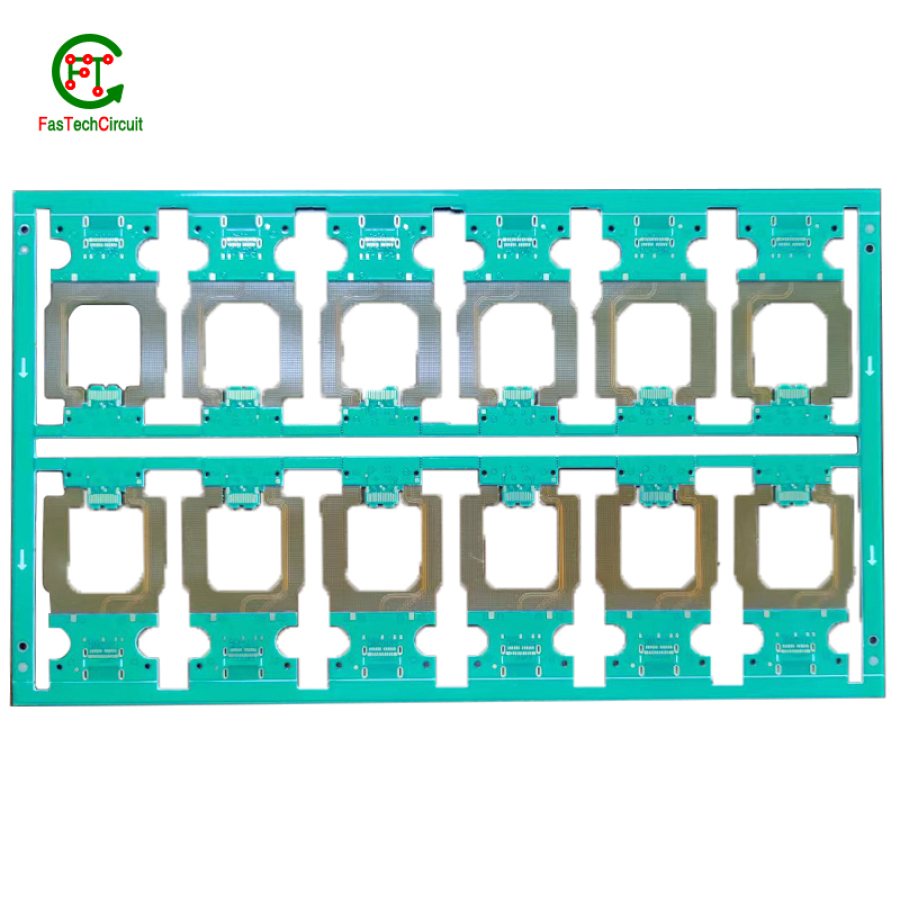

"PCB One-Stop" service=PCB Reverse+pcb board manufacturing+component sourcing+PCB assembly.FasTechCircuit A professional pcb board manufacturing and production control service,Total commitment to pcb board manufacturing quality,Our pcb board manufacturing are currently at work in countless industries, powering the next generation of electronic devices. By providing high-quality printed circuit boards manufactured using industry-leading processes and technologies,Every element of our pcb board manufacturing process is designed to advance the business performance of our clients,With us you can be assured of fast turnaround times, unparalleled customer service and a superior pcb board manufacturing product.

HOW TO WORK WITH US

Step1

Send GERBER file and BOM list to us by e-mail.

Step2

We will check and offer price in 4 hours.

Step3

Place your order to us and we will send Engineer Questions in 24 hours.

Step4

We will send board by our forwarder and you will get your product soon.

OUR PCB BOARD MAUNFACTURING FACTORY

FasTechCircuit is one of pcb board manufacturing in china , Have 20 years experience on PCB board manufacturing .

PCB BOARD Manufacturing

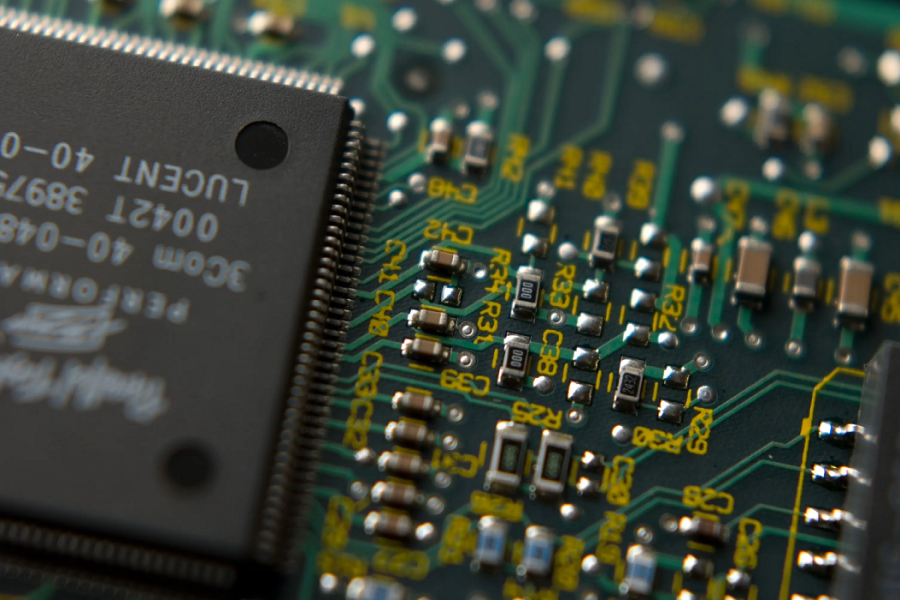

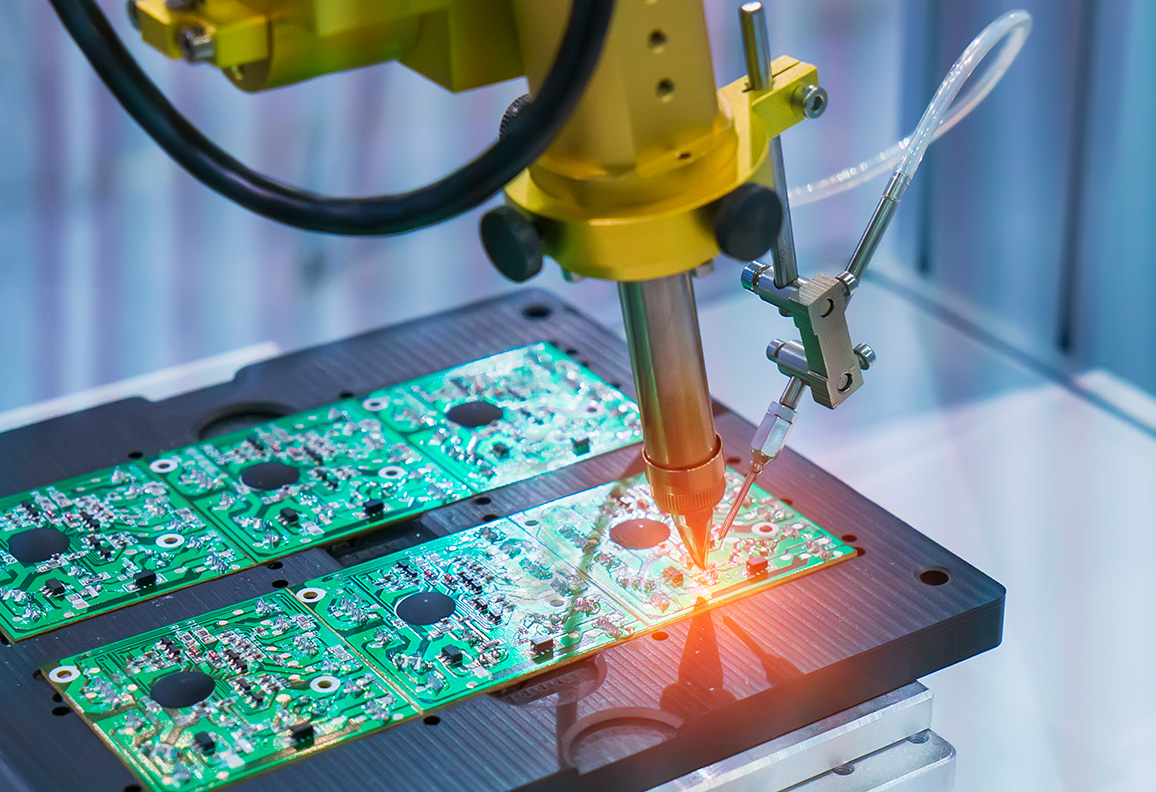

At FasTechCircuit, we take intrinsic steps to ensure that the quality of our work matches and exceeds the expectations of our customers. The FasTechCircuit team utilizes the latest in PCB board manufacturing technology and equipment to meet the demand for quality. Our dedication to providing quality PCB products and services have helped us earn the trust and respect of our customers.

We constantly work towards creating innovative solutions, and we spare no expense in acquiring the latest in PCB board manufacturing technologies and an experienced workforce. This places us in a strong position to provide top notch services, from pcb board manufacturing to assembly ,testing and delivery.

printed circuit board assembly

PCB assembly

pcba supplier

printed curcuit board

pcb board manufacturing

pcb board manufacturing services

PCB circuit board supplie

Printed Circuit Board Assembly Requirements

pcb assembly manufacturer

pcb board manufacturing Since 2003

FasTechCircuit devotes to pcb board manufacturing technology innovation and strict Printed Circuit Board Assembly Requirements and to be an outstanding world-class one-stop hardware solution provider.

We were found in 2003, who is a one-stop-shop that can provide PCB assembly+PCB reverse design + pcb board manufacturing + Component Sourcing + Final Product Function Testing.

We PCB board manufacturing factory has cooperated with 5000+enterprises from over 40+ conuntries , our pcb board manufacturing are widely PCB assembly used in communications, industrial control, semiconductors, power and energy, medical equipment, automotive electronics....

FasTechCircuit shaped the international network of marketing and technique, offering good service PCB board manufacturing and processing i n electronic industry.

pcb board manufacturing Factory Tour

FasTechCircuit is a pcb board manufacturing and PCB assembly produced by Chinese high-tech enterprises. We pcb board manufacturing have invested in advanced equipment from Germany, Israel, the United Kingdom and the United States... Advanced equipment and first-class management team ensure our high quality pcb board manufacturing, punctual delivery and competitive pcb board manufacturing price.

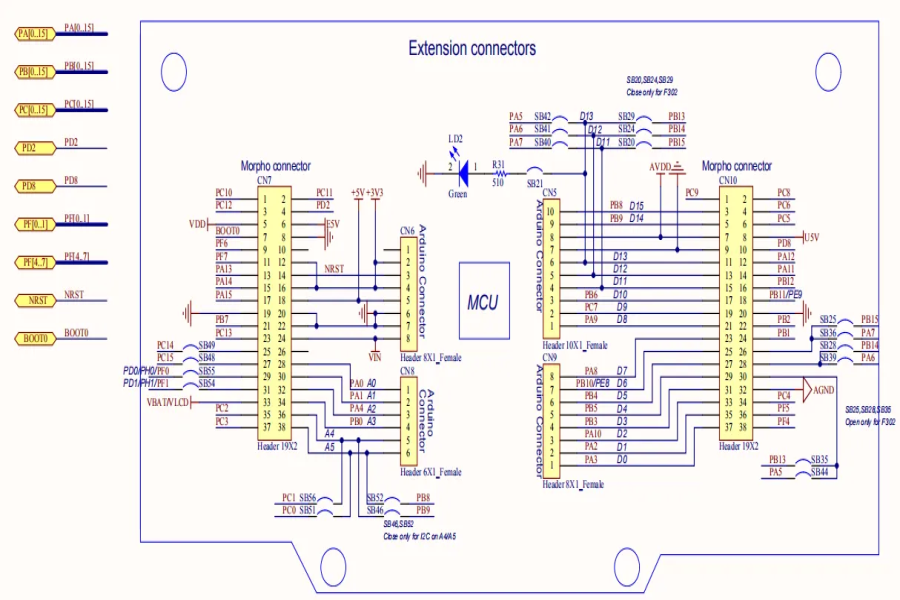

pcb board manufacturing design

PCB board manufacturing design is a complex process that involves the use of specialized software and equipment to create a circuit board design. pcb board manufacturing The design process begins with the creation of a schematic diagram. This diagram outlines the connections between components and serves as a blueprint for the board. Once the schematic is complete, pcb board manufacturing the design is converted into a netlist, which is a detailed list of the electrical connections between components. Next, pcb board manufacturing the netlist is used to generate a layout using various design tools, such as CAD software. The layout includes the placement of components, tracks, and vias, as well as the routing of electrical signals. Finally, pcb board manufacturing the design is tested and verified before being sent to the fabrication facility.

Our pcb board manufacturing parameters and process

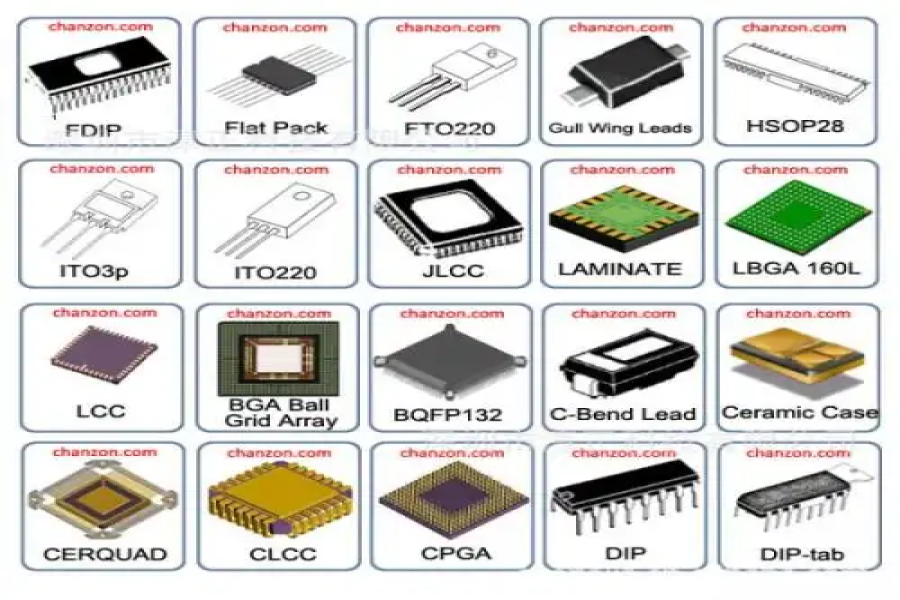

The PCB board manufacturing process consists of a series of steps, including designing the board, preparing the board, etching, drilling, plating, surface treatment, testing, and assembly. The materials used in PCB board manufacturing vary depending on the application. Common materials include FR-4, CEM-3, FR-1, FR-2, CEM-1, and Polyimide. The substrate is the base material for the PCB board manufacturing and it can be made of different materials. Common substrates include FR-4, CEM-3, FR-1, FR-2, CEM-1, and Polyimide. The number of layers in a PCB board manufacturing depends on the application and complexity. Commonly used layers are single-layer, double-layer, and multi-layer. PCB board manufacturing Drilling is used to create the holes necessary to mount components and connect traces. There are four main types of drills used in PCB board manufacturing: mechanical, laser, CNC, and chemical. PCB board manufacturing Plating is used to protect the board and to provide electrical connections between components. The most common plating materials are tin, copper, gold, and silver.

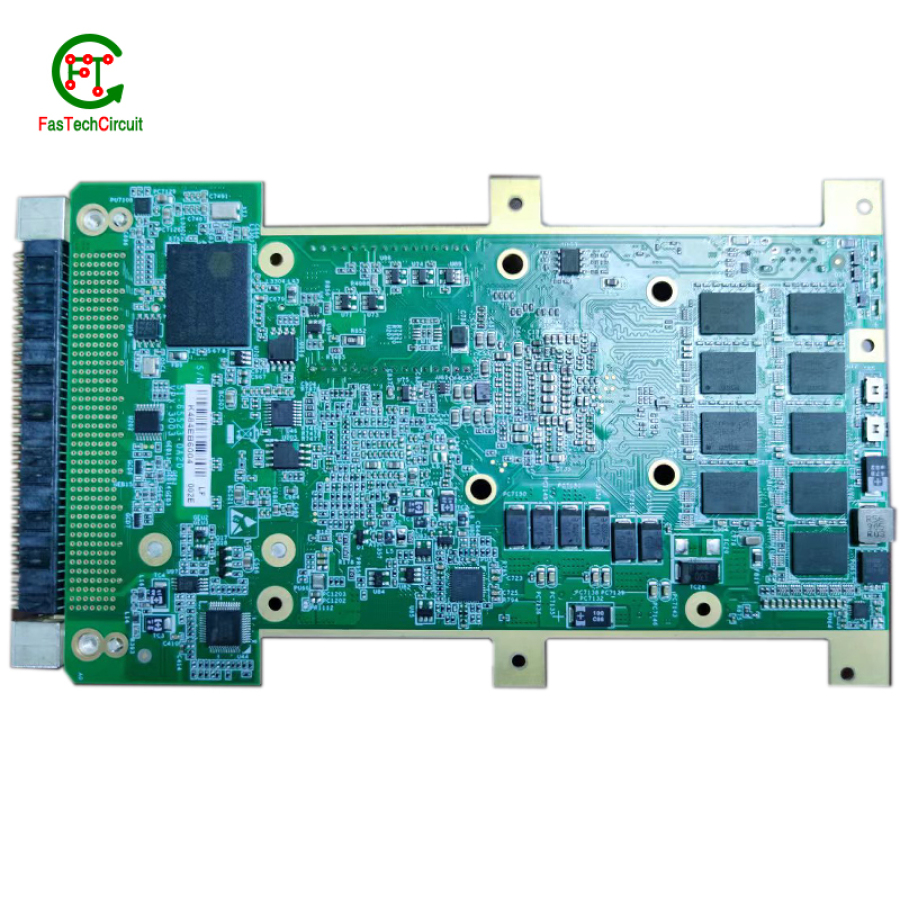

PCBA(SMT+DIP+function test) pcb board manufacturing

20 layer board used in communications and aerospace

pcb board manufacturing Rogers material PCB(25G)

RO3035, RO4003, RO4350. High frequency material

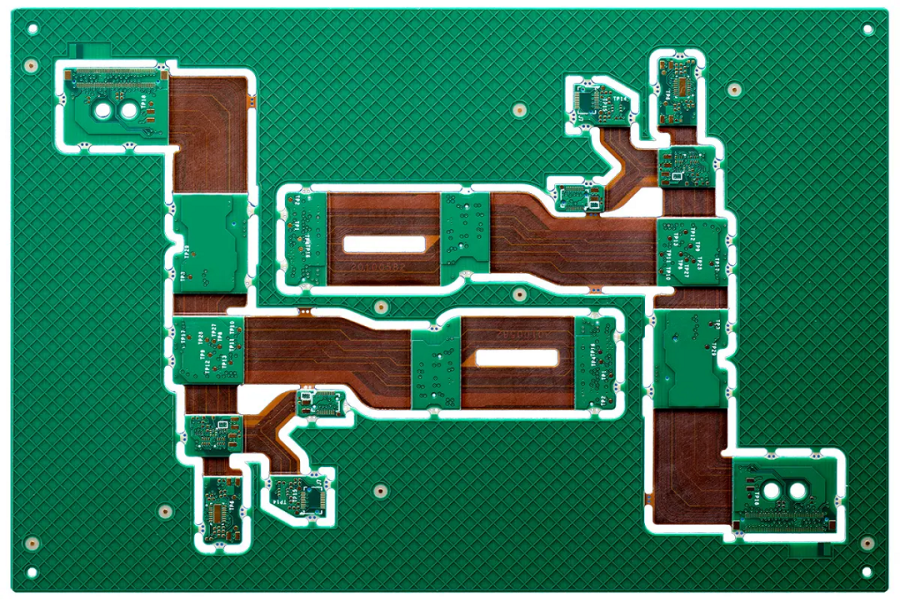

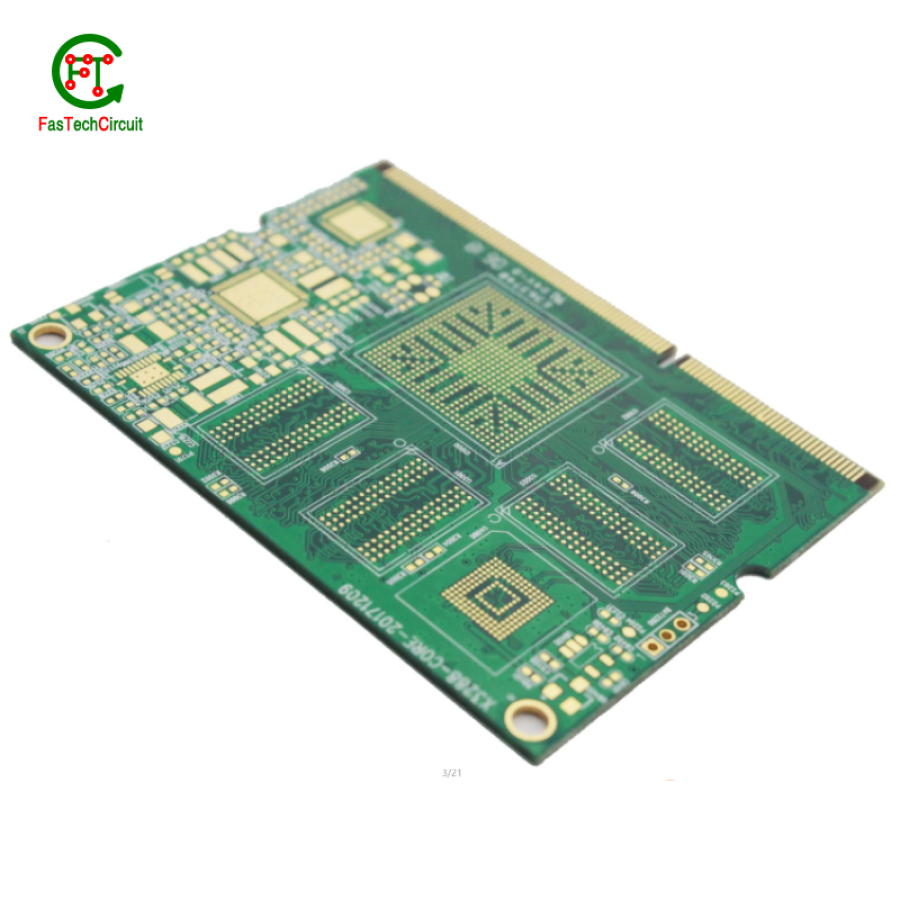

pcb board manufacturing HDI board with laser drill

16 layer board, L1-L2/L2-L3/L14-L15/L15-L16 laser holes, L3-L15 bury holes

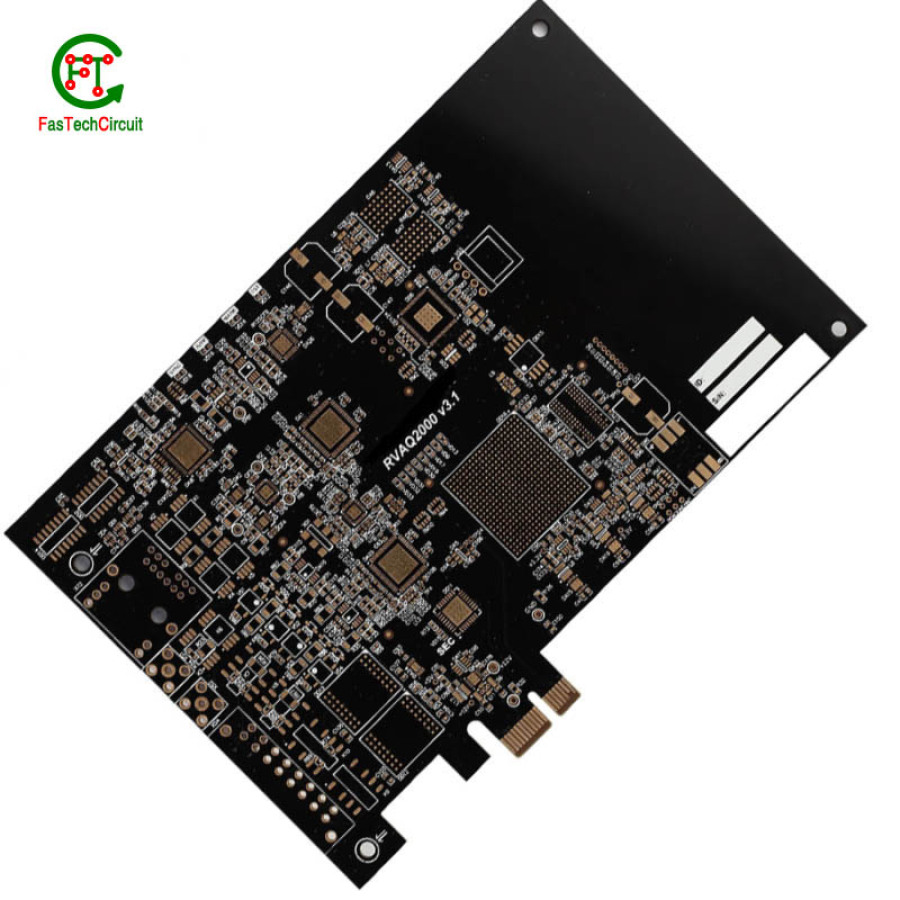

pcb board manufacturing Selective hard gold board

Hard gold on selective pads, gold thickness 50u

pcb board manufacturing 30 layer high precision PCB

thickness 5.0mm, aspect ratio=10:1

pcb board manufacturing Heavy copper PCB up to 12 OZ

14 layer board, 4 OZ for inner and outer layer

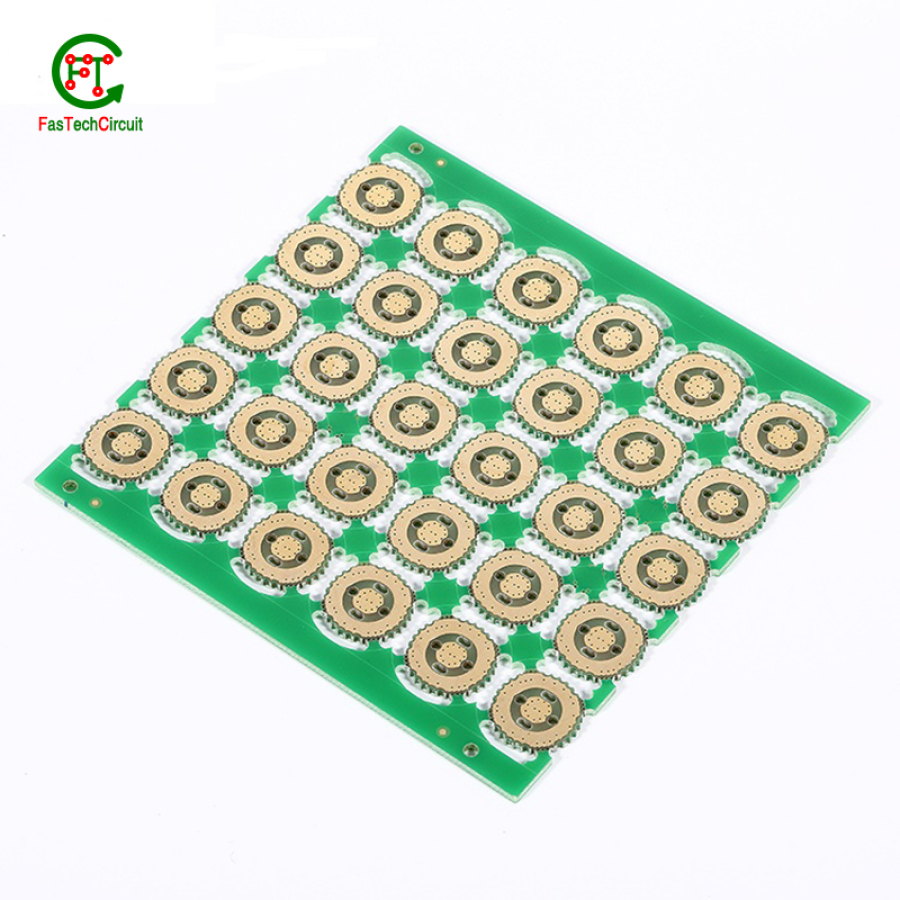

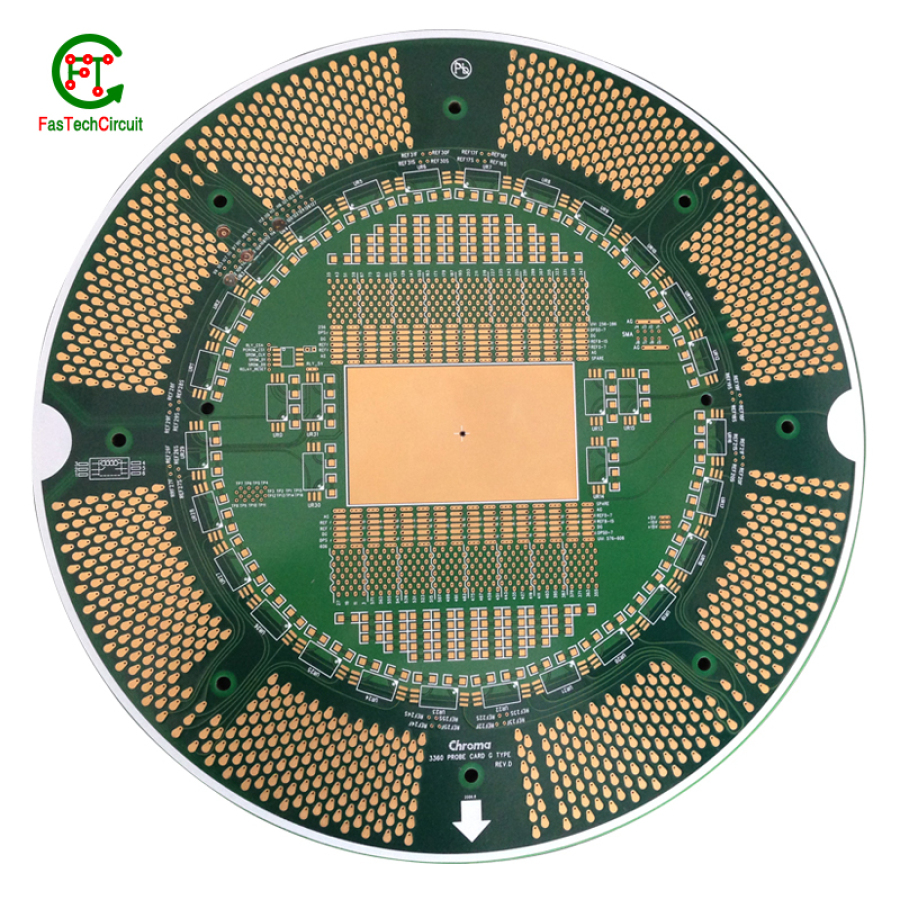

pcb board manufacturing Semiconductor test board

L18, hard gold 50upcb board manufacturing How To Contact US

PCB from 1 to 30 layers, HDI, Heavy Copper, Rigid-flex board with "pcb board manufacturing One-Stop" service.