why you should choose MULTILAYER PCB?

MULTILAYER PCB, also known as printed circuit boards, is a type of advanced electronic component widely used in various electronic products. It is a crucial component that connects different electronic components and provides a platform for the smooth functioning of electronic devices.

In recent years, multilayer PCB have gained immense popularity in different industries due to their numerous benefits. In this article, we will discuss why you should choose multilayer PCB for your electronic products.

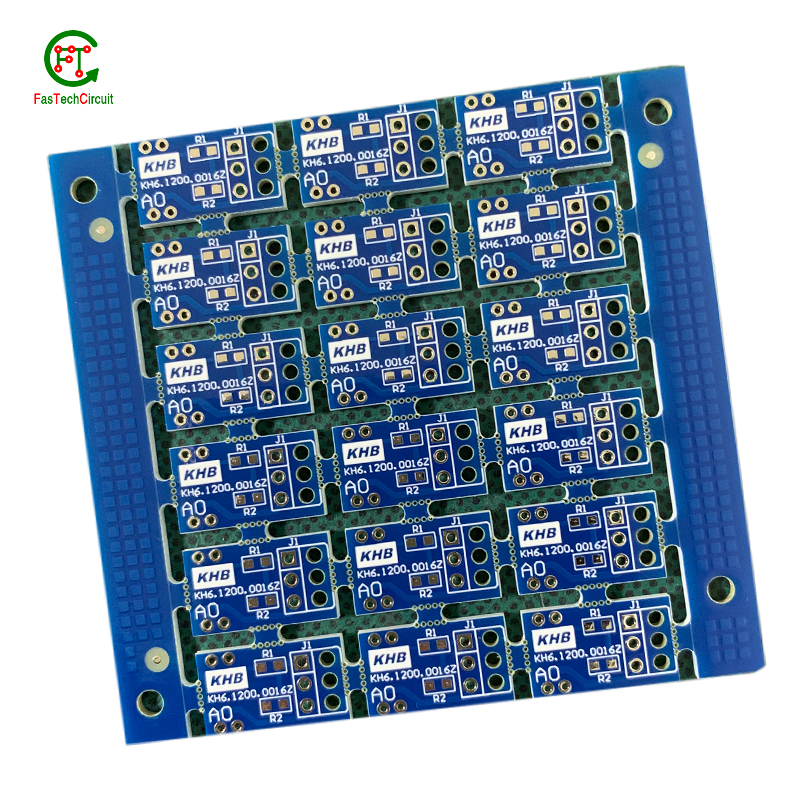

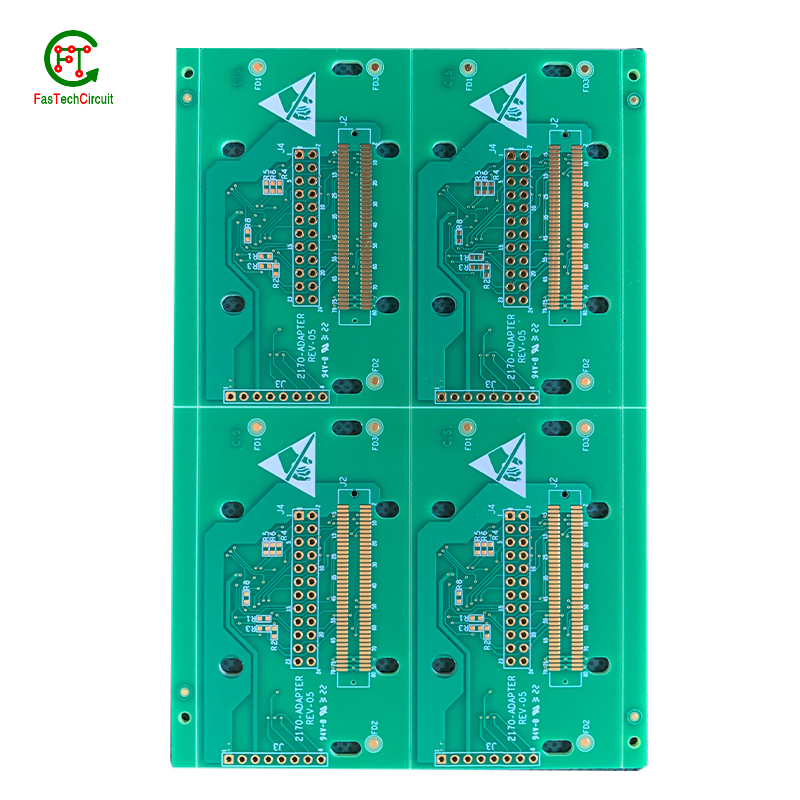

1. High Density and Compact Design: One of the main reasons to choose multilayer PCB is its high density and compact design. As compared to single-layer or double-layer PCBs, multilayer PCBs have multiple layers of circuits stacked together, providing more surface area for components to be placed. This makes it ideal for complex and compact electronic designs, saving valuable space in the final product.

2. High Reliability: Multilayer PCB have multiple electrical connections, which provide high reliability and stability. It ensures the proper functioning of the electronic product, even under extreme conditions, making it suitable for various industries such as aerospace, medical, automotive, and more.

3. Reduced Signal Interference: The multiple layers of circuits in multilayer PCB are separated by a dielectric material, which reduces the signal interference or noise between different signals. This results in better signal integrity and improves the overall performance of the electronic device.

4. Enhanced Thermal Performance: Multilayer PCB have a higher thermal performance as compared to single-layer or double-layer PCBs. The multiple layers and copper fillings in multilayer PCBs help to dissipate heat more efficiently, reducing the chances of overheating and damage to the electronic components.

5. Better Electrical Properties: Multilayer PCB are designed with a variety of materials with different dielectric constants, which helps to improve its electrical properties such as impedance control, signal integrity, and capacitive loading. It makes them suitable for applications that require high-speed and high-frequency signals.

6. Cost-Effective: Although multilayer PCB are more complex and require more manufacturing steps, their cost per unit decreases as the number of layers increases. This makes them more cost-effective in the long run, especially for large production runs.

7. Faster and Easier Assembly: As multilayer PCB have multiple layers of circuits, it eliminates the need for point-to-point wiring, which significantly reduces the assembly time and effort. This makes it easier to manufacture complex and advanced electronic products.

8. Flexibility in Design: Multilayer PCB offer flexibility in design, allowing engineers to design more complex and compact electronics with ease. With multiple layers, they can incorporate different design elements such as ground and power planes, signal routing, and more, making them suitable for a wide range of applications.

9. Customization Options: Multilayer PCB offer customization options, allowing engineers to design PCBs according to their specific requirements. They can choose the number of layers, materials, and design elements to meet the needs of their electronic products.

10. Reliable Electrical Connections: Multilayer PCB have multiple layers of electrical connections, making them more reliable and reducing the chances of open circuits or short circuits. This makes them suitable for high-performance and critical applications where reliability is crucial.

multilayer PCB offer a wide range of benefits that make them an ideal choice for electronic products. With their high density, compact design, high reliability, enhanced thermal performance, and customization options, they are suitable for various industries and applications. Furthermore, with the continuous advancement in technology, multilayer PCB are only going to get better, making them a wise choice for electronic product designers and manufacturers.

Our multilayer PCB prototype is designed to provide high-quality and fast turnaround for your electronic projects. With up to 6 layers, this customizable PCB can accommodate complex circuit designs and provide superior signal integrity. Our state-of-the-art manufacturing process ensures precise and reliable production, while our experienced engineers are available to review and optimize your design. With quick turnarounds and affordable pricing, our multilayer PCB prototype is the perfect solution for your next project.

2.How is the thickness of a multilayer PCB determined?

3.What is the difference between a multilayer and a flex PCB?

4.Are multilayer PCBs more expensive than single-sided PCBs?

5.How can I ensure the reliability of my multilayer PCB?

6.What is the process for manufacturing a multilayer PCB?

7.Can multilayer PCBs be used in automotive applications?

1.How many conductive layers can a multilayer PCB have?

Multilayer PCBs can have anywhere from 4 to 32 or more conductive layers, depending on the complexity of the circuit design and the specific requirements of the device.

2.How is the thickness of a multilayer PCB determined?

The thickness of a multilayer PCB is determined by the number and thickness of the copper layers, the thickness of the insulating layers, and the overall thickness tolerance specified by the designer.

3.What is the difference between a multilayer and a flex PCB?

A multilayer PCB is rigid and does not allow bending, while a flex PCB is made of flexible materials and allows for bending and twisting. Both types can have multiple conductive layers.

4.Are multilayer PCBs more expensive than single-sided PCBs?

Yes, multilayer PCBs are generally more expensive than single-sided PCBs due to the complexity and additional layers involved in their manufacturing.

5.How can I ensure the reliability of my multilayer PCB?

To ensure the reliability of a multilayer PCB, it is important to work with a reputable manufacturer, adhere to industry standards and guidelines, and perform thorough testing before production.

6.What is the process for manufacturing a multilayer PCB?

The process for manufacturing a multilayer PCB involves several steps, including layer stackup, drilling, plating, etching, and solder masking. It also involves inspections and testing to ensure quality and accuracy.

7.Can multilayer PCBs be used in automotive applications?

Yes, multilayer PCBs are commonly used in automotive applications due to their reliability and compact design.

RELATED NEWS

pcb board manufacturing How To Contact US

PCB from 1 to 30 layers, HDI, Heavy Copper, Rigid-flex board with "pcb board manufacturing One-Stop" service.