Key technologies and considerations in PCB design

With the wide application of electronic products, PCB (Printed Circuit Board, printed circuit board) has become an indispensable part of modern electronic products. In the process of PCB design, there are many key technologies and precautions that need our attention. FasTechCircuit will introduce key technologies and considerations in PCB design.

1. Key technologies in PCB design

(1)Schematic design technology

Schematic design technology is one of the most basic and critical technologies in PCB design. Schematic design technology can draw circuit schematic diagrams through software to provide a basis for subsequent PCB layout and wiring.

(2)Layout Design Technology

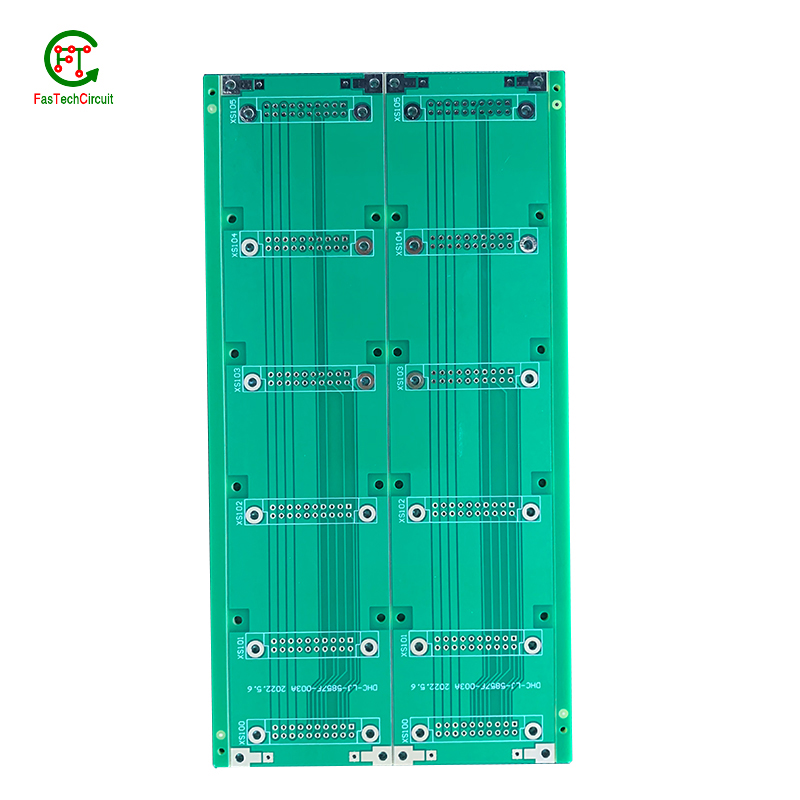

Layout design technology is one of the very important technologies in PCB design. Layout design technology can determine the position of each component on the PCB, as well as the relative position and layout mode between components, providing the basis for subsequent wiring design.

(3)Wiring design technology

Wiring design technology is one of the very important technologies in PCB design. Wiring design technology can realize the transmission and connection of circuit signals, so that the circuit can work normally. Wiring design technology needs to consider factors such as transmission speed, anti-interference, and signal integrity of circuit signals.

(4) Package Design Technology

Packaging design technology is one of the very important technologies in PCB design. Packaging design technology can package components into packages of a certain shape and size, so as to facilitate the layout and wiring of components on the PCB. Packaging design technology needs to consider factors such as the size, shape, number of pins, and arrangement of components.

(5)Simulation analysis technology

Simulation analysis technology is one of the very important technologies in PCB design. Simulation analysis technology can conduct electromagnetic simulation, thermal simulation, mechanical simulation and other analysis on PCB in order to optimize design scheme and improve design quality.

2. Matters needing attention in PCB design

(1)Determination of PCB size

In PCB design, the size of the PCB needs to be determined according to the complexity of the circuit, the size and quantity of components and other factors. Generally speaking, the size of the PCB should be as small as possible, but also ensure that the spacing between components is sufficient for wiring and repair.

(2)How components are laid out

When designing the PCB, it is necessary to arrange the position of the components reasonably to make the layout compact and beautiful. At the same time, the transmission speed of the circuit signal, anti-interference and other factors should also be considered. Generally speaking, the layout should follow certain rules and principles, such as the arrangement of components, the direction of pins, etc.

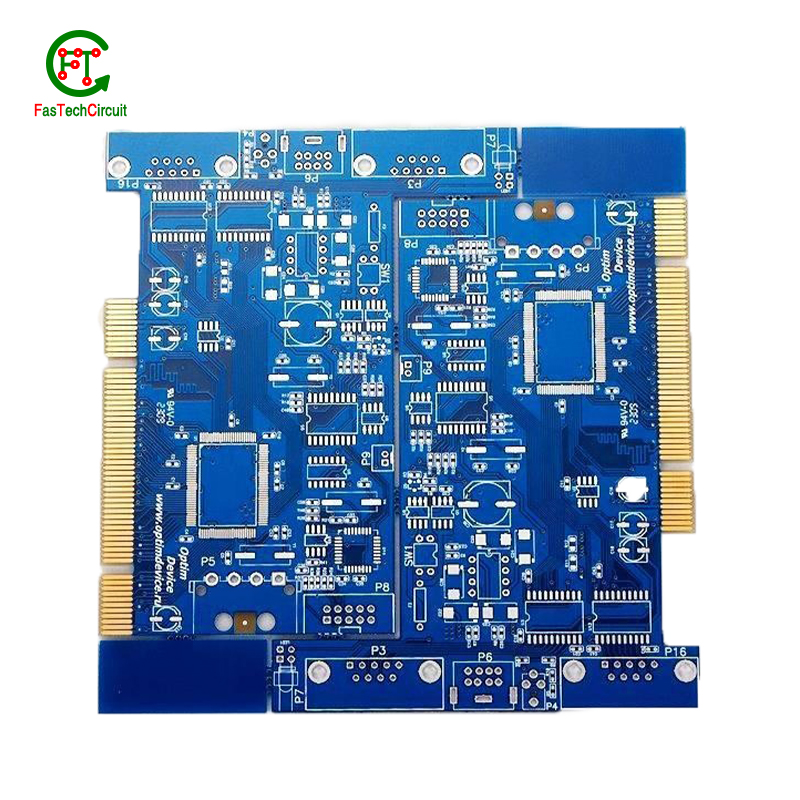

(3)PCB layer selection

When designing a PCB, it is necessary to select the number of layers of the PCB according to the complexity of the circuit and the number of components. Generally speaking, the more layers of PCB, the higher the complexity of the circuit, but the cost will increase accordingly.

(4)PCB grounding and power supply design

When designing the PCB, it is necessary to reasonably design the grounding and power supply of the PCB in order to ensure the stability and reliability of the circuit. Generally speaking, the ground and power supply should be laid out at both ends of the PCB in order to reduce the interference and noise of the circuit.

(5)Impedance matching design of PCB

In PCB design, it is necessary to carry out impedance matching design according to the transmission speed and frequency of the circuit signal in order to ensure the stability and integrity of the signal. Impedance matching design needs to consider factors such as the characteristic impedance of components and the characteristic impedance of PCB lines.

The key technologies and precautions in PCB design are very important, and we need to take them seriously and master them. In the actual design, it is necessary to select the appropriate technology and method according to the specific situation in order to ensure the quality and reliability of the PCB design.

RELATED NEWS

pcb board manufacturing How To Contact US

PCB from 1 to 30 layers, HDI, Heavy Copper, Rigid-flex board with "pcb board manufacturing One-Stop" service.