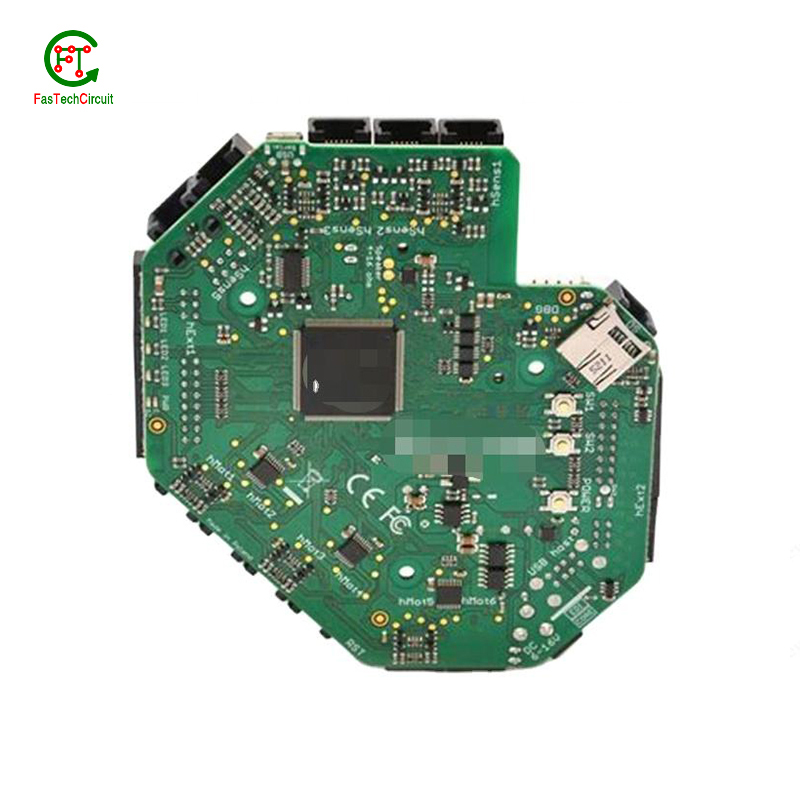

printed circuit board assembly

The main function of the printed circuit board assembly

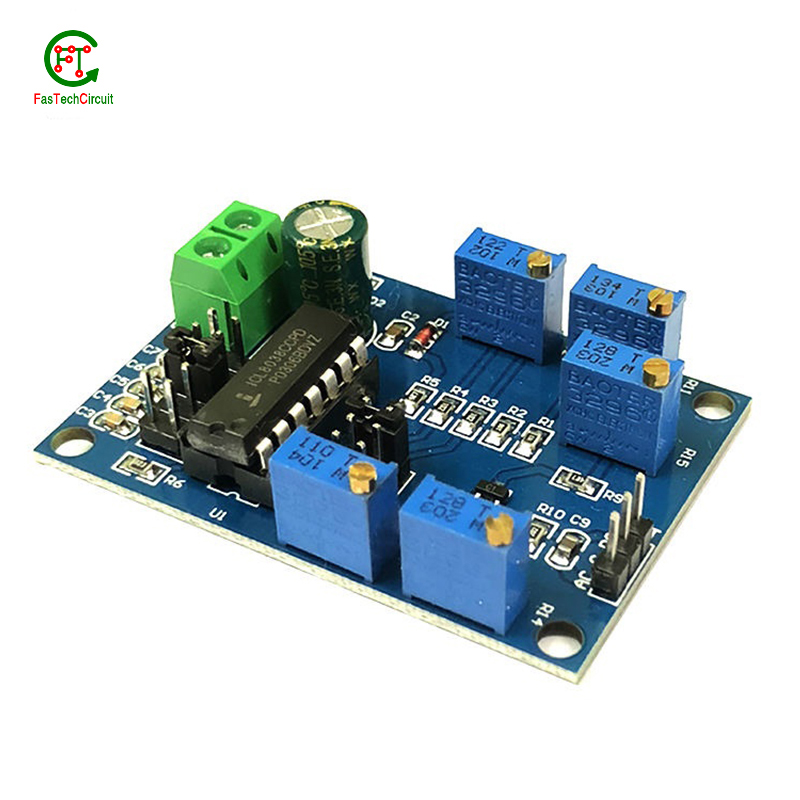

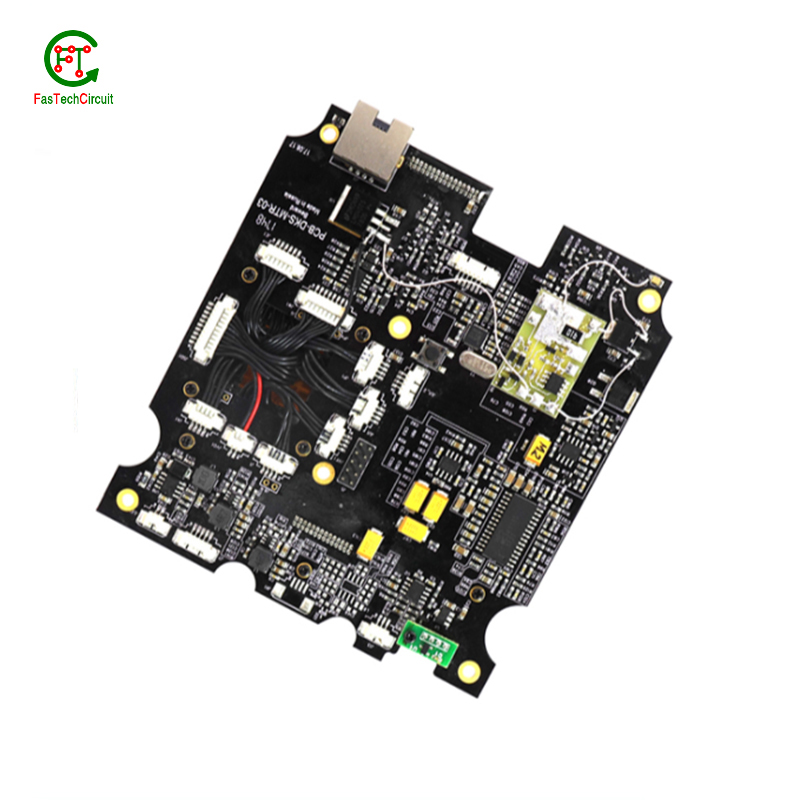

Printed circuit board assembly (PCBA), printed curcuit board, is the process of welding components to printed circuit board (PCB) to create electronic equipment. The PCBA process includes assembling components such as resistors, capacitors, integrated circuits and connectors onto PCBs. The PCBA process also includes testing the assembly board to ensure its normal operation. PCBA process is very important for the production of electronic equipment, because it ensures the correct connection of components and the normal operation of equipment.

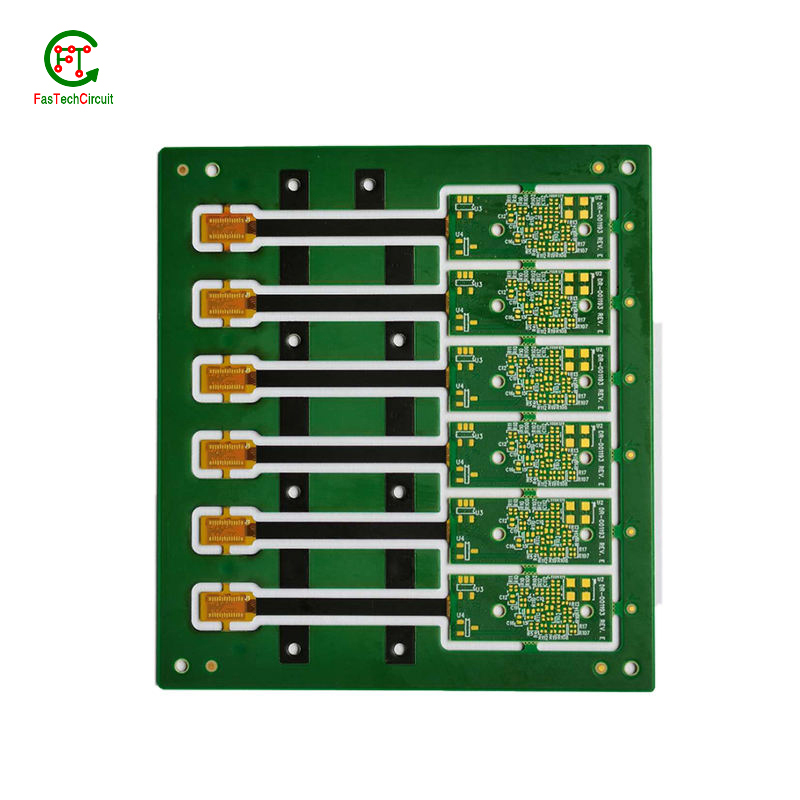

How many types of printed circuit board assembly are there?

There are four main types of printed circuit board assembly: surface mount technology (SMT), through-hole technology (THT), mixed technology, and ball grid array (BGA).

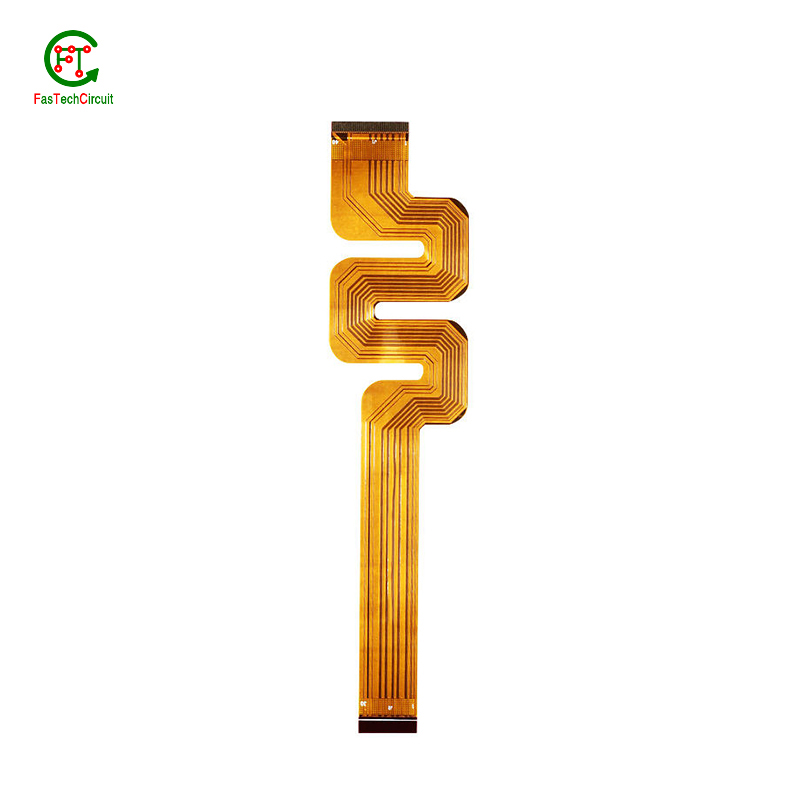

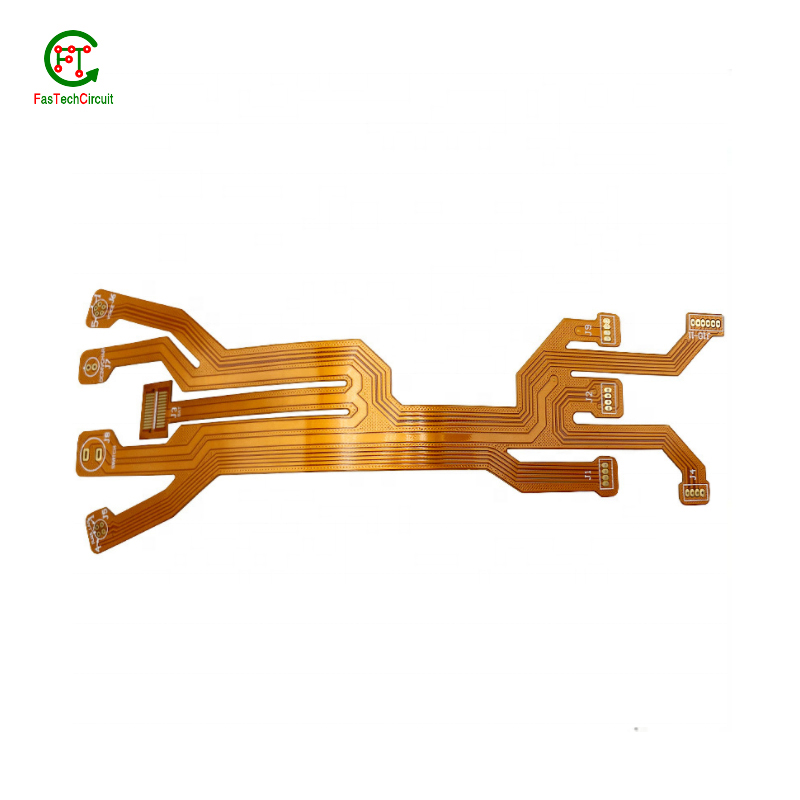

Which material printed circuit board assembly is the most comfortable to wear?

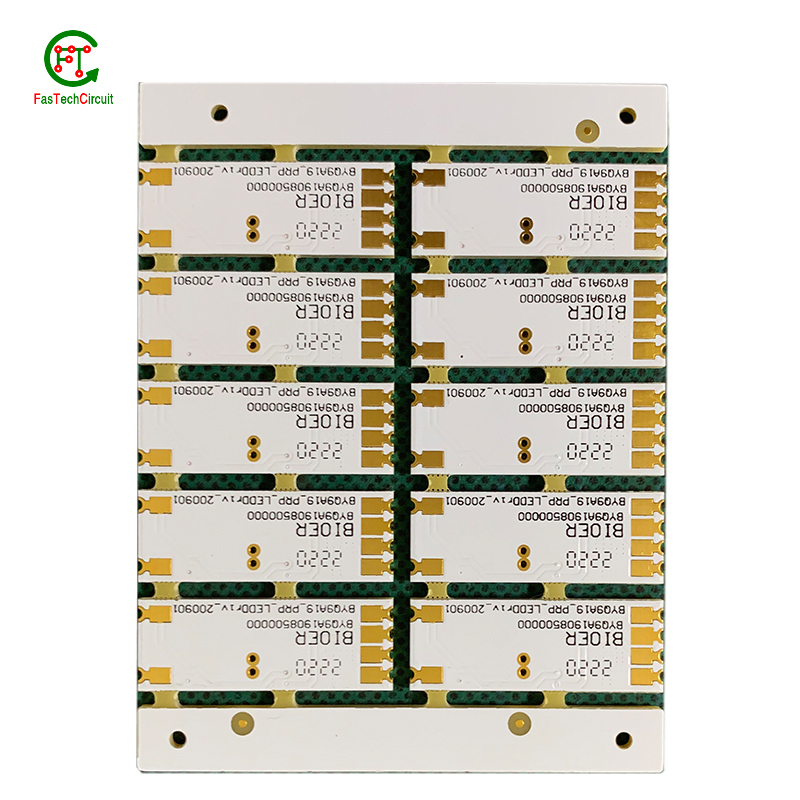

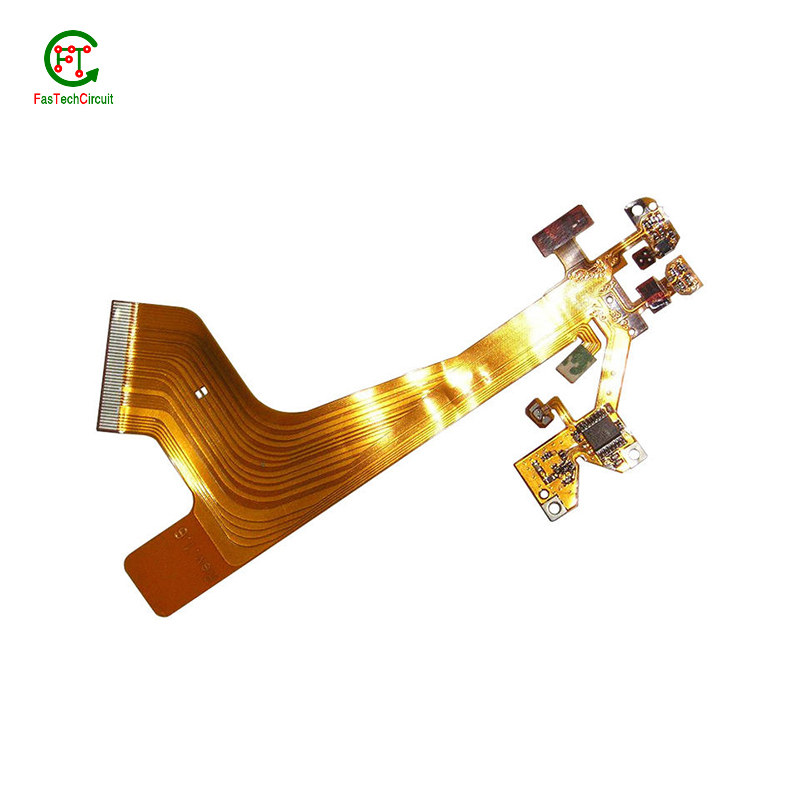

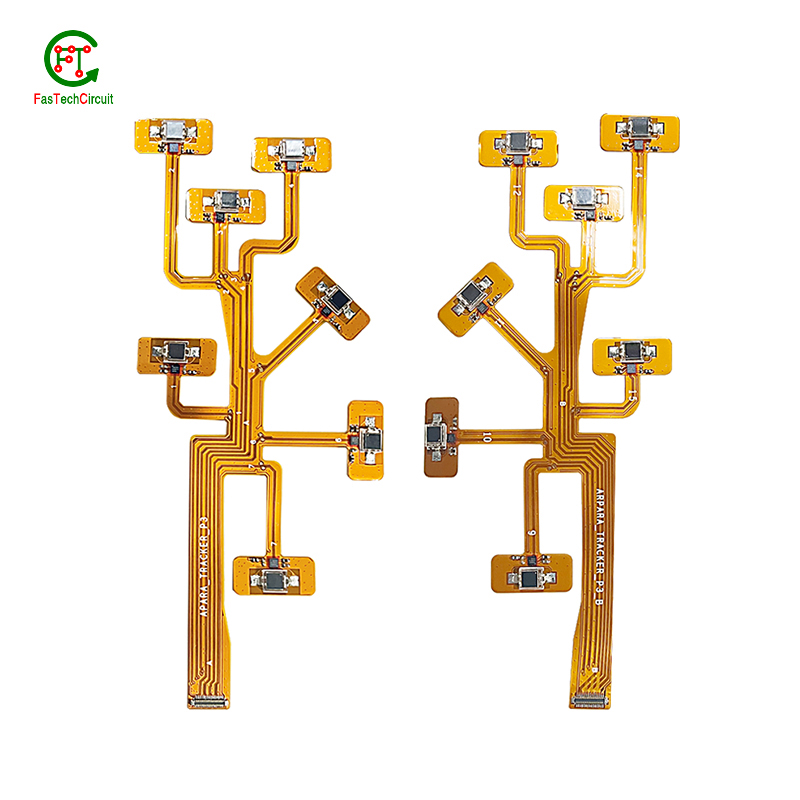

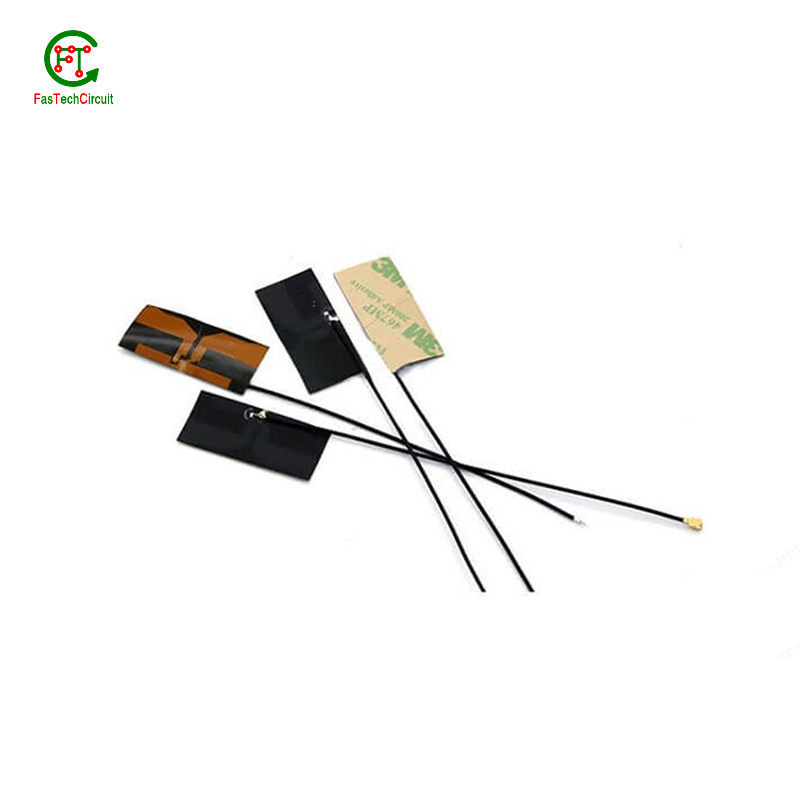

The most comfortable printed circuit board assembly to wear is one made from flexible materials such as polyimide or polyester. These materials are lightweight and flexible, making them comfortable to wear for extended periods of time. They also provide excellent electrical insulation and are resistant to heat, chemicals, and abrasion.

How to purchase printed circuit board assembly from China?

1. Research and select a reliable printed circuit board assembly manufacturer in China. You can use online resources such as Alibaba or Global Sources to find a list of potential suppliers.

2. Contact the manufacturer and discuss your requirements. Provide them with detailed information about your project, such as the type of components you need, the quantity, and the timeline.

3. Request a quote from the manufacturer. Make sure to include all the details of your project in the quote request.

4. Negotiate the terms of the agreement. This includes the price, payment terms, delivery time, and any other details that need to be discussed.

5. Place the order and make the payment. Make sure to keep all the documents related to the order in case you need to refer to them in the future.

6. Track the progress of the order. Make sure to stay in contact with the manufacturer and ask for updates on the progress of the order.

7. Receive the printed circuit board assembly and inspect it. Make sure that the product meets your requirements and that it is of good quality.

What kinds of fabrics are there for making printed circuit board assembly?

The most common fabrics used for making printed circuit board assembly are polyimide, polyester, and polytetrafluoroethylene (PTFE). Polyimide is a heat-resistant material that is often used for high-temperature applications. Polyester is a strong and durable material that is often used for high-frequency applications. PTFE is a non-conductive material that is often used for insulation and protection.

When was the printed circuit board assembly invented?

The printed circuit board assembly was invented in the early 1950s.

How is the printed circuit board assembly produced?

The printed circuit board assembly is produced through a process called surface mount technology (SMT). This process involves placing components onto the board and soldering them in place. The components are placed onto the board using a pick-and-place machine, which is a robotic arm that is programmed to place the components in the correct locations. Once the components are in place, they are soldered to the board using a reflow oven. This process melts the solder and creates a strong bond between the components and the board. After the soldering process is complete, the board is tested to ensure that all components are functioning correctly.

What is the original appearance of the printed circuit board assembly?

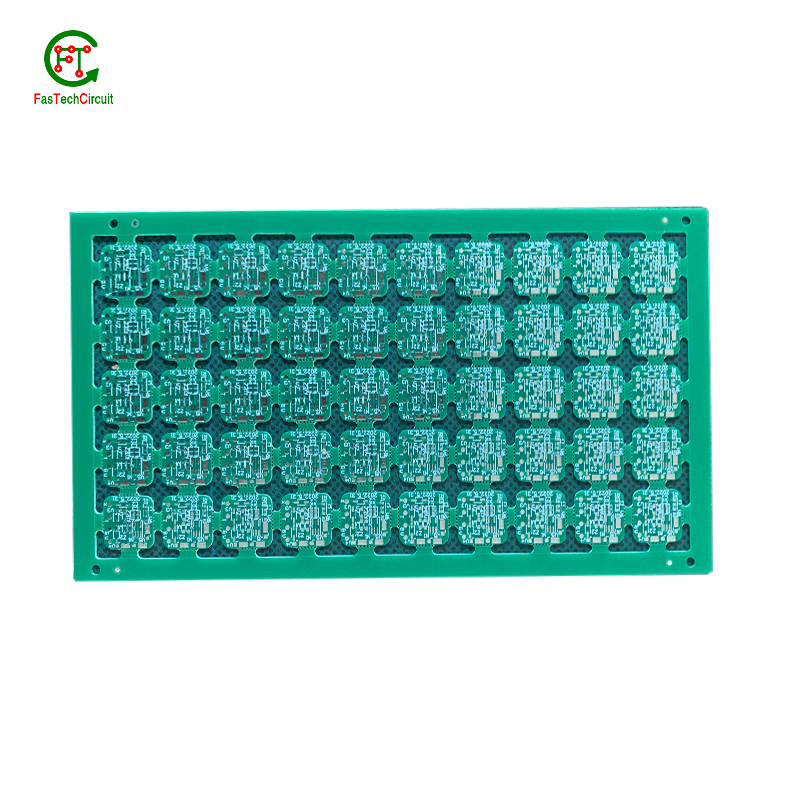

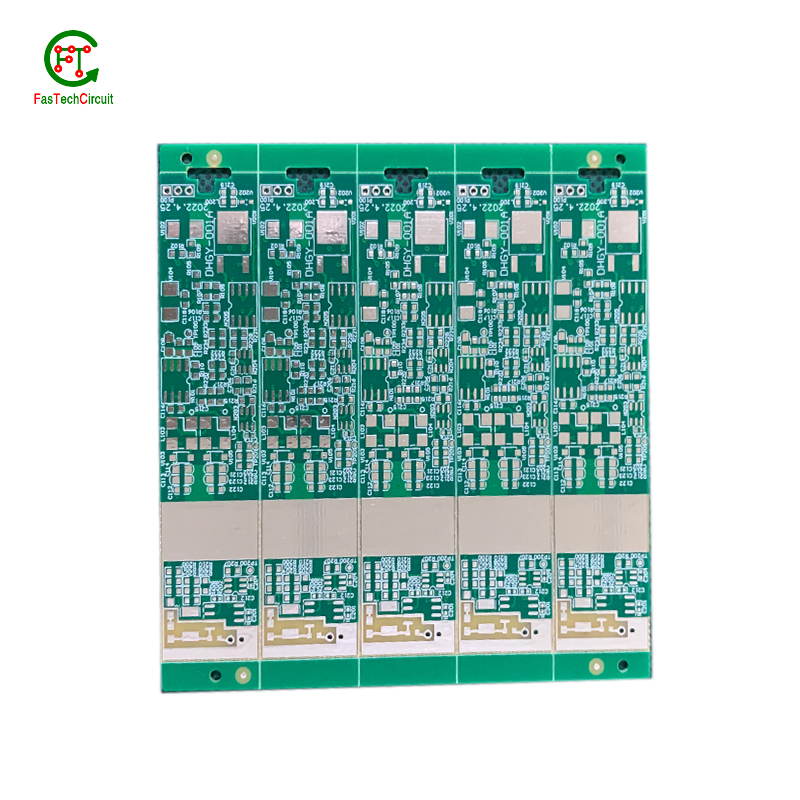

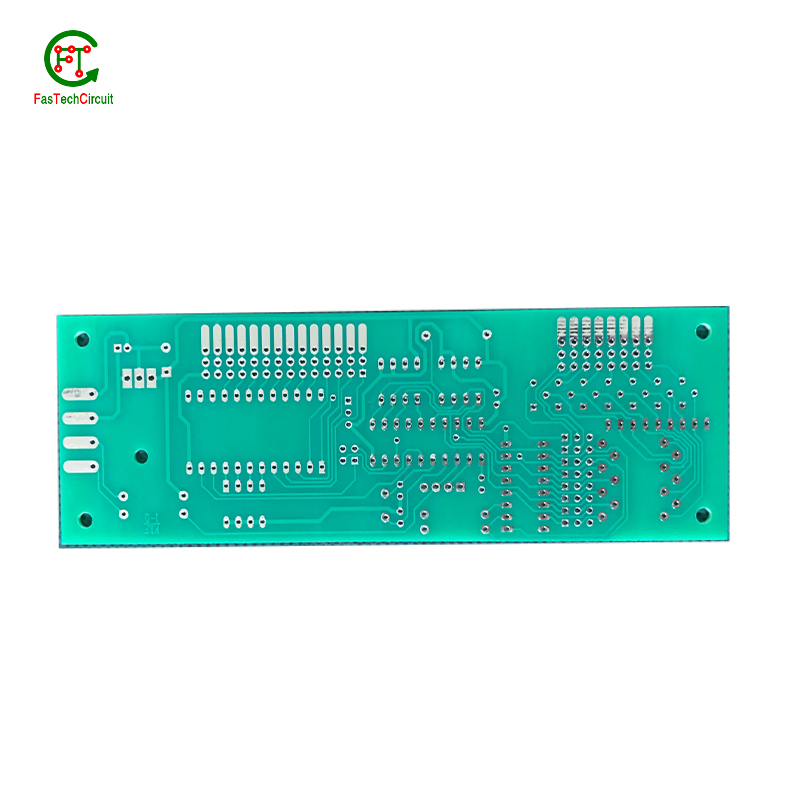

The original appearance of a printed circuit board assembly typically includes a board made of a non-conductive material, such as fiberglass, with copper tracks etched onto it. The board is then populated with components such as resistors, capacitors, transistors, and integrated circuits. The components are soldered onto the board, and the board is then tested to ensure that it is functioning correctly.

How does the printed circuit board assembly manufacturer produce the printed circuit board assembly?

The printed circuit board assembly manufacturer typically follows a process that includes designing the printed circuit board, ordering the components, soldering the components to the board, testing the board, and packaging the board for shipment. The specific steps may vary depending on the complexity of the board and the components used.

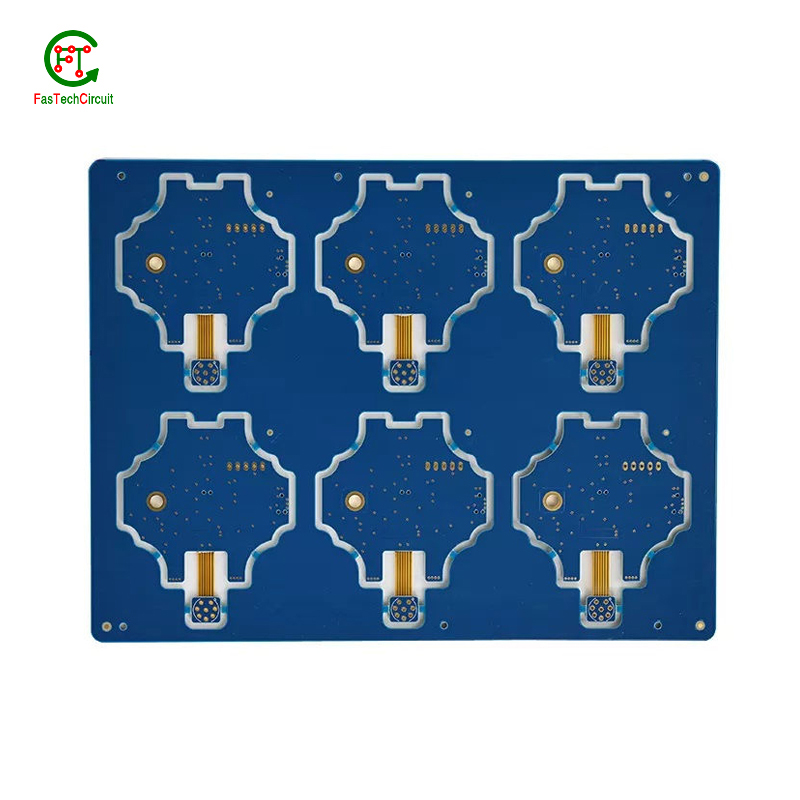

What products can printed circuit board assembly manufacturer produce?

A printed circuit board assembly manufacturer can produce a wide range of products, including single-sided, double-sided, and multi-layer printed circuit boards, as well as components such as resistors, capacitors, transistors, and integrated circuits. They can also produce custom-designed circuit boards and assemblies, as well as provide services such as testing, programming, and rework.

Design prototype of printed circuit board assembly printed circuit board assembly

1. Start by creating a schematic diagram of the printed circuit board assembly. This should include all components, connections, and power sources.

2. Create a layout of the printed circuit board assembly. This should include the placement of components, connections, and power sources.

3. Create a bill of materials for the printed circuit board assembly. This should include all components, their quantities, and their specifications.

4. Create a prototype of the printed circuit board assembly. This should include the printed circuit board, components, and connections.

5. Test the prototype of the printed circuit board assembly. This should include testing for functionality, power, and signal integrity.

6. Create a manufacturing plan for the printed circuit board assembly. This should include the steps for assembly, testing, and quality control.

7. Create a final design of the printed circuit board assembly. This should include the finalized schematic, layout, and bill of materials.

printed circuit board assembly manufacturer need to have the following production equipment

1. Pick and Place Machine: This machine is used to place components onto the printed circuit board.

2. Reflow Oven: This machine is used to heat the components and solder them onto the board.

3. Wave Soldering Machine: This machine is used to solder components onto the board using a wave of molten solder.

4. Automated Optical Inspection (AOI) Machine: This machine is used to inspect the board for any defects or errors.

5. X-Ray Machine: This machine is used to inspect the board for any hidden defects or errors.

6. Test Equipment: This equipment is used to test the board for functionality.

7. Cleaning Equipment: This equipment is used to clean the board after assembly.

Some suggestions for improving the utilization rate of equipment for printed circuit board assembly manufacturer

1. Implement preventive maintenance: Regularly inspect and maintain equipment to ensure it is running at peak efficiency.

2. Utilize automation: Automate processes to reduce manual labor and increase efficiency.

3. Invest in new technology: Invest in new technology to increase the speed and accuracy of production.

4. Improve process flow: Streamline processes to reduce downtime and increase throughput.

5. Train employees: Train employees on the proper use of equipment to reduce errors and increase efficiency.

6. Monitor performance: Monitor equipment performance to identify areas for improvement.

7. Utilize data: Utilize data to identify areas of inefficiency and develop strategies to improve utilization.

8. Reduce waste: Reduce waste by optimizing processes and eliminating unnecessary steps.

9. Invest in quality control: Invest in quality control measures to ensure that products are produced correctly and efficiently.

10. Utilize lean manufacturing: Utilize lean manufacturing principles to reduce waste and increase efficiency.

What are the advantages of printed circuit board assembly manufacturer with large-scale production compared with small-scale production?

1. Cost Savings: Large-scale production allows for economies of scale, which can result in cost savings for the customer.

2. Quality Control: Large-scale production allows for more stringent quality control measures, resulting in higher quality products.

3. Faster Turnaround Time: Large-scale production allows for faster turnaround times, resulting in faster delivery of products.

4. Increased Capacity: Large-scale production allows for increased capacity, resulting in more products being produced in a shorter amount of time.

5. Automation: Large-scale production allows for more automation, resulting in more efficient production processes.

Who are the global printed circuit board assembly manufacturer with strong research and development capabilities? What are their advantages?

1. Flextronics: Flextronics is a global printed circuit board assembly manufacturer with strong research and development capabilities. Their advantages include a global presence, advanced manufacturing capabilities, and a commitment to quality and innovation.

2. Jabil: Jabil is a global printed circuit board assembly manufacturer with strong research and development capabilities. Their advantages include a comprehensive portfolio of services, advanced manufacturing capabilities, and a commitment to quality and customer service.

3. Sanmina: Sanmina is a global printed circuit board assembly manufacturer with strong research and development capabilities. Their advantages include a comprehensive portfolio of services, advanced manufacturing capabilities, and a commitment to quality and customer service.

4. Celestica: Celestica is a global printed circuit board assembly manufacturer with strong research and development capabilities. Their advantages include a comprehensive portfolio of services, advanced manufacturing capabilities, and a commitment to quality and customer service.

5. Benchmark Electronics: Benchmark Electronics is a global printed circuit board assembly manufacturer with strong research and development capabilities. Their advantages include a comprehensive portfolio of services, advanced manufacturing capabilities, and a commitment to quality and customer service.

When purchasing printed circuit board assembly from Chinese printed circuit board assembly manufacturer, you need to pay attention to the following payment and delivery terms

1. Payment Terms: Most Chinese printed circuit board assembly manufacturers accept payment by wire transfer, PayPal, or credit card. It is important to confirm the payment terms with the manufacturer before placing an order.

2. Delivery Terms: Most Chinese printed circuit board assembly manufacturers offer a variety of delivery options, including air freight, sea freight, and express delivery. It is important to confirm the delivery terms with the manufacturer before placing an order.

3. Quality Assurance: It is important to ensure that the printed circuit board assembly is manufactured to the highest quality standards. It is important to confirm the quality assurance measures taken by the manufacturer before placing an order.

4. Warranty: Most Chinese printed circuit board assembly manufacturers offer a warranty on their products. It is important to confirm the warranty terms with the manufacturer before placing an order.

printed circuit board assembly manufacturer raw material supply chain development and maintenance experience sharing

1. Establish a reliable supply chain: Establishing a reliable supply chain is essential for any PCB assembly manufacturer. It is important to identify reliable suppliers who can provide quality raw materials at competitive prices. It is also important to establish a good relationship with the suppliers to ensure that they can provide timely delivery of the materials.

2. Monitor the quality of raw materials: Quality control is essential for any PCB assembly manufacturer. It is important to monitor the quality of the raw materials to ensure that they meet the required standards. This can be done by conducting regular inspections and tests on the materials.

3. Develop a cost-effective procurement strategy: Developing a cost-effective procurement strategy is essential for any PCB assembly manufacturer. It is important to identify the most cost-effective sources of raw materials and to negotiate the best prices.

4. Maintain a good relationship with suppliers: Maintaining a good relationship with suppliers is essential for any PCB assembly manufacturer. It is important to ensure that the suppliers are reliable and can provide timely delivery of the materials.

5. Monitor the market trends: It is important to monitor the market trends to ensure that the raw materials are available at competitive prices. This can be done by keeping track of the prices of the raw materials and the demand for them.

Several update iterations experienced by printed circuit board assembly manufacturer in production technology

1. Automation: Automation has been a major focus of PCB assembly manufacturers in recent years. Automation has allowed for faster production times, improved accuracy, and reduced labor costs. Automation technologies such as pick-and-place machines, reflow ovens, and automated optical inspection systems have been implemented to streamline the production process.

2. Quality Control: Quality control is essential for PCB assembly manufacturers to ensure that their products meet customer requirements. Quality control measures such as visual inspection, X-ray inspection, and automated optical inspection are used to detect any defects in the assembly process.

3. Process Optimization: Process optimization is a key factor in improving the efficiency of PCB assembly production. Process optimization techniques such as Six Sigma and Lean Manufacturing are used to identify and eliminate any inefficiencies in the production process.

4. Component Selection: Component selection is an important factor in PCB assembly production. Components must be chosen based on their electrical and mechanical properties, as well as their cost. Component selection is also important for ensuring that the assembly process is reliable and cost-effective.

5. Traceability: Traceability is a key factor in PCB assembly production. Traceability systems are used to track the components used in the assembly process, as well as the production process itself. This allows for better quality control and improved product reliability.

How many operators do printed circuit board assembly manufacturer need for a production line?

The number of operators needed for a production line in a printed circuit board assembly manufacturer will depend on the size and complexity of the production line. Generally, a production line will require at least one operator to oversee the entire process, as well as additional operators to perform specific tasks such as soldering, testing, and inspection.

The comparison between the production profit of Chinese printed circuit board assembly manufacturer and the previous 10 years

The production profit of Chinese printed circuit board assembly manufacturers has increased significantly over the past 10 years. This is due to the rapid growth of the electronics industry in China, which has led to increased demand for printed circuit board assembly services. In addition, the Chinese government has implemented policies to encourage the development of the electronics industry, which has further boosted the production profit of Chinese printed circuit board assembly manufacturers. As a result, the production profit of Chinese printed circuit board assembly manufacturers has grown significantly over the past 10 years.

Who invented the production process of printed circuit board assembly manufacturer at first?

The first printed circuit board assembly manufacturer was developed by Paul Eisler in 1936. He was an Austrian engineer who developed the process of using a printed circuit board to connect electronic components.

printed circuit board assembly manufacturer production process management

1. Establish a production plan: Establish a production plan that outlines the production process, including the number of products to be produced, the timeline for production, and the resources needed.

2. Source components: Source the components needed for the production process, such as printed circuit boards, components, and other materials.

3. Assemble components: Assemble the components according to the production plan.

4. Test and inspect: Test and inspect the assembled components to ensure they meet quality standards.

5. Package and ship: Package the assembled components and ship them to the customer.

6. Monitor production: Monitor the production process to ensure it is running smoothly and efficiently.

7. Track and report: Track and report on the production process, including any issues that arise.

The production process of the printed circuit board assembly manufacturer

1. Design: The first step in the printed circuit board assembly process is the design phase. This is where the customer provides the manufacturer with the design specifications for the board. The manufacturer then creates a schematic and layout for the board.

2. Fabrication: Once the design is finalized, the manufacturer will fabricate the board. This involves creating the physical board from the design. The board is then populated with components and soldered.

3. Testing: After the board is populated and soldered, it is tested to ensure that it meets the customer’s specifications. This includes testing for electrical and mechanical performance.

4. Assembly: Once the board passes testing, it is ready for assembly. This involves mounting the board in an enclosure and connecting it to other components.

5. Final Testing: After the board is assembled, it is tested again to ensure that it meets the customer’s specifications. This includes testing for electrical and mechanical performance.

6. Shipping: Once the board passes final testing, it is ready to be shipped to the customer.

Compared with 10 years ago, the manufacturing process of printed circuit board assembly manufacturer has the following improvements

1. Increased Automation: Automation has been greatly increased in the manufacturing process of printed circuit board assembly manufacturers. Automated machines are now used to perform tasks such as drilling, soldering, and testing, which were previously done by hand. This has increased the speed and accuracy of the manufacturing process.

2. Improved Quality Control: Quality control has been improved in the manufacturing process of printed circuit board assembly manufacturers. Automated machines are now used to detect defects in the boards and components, which helps to ensure that only high-quality products are produced.

3. Increased Efficiency: The efficiency of the manufacturing process has been increased due to the use of automated machines. This has allowed manufacturers to produce more products in a shorter amount of time.

4. Reduced Costs: The cost of manufacturing printed circuit board assembly has been reduced due to the increased automation and improved quality control. This has allowed manufacturers to offer their products at lower prices.

Three plans for printed circuit board assembly manufacturer to improve production efficiency

1. Automate Production Processes: Automating production processes can help reduce labor costs and increase production efficiency. Automation can also help reduce errors and improve quality control. Automation can be achieved through the use of robotic arms, automated pick-and-place machines, and other automated equipment.

2. Implement Lean Manufacturing: Lean manufacturing is a production system that focuses on eliminating waste and improving efficiency. Lean manufacturing techniques can help reduce costs, improve quality, and increase production speed.

3. Invest in Quality Control: Quality control is essential for printed circuit board assembly manufacturers. Investing in quality control measures such as automated testing and inspection can help reduce errors and improve product quality. Quality control measures can also help reduce costs and improve production efficiency.

The introduction of the latest production technology can make a printed circuit board assembly manufacturer more profitable

The introduction of the latest production technology can make a printed circuit board assembly manufacturer more profitable by increasing efficiency, reducing costs, and improving product quality. By investing in the latest production technology, a manufacturer can reduce the time and labor required to produce a printed circuit board assembly, resulting in lower costs and higher profits. Additionally, the latest production technology can help to improve product quality by ensuring that the components are accurately placed and soldered, and that the boards are free from defects. This can help to reduce the number of returns and warranty claims, resulting in increased customer satisfaction and higher profits.

Analysis of the cost that the printed circuit board assembly manufacturer pays for the implementation of new product research and development every year

The cost of implementing new product research and development (R&D) for a printed circuit board assembly manufacturer can vary significantly depending on the complexity of the product and the resources required to develop it. Generally, the cost of R&D for a printed circuit board assembly manufacturer can include the following:

1. Personnel costs: This includes the salaries of the engineers and other personnel involved in the R&D process.

2. Equipment costs: This includes the cost of purchasing or leasing the necessary equipment for the R&D process.

3. Materials costs: This includes the cost of purchasing the necessary materials for the R&D process.

4. Testing costs: This includes the cost of testing the product during the R&D process.

5. Regulatory costs: This includes the cost of obtaining the necessary regulatory approvals for the product.

6. Marketing costs: This includes the cost of marketing the product once it is developed.

The total cost of implementing new product R&D for a printed circuit board assembly manufacturer can range from tens of thousands of dollars to millions of dollars, depending on the complexity of the product and the resources required to develop it.

The production of printed circuit board assembly manufacturer needs to meet the following environmental protection conditions

1. Adhere to the principle of environmental protection and energy conservation, and strictly abide by the relevant environmental protection laws and regulations.

2. Establish an environmental management system and continuously improve it.

3. Strengthen environmental protection education and training for employees.

4. Strengthen the monitoring and control of environmental pollution sources.

5. Strengthen the control of hazardous substances and waste.

6. Strengthen the control of noise and vibration.

7. Strengthen the control of air pollution.

8. Strengthen the control of water pollution.

9. Strengthen the control of soil pollution.

10. Strengthen the control of radiation pollution.

11. Strengthen the control of ecological environment.

12. Strengthen the control of hazardous waste.

13. Strengthen the control of hazardous chemicals.

14. Strengthen the control of hazardous waste disposal.

15. Strengthen the control of hazardous waste recycling.

16. Strengthen the control of hazardous waste incineration.

17. Strengthen the control of hazardous waste landfill.

18. Strengthen the control of hazardous waste transportation.

19. Strengthen the control of hazardous waste storage.

20. Strengthen the control of hazardous waste treatment.

printed circuit board assembly manufacturer service and quality system

A printed circuit board assembly manufacturer should have a quality system in place to ensure that their products meet customer requirements and industry standards. This system should include processes for design, manufacturing, testing, and inspection. The system should also include procedures for corrective and preventive action, as well as documentation and record keeping. The system should also include a process for customer feedback and continuous improvement. The system should be regularly reviewed and updated to ensure that it is meeting customer needs and industry standards.

printed circuit board assembly manufacturer need to observe the following 5 points to establish a sound supply chain management

1. Establish a Clear Communication System: Establishing a clear communication system between the manufacturer and its suppliers is essential for effective supply chain management. This includes setting up a system for exchanging information, such as order status, delivery schedules, and product specifications.

2. Develop a Supplier Evaluation System: Developing a supplier evaluation system is important for ensuring that the manufacturer is working with reliable and trustworthy suppliers. This system should include criteria for evaluating suppliers, such as quality, cost, delivery, and customer service.

3. Monitor Supplier Performance: Monitoring supplier performance is essential for ensuring that the manufacturer is getting the best value for its money. This includes tracking supplier performance metrics, such as on-time delivery, quality, and cost.

4. Establish a Risk Management System: Establishing a risk management system is important for mitigating the risks associated with supply chain management. This includes identifying potential risks, such as supplier failure, and developing strategies for mitigating them.

5. Implement a Continuous Improvement Process: Implementing a continuous improvement process is essential for ensuring that the manufacturer is always striving to improve its supply chain management. This includes regularly reviewing supplier performance and making changes to the system as needed.

printed circuit board assembly manufacturer need to pay attention to the following 6 points when establishing their own printed circuit board assembly dealer channels

1. Establish a good relationship with the printed circuit board assembly manufacturer: Establishing a good relationship with the printed circuit board assembly manufacturer is the key to success in the printed circuit board assembly dealer channel. The manufacturer should be able to provide the dealer with the necessary technical support and product information.

2. Develop a comprehensive marketing plan: A comprehensive marketing plan should be developed to ensure that the printed circuit board assembly dealer channel is successful. This plan should include the target market, pricing strategy, promotional activities, and other marketing strategies.

3. Develop a strong customer service system: A strong customer service system should be developed to ensure that the printed circuit board assembly dealer channel is successful. This system should include customer service representatives, technical support, and other customer service initiatives.

4. Develop a comprehensive training program: A comprehensive training program should be developed to ensure that the printed circuit board assembly dealer channel is successful. This program should include product training, sales training, and other training initiatives.

5. Develop a comprehensive sales strategy: A comprehensive sales strategy should be developed to ensure that the printed circuit board assembly dealer channel is successful. This strategy should include sales goals, sales tactics, and other sales initiatives.

6. Develop a comprehensive customer service strategy: A comprehensive customer service strategy should be developed to ensure that the printed circuit board assembly dealer channel is successful. This strategy should include customer service initiatives, customer feedback, and other customer service initiatives.

What are the services of printed circuit board assembly manufacturer?

1. Design and fabrication of printed circuit boards (PCBs)

2. Component sourcing and procurement

3. PCB assembly and soldering

4. Testing and inspection

5. Final assembly and packaging

6. Repair and rework services

7. Prototype and low-volume production

8. High-volume production

9. Turnkey solutions

10. Supply chain management

How to improve the quality of printed circuit board assembly manufacturer

1. Invest in Quality Control: Quality control is essential for any printed circuit board assembly manufacturer. Invest in quality control processes and equipment to ensure that all products meet the highest standards.

2. Utilize Automation: Automation can help reduce errors and improve efficiency. Invest in automated processes and equipment to streamline production and reduce costs.

3. Train Employees: Invest in training for your employees to ensure that they are knowledgeable and skilled in the latest technologies and processes.

4. Invest in Testing: Invest in testing equipment and processes to ensure that all products meet the highest standards.

5. Utilize Quality Materials: Invest in quality materials to ensure that all products are of the highest quality.

6. Monitor Production: Monitor production processes to ensure that all products are being produced correctly and efficiently.

7. Invest in Research and Development: Invest in research and development to stay ahead of the competition and ensure that all products are of the highest quality.

R&D direction of printed circuit board assembly manufacturer industry

1. Automation: Automation is becoming increasingly important in the PCB assembly industry. Automation can help reduce costs, improve efficiency, and increase quality. Automation can also help reduce the need for manual labor, which can help reduce labor costs.

2. Miniaturization: Miniaturization is becoming increasingly important in the PCB assembly industry. Miniaturization can help reduce costs, improve efficiency, and increase quality. Miniaturization can also help reduce the need for manual labor, which can help reduce labor costs.

3. Quality Control: Quality control is becoming increasingly important in the PCB assembly industry. Quality control can help ensure that the products produced are of the highest quality and meet customer requirements. Quality control can also help reduce the need for manual labor, which can help reduce labor costs.

4. Design for Manufacturability: Design for manufacturability is becoming increasingly important in the PCB assembly industry. Design for manufacturability can help reduce costs, improve efficiency, and increase quality. Design for manufacturability can also help reduce the need for manual labor, which can help reduce labor costs.

5. Traceability: Traceability is becoming increasingly important in the PCB assembly industry. Traceability can help ensure that the products produced are of the highest quality and meet customer requirements. Traceability can also help reduce the need for manual labor, which can help reduce labor costs.

Customer group and service level of printed circuit board assembly manufacturer

The customer group for a printed circuit board assembly manufacturer typically includes electronics manufacturers, aerospace companies, medical device companies, and other industries that require printed circuit boards. The service level of the manufacturer depends on the specific needs of the customer. Some manufacturers offer a wide range of services, such as design, prototyping, assembly, testing, and packaging. Others may specialize in one or two services, such as assembly or testing. The service level also depends on the complexity of the project and the customer's budget.

After-sales compensation terms for printed circuit board assembly manufacturer

1. Warranty: The printed circuit board assembly manufacturer should provide a warranty for the products they manufacture. The warranty should cover any defects in materials or workmanship for a specified period of time.

2. Replacement: The printed circuit board assembly manufacturer should provide a replacement for any defective parts or assemblies within a specified period of time.

3. Refund: The printed circuit board assembly manufacturer should provide a refund for any defective parts or assemblies within a specified period of time.

4. Repair: The printed circuit board assembly manufacturer should provide repair services for any defective parts or assemblies within a specified period of time.

5. Technical Support: The printed circuit board assembly manufacturer should provide technical support for any questions or issues related to the products they manufacture.

What services are included in the printed circuit board assembly manufacturer's after-sales service?

The after-sales service of a printed circuit board assembly manufacturer typically includes technical support, warranty services, repair services, and spare parts supply. Technical support may include providing technical advice, troubleshooting, and software updates. Warranty services may include repair or replacement of defective parts. Repair services may include diagnostics, repair, and testing of components. Spare parts supply may include providing replacement parts for defective components.

Product quality control of printed circuit board assembly manufacturer

1. Pre-Production Quality Control: The printed circuit board assembly manufacturer should conduct a thorough inspection of all components and materials prior to production. This includes verifying the accuracy of the design, checking for any defects in the components, and ensuring that all materials meet the required specifications.

2. In-Process Quality Control: During the production process, the manufacturer should monitor the quality of the assembly process and inspect the finished product for any defects. This includes checking for any shorts, opens, or other issues that could affect the performance of the board.

3. Post-Production Quality Control: After the assembly is complete, the manufacturer should conduct a final inspection to ensure that the board meets all of the required specifications. This includes verifying the accuracy of the design, checking for any defects in the components, and ensuring that all materials meet the required specifications.

printed circuit board assembly manufacturer are more worthy of cooperation if they have patents

Yes, it is beneficial to work with a printed circuit board assembly manufacturer that has patents. Patents provide a manufacturer with exclusive rights to produce and sell a product, which can help them to stand out from the competition. Additionally, patents can provide a manufacturer with a competitive edge, as they can use the patent to protect their products from being copied or reverse engineered. This can help to ensure that the manufacturer is able to maintain their competitive advantage in the market.

The international production mode adopted by printed circuit board assembly manufacturer

Printed circuit board assembly manufacturers typically use an international production mode that involves outsourcing components from different countries. This allows them to take advantage of lower labor costs and access to specialized components. The components are then shipped to the manufacturer’s facility, where they are assembled into the finished product. This production mode is often used to produce high-volume products, such as consumer electronics, at a lower cost than if the components were sourced and assembled domestically.

What is printed circuit board assembly design?

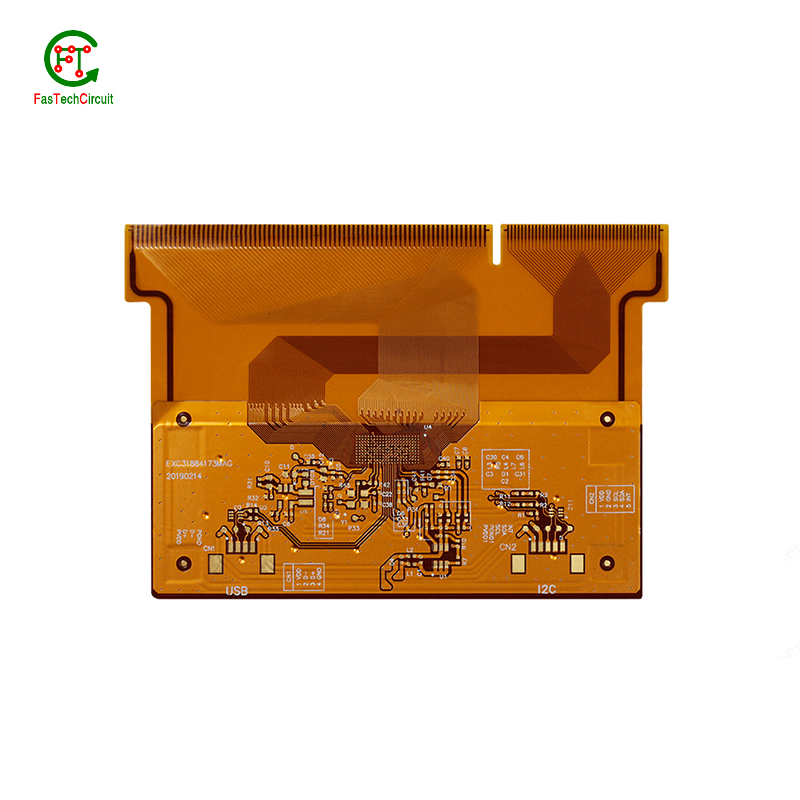

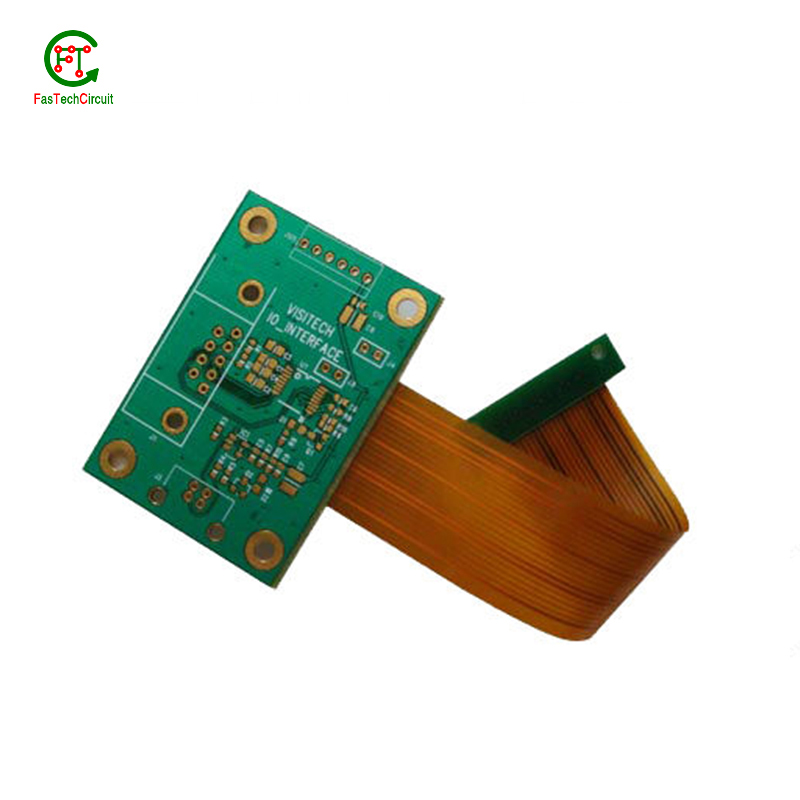

Printed circuit board assembly (PCBA) design is the process of designing and creating a printed circuit board (PCB) with components that are soldered onto the board. This process involves designing the layout of the board, selecting components, and then soldering them onto the board. The design of the board must be carefully considered to ensure that the components are properly connected and that the board will function correctly.

printed circuit board assembly manufacturer' skill requirements for production operators

1. Ability to read and understand assembly drawings, schematics, and other technical documents.

2. Ability to use hand tools and small power tools to assemble printed circuit boards.

3. Ability to use soldering equipment to solder components to printed circuit boards.

4. Ability to inspect and test printed circuit boards for quality assurance.

5. Ability to troubleshoot and repair printed circuit boards.

6. Ability to work with a team to meet production goals.

7. Ability to follow safety procedures and use personal protective equipment.

8. Ability to work with a variety of materials, including metals, plastics, and composites.

9. Ability to use computers to enter data and access information.

10. Ability to lift and move heavy objects.

printed circuit board assembly design, what are the shortcomings of Chinese enterprises?

1. Lack of innovation: Chinese enterprises often lack the ability to innovate and develop new products.

2. Poor quality control: Chinese enterprises often lack the necessary quality control measures to ensure the quality of their products.

3. Low cost: Chinese enterprises often offer lower costs than their competitors, but this can lead to lower quality products.

4. Limited resources: Chinese enterprises often lack the resources to invest in research and development, which can limit their ability to develop new products.

5. Poor customer service: Chinese enterprises often lack the customer service infrastructure to provide timely and effective customer service.

Effect drawing of printed circuit board assembly design

A drawing of a printed circuit board assembly design may include a diagram of the board itself, showing the various components and their locations. It may also include a schematic diagram of the electrical connections between the components, as well as a bill of materials listing the components and their specifications. The drawing may also include a layout of the board, showing the placement of the components and the routing of the electrical connections. Finally, the drawing may include a 3D rendering of the board, showing the components in their final assembled form.

printed circuit board assembly design, comparison of advantages and disadvantages of Chinese and American design levels

Advantages of Chinese PCB Assembly Design:

1. Cost-effective: Chinese PCB assembly design is generally more cost-effective than American design. This is because Chinese manufacturers have access to cheaper labor and materials, allowing them to offer lower prices.

2. Faster turnaround time: Chinese PCB assembly design is often faster than American design. This is because Chinese manufacturers have access to more advanced technology and can produce PCBs faster.

3. Quality: Chinese PCB assembly design is generally of high quality. This is because Chinese manufacturers have access to more advanced technology and can produce PCBs with higher precision and accuracy.

Disadvantages of Chinese PCB Assembly Design:

1. Language barrier: Chinese PCB assembly design can be difficult to understand due to the language barrier. This can lead to misunderstandings and delays in the design process.

2. Quality control: Chinese PCB assembly design may not be as reliable as American design due to the lack of quality control. This can lead to problems with the finished product.

3. Intellectual property: Chinese PCB assembly design may not be as secure as American design due to the lack of intellectual property protection. This can lead to the theft of ideas and designs.

Classification of printed circuit board assembly design styles

1. Through-Hole Assembly: This is the most traditional type of printed circuit board assembly design. It involves inserting components into holes drilled into the board and soldering them in place.

1. Through-Hole Assembly: This is the most traditional type of printed circuit board assembly design. It involves inserting components into holes drilled into the board and soldering them in place.

2. Surface Mount Assembly: This type of assembly involves placing components directly onto the surface of the board and soldering them in place.

3. Mixed Assembly: This type of assembly combines both through-hole and surface mount components.

4. Automated Assembly: This type of assembly uses automated machines to place and solder components onto the board.

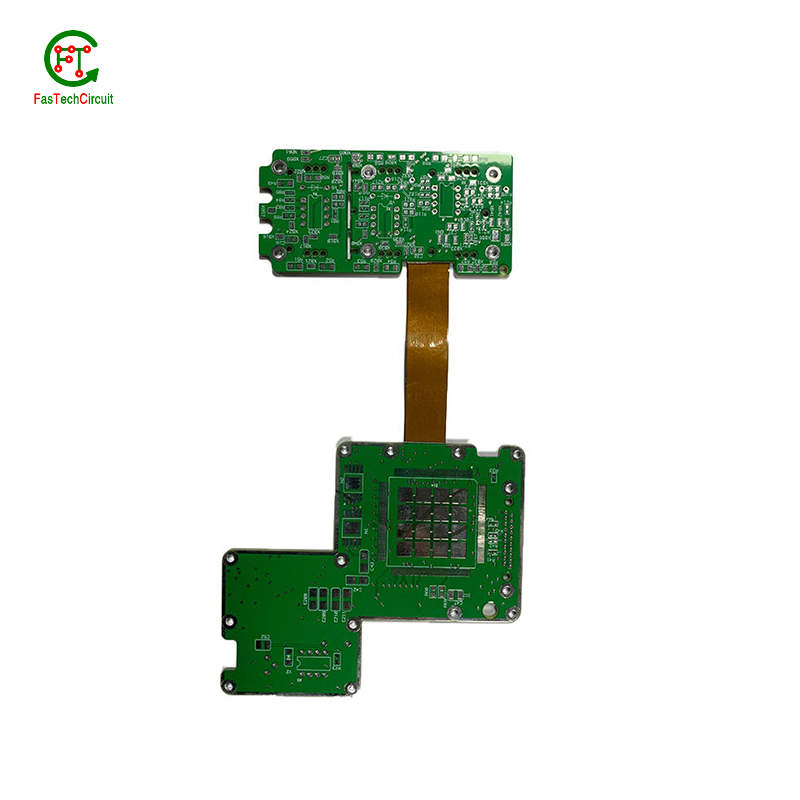

5. Flexible Assembly: This type of assembly uses flexible printed circuit boards that can be bent or folded to fit into tight spaces.

About the brand of the printed circuit board assembly manufacturer

The printed circuit board assembly manufacturer is a company called PCBCart. PCBCart is a professional PCB manufacturing and assembly service provider based in China. They specialize in providing high-quality, low-cost PCB fabrication and assembly services for customers around the world. They offer a wide range of services, including PCB design, PCB fabrication, PCB assembly, and more. They have a team of experienced engineers and technicians who are dedicated to providing the best quality products and services to their customers.

Skill requirements for designers

1. Knowledge of design principles and techniques: Designers should have a strong understanding of design principles such as composition, color theory, typography, and layout. They should also be familiar with various design techniques such as wireframing, prototyping, and user experience design.

2. Knowledge of software: Designers should be proficient in the use of design software such as Adobe Photoshop, Illustrator, InDesign, and Sketch. They should also be familiar with other software such as HTML, CSS, and JavaScript.

3. Creative thinking: Designers should be able to think creatively and come up with innovative solutions to design problems. They should also be able to think outside the box and come up with unique ideas.

4. Communication skills: Designers should be able to communicate effectively with clients, colleagues, and other stakeholders. They should be able to explain their design decisions and present their work in a clear and concise manner.

5. Time management: Designers should be able to manage their time effectively and meet deadlines. They should also be able to prioritize tasks and manage multiple projects at once.

Analysis of the competition trend of China's printed circuit board assembly market

The printed circuit board assembly (PCBA) market in China is highly competitive and has seen rapid growth in recent years. The market is dominated by a few large players, such as Foxconn, Flextronics, and Jabil, who have established a strong presence in the market. However, there are also a number of smaller players who are increasingly competing for market share.

The competition in the Chinese PCBA market is driven by several factors. First, the cost of production in China is relatively low, making it an attractive destination for companies looking to outsource their production. Second, the Chinese government has implemented a number of policies to encourage the development of the PCBA industry, such as tax incentives and subsidies. Finally, the Chinese market is highly competitive, with a large number of players competing for market share.

In terms of trends, the Chinese PCBA market is expected to continue to grow in the coming years. This growth is driven by the increasing demand for electronic products, such as smartphones and tablets, as well as the increasing demand for high-end components. Additionally, the Chinese government is expected to continue to support the industry with policies and incentives. As a result, the competition in the Chinese PCBA market is expected to remain strong.

Top ten international printed circuit board assembly brands

1. Jabil

2. Flextronics

3. Sanmina

4. Celestica

5. Benchmark Electronics

6. TTM Technologies

7. Viasystems

8. Plexus

9. New Kinpo Group

10. Universal Scientific Industrial Co.

pcb board manufacturing How To Contact US

PCB from 1 to 30 layers, HDI, Heavy Copper, Rigid-flex board with "pcb board manufacturing One-Stop" service.