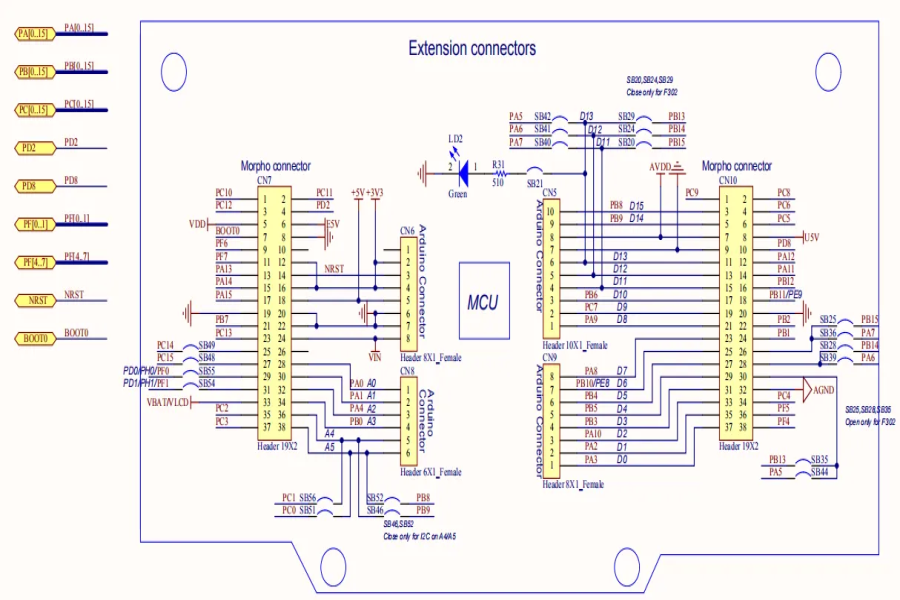

How to minimize EMI and EMC issues in PCB design

Making IM PEDANCE PCB usually requires process steps such as circuit design, raw material selection, drawing, printing, gold plating and drilling. Each of these steps requires strict control and testing to ensure the quality of the keyboard pcb.

PCB design trends for the future

We are committed to using environmentally friendly materials and production processes in the manufacturing of our PCB products, reducing our carbon footprint and promoting sustainability.

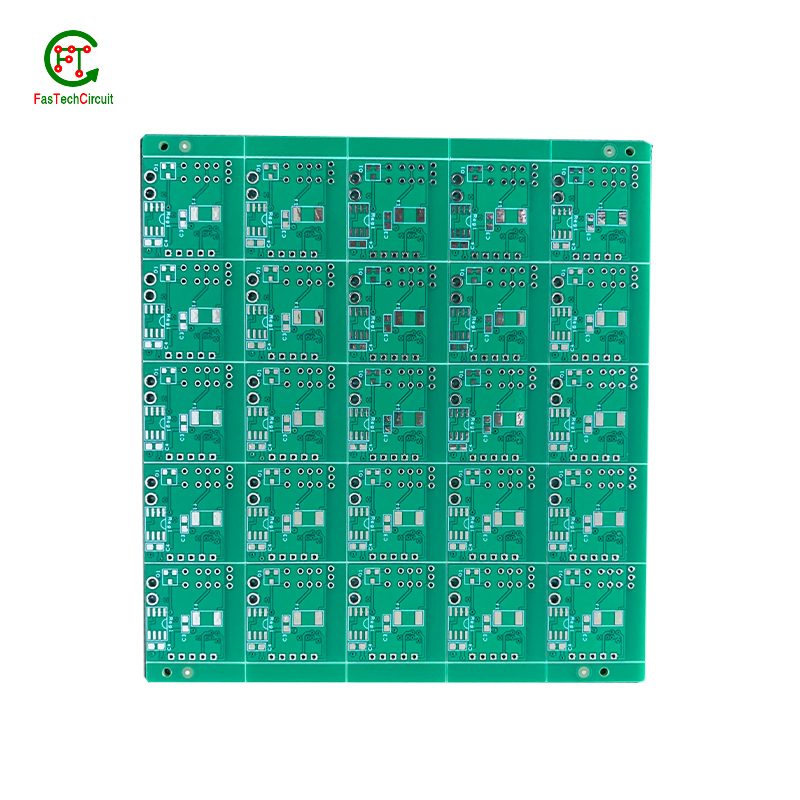

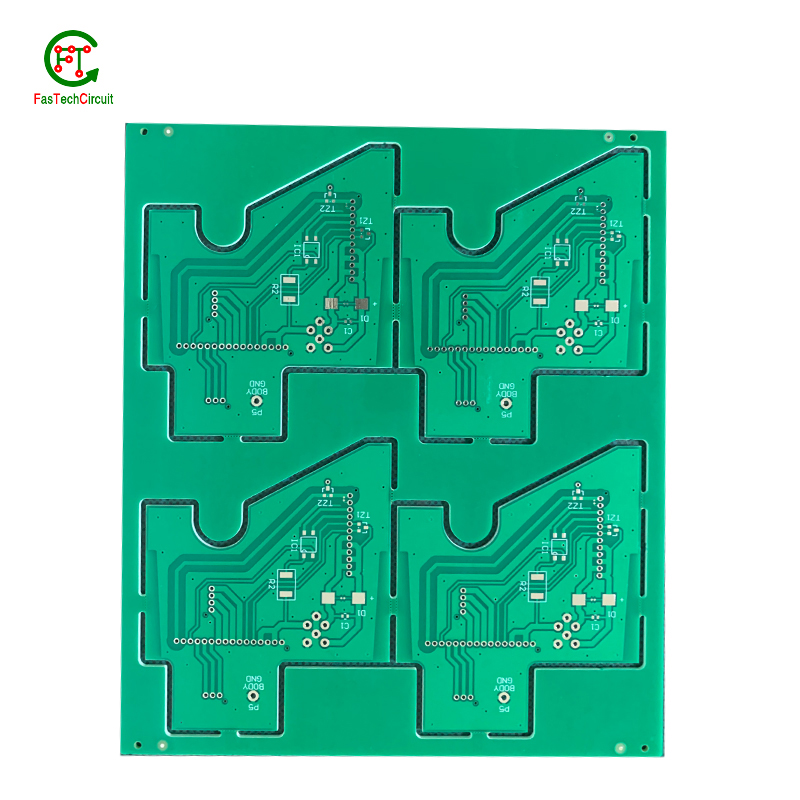

By utilizing advanced manufacturing techniques and high-density component placement, our PCB products are able to achieve compact and lightweight designs, saving valuable space in electronic devices.

PCB--An Ultimate FAQ Guide.

2.What is the difference between PCB FasTechCircuit vs PCB Colorful vs PCB Zotac

3.About PCB raw material procurement system

4.About PCB quality system

5.About PCB raw materials

6.What are the dimensions of PCB products?

7.What materials are used in this PCB product?

8.About PCB overseas warehouse

9.About PCB production skills training

10.Does PCB comply with ROHS standards?

11.About PCB payment method

12.About PCB production skills training

13.What is the thickness of the PCB product?

14.What is the processing accuracy of PCB products?

15.About the scale of PCB factory

16.What is the difference between PCB FasTechCircuit vs PCB ASUS vs PCB MSI

17.What are the electrical characteristics of PCB?

18.About PCB customization services

1.About PCB payment method

The payment method for PCB (Printed Circuit Board) orders typically involves various options for customers to choose from. Common payment methods include credit card payments, bank transfers, electronic funds transfer (EFT), and online payment platforms like PayPal. Additionally, some PCB manufacturers may offer specific payment terms and options, such as advance payment or net payment within agreed credit terms for established business relationships. The choice of payment method can vary depending on the PCB manufacturer and the agreement between the parties involved in the transaction. It's essential to discuss and confirm the preferred payment method with the PCB manufacturer before placing an order.

2.What is the difference between PCB FasTechCircuit vs PCB Colorful vs PCB Zotac

The choice between these manufacturers should be based on your specific project requirements. PCB FasTechCircuit is suitable for rapid prototyping, while PCB Colorful and PCB Zotac are trusted options for high-quality components in computer hardware, with a specific emphasis on gaming and graphics cards. Your decision should align with the goals and needs of your project.

3.About PCB raw material procurement system

The PCB raw material procurement system is a crucial aspect of the production process for printed circuit boards. It involves the sourcing and acquisition of all necessary materials, such as copper foil, laminate sheets, solder mask, and components, needed for the manufacturing of PCBs. This system requires efficient coordination between suppliers and the PCB manufacturer to ensure timely delivery and high-quality materials. Additionally, proper management of inventory levels and cost control are essential components of the procurement system to ensure smooth and cost-effective production of PCBs.

4.About PCB quality system

The PCB quality system is a comprehensive and structured approach to ensuring the quality of printed circuit boards. It encompasses various processes and procedures, from design and manufacturing to testing and inspection, to ensure that the final product meets the required standards and specifications. By implementing a robust quality system, manufacturers can achieve consistent and reliable quality, reduce defects and errors, and ultimately deliver high-quality PCBs that meet the expectations of their customers. This system is crucial in the electronics industry, as PCBs are integral components in most electronic devices and their quality can greatly impact the performance and reliability of these devices.

5.About PCB raw materials

PCB (Printed Circuit Board) raw materials refer to the base materials used in the manufacturing of electronic circuit boards. These materials typically include copper-clad laminates, solder mask, silkscreen, and various types of coatings and films. The selection of high-quality raw materials is crucial for ensuring the functionality, durability and reliability of PCBs, which are the backbone of electronic devices. Different applications require different types of raw materials, such as high-speed signal transmission, thermal management, and environmental protection. With the constant advancement of technology, the demand for more innovative and sustainable PCB raw materials continues to rise, driving the development of the electronics industry towards a more efficient and eco-friendly future.

6.What are the dimensions of PCB products?

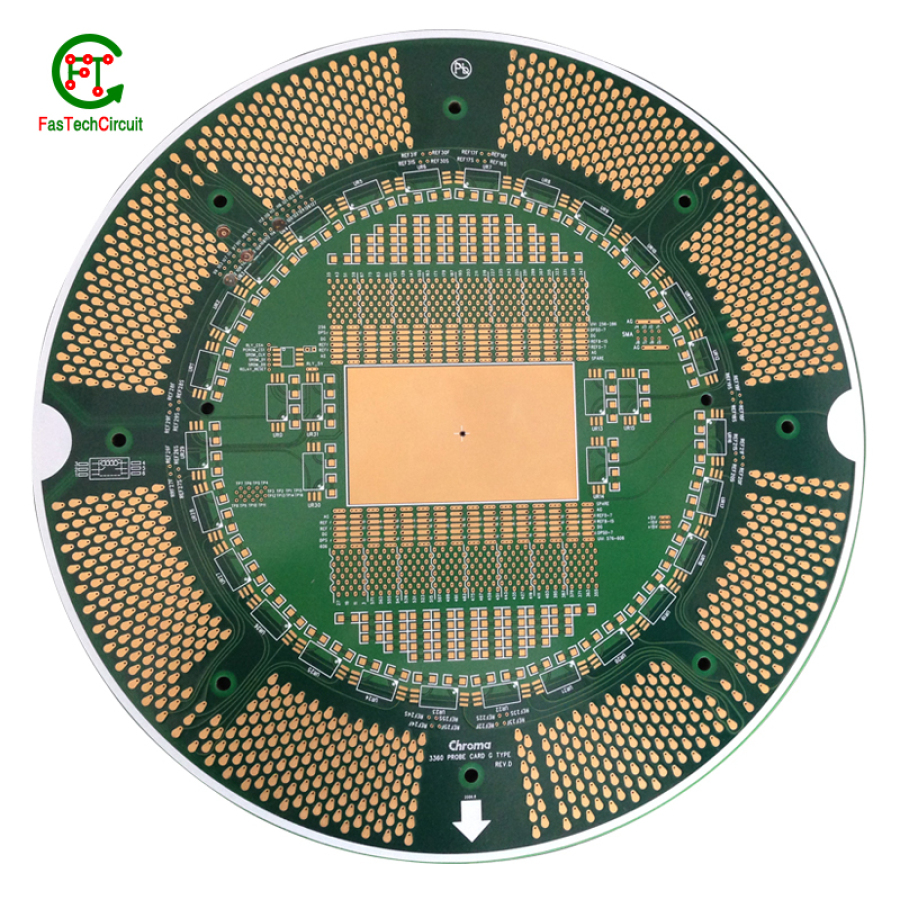

The dimensions of PCB (Printed Circuit Board) products can vary widely depending on the specific application and requirements. PCBs come in various sizes and shapes to accommodate different electronic devices and systems. They can range from small and compact boards used in mobile phones or wearables to larger and more intricate boards found in computers, industrial equipment, or automotive systems. The dimensions are tailored to fit the intended space within the electronic device and to support the necessary components and connections. As a result, PCBs are available in a diverse range of sizes and configurations to meet the unique needs of various applications.

7.What materials are used in this PCB product?

The PCB (Printed Circuit Board) product utilizes a variety of materials in its construction to ensure efficient and reliable electronic connections. These materials typically include a non-conductive substrate (often made of fiberglass or other materials), a copper layer for electrical conductivity, solder mask for protection, and various components like resistors, capacitors, and integrated circuits. The specific materials and their quality play a crucial role in the performance and durability of the PCB, making it a critical component in electronic devices and systems.

8.About PCB overseas warehouse

PCB overseas warehouse is a facility used by companies to store and distribute printed circuit boards (PCBs) in international locations. This helps companies to reduce shipping and handling costs, shorten lead times, and improve their supply chain management. The overseas warehouse usually stores a wide range of PCBs to meet the needs of different markets and customers. It allows companies to expand their global reach and provide quicker and more cost-effective services to their clients. Additionally, the overseas warehouse provides added convenience for customers who may need urgent delivery of PCBs in their region. Overall, PCB overseas warehouse plays a crucial role in facilitating efficient and seamless international distribution of PCBs for companies.

9.About PCB production skills training

PCB production skills training is a crucial aspect of the manufacturing process in the electronics industry. It involves providing individuals with the necessary knowledge and expertise required for the production of high-quality printed circuit boards (PCBs). This training covers various techniques and methodologies, such as design principles, fabrication processes, and assembly methods, to ensure efficient and accurate production. With a strong emphasis on practical learning, this training equips individuals with the skills needed to meet the ever-evolving demands of the industry and deliver top-notch PCBs.

10.Does PCB comply with ROHS standards?

Many PCB (Printed Circuit Board) manufacturers and products aim to comply with RoHS (Restriction of Hazardous Substances) standards. RoHS is a regulation that restricts the use of certain hazardous materials, such as lead, mercury, and cadmium, in electronic and electrical equipment. Compliance with RoHS standards is crucial for environmental and safety reasons, as it helps reduce the use of harmful substances in electronics and their potential impact on health and the environment. However, RoHS compliance can vary between manufacturers and specific PCB products, so it's essential to verify compliance with the relevant regulations and standards for a particular PCB product.

11.About PCB payment method

The PCB (Printed Circuit Board) payment method is a type of electronic payment method that utilizes a pre-printed circuit board with integrated circuits to process transactions. This method allows users to make secure payments using electronic cards, such as credit or debit cards, by simply inserting or swiping the card into a terminal. PCB payment systems are widely used in retail, hospitality, and other industries, providing a fast and efficient way to process transactions and reduce the risk of fraud. With the rise of technology, PCB payments are becoming increasingly popular due to their convenience, security, and ease of use.

12.About PCB production skills training

PCB production skills training is designed to provide individuals with the necessary knowledge and techniques for manufacturing high-quality printed circuit boards (PCBs). Through this training, participants will learn about the different types of PCBs, the process of PCB production, and the latest industry standards and techniques. This training will equip individuals with the skills to handle various equipment and tools used in PCB production, as well as to troubleshoot and resolve any issues that may arise during the process. Ultimately, the goal of this training is to foster a competent and skilled workforce capable of producing reliable and efficient PCBs for a variety of electronic devices.

13.What is the thickness of the PCB product?

The thickness of a PCB (Printed Circuit Board) product can vary based on its design and intended application. PCBs are available in a range of thicknesses, typically measured in millimeters (mm) or mils (1 mil = 0.001 inches). Standard PCB thicknesses often include 0.8mm, 1.6mm, and 2.0mm, but custom thicknesses can be specified to meet specific requirements. Thicker PCBs provide greater mechanical rigidity and heat dissipation, while thinner ones are suitable for applications with space constraints. The choice of thickness depends on the PCB's function and the design needs of the electronic system it will be a part of.

14.What is the processing accuracy of PCB products?

The processing accuracy of PCB (Printed Circuit Board) products is a critical aspect of their quality. It involves ensuring that the dimensions, traces, holes, and other features of the PCB are fabricated with precision. The accuracy is typically specified in terms of tolerances for various parameters, including trace width, hole diameter, and overall dimensions. Common processing accuracy standards for PCBs include a minimum trace width and spacing, as well as specific tolerances for holes and cutouts. Achieving high processing accuracy is essential to ensure that the PCB functions as intended and that components can be soldered onto it without issues. The specific processing accuracy requirements can vary based on the PCB's design and application.

15.About the scale of PCB factory

A PCB factory, also known as a printed circuit board factory, is a manufacturing facility that specializes in the production of printed circuit boards. These are used in a wide range of electronic devices, from smartphones and laptops to cars and airplanes. These factories vary in scale, with some producing small volumes for niche markets, while others are large operations that mass-produce PCBs for mainstream electronics companies. The scale of a PCB factory can be measured by its annual production output, the number of employees, and the size of its production facility. The larger the scale of a PCB factory, the more advanced and complex its production processes are likely to be, allowing it to produce high-quality boards in large quantities.

16.What is the difference between PCB FasTechCircuit vs PCB ASUS vs PCB MSI

The choice between these manufacturers depends on the specific requirements of your project. PCB FasTechCircuit might be suitable for rapid prototyping, while PCB ASUS and PCB MSI are trusted choices for high-quality components in gaming and consumer electronics. Ultimately, the decision should be based on your project's needs and goals.

17.What are the electrical characteristics of PCB?

The electrical characteristics of PCB (Printed Circuit Board) are vital for its performance in electronic systems. These characteristics include impedance, dielectric constant (Dk), crosstalk, signal integrity, capacitance, inductance, voltage and current handling, frequency response, and high-frequency performance. PCBs are designed to maintain controlled impedance, minimize signal interference, and handle specific voltage and current levels, ensuring their reliability and functionality in various electronic applications. The choice of materials and design considerations plays a significant role in achieving the desired electrical characteristics for PCBs.

18.About PCB customization services

PCB customization services involve creating personalized printed circuit boards (PCBs) to meet specific design and functionality requirements. This process includes collaborating with the client to understand their unique needs and customizing the PCB layout, material, and components accordingly. Through PCB customization services, clients can obtain tailor-made solutions for their specific applications, ensuring high-quality and efficient performance. These services are essential for industries such as automotive, aerospace, and telecommunications, where precision and reliability are crucial. With the help of experienced professionals and advanced technologies, PCB customization services offer a cost-effective and timely solution for businesses seeking customized electronic components.

RELATED NEWS

pcb board manufacturing How To Contact US

PCB from 1 to 30 layers, HDI, Heavy Copper, Rigid-flex board with "pcb board manufacturing One-Stop" service.