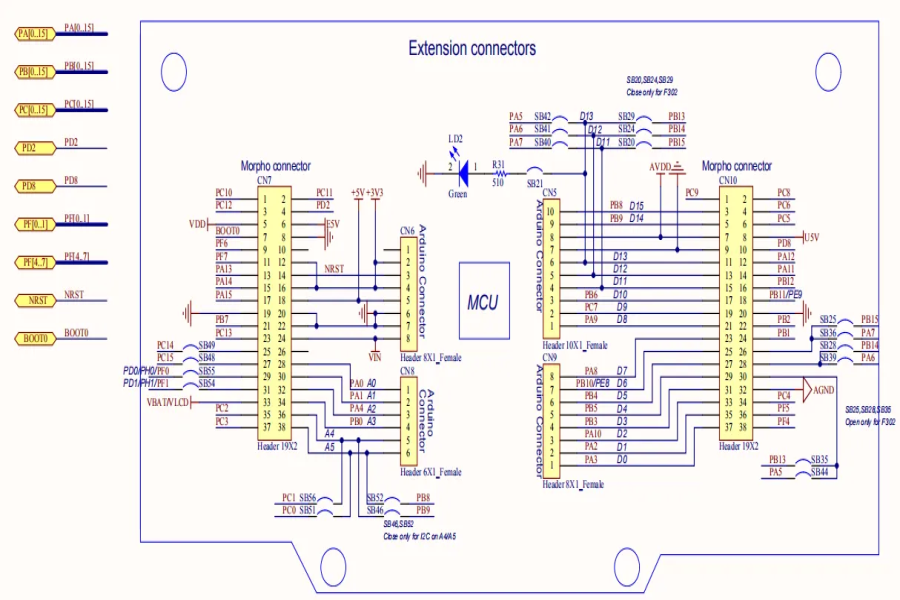

Exploring the design guidelines for effective PCB layout

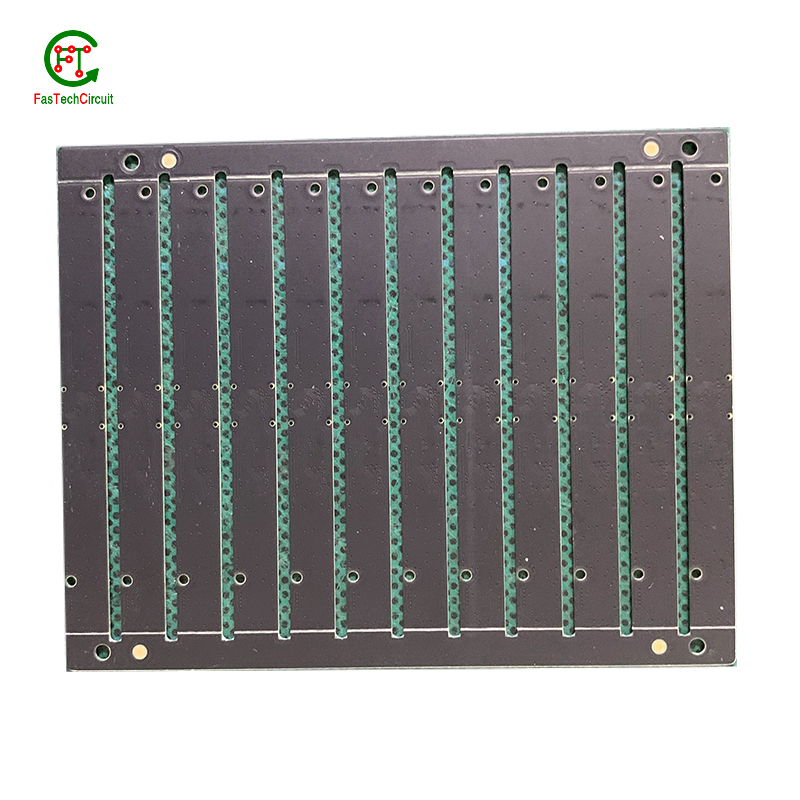

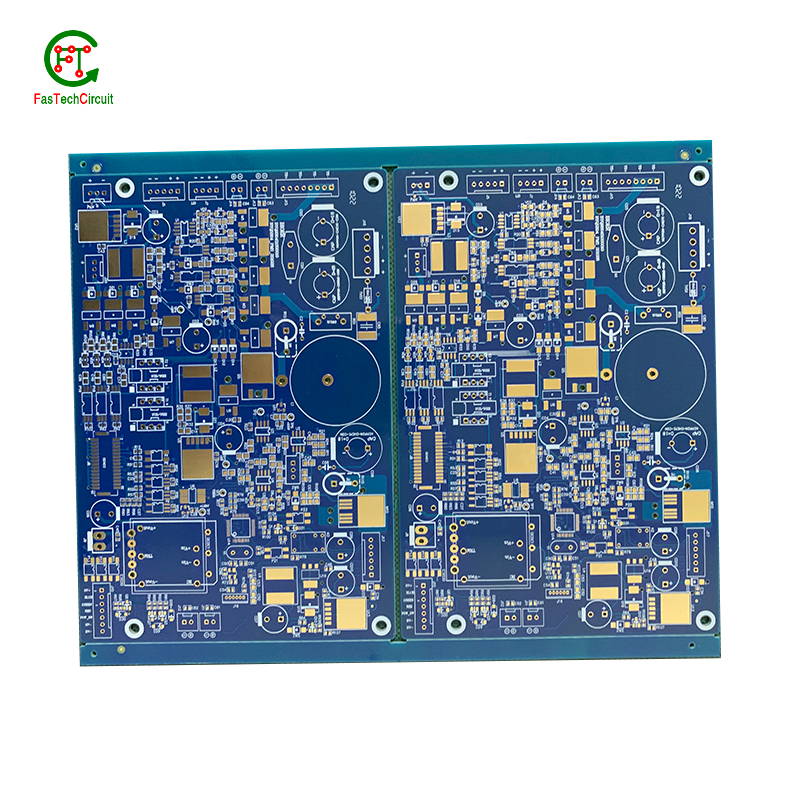

custom pcb board wiring structures are usually divided into single-layer, double-layer and multi-layer structures. Multi-layer structures can effectively reduce the size of circuit boards and improve wiring efficiency, and are often used in the design of high-density and complex circuits.

current situation and prospects of PCB manufacturing

Our PCB products are available in a wide range of multi-layer configurations, allowing for complex circuit designs and enabling greater functionality in electronic devices.

Our PCB products are designed and manufactured to ensure high reliability under various operating conditions, minimizing the risk of failure and downtime.

PCB--An Ultimate FAQ Guide.

2.About PCB raw materials

3.Do PCB products have self-healing properties?

4.About PCB inventory

5.Do PCB products use environmentally friendly materials?

6.About PCB payment method

7.About PCB production equipment

8.About PCB overseas warehouse

9.About PCB inventory

10.About PCB quality system

11.What materials are used in this PCB product?

12.About the scale of PCB factory

13.Does the PCB have a special anti-theft design?

14.Is this PCB product single-sided or double-sided?

15.How much does the PCB product weigh?

16.Is the PCB UL certified?

17.About the development history of PCB factory

18.About PCB warranty

19.What electronic fields is PCB suitable for?

20.Does the PCB have special anti-corrosion treatment?

21.What electronic components can this PCB product support?

22.What is the processing accuracy of PCB products?

23.What is the difference between PCB FasTechCircuit vs PCB Biostar vs PCB EVGA

1.About PCB patent

PCB patent is a form of intellectual property protection that grants inventors and companies the exclusive right to produce and sell printed circuit boards (PCBs) with unique designs, functions, or processes. It serves as a means to encourage innovation and reward originality in the field of electronic circuitry and technology. PCB patents can cover a wide range of aspects, such as layout designs, fabrication methods, and manufacturing processes. However, in order to obtain a PCB patent, the design or process must meet specific criteria, including being novel, non-obvious, and useful. This type of patent is essential for companies and individuals in the electronics industry to protect their ideas and prevent others from copying or profiting from their innovations. By securing a PCB patent, inventors and companies can have a competitive advantage in the market and ensure the long-term success of their products.

2.About PCB raw materials

PCB (printed circuit board) raw materials refer to the materials used to manufacture PCBs, which serve as the backbone of electronic devices. These materials can include various types of substrates, such as fiberglass, ceramic, and plastic, as well as copper, tin, and other metals for the conductive layers and traces. Other essential components include solder masks, silkscreen printing inks, and metal finishes. The selection of these raw materials is crucial in determining the quality, durability, and performance of the final PCB product. Advances in technology have led to the development of new and improved raw materials, allowing for more compact and efficient PCB designs.

3.Do PCB products have self-healing properties?

PCB (Printed Circuit Board) products do not possess self-healing properties. Self-healing is a property associated with certain materials or components that can repair or regenerate when damaged, such as self-healing polymers. PCBs are typically constructed from rigid materials like fiberglass or epoxy, which do not have self-healing capabilities. Therefore, if a PCB is damaged or experiences a fault, it typically requires manual repair or replacement by a skilled technician or engineer to restore its functionality. PCBs are designed for reliable electrical connections but do not have the ability to self-repair when damaged.

4.About PCB inventory

PCB inventory, or printed circuit board inventory, refers to the collection of all available PCBs (printed circuit boards) in stock for a particular company or organization. These PCBs are crucial components in the production of electronic devices and serve as the foundation for the electrical connections between various components. Maintaining an efficient and well-managed PCB inventory is essential for companies to meet the demand for their products, reduce production costs, and stay competitive in the market. Regular inventory checks, tracking of usage, and proper storage and handling of PCBs are key factors in managing a successful PCB inventory.

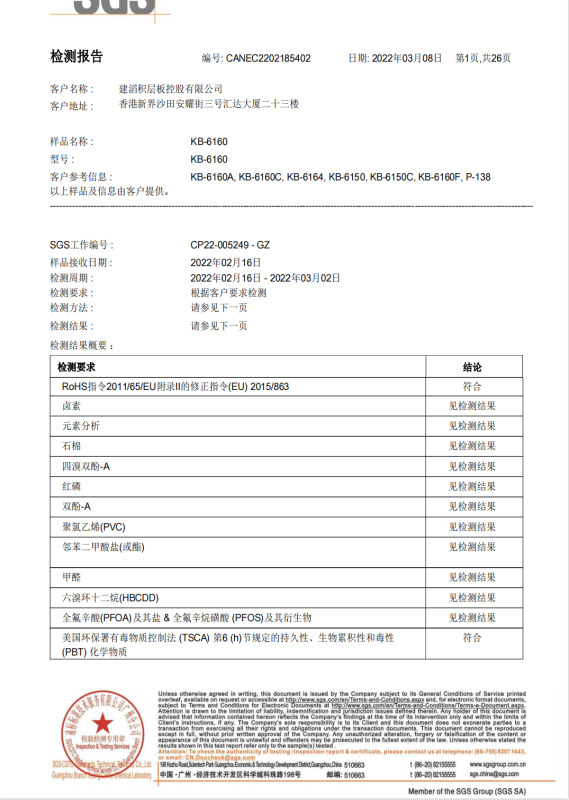

5.Do PCB products use environmentally friendly materials?

PCB (Printed Circuit Board) products can be manufactured using environmentally friendly materials and processes, depending on the manufacturer's practices and the specific requirements of the application. Environmentally friendly PCBs may incorporate lead-free solder materials, halogen-free substrates, and other eco-friendly alternatives. In many regions, there are regulations and standards, such as RoHS (Restriction of Hazardous Substances) directives, which require the reduction or elimination of hazardous materials in electronics, including PCBs. Manufacturers often aim to meet these environmental standards by using eco-friendly materials and processes in their PCB production. However, the extent to which a PCB product is environmentally friendly depends on the manufacturer's practices and adherence to such regulations.

6.About PCB payment method

The payment method for PCB (Printed Circuit Board) orders typically involves various options for customers to choose from. Common payment methods include credit card payments, bank transfers, electronic funds transfer (EFT), and online payment platforms like PayPal. Additionally, some PCB manufacturers may offer specific payment terms and options, such as advance payment or net payment within agreed credit terms for established business relationships. The choice of payment method can vary depending on the PCB manufacturer and the agreement between the parties involved in the transaction. It's essential to discuss and confirm the preferred payment method with the PCB manufacturer before placing an order.

7.About PCB production equipment

PCB (Printed Circuit Board) production equipment is an essential component in the manufacturing process of electronic devices. It includes various machines and tools used to fabricate, assemble, and test printed circuit boards, which are the foundation of all electronic devices. These equipment typically include drills, routers, plating machines, soldering machines, inspection systems, and more. With the advancement of technology, PCB production equipment has become more sophisticated and efficient, allowing for higher precision and faster production times. As electronic devices continue to evolve and become more intricate, the demand for advanced PCB production equipment will only continue to grow.

8.About PCB overseas warehouse

PCB overseas warehouse is a facility used by companies to store and distribute printed circuit boards (PCBs) in international locations. This helps companies to reduce shipping and handling costs, shorten lead times, and improve their supply chain management. The overseas warehouse usually stores a wide range of PCBs to meet the needs of different markets and customers. It allows companies to expand their global reach and provide quicker and more cost-effective services to their clients. Additionally, the overseas warehouse provides added convenience for customers who may need urgent delivery of PCBs in their region. Overall, PCB overseas warehouse plays a crucial role in facilitating efficient and seamless international distribution of PCBs for companies.

9.About PCB inventory

PCB inventory is an essential aspect of electronic manufacturing industry, which refers to the storage and management of printed circuit boards (PCBs) used in various electronic devices. PCB inventory helps companies maintain a steady supply of circuit boards for production, repair, and custom-made projects. It is crucial for companies to keep track of their PCB inventory to ensure timely production and avoid delays in delivery. Furthermore, efficient management of PCB inventory can help companies reduce costs and eliminate the risk of excess or shortage of materials. With the continuous advancement of technology, effective management of PCB inventory is becoming increasingly important for companies to stay competitive in the market.

10.About PCB quality system

The PCB quality system is a comprehensive and structured approach to ensuring the quality of printed circuit boards. It encompasses various processes and procedures, from design and manufacturing to testing and inspection, to ensure that the final product meets the required standards and specifications. By implementing a robust quality system, manufacturers can achieve consistent and reliable quality, reduce defects and errors, and ultimately deliver high-quality PCBs that meet the expectations of their customers. This system is crucial in the electronics industry, as PCBs are integral components in most electronic devices and their quality can greatly impact the performance and reliability of these devices.

11.What materials are used in this PCB product?

The PCB (Printed Circuit Board) product utilizes a variety of materials in its construction to ensure efficient and reliable electronic connections. These materials typically include a non-conductive substrate (often made of fiberglass or other materials), a copper layer for electrical conductivity, solder mask for protection, and various components like resistors, capacitors, and integrated circuits. The specific materials and their quality play a crucial role in the performance and durability of the PCB, making it a critical component in electronic devices and systems.

12.About the scale of PCB factory

The scale of a PCB factory refers to its size and production capacity. It may vary greatly depending on the company's resources and operations. Typically, a PCB factory will have a large and well-equipped manufacturing facility, with specialized equipment and machinery to produce circuit boards in large quantities. The factory may also have a sizeable workforce, including engineers, technicians, and workers, who are trained and experienced in PCB production. The scale of the factory also plays an essential role in meeting the demands of clients and keeping up with the rapid advancements in technology. A larger and more advanced PCB factory can provide a wider range of services and offer faster production times, making them more competitive in the market. Overall, the scale of a PCB factory reflects its capabilities and success in meeting the growing demands of the electronics industry.

13.Does the PCB have a special anti-theft design?

PCB (Printed Circuit Board) products typically do not have a special anti-theft design themselves. Anti-theft features are usually implemented at the level of the entire electronic system or device in which the PCB is incorporated. These features may include encryption, secure access control, or tamper-evident packaging to prevent unauthorized access or use of the device. While the PCB may play a role in security by facilitating secure connections or encryption features, its primary function is to provide electrical connectivity within electronic devices. Anti-theft measures are usually implemented at the system level, not at the PCB level.

14.Is this PCB product single-sided or double-sided?

This PCB (Printed Circuit Board) product can be configured as either single-sided or double-sided, depending on the specific application and design requirements. Single-sided PCBs have circuitry on one side of the board, while double-sided PCBs feature electrical connections on both sides. The choice between single-sided and double-sided PCBs is made based on factors like the complexity of the circuit, space constraints, and cost considerations. This flexibility in design allows the PCB product to adapt to a variety of electronic applications, ensuring it can meet the needs of different projects and devices.

15.How much does the PCB product weigh?

The weight of the PCB (Printed Circuit Board) product can vary significantly depending on its size, material, and complexity. Typically, PCBs are lightweight components in electronic devices, with smaller PCBs weighing only a few grams, while larger and more intricate PCBs may weigh several ounces or more. The weight of the PCB is influenced by factors such as the thickness of the board, the number of layers, the presence of additional components, and the type of materials used in its construction. It is essential to consider the weight of the PCB when designing electronic systems to ensure that it meets the specific requirements of the application.

16.Is the PCB UL certified?

UL (Underwriters Laboratories) certification is typically not associated with individual PCB (Printed Circuit Board) products. Instead, UL certification is generally applied to the end-use electronic equipment or devices in which PCBs are integrated. UL certification ensures that the entire electronic system complies with safety and performance standards. The PCB itself is just one component of the larger system. While PCB manufacturers may use materials and processes that meet UL requirements, the certification process focuses on the overall safety and performance of the complete electronic product, which includes the PCB. Therefore, PCBs are not UL certified on their own, but they contribute to the overall compliance of the electronic equipment in which they are used.

17.About the development history of PCB factory

The development of PCB factories can be traced back to the early 20th century when the technology for producing printed circuit boards was first invented. Over the years, with the advancements in electronics and manufacturing processes, the demand for PCBs grew rapidly. This led to the establishment of more specialized and efficient PCB factories, which played a crucial role in the development of modern electronics. With the introduction of more sophisticated machinery and techniques, these factories were able to mass produce high-quality PCBs at a faster pace, meeting the growing demand from various industries. Today, PCB factories continue to evolve and innovate, adopting new technologies such as automation and AI to streamline processes and produce higher quality and more complex circuit boards for the ever-expanding electronics market.

18.About PCB warranty

PCB warranty refers to the guarantee provided by manufacturers for printed circuit boards (PCBs). It ensures that the PCBs are free from defects in materials and workmanship for a specific period of time. This warranty is important as it can protect customers from potential losses caused by product defects and provides assurance of quality and reliability. Customers should pay attention to the terms and conditions of the warranty when purchasing PCBs to fully understand their rights and responsibilities in case of any issues with the product.

19.What electronic fields is PCB suitable for?

PCB (Printed Circuit Board) technology is versatile and adaptable, making it suitable for a wide range of electronic fields and applications. PCBs are commonly used in industries such as consumer electronics, automotive, industrial machinery, aerospace, medical devices, telecommunications, IoT, renewable energy, robotics, and consumer appliances. Their ability to provide reliable and efficient connections for electronic components makes PCBs an essential element in various electronic systems, enabling innovation and functionality in diverse fields.

20.Does the PCB have special anti-corrosion treatment?

PCB (Printed Circuit Board) products can undergo special anti-corrosion treatments to enhance their durability and resistance to environmental factors. Anti-corrosion treatments typically involve the application of conformal coatings, which create a protective layer over the PCB to shield it from moisture, humidity, and corrosive elements. These coatings act as a barrier against oxidation and chemical corrosion, preserving the integrity of the PCB components and connections. The choice to apply anti-corrosion treatment depends on the specific application and the potential exposure to corrosive agents, ensuring that the PCB remains reliable and functional in challenging conditions.

21.What electronic components can this PCB product support?

The capabilities of this PCB (Printed Circuit Board) product extend to supporting a wide array of electronic components. These components include but are not limited to integrated circuits (ICs), microcontrollers, resistors, capacitors, diodes, transistors, connectors, and various sensors. The PCB's design and layout are tailored to accommodate these components and establish electrical connections between them. This versatility enables the PCB to be used in a broad spectrum of electronic devices and systems, where it acts as the central hub for component integration and electrical functionality.

22.What is the processing accuracy of PCB products?

The processing accuracy of PCB (Printed Circuit Board) products is a critical aspect of their quality. It involves ensuring that the dimensions, traces, holes, and other features of the PCB are fabricated with precision. The accuracy is typically specified in terms of tolerances for various parameters, including trace width, hole diameter, and overall dimensions. Common processing accuracy standards for PCBs include a minimum trace width and spacing, as well as specific tolerances for holes and cutouts. Achieving high processing accuracy is essential to ensure that the PCB functions as intended and that components can be soldered onto it without issues. The specific processing accuracy requirements can vary based on the PCB's design and application.

23.What is the difference between PCB FasTechCircuit vs PCB Biostar vs PCB EVGA

The choice between these manufacturers should be based on your specific project requirements. PCB FasTechCircuit is ideal for fast prototyping, while PCB Biostar and PCB EVGA are trusted options for high-quality components in computer hardware, with EVGA specifically known for its gaming-oriented graphics cards. Your decision should align with the goals and needs of your project.

RELATED NEWS

pcb board manufacturing How To Contact US

PCB from 1 to 30 layers, HDI, Heavy Copper, Rigid-flex board with "pcb board manufacturing One-Stop" service.