Exploring the benefits of using flexible PCB

patches pcb is a printed circuit board that uses printing technology to connect circuit components and wires in the circuit diagram to the board to support and fix electronic components.

Demystifying the PCB manufacturing process: from layout to board making

Our PCB products are designed and manufactured to ensure high reliability under various operating conditions, minimizing the risk of failure and downtime.

Our PCB products incorporate advanced thermal management techniques and materials, ensuring efficient dissipation of heat and preventing overheating, which can lead to reduced performance or device failure.

PCB--An Ultimate FAQ Guide.

2.What electronic components can this PCB product support?

3.Do PCB products use environmentally friendly materials?

4.About PCB production management system

5.Do PCB products have assembly functions?

6.What electronic fields is PCB suitable for?

7.About PCB quality system

8.About the development history of PCB factory

9.About PCB patent

10.What is the difference between PCB FasTechCircuit vs PCB ASRock vs PCB Gigabyte

11.About PCB production capacity

12.Is this PCB product single-sided or double-sided?

13.About PCB production capacity

14.About PCB overseas warehouse

15.About PCB origin

16.About PCB technology

17.About PCB raw material procurement system

18.About PCB customization services

19.What is the price of PCB products?

20.About PCB technology

21.Do PCB products have anti-static functions?

1.What are the dimensions of PCB products?

The dimensions of PCB (Printed Circuit Board) products can vary widely depending on the specific application and requirements. PCBs come in various sizes and shapes to accommodate different electronic devices and systems. They can range from small and compact boards used in mobile phones or wearables to larger and more intricate boards found in computers, industrial equipment, or automotive systems. The dimensions are tailored to fit the intended space within the electronic device and to support the necessary components and connections. As a result, PCBs are available in a diverse range of sizes and configurations to meet the unique needs of various applications.

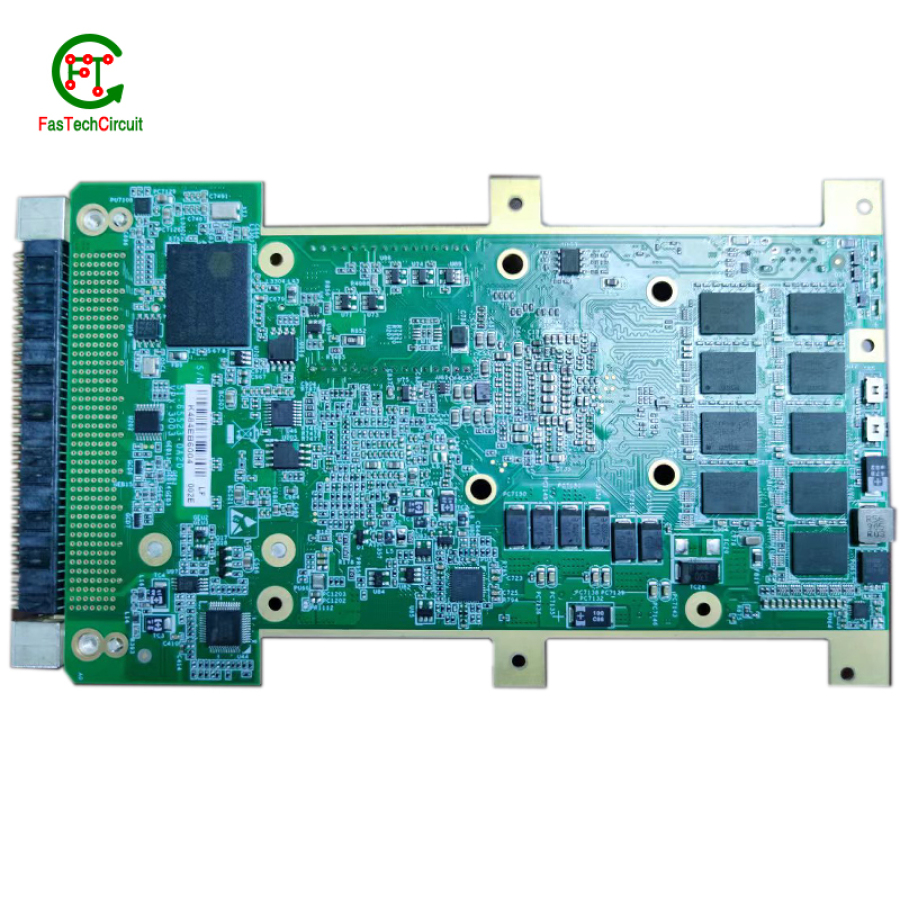

2.What electronic components can this PCB product support?

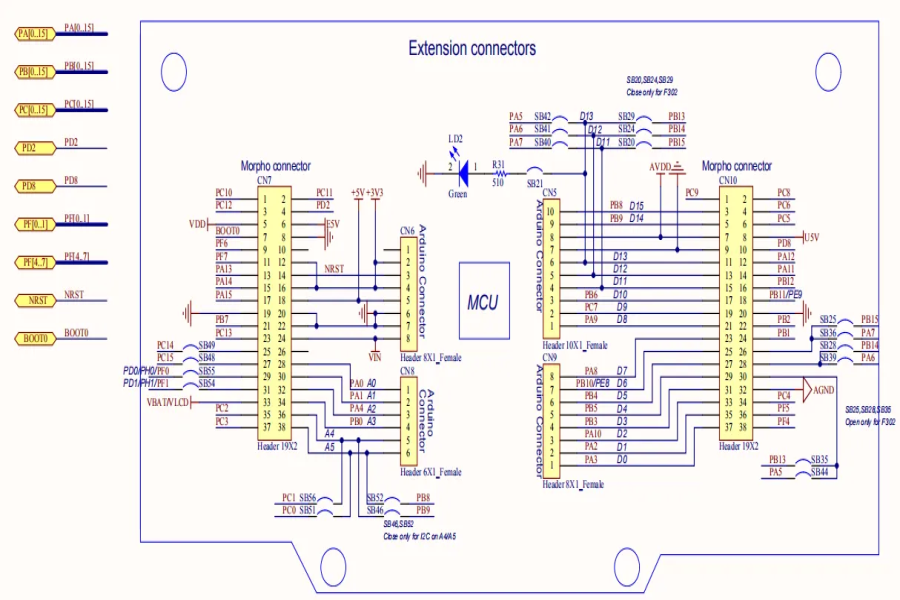

The capabilities of this PCB (Printed Circuit Board) product extend to supporting a wide array of electronic components. These components include but are not limited to integrated circuits (ICs), microcontrollers, resistors, capacitors, diodes, transistors, connectors, and various sensors. The PCB's design and layout are tailored to accommodate these components and establish electrical connections between them. This versatility enables the PCB to be used in a broad spectrum of electronic devices and systems, where it acts as the central hub for component integration and electrical functionality.

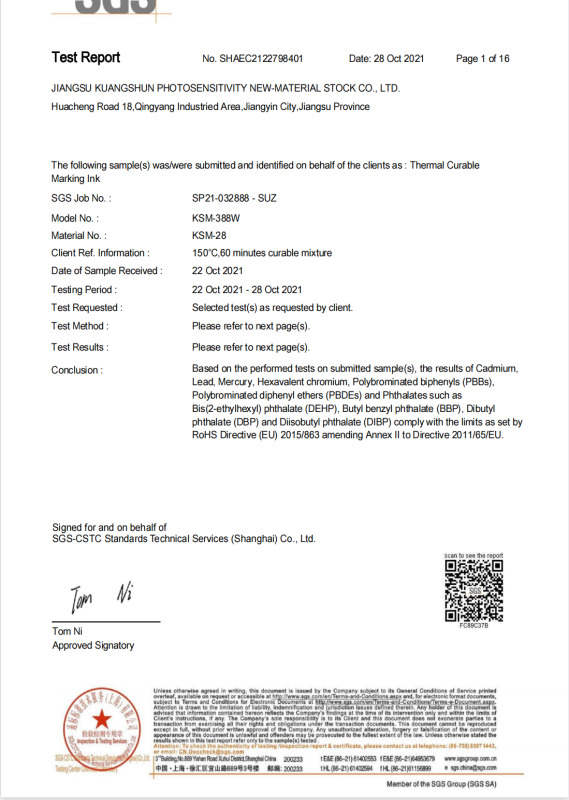

3.Do PCB products use environmentally friendly materials?

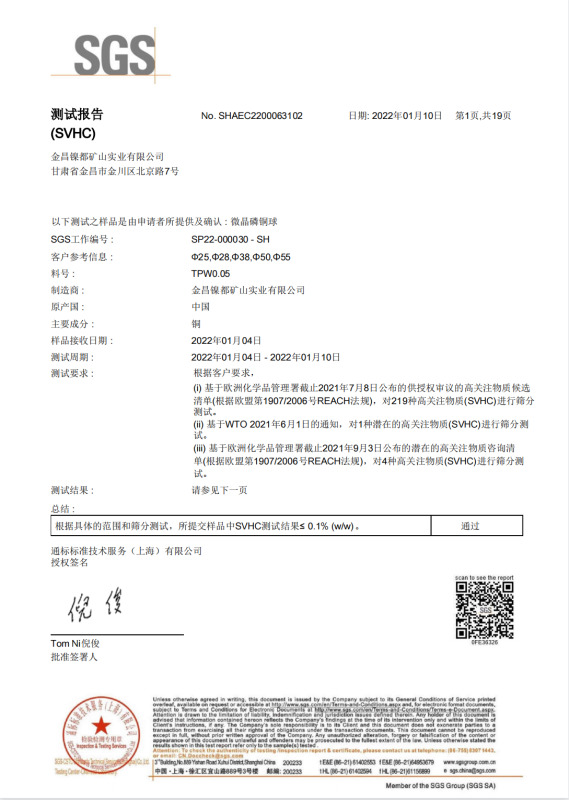

PCB (Printed Circuit Board) products can be manufactured using environmentally friendly materials and processes, depending on the manufacturer's practices and the specific requirements of the application. Environmentally friendly PCBs may incorporate lead-free solder materials, halogen-free substrates, and other eco-friendly alternatives. In many regions, there are regulations and standards, such as RoHS (Restriction of Hazardous Substances) directives, which require the reduction or elimination of hazardous materials in electronics, including PCBs. Manufacturers often aim to meet these environmental standards by using eco-friendly materials and processes in their PCB production. However, the extent to which a PCB product is environmentally friendly depends on the manufacturer's practices and adherence to such regulations.

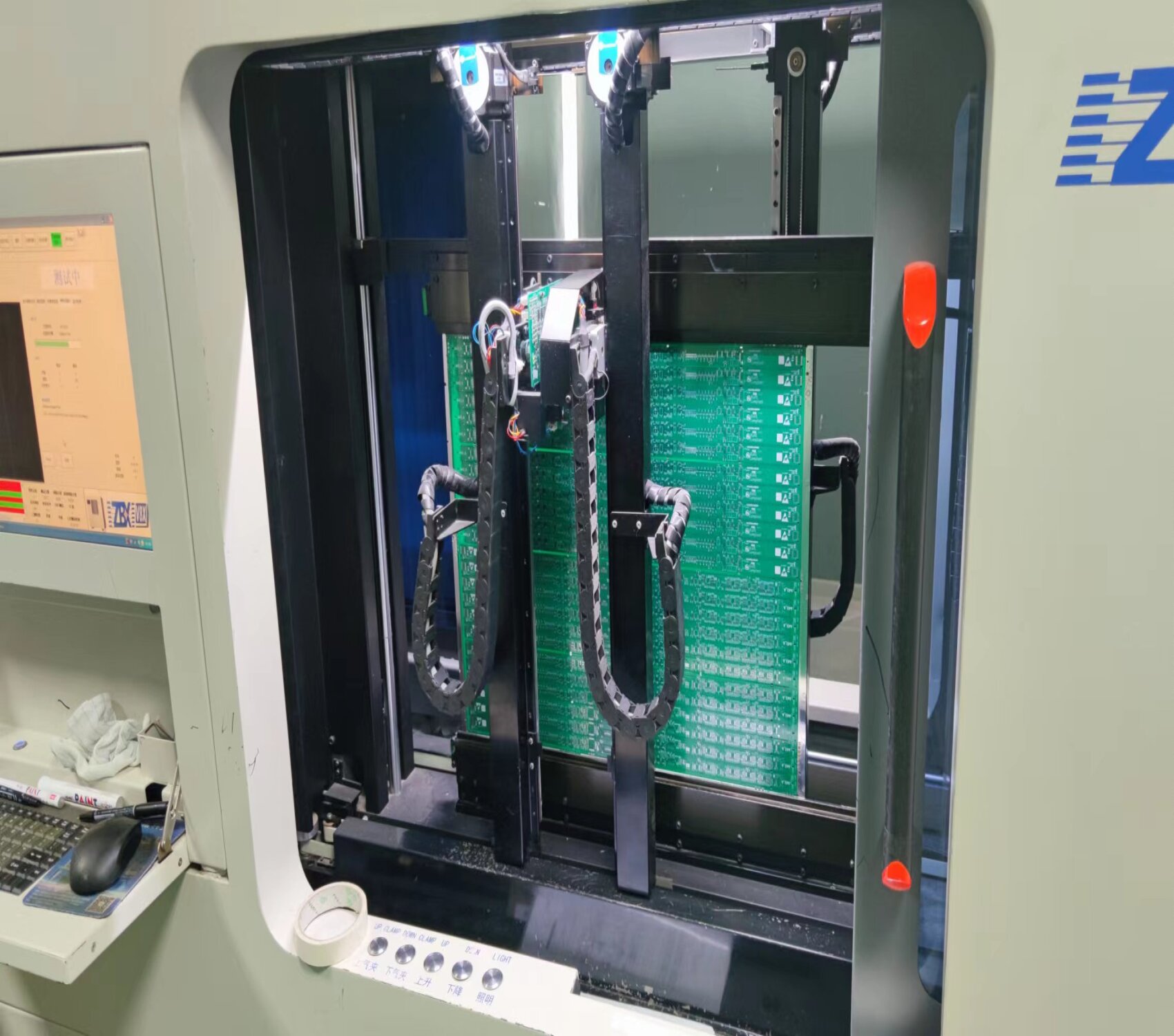

4.About PCB production management system

The PCB production management system is a software program designed to effectively manage the entire process of producing printed circuit boards. It utilizes advanced technology to streamline and automate various tasks involved, such as order management, design and layout, material procurement, production scheduling, quality control, and shipping. This system aims to improve efficiency, reduce production time and costs, increase accuracy and quality, and provide real-time tracking and monitoring of the production process. With its comprehensive features and user-friendly interface, the PCB production management system is an essential tool for optimizing the production of printed circuit boards.

5.Do PCB products have assembly functions?

PCB (Printed Circuit Board) products do not inherently have assembly functions themselves but are designed to support the assembly of electronic components. PCBs serve as the foundational platform for mounting and interconnecting various electronic parts, such as resistors, capacitors, integrated circuits, and connectors. The assembly of these components onto the PCB is a critical part of the manufacturing process of electronic devices. The design of the PCB includes features like component footprints, solder pads, and traces to facilitate the precise placement and soldering of components. While PCBs are not responsible for the assembly process, their design is tailored to enable the efficient and reliable assembly of electronic components.

6.What electronic fields is PCB suitable for?

PCB (Printed Circuit Board) technology is versatile and adaptable, making it suitable for a wide range of electronic fields and applications. PCBs are commonly used in industries such as consumer electronics, automotive, industrial machinery, aerospace, medical devices, telecommunications, IoT, renewable energy, robotics, and consumer appliances. Their ability to provide reliable and efficient connections for electronic components makes PCBs an essential element in various electronic systems, enabling innovation and functionality in diverse fields.

7.About PCB quality system

The PCB quality system is a set of processes and procedures for ensuring that printed circuit boards meet the required quality standards. It encompasses various aspects such as design, fabrication, assembly, and testing, to ensure consistent and reliable performance of the PCBs. The system involves rigorous quality control measures, continuous improvement efforts, and strict adherence to industry standards and regulations. This comprehensive approach to PCB quality management is crucial for achieving high quality products and maintaining customer satisfaction.

8.About the development history of PCB factory

The development of PCB factories can be traced back to the early 20th century when the technology for producing printed circuit boards was first invented. Over the years, with the advancements in electronics and manufacturing processes, the demand for PCBs grew rapidly. This led to the establishment of more specialized and efficient PCB factories, which played a crucial role in the development of modern electronics. With the introduction of more sophisticated machinery and techniques, these factories were able to mass produce high-quality PCBs at a faster pace, meeting the growing demand from various industries. Today, PCB factories continue to evolve and innovate, adopting new technologies such as automation and AI to streamline processes and produce higher quality and more complex circuit boards for the ever-expanding electronics market.

9.About PCB patent

PCB patent is a form of intellectual property protection that grants inventors and companies the exclusive right to produce and sell printed circuit boards (PCBs) with unique designs, functions, or processes. It serves as a means to encourage innovation and reward originality in the field of electronic circuitry and technology. PCB patents can cover a wide range of aspects, such as layout designs, fabrication methods, and manufacturing processes. However, in order to obtain a PCB patent, the design or process must meet specific criteria, including being novel, non-obvious, and useful. This type of patent is essential for companies and individuals in the electronics industry to protect their ideas and prevent others from copying or profiting from their innovations. By securing a PCB patent, inventors and companies can have a competitive advantage in the market and ensure the long-term success of their products.

10.What is the difference between PCB FasTechCircuit vs PCB ASRock vs PCB Gigabyte

The choice between these manufacturers should be based on your specific project requirements. PCB FasTechCircuit is suitable for fast prototyping, while PCB ASRock and PCB Gigabyte are trusted options for high-quality components in computer hardware. Your decision should align with the objectives and needs of your project.

11.About PCB production capacity

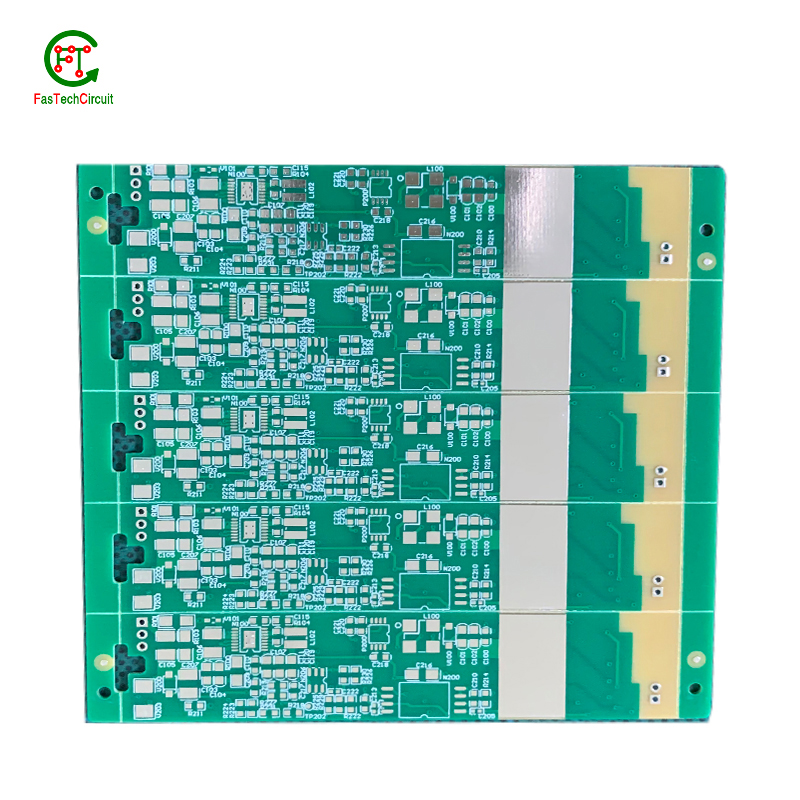

PCB production capacity refers to the maximum quantity of printed circuit boards (PCBs) that a manufacturer is able to produce within a given timeframe. This not only includes the physical space and equipment available for production, but also considers factors such as production time, manpower, and efficiency. A high production capacity allows for a larger volume of PCBs to be manufactured, meeting the demands of customers and addressing the growing market for electronic devices. Advances in technology and process optimization have continually increased PCB production capacity, allowing for more efficient and cost-effective production processes.

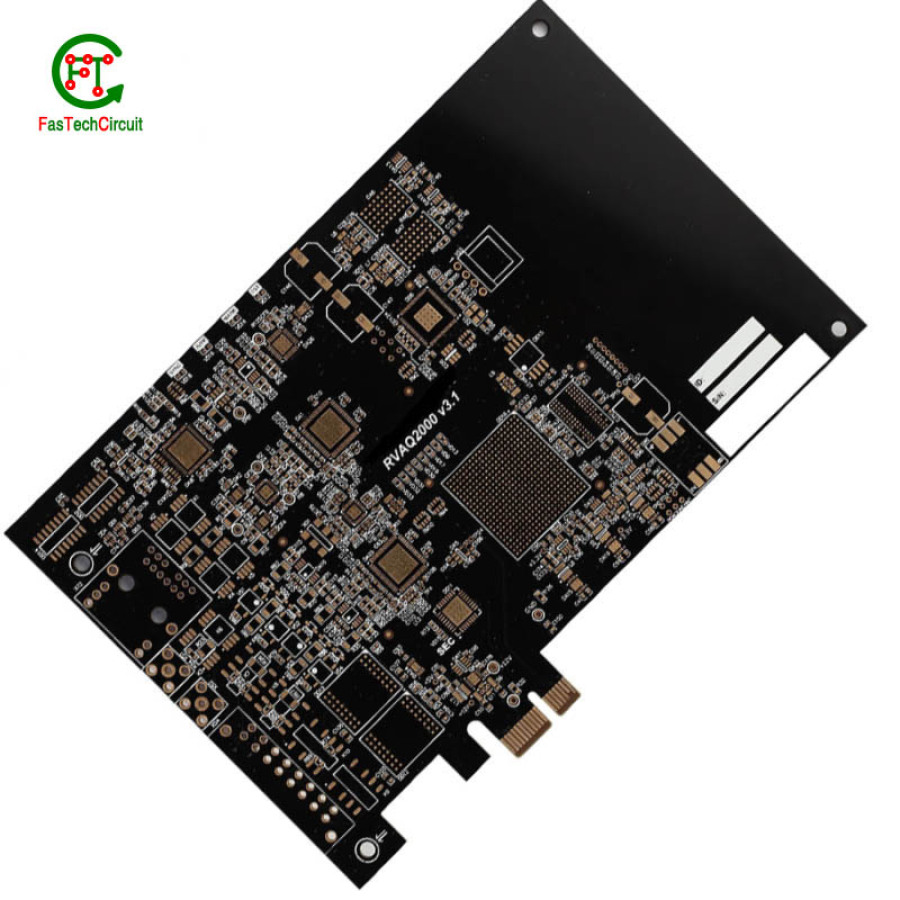

12.Is this PCB product single-sided or double-sided?

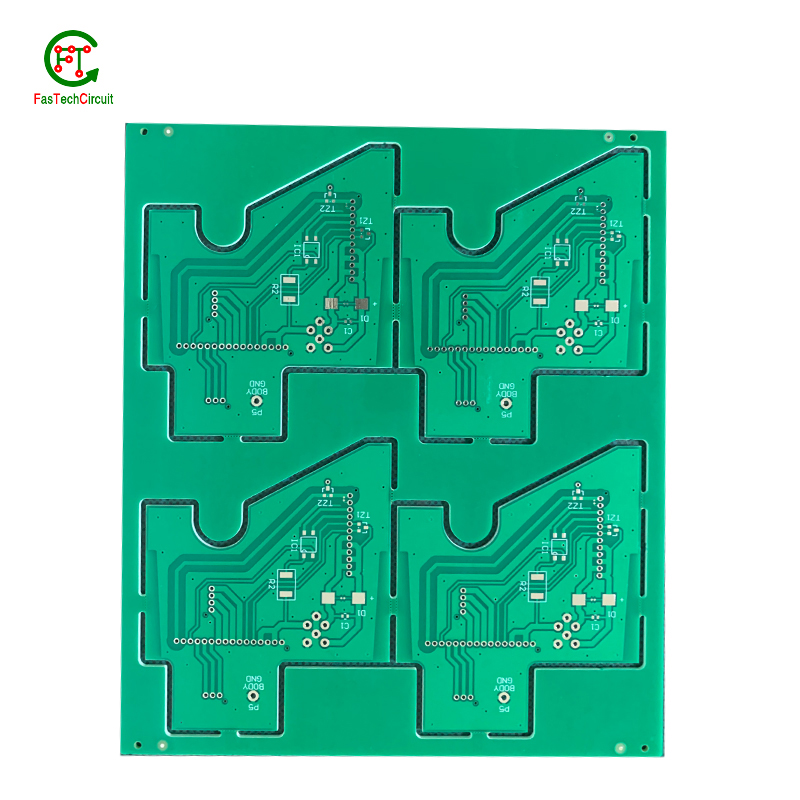

This PCB (Printed Circuit Board) product can be configured as either single-sided or double-sided, depending on the specific application and design requirements. Single-sided PCBs have circuitry on one side of the board, while double-sided PCBs feature electrical connections on both sides. The choice between single-sided and double-sided PCBs is made based on factors like the complexity of the circuit, space constraints, and cost considerations. This flexibility in design allows the PCB product to adapt to a variety of electronic applications, ensuring it can meet the needs of different projects and devices.

13.About PCB production capacity

PCB production capacity refers to the amount and ability of a PCB (Printed Circuit Board) manufacturer to produce electronic circuit boards in a given period of time. This includes the company's production capabilities, resources, and efficiency in producing PCBs. The capacity of a PCB manufacturer is an important consideration for businesses and industries that rely on PCBs for their electronic devices, as it directly impacts the supply and turnaround time for these crucial components. With the constant demand for smaller, faster, and more complex electronic devices, there is a growing need for PCB production capacity to keep up with the industry's evolving requirements. Therefore, manufacturers are continuously investing in technology and expanding their production capabilities to meet the demands of the market.

14.About PCB overseas warehouse

A PCB overseas warehouse is a storage facility strategically located in a different country than the manufacturer's main facility, allowing for easy shipment and delivery of printed circuit boards (PCBs) to international customers. This provides numerous benefits including faster shipping times, reduced shipping costs, and improved customer service. These warehouses serve as a key component in the global supply chain of PCBs, facilitating efficient and timely distribution of products to meet the demands of a global market.

15.About PCB origin

Printed circuit boards (PCBs) have a rich history, dating back to the early 20th century. They were first developed as a replacement for complicated, hand-wired circuits in radio sets and are now an integral part of modern electronics. PCBs originated through the evolution of various technologies and have undergone significant advancements in design, materials, and production methods over the years. Today, they are widely used in a diverse range of industries, from consumer electronics to aerospace and automotive, making them an essential component in our daily lives.

16.About PCB technology

PCB technology, also known as printed circuit board technology, refers to the process of designing, manufacturing and assembling electronic circuit boards used in various electronic devices. This technology involves the use of specialized software for design, advanced manufacturing techniques such as surface mount technology and through-hole technology, and various testing methods to ensure the functionality and reliability of the PCBs. It plays a crucial role in the development and production of electronic devices, making it one of the fundamental technologies in the modern electronics industry.

17.About PCB raw material procurement system

The PCB raw material procurement system is a crucial aspect of the production process for printed circuit boards. It involves the sourcing and acquisition of all necessary materials, such as copper foil, laminate sheets, solder mask, and components, needed for the manufacturing of PCBs. This system requires efficient coordination between suppliers and the PCB manufacturer to ensure timely delivery and high-quality materials. Additionally, proper management of inventory levels and cost control are essential components of the procurement system to ensure smooth and cost-effective production of PCBs.

18.About PCB customization services

PCB customization services involve creating personalized printed circuit boards (PCBs) to meet specific design and functionality requirements. This process includes collaborating with the client to understand their unique needs and customizing the PCB layout, material, and components accordingly. Through PCB customization services, clients can obtain tailor-made solutions for their specific applications, ensuring high-quality and efficient performance. These services are essential for industries such as automotive, aerospace, and telecommunications, where precision and reliability are crucial. With the help of experienced professionals and advanced technologies, PCB customization services offer a cost-effective and timely solution for businesses seeking customized electronic components.

19.What is the price of PCB products?

The price of PCB (Printed Circuit Board) products can vary widely depending on several factors, including the PCB's complexity, size, design specifications, quantity, and the choice of materials. Basic single-layer PCBs with standard features are generally more affordable, while complex multi-layer PCBs with specific requirements, such as high-speed signaling or special materials, may be more expensive. Quantity also plays a role, as larger production runs often lead to cost savings per unit. Additionally, custom-designed PCBs tailored to specific applications may be priced higher than off-the-shelf PCBs. To determine the exact price of a PCB product, it is essential to contact PCB manufacturers or suppliers, as pricing can vary based on individual project specifications and market conditions.

20.About PCB technology

PCB technology, also known as Printed Circuit Board technology, is a fundamental aspect of modern electronics. It involves designing and manufacturing electronic circuits and interconnecting components using conductive pathways, or traces, on a non-conductive substrate. This technology has revolutionized the electronic industry and has enabled the creation of highly efficient and compact electronic devices, from smartphones to computers and medical equipment. PCB technology continues to advance with the demand for smaller, faster, and more complex electronic devices, making it a crucial component in the development of new technologies.

21.Do PCB products have anti-static functions?

PCB (Printed Circuit Board) products themselves do not typically have inherent anti-static functions. However, anti-static precautions are essential during the manufacturing and handling of PCBs. Static electricity can potentially damage sensitive electronic components on a PCB. To mitigate this risk, anti-static measures such as using anti-static workstations, wearing anti-static garments, and using anti-static tools and packaging materials are employed when working with PCBs. These precautions help prevent electrostatic discharge (ESD) and protect the integrity of the components and the PCB itself, ensuring that the final product functions reliably in electronic systems.

TAG: PCBA, HIGH SPEED PCB, MULTILAYER PCB

RELATED NEWS

pcb board manufacturing How To Contact US

PCB from 1 to 30 layers, HDI, Heavy Copper, Rigid-flex board with "pcb board manufacturing One-Stop" service.