Understanding PCB assembly and manufacturing processes

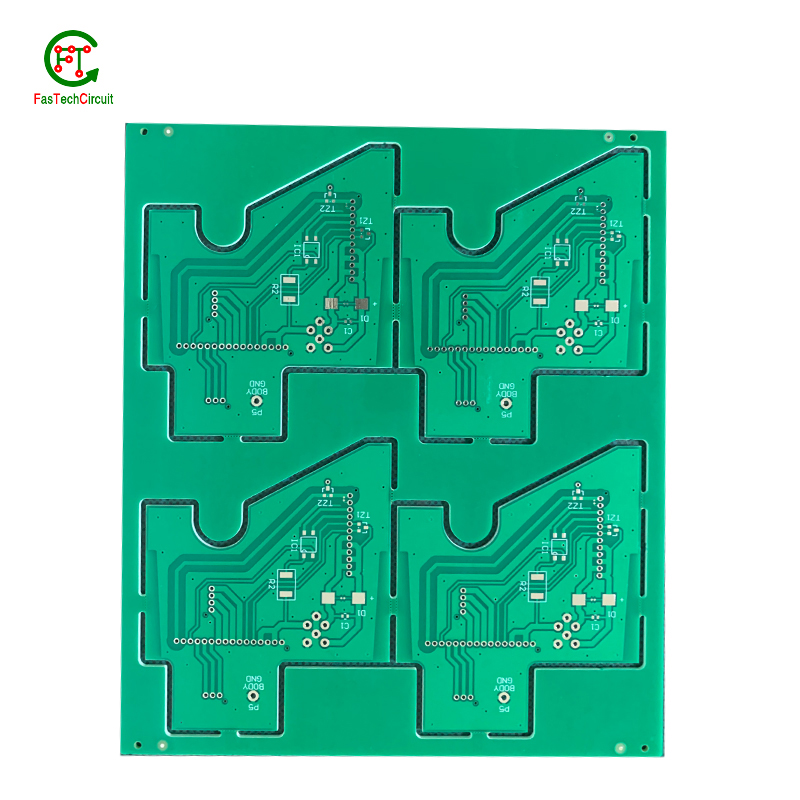

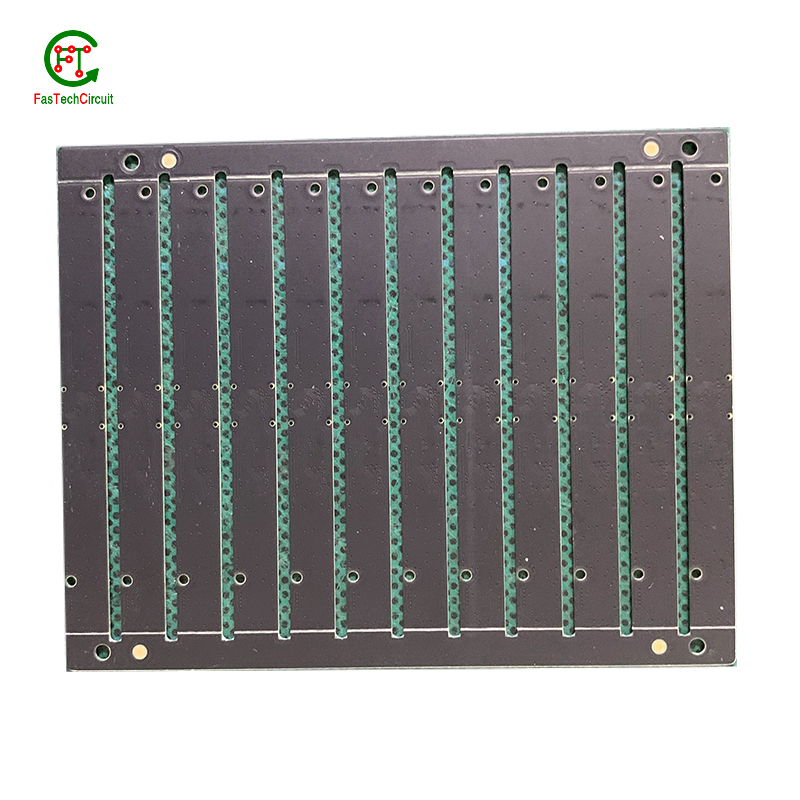

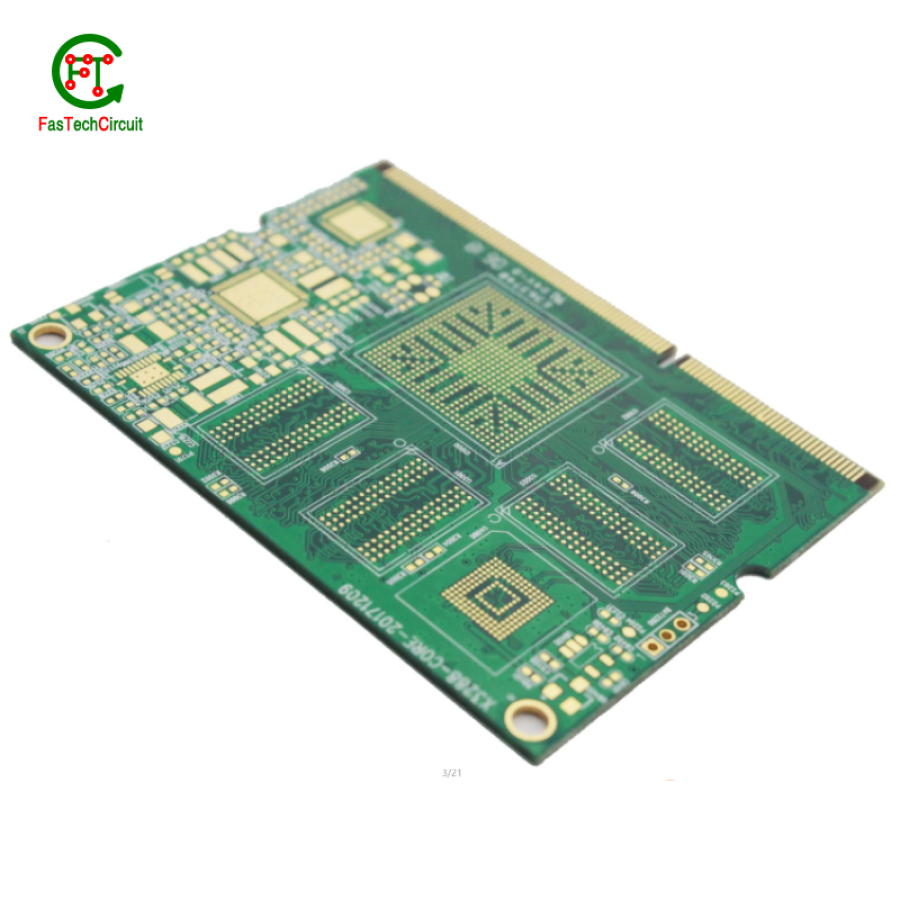

PCB ASSEMBLY wiring structures are usually divided into single-layer, double-layer and multi-layer structures. Multi-layer structures can effectively reduce the size of circuit boards and improve wiring efficiency, and are often used in the design of high-density and complex circuits.

Optimizing PCB layout: the key to improving circuit performance

By utilizing advanced manufacturing techniques and high-density component placement, our PCB products are able to achieve compact and lightweight designs, saving valuable space in electronic devices.

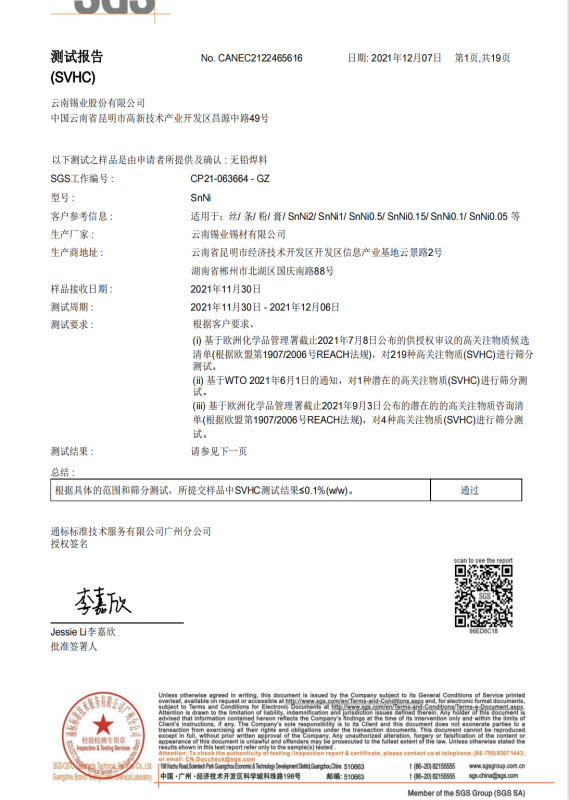

We are committed to using environmentally friendly materials and production processes in the manufacturing of our PCB products, reducing our carbon footprint and promoting sustainability.

PCB--An Ultimate FAQ Guide.

2.Are PCB products waterproof?

3.About PCB production management system

4.About PCB production capacity

5.Does the PCB have EMC testing certification?

6.About PCB raw material procurement system

7.About PCB raw materials

8.What is the difference between PCB FasTechCircuit vs PCB ASUS vs PCB MSI

9.About PCB overseas warehouse

10.About the scale of PCB factory

11.What electronic components can this PCB product support?

12.About PCB quality system

13.About PCB technology

14.About PCB delivery date

15.What is the difference between PCB FasTechCircuit vs PCB ECS vs PCB Foxconn

16.About PCB payment method

17.About PCB warranty

18.About PCB origin

1.About PCB payment method

The payment method for PCB (Printed Circuit Board) orders typically involves various options for customers to choose from. Common payment methods include credit card payments, bank transfers, electronic funds transfer (EFT), and online payment platforms like PayPal. Additionally, some PCB manufacturers may offer specific payment terms and options, such as advance payment or net payment within agreed credit terms for established business relationships. The choice of payment method can vary depending on the PCB manufacturer and the agreement between the parties involved in the transaction. It's essential to discuss and confirm the preferred payment method with the PCB manufacturer before placing an order.

2.Are PCB products waterproof?

PCB (Printed Circuit Board) products are not inherently waterproof, but they can be made water-resistant or waterproof by applying specific protective measures during the design and manufacturing process. Water-resistant PCBs are often coated with conformal coatings or encapsulated in waterproof housings to shield them from moisture and environmental factors. The degree of waterproofing can vary, with some PCBs designed to withstand exposure to water and others being more water-resistant. The level of protection depends on the intended application and the environmental conditions in which the PCB will operate. Waterproofing is crucial for applications where PCBs may be exposed to moisture, such as in outdoor electronics, automotive systems, and marine devices.

3.About PCB production management system

The PCB production management system is an advanced and comprehensive software solution designed to streamline and optimize the production process of printed circuit boards. This system offers a centralized platform for tracking, managing and monitoring all stages of the production cycle, from design and material procurement to assembly and testing. By implementing this system, PCB manufacturers can increase efficiency, reduce errors and boost productivity. It also provides real-time visibility into production progress, inventory levels, and quality control, allowing for better decision-making and quicker response to any issues that may arise. With its user-friendly interface and powerful features, the PCB production management system is a valuable tool for modern production facilities seeking to stay competitive in the ever-evolving electronics industry.

4.About PCB production capacity

PCB production capacity refers to the amount and ability of a PCB (Printed Circuit Board) manufacturer to produce electronic circuit boards in a given period of time. This includes the company's production capabilities, resources, and efficiency in producing PCBs. The capacity of a PCB manufacturer is an important consideration for businesses and industries that rely on PCBs for their electronic devices, as it directly impacts the supply and turnaround time for these crucial components. With the constant demand for smaller, faster, and more complex electronic devices, there is a growing need for PCB production capacity to keep up with the industry's evolving requirements. Therefore, manufacturers are continuously investing in technology and expanding their production capabilities to meet the demands of the market.

5.Does the PCB have EMC testing certification?

EMC (Electromagnetic Compatibility) testing certification is typically not a feature of PCB (Printed Circuit Board) products themselves. Instead, EMC testing and certification are applied to the entire electronic system or device in which the PCB is used. EMC testing ensures that the electronic system complies with electromagnetic compatibility standards, meaning it can operate without causing or suffering from electromagnetic interference. While PCBs play a role in ensuring EMC compliance, the certification process involves evaluating the entire system's performance, including the PCB, components, and enclosure. Therefore, PCBs do not have EMC testing certification on their own but contribute to the overall EMC compliance of the electronic systems they are a part of.

6.About PCB raw material procurement system

The PCB raw material procurement system is a crucial aspect of the production process for printed circuit boards. It involves the sourcing and acquisition of all necessary materials, such as copper foil, laminate sheets, solder mask, and components, needed for the manufacturing of PCBs. This system requires efficient coordination between suppliers and the PCB manufacturer to ensure timely delivery and high-quality materials. Additionally, proper management of inventory levels and cost control are essential components of the procurement system to ensure smooth and cost-effective production of PCBs.

7.About PCB raw materials

PCB (Printed Circuit Board) raw materials refer to the base materials used in the manufacturing of electronic circuit boards. These materials typically include copper-clad laminates, solder mask, silkscreen, and various types of coatings and films. The selection of high-quality raw materials is crucial for ensuring the functionality, durability and reliability of PCBs, which are the backbone of electronic devices. Different applications require different types of raw materials, such as high-speed signal transmission, thermal management, and environmental protection. With the constant advancement of technology, the demand for more innovative and sustainable PCB raw materials continues to rise, driving the development of the electronics industry towards a more efficient and eco-friendly future.

8.What is the difference between PCB FasTechCircuit vs PCB ASUS vs PCB MSI

The choice between these manufacturers depends on the specific requirements of your project. PCB FasTechCircuit might be suitable for rapid prototyping, while PCB ASUS and PCB MSI are trusted choices for high-quality components in gaming and consumer electronics. Ultimately, the decision should be based on your project's needs and goals.

9.About PCB overseas warehouse

A PCB overseas warehouse is a storage facility strategically located in a different country than the manufacturer's main facility, allowing for easy shipment and delivery of printed circuit boards (PCBs) to international customers. This provides numerous benefits including faster shipping times, reduced shipping costs, and improved customer service. These warehouses serve as a key component in the global supply chain of PCBs, facilitating efficient and timely distribution of products to meet the demands of a global market.

10.About the scale of PCB factory

A PCB factory, also known as a printed circuit board factory, is a manufacturing facility that specializes in the production of printed circuit boards. These are used in a wide range of electronic devices, from smartphones and laptops to cars and airplanes. These factories vary in scale, with some producing small volumes for niche markets, while others are large operations that mass-produce PCBs for mainstream electronics companies. The scale of a PCB factory can be measured by its annual production output, the number of employees, and the size of its production facility. The larger the scale of a PCB factory, the more advanced and complex its production processes are likely to be, allowing it to produce high-quality boards in large quantities.

11.What electronic components can this PCB product support?

The capabilities of this PCB (Printed Circuit Board) product extend to supporting a wide array of electronic components. These components include but are not limited to integrated circuits (ICs), microcontrollers, resistors, capacitors, diodes, transistors, connectors, and various sensors. The PCB's design and layout are tailored to accommodate these components and establish electrical connections between them. This versatility enables the PCB to be used in a broad spectrum of electronic devices and systems, where it acts as the central hub for component integration and electrical functionality.

12.About PCB quality system

The PCB quality system is a comprehensive and structured approach to ensuring the quality of printed circuit boards. It encompasses various processes and procedures, from design and manufacturing to testing and inspection, to ensure that the final product meets the required standards and specifications. By implementing a robust quality system, manufacturers can achieve consistent and reliable quality, reduce defects and errors, and ultimately deliver high-quality PCBs that meet the expectations of their customers. This system is crucial in the electronics industry, as PCBs are integral components in most electronic devices and their quality can greatly impact the performance and reliability of these devices.

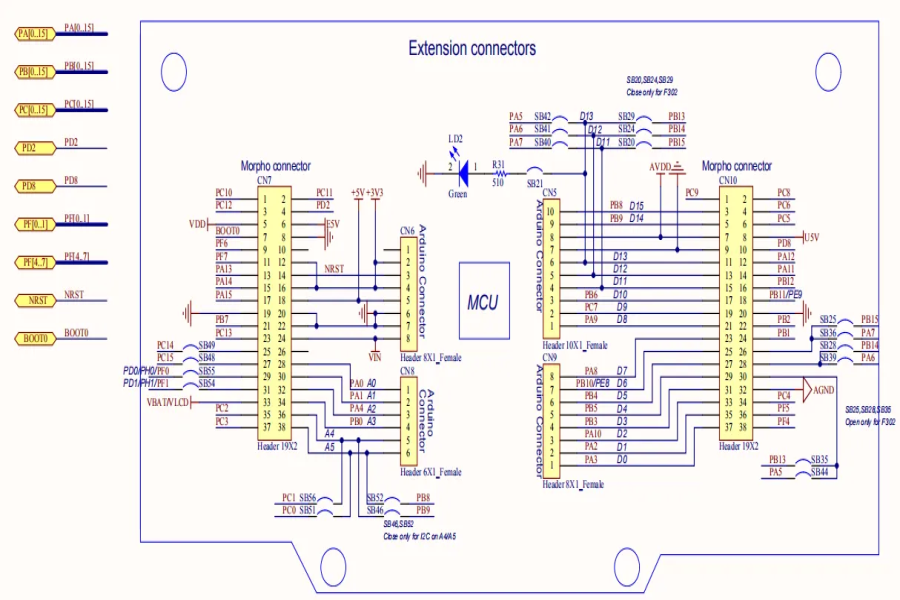

13.About PCB technology

PCB technology, also known as printed circuit board technology, refers to the process of designing, manufacturing and assembling electronic circuit boards used in various electronic devices. This technology involves the use of specialized software for design, advanced manufacturing techniques such as surface mount technology and through-hole technology, and various testing methods to ensure the functionality and reliability of the PCBs. It plays a crucial role in the development and production of electronic devices, making it one of the fundamental technologies in the modern electronics industry.

14.About PCB delivery date

The PCB (Printed Circuit Board) delivery date refers to the estimated time or deadline for the production and shipment of the circuit boards. This date is an important factor for customers who rely on the timely delivery of their ordered PCBs to meet their project or production deadlines. The delivery date is influenced by various factors such as the complexity of the PCB design, the materials used, and the production capacity of the manufacturer. It is essential for both the customer and the manufacturer to communicate effectively and set realistic delivery dates to ensure a smooth and efficient production process. Adhering to the delivery date is crucial for customer satisfaction and maintaining a good reputation in the market. Timely delivery not only showcases the reliability and efficiency of the manufacturer but also helps customers stay on schedule with their projects and plans.

15.What is the difference between PCB FasTechCircuit vs PCB ECS vs PCB Foxconn

The choice between these manufacturers should be based on your specific project requirements. PCB FasTechCircuit is suitable for rapid prototyping, while PCB ECS and PCB Foxconn are trusted options for high-quality components in computer hardware and various electronics. Your decision should align with the objectives and needs of your project.

16.About PCB payment method

The PCB (Printed Circuit Board) payment method is a type of electronic payment method that utilizes a pre-printed circuit board with integrated circuits to process transactions. This method allows users to make secure payments using electronic cards, such as credit or debit cards, by simply inserting or swiping the card into a terminal. PCB payment systems are widely used in retail, hospitality, and other industries, providing a fast and efficient way to process transactions and reduce the risk of fraud. With the rise of technology, PCB payments are becoming increasingly popular due to their convenience, security, and ease of use.

17.About PCB warranty

The PCB warranty provides assurance for customers that their purchased circuit boards are free from defects and will function as intended within a specified time frame. This warranty ensures that customers receive high-quality products and can have peace of mind when using them for their electronic applications. It typically covers repair or replacement of faulty boards, offering protection and support to customers, thereby building trust and confidence in the manufacturer's products.

18.About PCB origin

Printed circuit boards (PCBs) have a rich history, dating back to the early 20th century. They were first developed as a replacement for complicated, hand-wired circuits in radio sets and are now an integral part of modern electronics. PCBs originated through the evolution of various technologies and have undergone significant advancements in design, materials, and production methods over the years. Today, they are widely used in a diverse range of industries, from consumer electronics to aerospace and automotive, making them an essential component in our daily lives.

TAG: PCB, PCBA, HIGH SPEED PCB, MULTILAYER PCB, HDI PCB BOARD

RELATED NEWS

pcb board manufacturing How To Contact US

PCB from 1 to 30 layers, HDI, Heavy Copper, Rigid-flex board with "pcb board manufacturing One-Stop" service.