What are the materials used in PCB assembly?

Efficiency and Reliability:

One of the main advantages of PCB assembly is its efficiency and reliability. With automated assembly processes, PCBs can be assembled quickly and accurately, reducing human error and increasing productivity. The use of advanced equipment and techniques also ensures the reliability and consistency of the assembled boards.

Versatility:

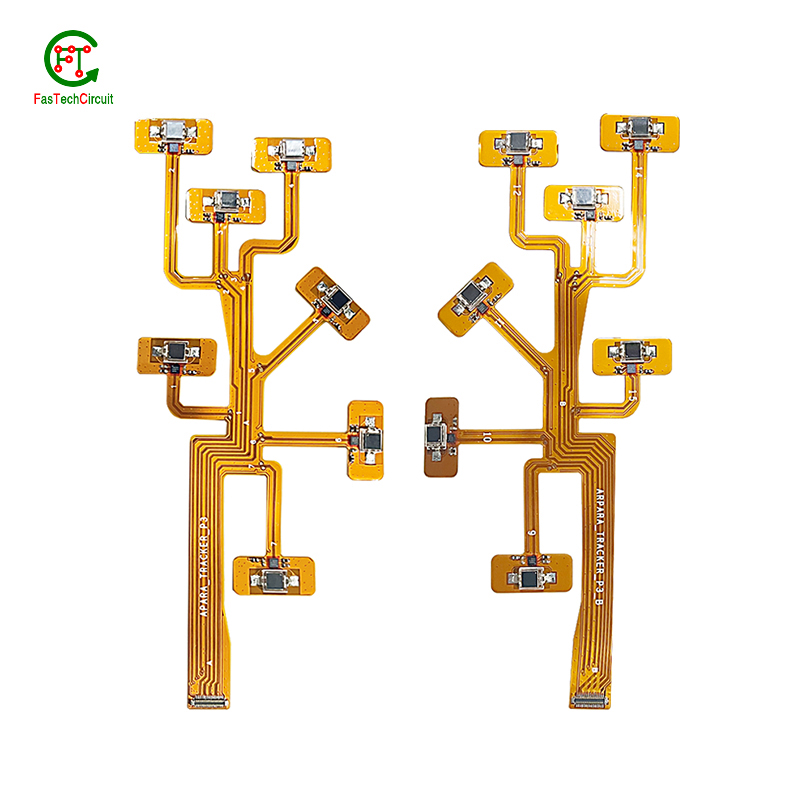

PCB assembly offers a high level of versatility, as it can accommodate various types of components, including small and delicate surface mount components. This flexibility allows for the assembly of complex and advanced electronic devices, making it a preferred choice in the manufacturing industry.

Cost-Effective:

Compared to traditional wiring methods, PCB assembly is more cost-effective in the long run. With automated processes, production costs are reduced, and the chances of errors and defects are minimized. This results in higher-quality products at a lower cost, making it a cost-effective option for manufacturers.

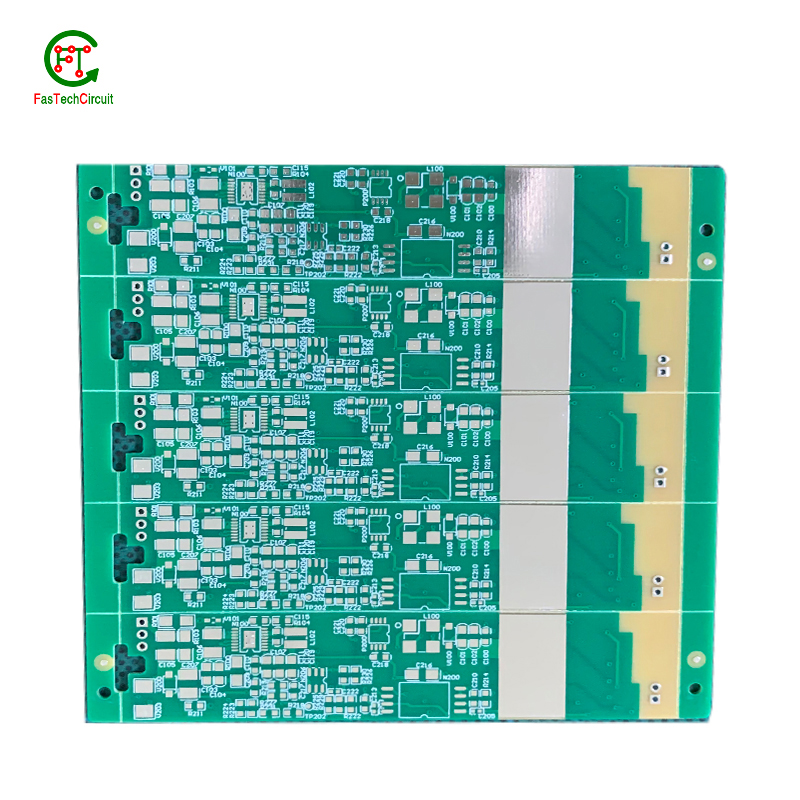

Smaller Size:

Another significant advantage of PCB assembly is its ability to create smaller and more compact electronic devices. With the use of surface mount components and advanced techniques, PCBs can be designed to be smaller and thinner than traditional circuit boards, making them ideal for modern electronic devices that require compact designs.

Durability:

PCB assembly also offers durable and long-lasting electronic devices. The use of high-quality materials and advanced manufacturing processes ensures that the assembled boards can withstand various environmental challenges, such as heat, moisture, and vibrations.

Higher Performance:

PCBs assembled through surface mount technology have better electrical performance compared to traditional through-hole technology. This is because surface mount components have shorter connection paths, resulting in higher speeds and better signal integrity.

Ease of Repairs and Upgrades:

In case of any malfunction or the need for upgrading, PCB assembly allows for easy repairs and upgrades. With the use of standardized components and the physical layout of the board, identifying and replacing faulty components is more straightforward and less time-consuming.

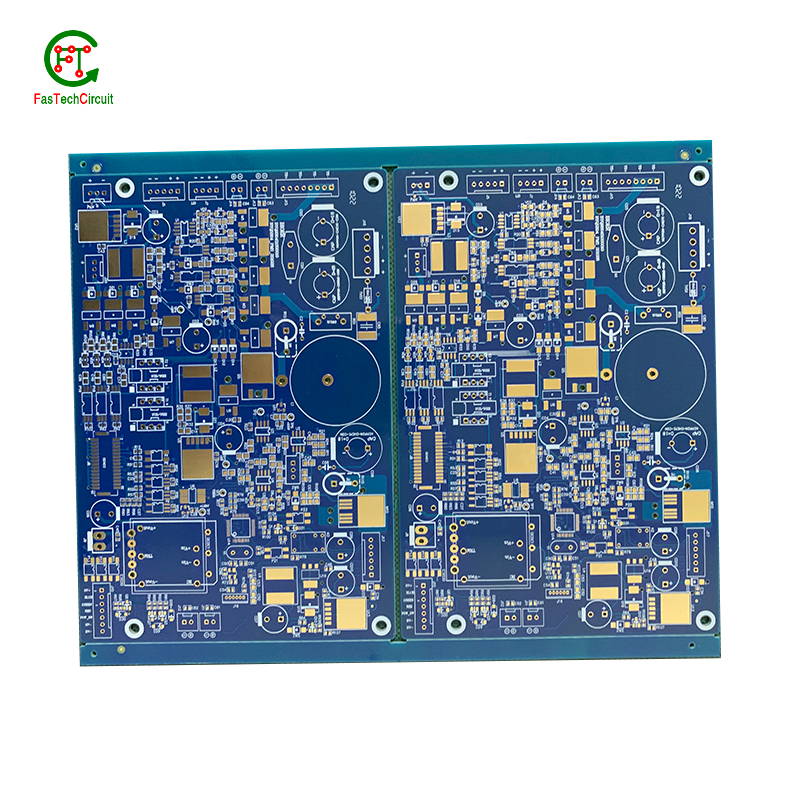

PCB assembly is a critical part of the electronic manufacturing process. The assembly of a PCB involves the use of a variety of components, including passive and active components, which are carefully placed and soldered to create an electronic circuit. Additional processes such as cleaning, coating, and testing are also carried out to ensure the quality and durability of the PCB.

PCB assembly is crucial in the electronics industry as it enables the production of complex and compact electronic devices. This process also allows for easy and efficient repairs and upgrades to electronic products, making them more sustainable and cost-effective.

PCB assembly is the process of assembling electronic components onto printed circuit boards (PCBs). It plays a critical role in the production of various electronic devices, from household appliances to advanced industrial equipment. However, as technology advances and the demand for higher quality products increases, there are often concerns and questions regarding the PCB assembly process. In this FQA (Frequently Asked Questions) section, we will address some commonly asked questions to provide a better understanding of PCB assembly.

2.What is a PCB assembly?

3.What is PCB laminate and prepreg materials?

4.What is PCB lamination process?

5.What is the most commonly used PCB material?

6.What machines are used in PCB manufacturing?

7.What is the quality of PCB assembly?

8.What is the difference between PCB and PCB assembly?

1.What is PCB baking?

PCB baking is a process used in the manufacturing of printed circuit boards (PCBs) to remove moisture from the board before it is assembled. This is done by placing the PCB in a specialized oven at a specific temperature for a set amount of time. The heat from the oven causes the moisture to evaporate, ensuring that the PCB is completely dry before it is assembled. This is important because moisture can cause defects and failures in the PCB during the assembly process. Baking also helps to improve the adhesion of components and solder to the board, resulting in a more reliable and durable product.

2.What is a PCB assembly?

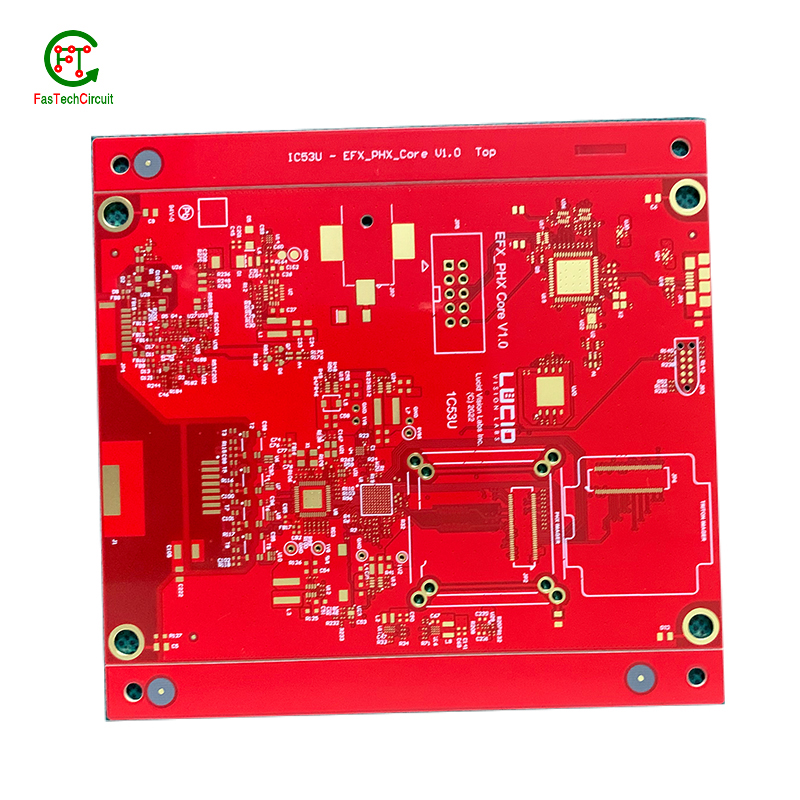

A PCB assembly, also known as a printed circuit board assembly, is the process of attaching electronic components to a printed circuit board (PCB). This process involves soldering or otherwise attaching the components to the board, as well as testing and inspecting the assembly for functionality and quality. PCB assemblies are used in a wide range of electronic devices, from simple household appliances to complex computer systems. They are an essential part of the manufacturing process for electronic products.

3.What is PCB laminate and prepreg materials?

PCB laminate and prepreg materials are used in the manufacturing of printed circuit boards (PCBs). They are essentially layers of insulating material that are used to separate and insulate the conductive layers of a PCB. Laminate materials are used as the base material for the PCB, providing mechanical support and stability. They are typically made of a reinforced composite material, such as fiberglass or epoxy resin, and are available in various thicknesses and grades. Prepreg materials, on the other hand, are used to bond the conductive layers of the PCB together. They are essentially layers of uncured resin that are impregnated with reinforcing fibers. When heated and pressed together, the prepreg material melts and bonds the conductive layers together, creating a solid and stable PCB. Both laminate and prepreg materials are essential components in the manufacturing of high-quality and reliable PCBs. They provide the necessary insulation and bonding properties to ensure the proper functioning of the circuit board.

4.What is PCB lamination process?

PCB lamination process is a manufacturing process used to bond multiple layers of a printed circuit board (PCB) together. This process involves the use of heat and pressure to fuse the layers of the PCB together, creating a single, solid board. The lamination process typically involves the following steps: 1. Preparation of the layers: The first step is to prepare the individual layers of the PCB. This includes cleaning, etching, and drilling the layers as per the design requirements. 2. Application of adhesive: A layer of adhesive material is applied to the surface of each layer. This adhesive helps to bond the layers together during the lamination process. 3. Layer alignment: The layers are then carefully aligned and stacked on top of each other, with the adhesive in between. 4. Lamination: The stacked layers are placed in a lamination press, which applies heat and pressure to fuse the layers together. The temperature and pressure are carefully controlled to ensure proper bonding without damaging the components on the PCB. 5. Cooling: After the lamination process, the PCB is cooled down to solidify the adhesive and create a strong bond between the layers. 6. Trimming and drilling: Once the PCB has cooled down, excess material is trimmed off the edges and holes are drilled to create the necessary connections between the layers. 7. Surface finishing: The final step is to apply a surface finish, such as solder mask or copper plating, to protect the PCB and provide a smooth surface for component placement. The lamination process is crucial in creating a strong and reliable PCB, as it ensures proper bonding between the layers and helps to maintain the integrity of the circuit.

5.What is the most commonly used PCB material?

The most commonly used PCB material is FR-4 (Flame Retardant 4), which is a type of fiberglass epoxy laminate. It is widely used due to its high strength, good electrical insulation properties, and low cost.

6.What machines are used in PCB manufacturing?

1. CNC Drilling Machine: This machine is used to drill holes in the PCB for component placement and routing. 2. PCB Etching Machine: This machine is used to remove unwanted copper from the PCB surface to create the circuit pattern. 3. Solder Mask Printing Machine: This machine is used to apply a protective layer of solder mask on the PCB to prevent short circuits and corrosion. 4. Pick and Place Machine: This machine is used to accurately place electronic components on the PCB according to the design layout. 5. Reflow Oven: This machine is used to solder the components onto the PCB using heat and a solder paste. 6. Automated Optical Inspection (AOI) Machine: This machine is used to inspect the PCB for any defects or errors in the manufacturing process. 7. Flying Probe Tester: This machine is used to test the electrical connectivity of the PCB by sending electrical signals through the circuit. 8. X-ray Inspection Machine: This machine is used to inspect the internal structure of the PCB and detect any defects that cannot be seen with the naked eye. 9. PCB Depaneling Machine: This machine is used to separate individual PCBs from a larger panel after the manufacturing process is complete. 10. PCB Washing Machine: This machine is used to clean the PCB after the manufacturing process to remove any residue or contaminants.

7.What is the quality of PCB assembly?

The quality of PCB assembly can vary depending on several factors such as the manufacturing process, materials used, and the expertise of the assembly team. Generally, a high-quality PCB assembly should have the following characteristics: 1. Accurate and precise placement of components: The components should be placed on the PCB accurately and precisely according to the design specifications. 2. Proper soldering: The soldering of components should be done correctly to ensure a strong and reliable connection. 3. Good electrical connections: The PCB assembly should have good electrical connections between components to ensure proper functioning. 4. Adequate testing: The assembled PCB should undergo thorough testing to ensure that all components are functioning correctly. 5. Use of high-quality materials: The use of high-quality materials such as PCBs, components, and soldering materials can greatly impact the overall quality of the assembly. 6. Compliance with industry standards: The assembly should comply with industry standards and regulations to ensure safety and reliability. Overall, a high-quality PCB assembly should have a low defect rate, meet design specifications, and function reliably.

8.What is the difference between PCB and PCB assembly?

PCB (Printed Circuit Board) refers to the physical board that contains electronic components and their interconnections. It is the foundation of an electronic device and provides a platform for the components to be mounted and connected. PCB assembly, on the other hand, refers to the process of attaching electronic components to the PCB. This includes soldering or mounting the components onto the board, as well as testing and inspecting the finished product. In summary, PCB is the physical board while PCB assembly is the process of assembling electronic components onto the board.

RELATED NEWS

pcb board manufacturing How To Contact US

PCB from 1 to 30 layers, HDI, Heavy Copper, Rigid-flex board with "pcb board manufacturing One-Stop" service.