How to effectively design for signal integrity in PCB layout

multilayer pcb is a printed circuit board that uses printing technology to connect circuit components and wires in the circuit diagram to the board to support and fix electronic components.

Challenges and Solutions: Common Problems in PCB Design

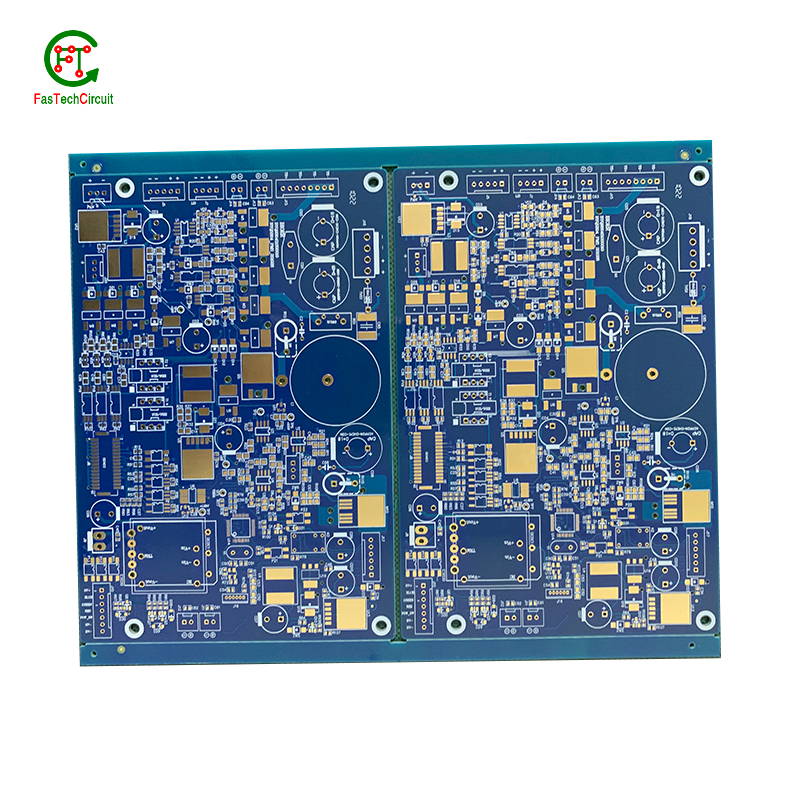

Our PCB products are designed to support high-speed signal transmission, allowing for faster data transfer rates and improved overall system performance.

By utilizing advanced manufacturing techniques and high-density component placement, our PCB products are able to achieve compact and lightweight designs, saving valuable space in electronic devices.

PCB--An Ultimate FAQ Guide.

2.About PCB inventory

3.About PCB patent

4.What is the difference between PCB FasTechCircuit vs PCB ECS vs PCB Foxconn

5.About PCB production capacity

6.About PCB raw material procurement system

7.About PCB technology

8.About PCB customization services

9.How much voltage can PCB products withstand?

10.About PCB production capacity

11.Do PCB products have assembly functions?

12.How is the circuit layout of PCB products designed?

13.Is this PCB product single-sided or double-sided?

14.Do PCB products have radiation anti-interference capabilities?

15.About PCB overseas warehouse

16.About PCB origin

17.About PCB production management system

18.Does PCB have special flame retardant treatment?

19.About the scale of PCB factory

1.About PCB warranty

The PCB warranty provides assurance for customers that their purchased circuit boards are free from defects and will function as intended within a specified time frame. This warranty ensures that customers receive high-quality products and can have peace of mind when using them for their electronic applications. It typically covers repair or replacement of faulty boards, offering protection and support to customers, thereby building trust and confidence in the manufacturer's products.

2.About PCB inventory

PCB inventory, or printed circuit board inventory, refers to the collection of all available PCBs (printed circuit boards) in stock for a particular company or organization. These PCBs are crucial components in the production of electronic devices and serve as the foundation for the electrical connections between various components. Maintaining an efficient and well-managed PCB inventory is essential for companies to meet the demand for their products, reduce production costs, and stay competitive in the market. Regular inventory checks, tracking of usage, and proper storage and handling of PCBs are key factors in managing a successful PCB inventory.

3.About PCB patent

PCB patent is a form of intellectual property protection that grants inventors and companies the exclusive right to produce and sell printed circuit boards (PCBs) with unique designs, functions, or processes. It serves as a means to encourage innovation and reward originality in the field of electronic circuitry and technology. PCB patents can cover a wide range of aspects, such as layout designs, fabrication methods, and manufacturing processes. However, in order to obtain a PCB patent, the design or process must meet specific criteria, including being novel, non-obvious, and useful. This type of patent is essential for companies and individuals in the electronics industry to protect their ideas and prevent others from copying or profiting from their innovations. By securing a PCB patent, inventors and companies can have a competitive advantage in the market and ensure the long-term success of their products.

4.What is the difference between PCB FasTechCircuit vs PCB ECS vs PCB Foxconn

The choice between these manufacturers should be based on your specific project requirements. PCB FasTechCircuit is suitable for rapid prototyping, while PCB ECS and PCB Foxconn are trusted options for high-quality components in computer hardware and various electronics. Your decision should align with the objectives and needs of your project.

5.About PCB production capacity

PCB production capacity refers to the maximum quantity of printed circuit boards (PCBs) that a manufacturer is able to produce within a given timeframe. This not only includes the physical space and equipment available for production, but also considers factors such as production time, manpower, and efficiency. A high production capacity allows for a larger volume of PCBs to be manufactured, meeting the demands of customers and addressing the growing market for electronic devices. Advances in technology and process optimization have continually increased PCB production capacity, allowing for more efficient and cost-effective production processes.

6.About PCB raw material procurement system

The PCB raw material procurement system is a process that involves the acquisition of necessary materials for the production of printed circuit boards. This system is essential in ensuring that the right materials are sourced in a timely and cost-effective manner to meet production demands. It involves sourcing materials from suppliers, negotiating prices, and monitoring inventory levels to maintain an efficient supply chain. A well-managed PCB raw material procurement system is crucial for maintaining the quality and efficiency of PCB production.

7.About PCB technology

PCB technology, also known as Printed Circuit Board technology, is a fundamental aspect of modern electronics. It involves designing and manufacturing electronic circuits and interconnecting components using conductive pathways, or traces, on a non-conductive substrate. This technology has revolutionized the electronic industry and has enabled the creation of highly efficient and compact electronic devices, from smartphones to computers and medical equipment. PCB technology continues to advance with the demand for smaller, faster, and more complex electronic devices, making it a crucial component in the development of new technologies.

8.About PCB customization services

PCB customization services involve creating personalized printed circuit boards (PCBs) to meet specific design and functionality requirements. This process includes collaborating with the client to understand their unique needs and customizing the PCB layout, material, and components accordingly. Through PCB customization services, clients can obtain tailor-made solutions for their specific applications, ensuring high-quality and efficient performance. These services are essential for industries such as automotive, aerospace, and telecommunications, where precision and reliability are crucial. With the help of experienced professionals and advanced technologies, PCB customization services offer a cost-effective and timely solution for businesses seeking customized electronic components.

9.How much voltage can PCB products withstand?

The voltage that PCB (Printed Circuit Board) products can withstand varies depending on several factors, including the design, materials, and intended application. PCBs are typically designed to withstand voltages ranging from a few volts to several hundred volts. Low-power electronic devices may have PCBs that can handle lower voltages, while high-power applications, such as power distribution or industrial equipment, may require PCBs designed to withstand higher voltages. Designers consider factors like insulation, spacing, and dielectric strength when determining the voltage tolerance of a PCB to ensure safe and reliable operation within its specified limits.

10.About PCB production capacity

PCB production capacity refers to the amount and ability of a PCB (Printed Circuit Board) manufacturer to produce electronic circuit boards in a given period of time. This includes the company's production capabilities, resources, and efficiency in producing PCBs. The capacity of a PCB manufacturer is an important consideration for businesses and industries that rely on PCBs for their electronic devices, as it directly impacts the supply and turnaround time for these crucial components. With the constant demand for smaller, faster, and more complex electronic devices, there is a growing need for PCB production capacity to keep up with the industry's evolving requirements. Therefore, manufacturers are continuously investing in technology and expanding their production capabilities to meet the demands of the market.

11.Do PCB products have assembly functions?

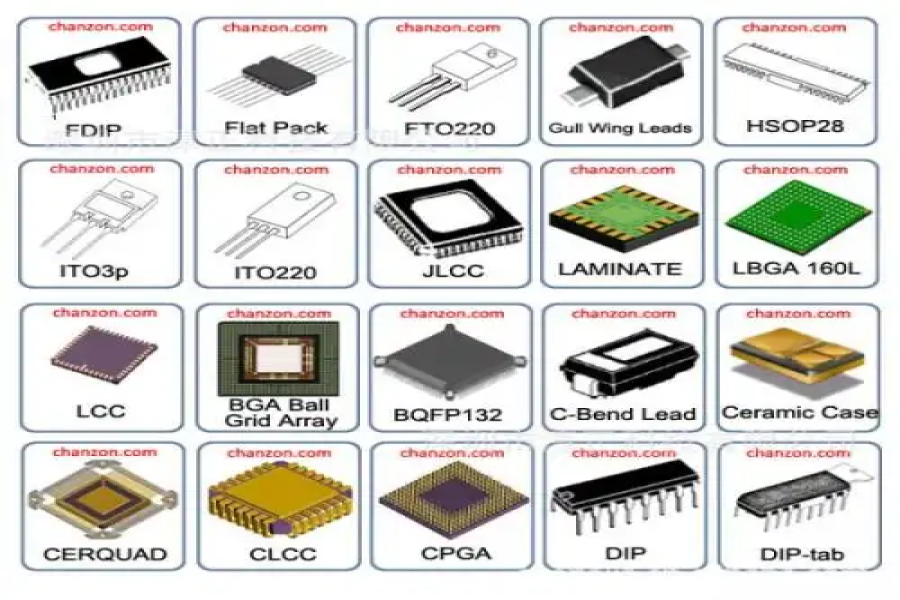

PCB (Printed Circuit Board) products do not inherently have assembly functions themselves but are designed to support the assembly of electronic components. PCBs serve as the foundational platform for mounting and interconnecting various electronic parts, such as resistors, capacitors, integrated circuits, and connectors. The assembly of these components onto the PCB is a critical part of the manufacturing process of electronic devices. The design of the PCB includes features like component footprints, solder pads, and traces to facilitate the precise placement and soldering of components. While PCBs are not responsible for the assembly process, their design is tailored to enable the efficient and reliable assembly of electronic components.

12.How is the circuit layout of PCB products designed?

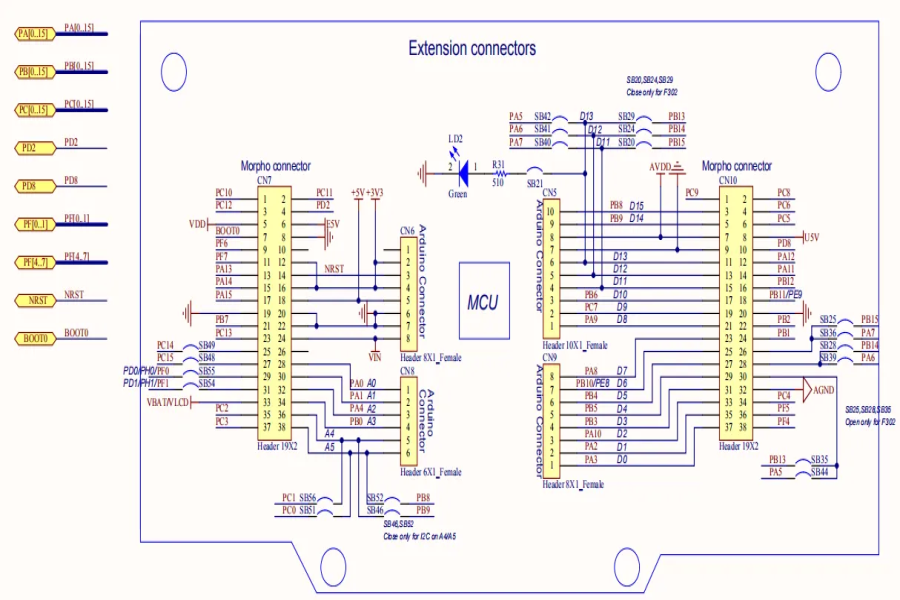

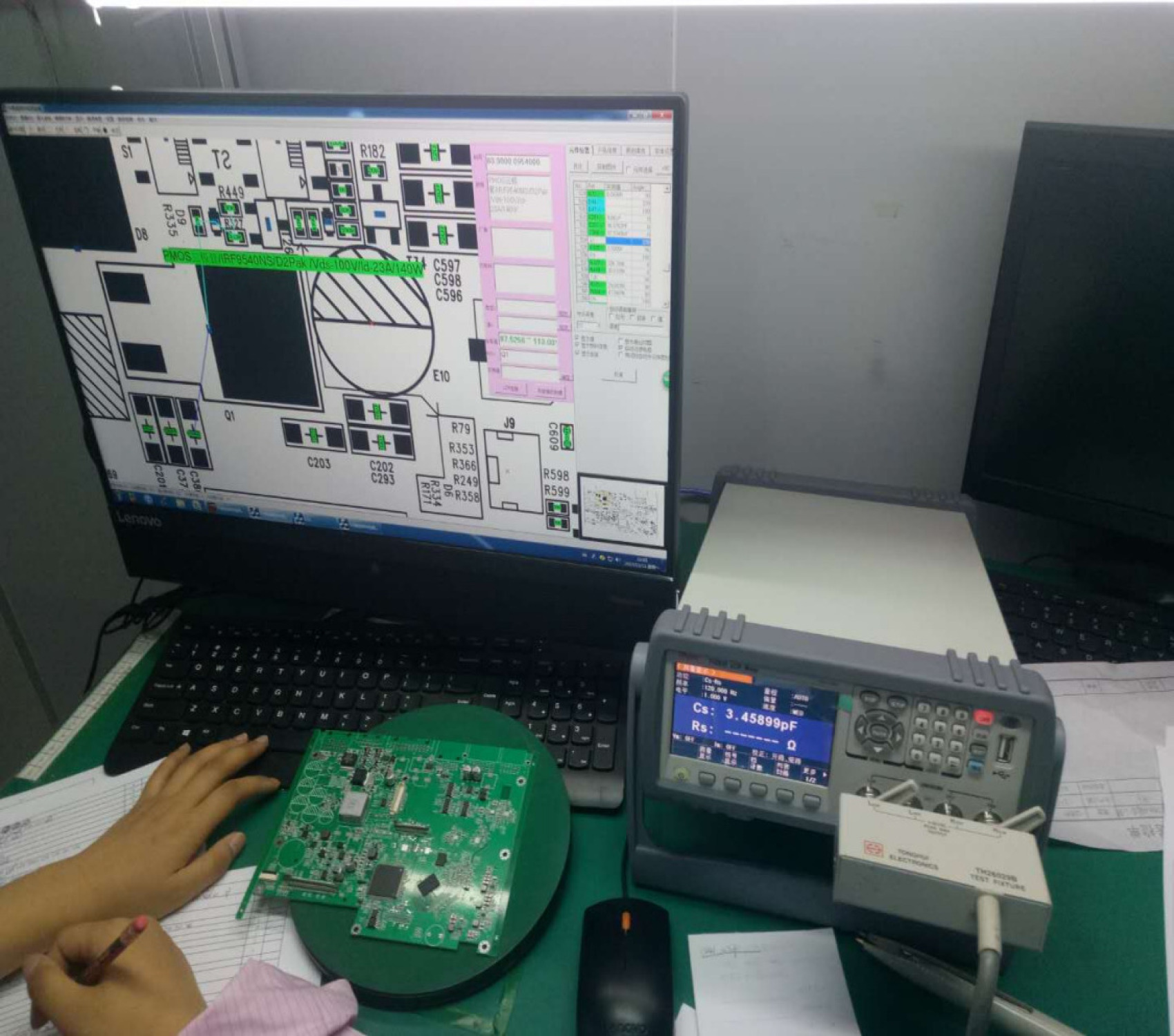

The design of the circuit layout for PCB (Printed Circuit Board) products is a meticulous process that involves the placement and interconnection of electronic components to create a functional circuit. Designers use specialized software to arrange components on the board, optimize signal flow, and ensure efficient use of space. Factors like component placement, signal traces, power distribution, and signal integrity are considered during the design process. The goal is to create an organized and efficient layout that minimizes signal interference, maximizes functionality, and meets the specific requirements of the electronic system. The final circuit layout is a critical aspect of PCB design, ensuring the reliable performance of the electronic device or system.

13.Is this PCB product single-sided or double-sided?

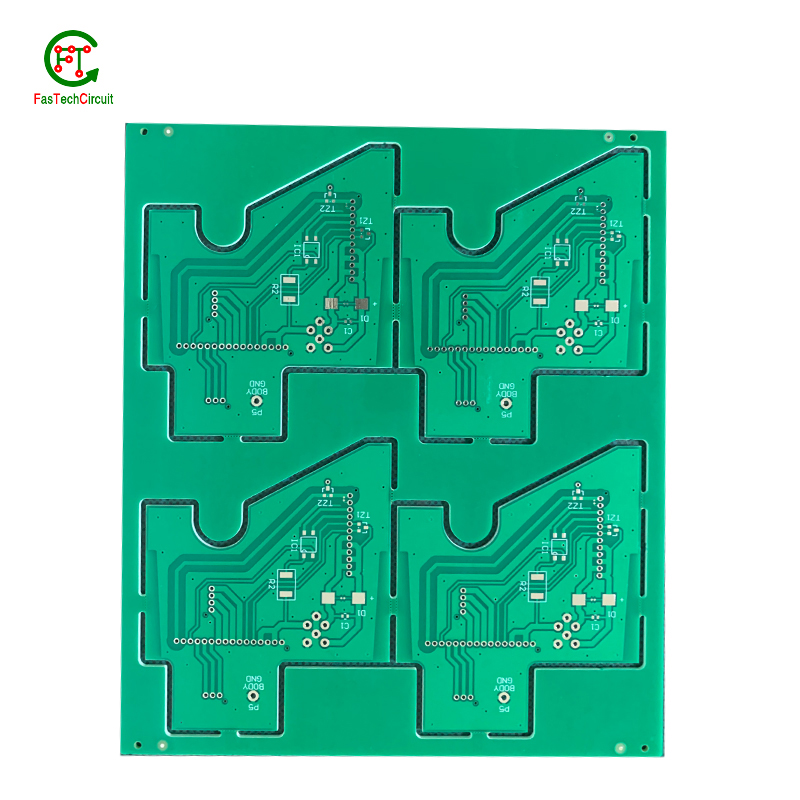

This PCB (Printed Circuit Board) product can be configured as either single-sided or double-sided, depending on the specific application and design requirements. Single-sided PCBs have circuitry on one side of the board, while double-sided PCBs feature electrical connections on both sides. The choice between single-sided and double-sided PCBs is made based on factors like the complexity of the circuit, space constraints, and cost considerations. This flexibility in design allows the PCB product to adapt to a variety of electronic applications, ensuring it can meet the needs of different projects and devices.

14.Do PCB products have radiation anti-interference capabilities?

PCB (Printed Circuit Board) products can be designed with radiation anti-interference capabilities to reduce the risk of electromagnetic interference (EMI) and improve the overall performance of electronic systems. Various techniques are employed to minimize EMI, including proper grounding, signal routing, shielding, and the use of filtering components. Additionally, some PCBs may incorporate specialized designs to mitigate radiation and reduce interference with other electronic components. These anti-interference measures are essential in applications where EMI can disrupt signal integrity and affect the functionality of sensitive electronic devices, ensuring that PCB products operate reliably in the presence of electromagnetic radiation.

15.About PCB overseas warehouse

A PCB overseas warehouse is a storage facility strategically located in a different country than the manufacturer's main facility, allowing for easy shipment and delivery of printed circuit boards (PCBs) to international customers. This provides numerous benefits including faster shipping times, reduced shipping costs, and improved customer service. These warehouses serve as a key component in the global supply chain of PCBs, facilitating efficient and timely distribution of products to meet the demands of a global market.

16.About PCB origin

PCB, short for Printed Circuit Board, is one of the essential components in electronic devices. It serves as a foundation and support for electronic components, allowing them to be connected and work together. The origin of PCB can be traced back to the early 20th century when people found a need to create a more efficient and reliable way to connect, mount, and organize electronic components. Over time, with the development of technology and manufacturing processes, PCB has become an integral part of modern electronic devices, making our daily lives more convenient and connected. Today, PCBs are widely used in various industries, from consumer electronics to medical equipment, highlighting their critical role and contribution to the advancement of technology.

17.About PCB production management system

The PCB production management system is an advanced and comprehensive software solution designed to streamline and optimize the production process of printed circuit boards. This system offers a centralized platform for tracking, managing and monitoring all stages of the production cycle, from design and material procurement to assembly and testing. By implementing this system, PCB manufacturers can increase efficiency, reduce errors and boost productivity. It also provides real-time visibility into production progress, inventory levels, and quality control, allowing for better decision-making and quicker response to any issues that may arise. With its user-friendly interface and powerful features, the PCB production management system is a valuable tool for modern production facilities seeking to stay competitive in the ever-evolving electronics industry.

18.Does PCB have special flame retardant treatment?

PCB (Printed Circuit Board) products can undergo special flame retardant treatments to enhance their fire resistance and safety characteristics. These treatments typically involve applying flame-retardant materials or coatings to the PCB to reduce the risk of combustion and the spread of fire. Flame retardant PCBs are commonly used in applications where safety is a critical concern, such as in automotive electronics, aerospace, and industrial equipment. The flame retardant treatment is designed to meet specific safety standards and regulations, ensuring that PCBs can withstand exposure to high temperatures and flames without contributing to a fire hazard. The flame retardant treatment is an important feature for applications where fire safety is paramount.

19.About the scale of PCB factory

A PCB factory, also known as a printed circuit board factory, is a manufacturing facility that specializes in the production of printed circuit boards. These are used in a wide range of electronic devices, from smartphones and laptops to cars and airplanes. These factories vary in scale, with some producing small volumes for niche markets, while others are large operations that mass-produce PCBs for mainstream electronics companies. The scale of a PCB factory can be measured by its annual production output, the number of employees, and the size of its production facility. The larger the scale of a PCB factory, the more advanced and complex its production processes are likely to be, allowing it to produce high-quality boards in large quantities.

RELATED NEWS

pcb board manufacturing How To Contact US

PCB from 1 to 30 layers, HDI, Heavy Copper, Rigid-flex board with "pcb board manufacturing One-Stop" service.