Choosing the right materials for PCB manufacturing

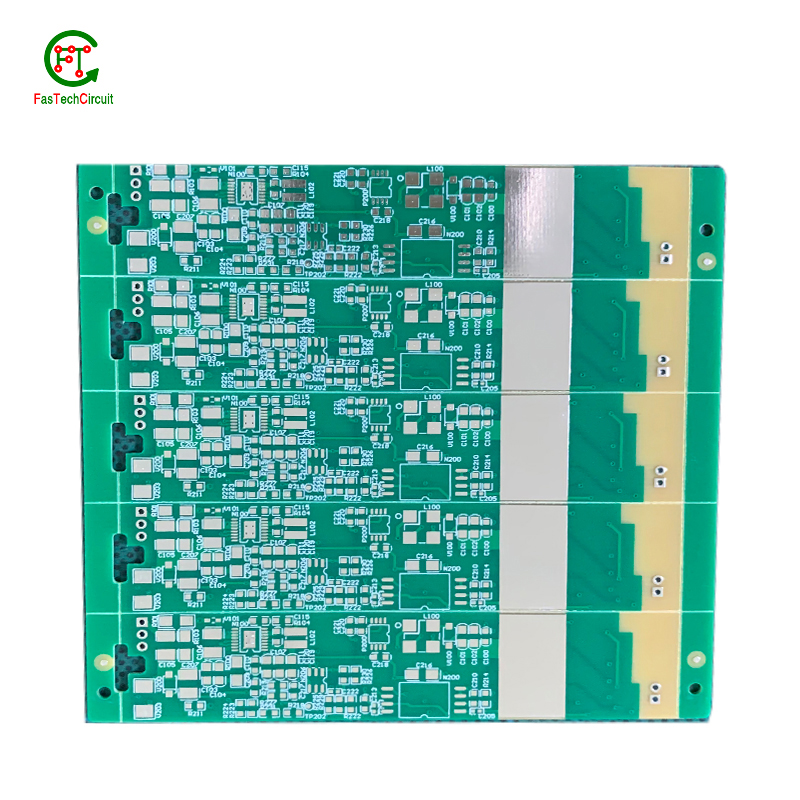

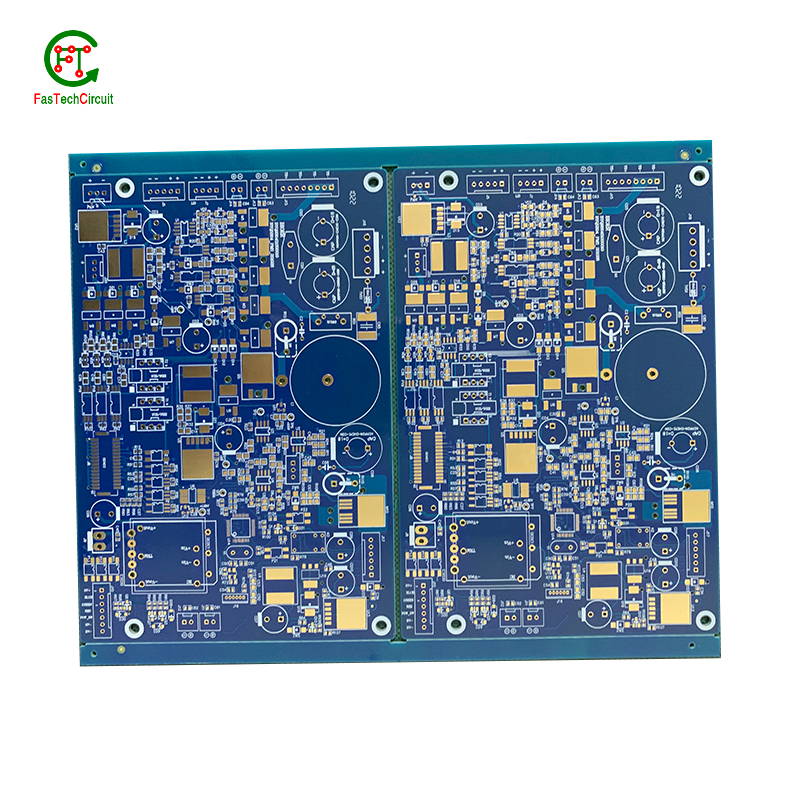

allegro pcb wiring structures are usually divided into single-layer, double-layer and multi-layer structures. Multi-layer structures can effectively reduce the size of circuit boards and improve wiring efficiency, and are often used in the design of high-density and complex circuits.

PCB design trends for the future

By utilizing advanced manufacturing techniques and high-density component placement, our PCB products are able to achieve compact and lightweight designs, saving valuable space in electronic devices.

Our PCB products incorporate advanced thermal management techniques and materials, ensuring efficient dissipation of heat and preventing overheating, which can lead to reduced performance or device failure.

PCB--An Ultimate FAQ Guide.

2.What is the operating temperature of PCB?

3.About PCB origin

4.About PCB origin

5.About PCB production equipment

6.What is the price of PCB products?

7.About PCB production skills training

8.Does PCB have fire protection function?

9.Is the PCB UL certified?

10.About PCB production skills training

11.About PCB overseas warehouse

12.About PCB payment method

13.How much does the PCB product weigh?

14.About PCB warranty

15.About PCB technology

16.About PCB production capacity

17.What electronic components can this PCB product support?

18.About PCB customization services

19.About PCB customization services

1.Do PCB products have anti-corrosion capabilities?

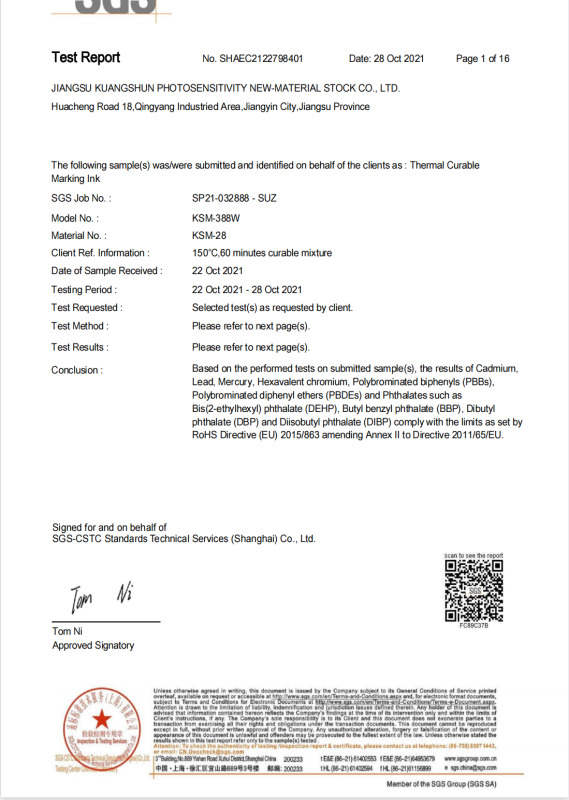

PCB (Printed Circuit Board) products can incorporate anti-corrosion capabilities, primarily through the choice of materials and surface treatments. Corrosion protection is vital, especially in environments with high humidity or exposure to corrosive agents. PCBs can be manufactured with materials that are resistant to corrosion, such as specific laminates and coatings. Surface treatments like ENIG (Electroless Nickel Immersion Gold) or OSP (Organic Solderability Preservatives) also provide a level of corrosion resistance. The extent of anti-corrosion capabilities depends on the design and materials used, ensuring the PCB's longevity and reliability, even in challenging conditions.

2.What is the operating temperature of PCB?

The operating temperature of a PCB (Printed Circuit Board) can vary depending on its design, materials, and intended application. PCBs are typically specified with an operating temperature range that indicates the temperatures at which they can safely and reliably function. Common temperature ranges for standard PCBs in electronic devices are -40°C to 85°C or 0°C to 70°C. However, for specialized applications, such as industrial or automotive electronics, PCBs may have wider operating temperature ranges, extending from -40°C to 125°C or higher. The choice of temperature range depends on the intended application and environmental conditions in which the PCB will be used, ensuring that it can withstand the required temperature extremes without degradation in performance.

3.About PCB origin

PCB, short for Printed Circuit Board, is one of the essential components in electronic devices. It serves as a foundation and support for electronic components, allowing them to be connected and work together. The origin of PCB can be traced back to the early 20th century when people found a need to create a more efficient and reliable way to connect, mount, and organize electronic components. Over time, with the development of technology and manufacturing processes, PCB has become an integral part of modern electronic devices, making our daily lives more convenient and connected. Today, PCBs are widely used in various industries, from consumer electronics to medical equipment, highlighting their critical role and contribution to the advancement of technology.

4.About PCB origin

Printed circuit boards (PCBs) have a rich history, dating back to the early 20th century. They were first developed as a replacement for complicated, hand-wired circuits in radio sets and are now an integral part of modern electronics. PCBs originated through the evolution of various technologies and have undergone significant advancements in design, materials, and production methods over the years. Today, they are widely used in a diverse range of industries, from consumer electronics to aerospace and automotive, making them an essential component in our daily lives.

5.About PCB production equipment

PCB (Printed Circuit Board) production equipment is an essential component in the manufacturing process of electronic devices. It includes various machines and tools used to fabricate, assemble, and test printed circuit boards, which are the foundation of all electronic devices. These equipment typically include drills, routers, plating machines, soldering machines, inspection systems, and more. With the advancement of technology, PCB production equipment has become more sophisticated and efficient, allowing for higher precision and faster production times. As electronic devices continue to evolve and become more intricate, the demand for advanced PCB production equipment will only continue to grow.

6.What is the price of PCB products?

The price of PCB (Printed Circuit Board) products can vary widely depending on several factors, including the PCB's complexity, size, design specifications, quantity, and the choice of materials. Basic single-layer PCBs with standard features are generally more affordable, while complex multi-layer PCBs with specific requirements, such as high-speed signaling or special materials, may be more expensive. Quantity also plays a role, as larger production runs often lead to cost savings per unit. Additionally, custom-designed PCBs tailored to specific applications may be priced higher than off-the-shelf PCBs. To determine the exact price of a PCB product, it is essential to contact PCB manufacturers or suppliers, as pricing can vary based on individual project specifications and market conditions.

7.About PCB production skills training

PCB production skills training is designed to provide individuals with the necessary knowledge and techniques for manufacturing high-quality printed circuit boards (PCBs). Through this training, participants will learn about the different types of PCBs, the process of PCB production, and the latest industry standards and techniques. This training will equip individuals with the skills to handle various equipment and tools used in PCB production, as well as to troubleshoot and resolve any issues that may arise during the process. Ultimately, the goal of this training is to foster a competent and skilled workforce capable of producing reliable and efficient PCBs for a variety of electronic devices.

8.Does PCB have fire protection function?

PCB (Printed Circuit Board) products typically do not have inherent fire protection functions, as they are primarily designed for electrical connections and circuitry. However, the fire resistance of a PCB can be influenced by the materials used in its construction. For example, some PCB materials may have fire-resistant properties and can inhibit the spread of flames when exposed to high temperatures. In applications where fire resistance is crucial, such as aerospace or critical industrial systems, special PCB materials with fire-resistant properties may be chosen to enhance safety. Fire protection, in such cases, is typically a consideration beyond the PCB itself, involving the overall design and materials used in the electronic system.

9.Is the PCB UL certified?

UL (Underwriters Laboratories) certification is typically not associated with individual PCB (Printed Circuit Board) products. Instead, UL certification is generally applied to the end-use electronic equipment or devices in which PCBs are integrated. UL certification ensures that the entire electronic system complies with safety and performance standards. The PCB itself is just one component of the larger system. While PCB manufacturers may use materials and processes that meet UL requirements, the certification process focuses on the overall safety and performance of the complete electronic product, which includes the PCB. Therefore, PCBs are not UL certified on their own, but they contribute to the overall compliance of the electronic equipment in which they are used.

10.About PCB production skills training

PCB production skills training is a crucial aspect of the manufacturing process in the electronics industry. It involves providing individuals with the necessary knowledge and expertise required for the production of high-quality printed circuit boards (PCBs). This training covers various techniques and methodologies, such as design principles, fabrication processes, and assembly methods, to ensure efficient and accurate production. With a strong emphasis on practical learning, this training equips individuals with the skills needed to meet the ever-evolving demands of the industry and deliver top-notch PCBs.

11.About PCB overseas warehouse

A PCB overseas warehouse is a storage facility strategically located in a different country than the manufacturer's main facility, allowing for easy shipment and delivery of printed circuit boards (PCBs) to international customers. This provides numerous benefits including faster shipping times, reduced shipping costs, and improved customer service. These warehouses serve as a key component in the global supply chain of PCBs, facilitating efficient and timely distribution of products to meet the demands of a global market.

12.About PCB payment method

The payment method for PCB (Printed Circuit Board) orders typically involves various options for customers to choose from. Common payment methods include credit card payments, bank transfers, electronic funds transfer (EFT), and online payment platforms like PayPal. Additionally, some PCB manufacturers may offer specific payment terms and options, such as advance payment or net payment within agreed credit terms for established business relationships. The choice of payment method can vary depending on the PCB manufacturer and the agreement between the parties involved in the transaction. It's essential to discuss and confirm the preferred payment method with the PCB manufacturer before placing an order.

13.How much does the PCB product weigh?

The weight of the PCB (Printed Circuit Board) product can vary significantly depending on its size, material, and complexity. Typically, PCBs are lightweight components in electronic devices, with smaller PCBs weighing only a few grams, while larger and more intricate PCBs may weigh several ounces or more. The weight of the PCB is influenced by factors such as the thickness of the board, the number of layers, the presence of additional components, and the type of materials used in its construction. It is essential to consider the weight of the PCB when designing electronic systems to ensure that it meets the specific requirements of the application.

14.About PCB warranty

The PCB warranty provides assurance for customers that their purchased circuit boards are free from defects and will function as intended within a specified time frame. This warranty ensures that customers receive high-quality products and can have peace of mind when using them for their electronic applications. It typically covers repair or replacement of faulty boards, offering protection and support to customers, thereby building trust and confidence in the manufacturer's products.

15.About PCB technology

PCB technology, also known as printed circuit board technology, refers to the process of designing, manufacturing and assembling electronic circuit boards used in various electronic devices. This technology involves the use of specialized software for design, advanced manufacturing techniques such as surface mount technology and through-hole technology, and various testing methods to ensure the functionality and reliability of the PCBs. It plays a crucial role in the development and production of electronic devices, making it one of the fundamental technologies in the modern electronics industry.

16.About PCB production capacity

PCB production capacity refers to the amount and ability of a PCB (Printed Circuit Board) manufacturer to produce electronic circuit boards in a given period of time. This includes the company's production capabilities, resources, and efficiency in producing PCBs. The capacity of a PCB manufacturer is an important consideration for businesses and industries that rely on PCBs for their electronic devices, as it directly impacts the supply and turnaround time for these crucial components. With the constant demand for smaller, faster, and more complex electronic devices, there is a growing need for PCB production capacity to keep up with the industry's evolving requirements. Therefore, manufacturers are continuously investing in technology and expanding their production capabilities to meet the demands of the market.

17.What electronic components can this PCB product support?

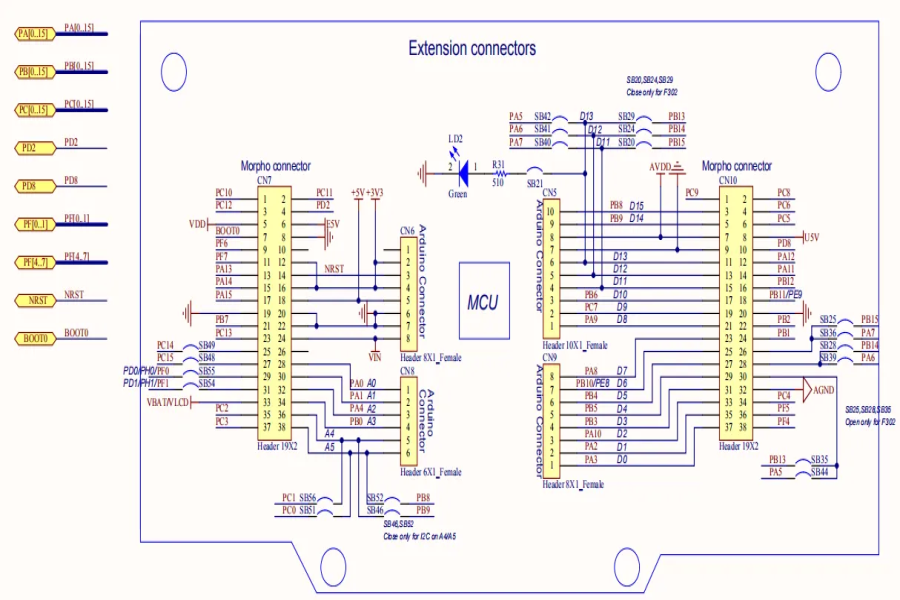

The capabilities of this PCB (Printed Circuit Board) product extend to supporting a wide array of electronic components. These components include but are not limited to integrated circuits (ICs), microcontrollers, resistors, capacitors, diodes, transistors, connectors, and various sensors. The PCB's design and layout are tailored to accommodate these components and establish electrical connections between them. This versatility enables the PCB to be used in a broad spectrum of electronic devices and systems, where it acts as the central hub for component integration and electrical functionality.

18.About PCB customization services

PCB customization services refer to the process of designing and producing customized printed circuit boards according to the specific needs and requirements of a customer. This service allows for the creation of unique and tailored PCBs that can meet the exact specifications of a project or product. Through collaboration with PCB manufacturers, customers can customize various aspects such as size, shape, number of layers, materials, and layout to achieve the desired functionality and performance. These services are essential for industries such as electronics, automotive, aerospace, and medical devices that require specialized PCBs for their products. With PCB customization services, companies can ensure high-quality and efficient production of their electronic devices.

19.About PCB customization services

PCB customization services involve creating personalized printed circuit boards (PCBs) to meet specific design and functionality requirements. This process includes collaborating with the client to understand their unique needs and customizing the PCB layout, material, and components accordingly. Through PCB customization services, clients can obtain tailor-made solutions for their specific applications, ensuring high-quality and efficient performance. These services are essential for industries such as automotive, aerospace, and telecommunications, where precision and reliability are crucial. With the help of experienced professionals and advanced technologies, PCB customization services offer a cost-effective and timely solution for businesses seeking customized electronic components.

RELATED NEWS

pcb board manufacturing How To Contact US

PCB from 1 to 30 layers, HDI, Heavy Copper, Rigid-flex board with "pcb board manufacturing One-Stop" service.