pcb board manufacturing services

Categories: details, about us, all products, PCB, PCBA

pcb board manufacturing services

PCB board is an indispensable part of electronic products, and its quality and performance have an important impact on the reliability and stability of the entire electronic product. Therefore, PCB board manufacturing related services are becoming more and more important. The following is an introduction about FasTechCircuit PCB board manufacturing related services.

1.PCB board design service

PCB board design is the first and most important step in PCB board manufacturing. A good PCB board design can ensure the performance and reliability of electronic products. PCB board design service provides professional technical support and experience, and can design a PCB board that meets the requirements according to the needs of customers.

2. PCB board production service

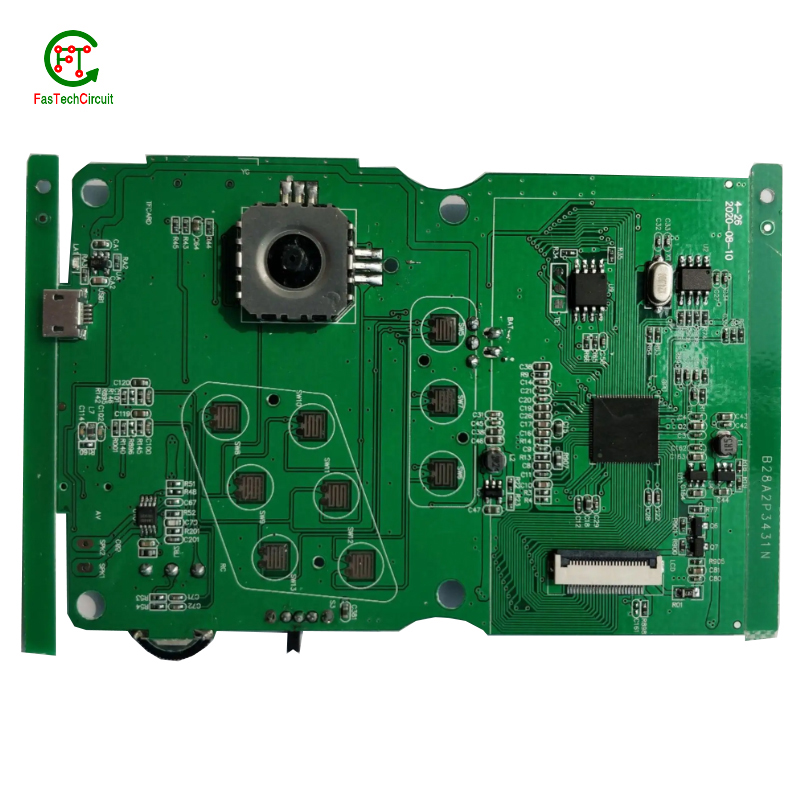

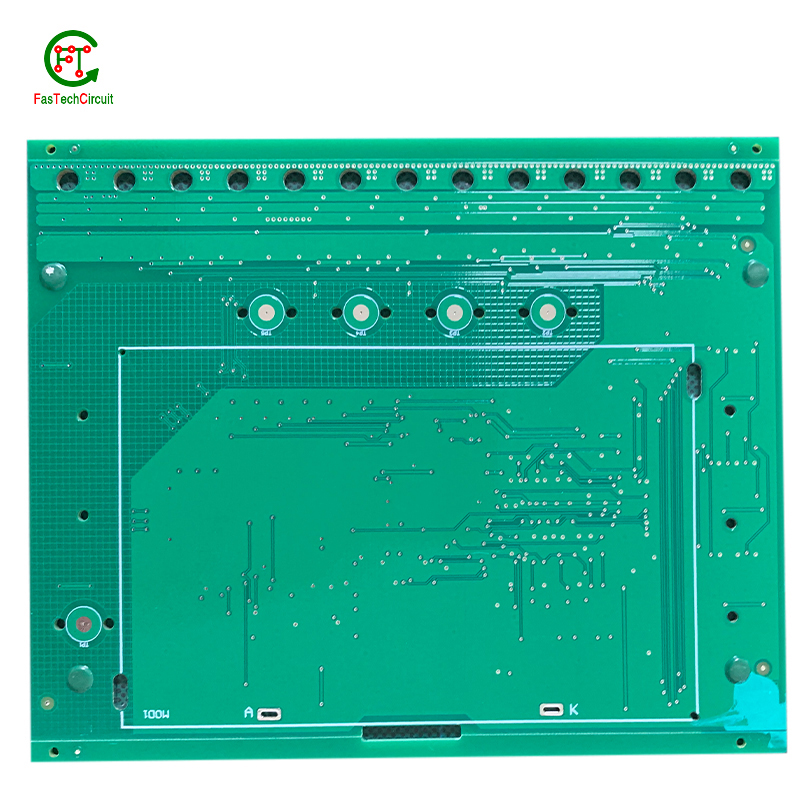

PCB board production is the core link of PCB board manufacturing, and it is also the most complicated step. PCB board production service provides a full range of PCB board production solutions, including raw material procurement, printed circuit board production, surface treatment, perforation, patch, testing and other links. These services can ensure the quality and performance of PCB boards.

3.PCB board assembly service

PCB board assembly is the process of combining PCB boards with electronic components, and it is also the last step in PCB board manufacturing. PCB board assembly service provides professional technology and equipment to ensure the perfect combination of electronic components and PCB boards. These services include SMT, hand soldering, wave soldering, and surface mount, among others.

4.PCB board testing service

PCB board testing is a key link to ensure the quality and performance of PCB boards. PCB board testing service can carry out various tests according to customer requirements, including electrical testing, visual inspection, circuit testing, environmental testing, etc. These tests can ensure the reliability and stability of the PCB board.

In conclusion, PCB board manufacturing related services are an integral part of electronics manufacturing. These services can ensure the quality and performance of PCB boards, thereby improving the reliability and stability of the entire electronic product. When you choose FasTechCircuit PCB board manufacturing related services, we have industry-leading production experience, technology and equipment to ensure the quality and reliability of the final product.

Advantages of pcb board manufacturing technology

PCB board (Printed Circuit Board) is an important part of electronic products, and its quality and performance have an important impact on the reliability and stability of the entire electronic product. With the continuous development of science and technology, PCB board manufacturing technology is also constantly innovating and improving. Below are the advantages of FasTechCircuit PCB board manufacturing technology.

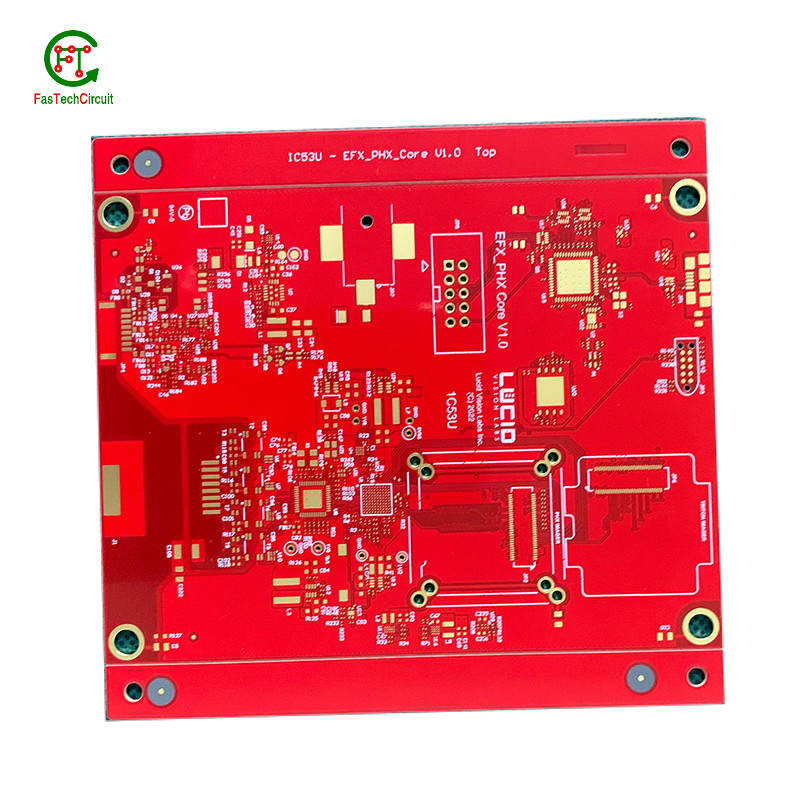

1. High precision and high density

With the continuous development of integrated circuits, PCB board manufacturing technology is also constantly improving. The current PCB board manufacturing technology can produce high-precision and high-density PCB boards, which can be used in small electronic devices. These high-precision and high-density PCB boards can achieve higher performance and lower power consumption.

2. Multilayer board manufacturing technology

The current PCB board manufacturing technology can produce multi-layer boards, which can realize more functions on the same PCB board. These multilayer boards can reduce the volume of electronic products and increase power density, resulting in higher performance and lower power consumption.

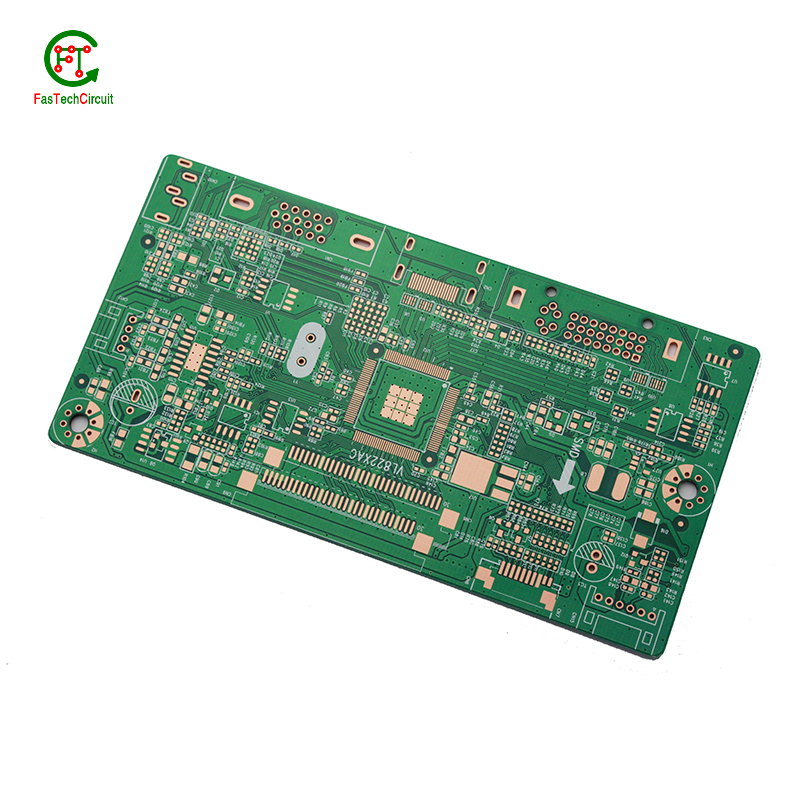

3. Refined manufacturing technology

PCB board manufacturing technology is also developing in a more refined direction. The current PCB board manufacturing technology can produce very fine circuits, which can realize more complex functions in electronic products. These refined circuits can improve the reliability and stability of electronic products.

4. Environmental protection and energy saving

The current PCB board manufacturing technology also pays great attention to environmental protection and energy saving. Modern PCB board manufacturing technology uses many environmentally friendly materials and processes, which can reduce environmental pollution. At the same time, modern PCB board manufacturing technology can also achieve energy saving and reduce energy consumption, thus contributing to environmental protection.

FasTechCircuit has the industry's top technical talents and manufacturing experience, and has partners all over the world. The advantages of PCB board manufacturing technology include high precision and high density, multilayer board manufacturing technology, fine manufacturing technology, environmental protection and energy saving. These advantages can improve the performance and reliability of PCB boards, resulting in better electronic product performance and lower power consumption. With the continuous development of science and technology, PCB board manufacturing technology will continue to innovate and progress, providing better support and guarantee for the development and application of electronic products.

PCB board manufacturing production equipment

PCB board (Printed Circuit Board) is an indispensable part of electronic products. With the continuous development of electronic products, PCB board manufacturing equipment is also constantly innovating and improving. The following is an introduction about FasTechCircuit PCB board manufacturing production equipment.

1. Printed circuit board production equipment

Printed circuit board manufacturing equipment is one of the most basic equipment in PCB board manufacturing. These equipment include copper plate cutting machines, drilling machines, general lathes and punching machines, etc. These devices can cut, process and stamp raw materials into the shape and size of PCB boards.

2. Surface treatment equipment

The surface treatment equipment is the equipment for treating the surface of the PCB board. These equipment include chemical copper plating machine, chemical gold plating machine, spraying machine, etc. These devices can clean, copper-plate, gold-plate, etc. the surface of the PCB, thereby improving the quality and performance of the PCB.

3. Piercing equipment

The punching device is a device that drills holes in the PCB board. These devices include CNC drilling machines, automatic piercing machines, etc. These devices can automatically drill holes according to the design requirements of PCB boards, so as to realize the production of PCB boards.

4. SMT equipment

SMT equipment is a device that attaches electronic components to PCB boards. These devices include placement machines, automatic placement machines, etc. These devices can automatically attach electronic components to the PCB board, thereby realizing the assembly of the PCB board.

5. Test equipment

Test equipment is equipment for testing the performance and quality of PCB boards. These devices include electrical testers, line testers, and more. These devices can perform various tests on PCB boards to ensure the quality and performance of PCB boards.

PCB board manufacturing production equipment is an integral part of PCB board manufacturing. These devices can realize all aspects of the PCB board, from raw material processing to finished product testing, are inseparable from the support and guarantee of these devices. FasTechCircuit possesses industry-leading equipment and technology to ensure the quality and reliability of the final product each customer requires.

PCB board manufacturing process

FasTechCircuit was established in 2003. In the past 20 years, we have provided PCB and PCBA to more than 4,000 customers from more than 50 countries. At the same time, we have been focusing on related manufacturing processes to ensure that every customer's needs are met. The PCB below Detailed introduction of the board manufacturing process:

1. Design

The manufacturing process of PCB boards begins with design. In the design stage, engineers will draw the layout and circuit diagram of the PCB board according to the requirements. Design software can help engineers with these tasks and generate documentation for the PCB board.

2. Printing

The first step in PCB board manufacturing is to print the layout and circuit diagram of the PCB board on the copper-covered substrate. This process uses photosensitive materials and a UV exposer. The layout and circuit diagram of the PCB board are printed on the copper-covered substrate to form the prototype of the PCB board.

3. Corrosion

After printing is complete, the unwanted parts need to be stripped from the copper. This process uses chemicals. Chemicals can corrode away unwanted parts that form the circuit of the PCB board.

4. Drilling

During the manufacturing process of the PCB board, it is necessary to drill the corroded circuit. This process uses a drilling machine. The drilling machine can drill holes according to the design requirements of the PCB board to form the holes of the PCB board.

5. Surface treatment

Surface treatment is the process of treating the surface of the PCB board. This process can help the PCB board to better connect electronic components. Surface treatment includes electroless copper plating and electroless gold plating.

6. SMD

In the last step of PCB board manufacturing, electronic components need to be attached to the PCB board. This process uses a pick and place machine. The placement machine can automatically attach electronic components to the PCB.

7. Test

After the PCB board is manufactured, it needs to be tested. Testing can help to check the quality and performance of PCB boards. Testing can be performed using equipment such as electrical testers and line testers.

Summary: FasTechCircuit PCB board manufacturing process includes design, printing, etching, drilling, surface treatment, placement and testing. These steps can be accomplished using a variety of equipment and tools. During the PCB board manufacturing process, attention needs to be paid to the quality and accuracy of each step to ensure the quality and performance of the final product.

pcb board manufacturing How To Contact US

PCB from 1 to 30 layers, HDI, Heavy Copper, Rigid-flex board with "pcb board manufacturing One-Stop" service.