Printed Circuit Board Assembly Requirements

Categories: pcb board manufacturing,PCB assembly

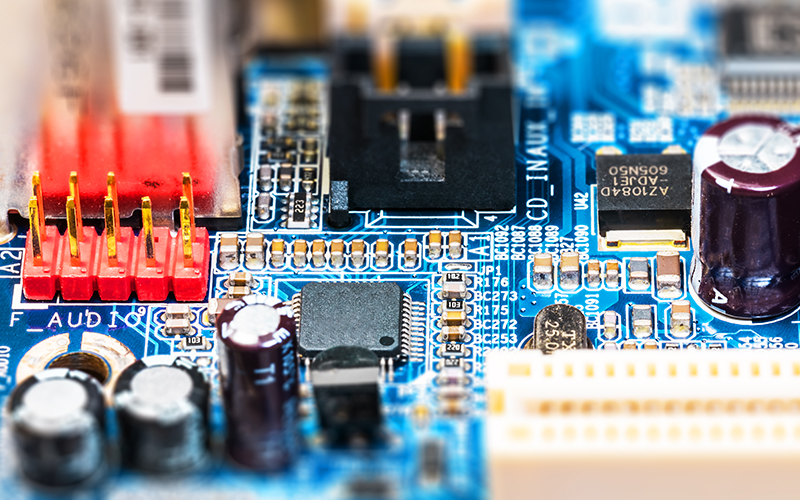

1. Layout of circuit board components: All components on the printed circuit board must be accurately placed on the fixed board and soldered correctly in accordance with the sequence and structure.

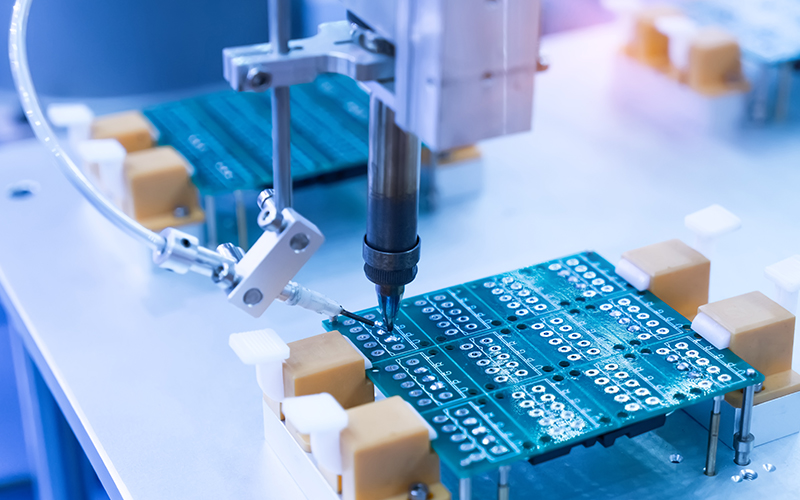

2. Printed circuit board solder joint quality: All solder joints on the circuit board must be clean and tidy, and the reliability of the solder joints must be monitored intelligently, without defects such as voids, bridges, and cold solder joints.

3. Positioning of circuit board components: All production circuit board components must be correctly positioned to avoid various errors, accurate placement and precise positioning to ensure the normal operation of the circuit board.

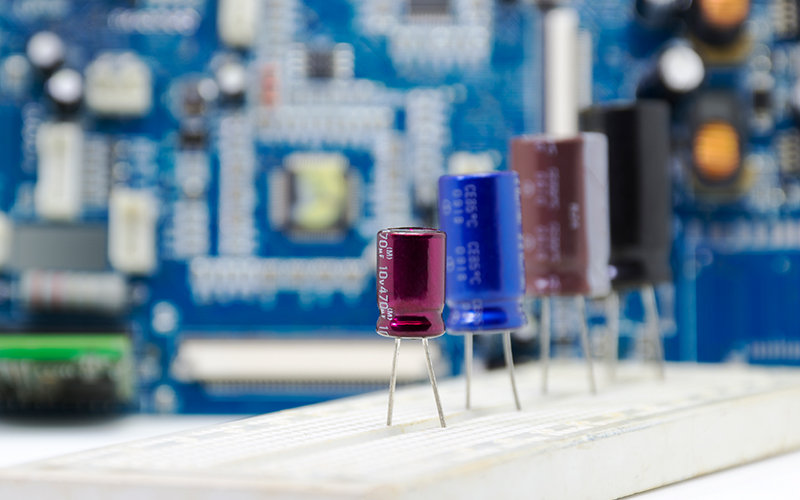

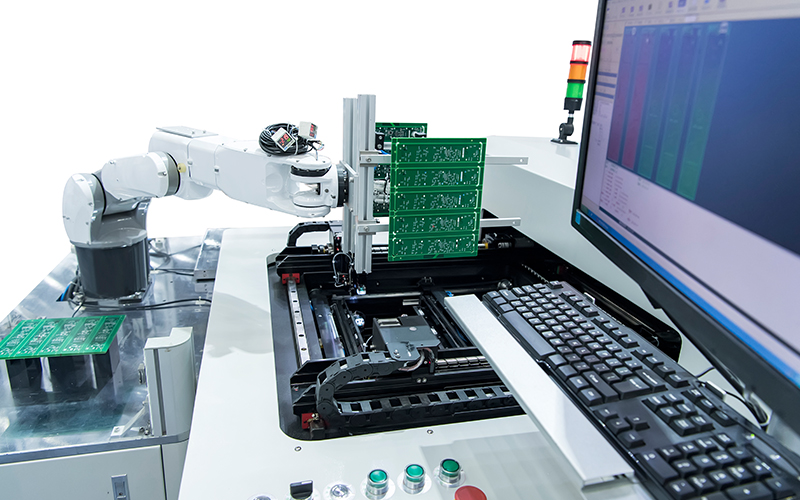

4. Safety performance electrical test: printed circuit boards must undergo strict and correct electrical operation tests to ensure the reliability of circuit board performance

5. Circuit board solder mask: All exposed copper on the circuit board must be covered with a protective coating to prevent oxidation and other damage to the circuit board and all components on the circuit board.

6. Circuit board cleaning: The circuit board must be cleaned of any flux residues attached to the board before completing various performance tests and packaging.

pcb board manufacturing How To Contact US

PCB from 1 to 30 layers, HDI, Heavy Copper, Rigid-flex board with "pcb board manufacturing One-Stop" service.