Inside the World of Cutting-Edge PCB Assembly Manufacturers

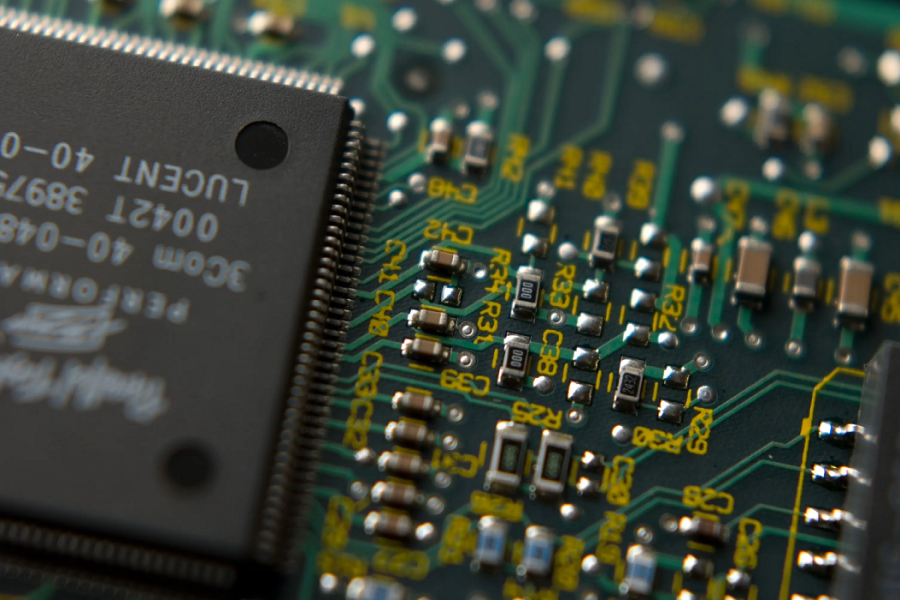

In the ever-evolving landscape of electronics, Printed Circuit Boards (PCBs) serve as the backbone of modern technology. They are the intricate networks that power our devices, from smartphones to medical equipment. Behind the scenes of these small, unassuming boards lies a critical process that ensures their functionality: PCB assembly. PCB assembly manufacturers play a pivotal role in bringing innovation to life by meticulously piecing together the components that power our digital world.

Hot Tags: About FasTechCircuit ,More PCB products

The Essence of PCB Assembly

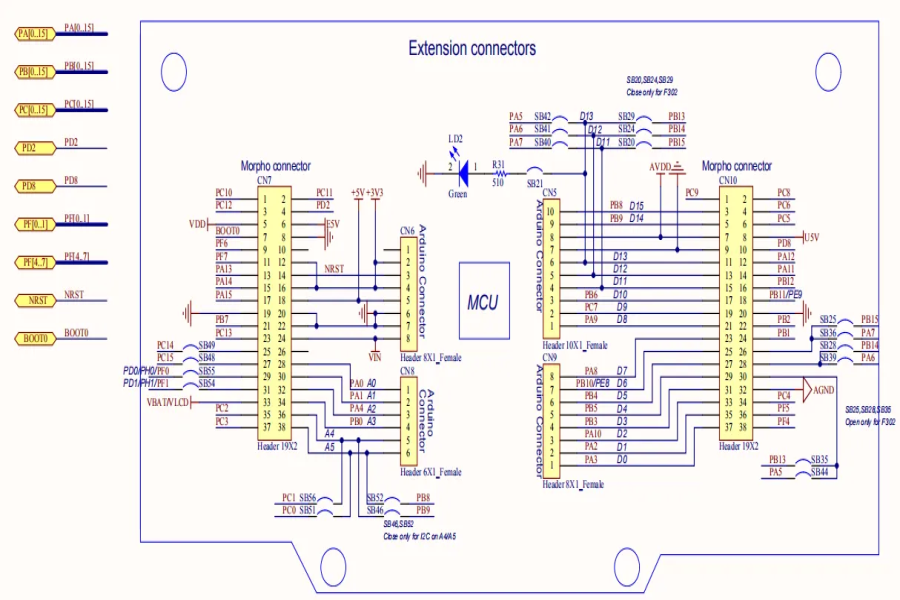

PCB assembly is the process of integrating electronic components onto a printed circuit board. This intricate task requires precision, technical expertise, and a comprehensive understanding of electronics. PCB assembly transforms a bare PCB into a functional device, making it the heart of countless electronic systems.

Technological Advancements and Innovation

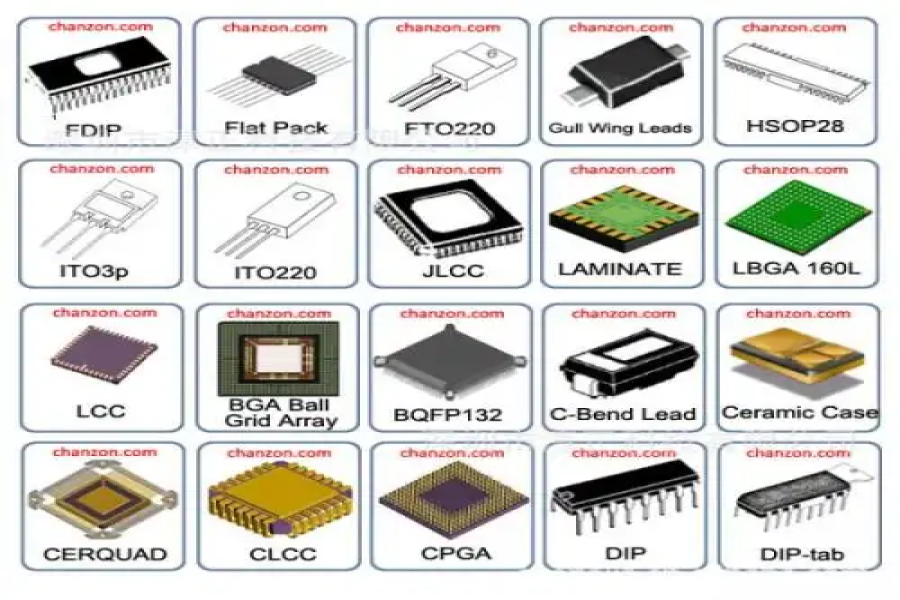

Miniaturization: As consumer demands for smaller and more powerful devices continue to grow, PCB assembly manufacturers have risen to the challenge. They have mastered the art of placing increasingly tiny components onto boards, resulting in compact yet powerful devices.

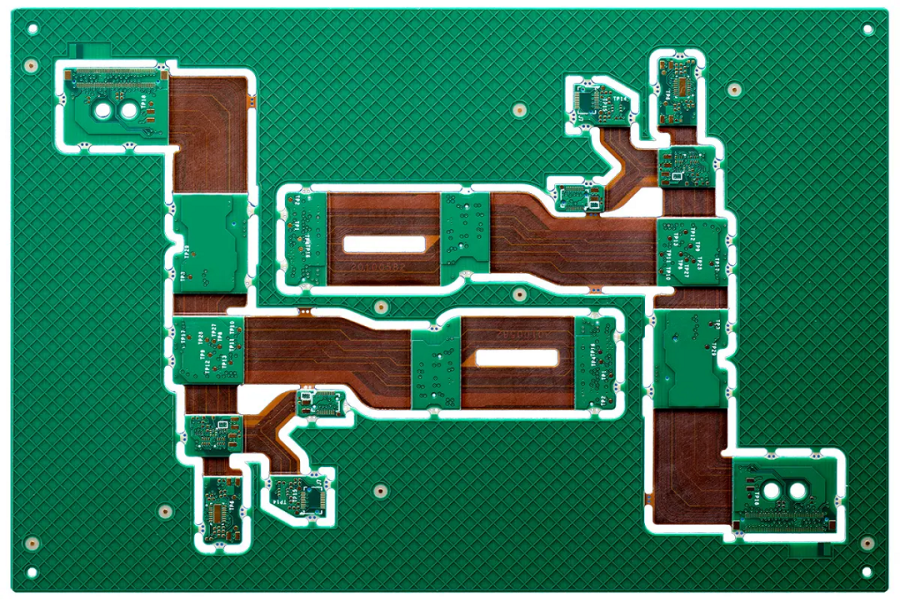

High Density Interconnects (HDI): The demand for increased functionality in smaller devices has led to the rise of HDI technology. PCB assembly manufacturers have embraced HDI techniques to achieve higher circuit density, improved signal integrity, and enhanced performance.

Advanced Materials: The continuous pursuit of performance improvement has driven the adoption of advanced materials in PCB assembly. Manufacturers are using innovative substrates and laminates to achieve higher thermal stability, reduced signal loss, and increased reliability.

Customization and Flexibility

PCB assembly manufacturers understand that innovation often requires customization. They excel at offering tailored solutions to meet the unique needs of various industries, whether it's automotive, aerospace, healthcare, or consumer electronics. This flexibility allows designers to push the boundaries of creativity and engineering, resulting in products that are not just functional, but revolutionary.

Quality Assurance and Reliability

The reliability of electronic devices hinges on the quality of PCB assembly. Manufacturers implement stringent quality control processes to ensure that each component is correctly placed, soldered, and tested. This commitment to quality extends the lifespan of devices, minimizes failure rates, and safeguards end-users' experiences.

Sustainability and Eco-Friendly Practices

As the world places greater emphasis on environmental sustainability, PCB assembly manufacturers are stepping up to adopt eco-friendly practices. From using lead-free soldering techniques to optimizing energy consumption in production facilities, the industry is aligning itself with global sustainability goals.

Globalization and Supply Chain Management

PCB assembly is a global endeavor, with manufacturers collaborating across borders to ensure the smooth flow of components and expertise. Effective supply chain management and global partnerships are vital to ensuring that high-quality components reach assembly lines promptly.

Challenges and Future Outlook

While PCB assembly manufacturers have propelled technological advancement, they also face several challenges:

Rapid Technological Evolution: Keeping up with the rapid pace of technological innovation requires continuous investment in research and development.

Complexity of Components: As devices become more intricate, assembling and soldering miniature components demand precise machinery and skilled operators.

Component Shortages: Global supply chain disruptions can impact the availability of components, necessitating proactive supply chain management.

In the future, PCB assembly manufacturers will be at the forefront of fostering innovation. The integration of Artificial Intelligence (AI) and Internet of Things (IoT) technologies in PCB manufacturing processes holds the promise of further enhancing efficiency, precision, and customization.

PCB assembly manufacturers stand as the unsung heroes of the digital age, breathing life into innovation and technological progress. Their expertise, dedication to quality, and commitment to sustainability lay the foundation for a future where electronics are seamlessly integrated into every facet of our lives. As we venture deeper into the realm of AI, IoT, and beyond, the importance of PCB assembly manufacturers in shaping our connected world will only become more pronounced.

RELATED NEWS

pcb board manufacturing How To Contact US

PCB from 1 to 30 layers, HDI, Heavy Copper, Rigid-flex board with "pcb board manufacturing One-Stop" service.