How to Choose the Right PCB Board Manufacturer for Your Project?

In today's rapidly evolving technological environment, printed circuit boards (PCBs) are an integral part of nearly all electronic equipment. Selecting the correct PCB board manufacturer is critical to the success of your project. With so many manufacturers, each offering a range of services and features, it can be difficult to make the right choice. Below, FasTechCircuit provides a comprehensive guide to help you through the selection process and choose the ideal PCB board manufacturer for your project.

Hot Tags: About FasTechCircuit, product details, PCB assembly

1. Determine Your Requirements:

Before you begin searching for a PCB board manufacturer, it's essential to define your project's specific requirements. Consider factors such as the type of PCB (single-layer, double-layer, or multi-layer), size, complexity, material specifications, quantity, and budget. Clearly defining your requirements will enable you to narrow down your options and focus on manufacturers who can meet your needs.

2. Evaluate Manufacturer's Expertise and Experience:

Look for a PCB board manufacturer with significant expertise and experience in the industry. Consider their track record, years of operation, and their experience in handling projects similar to yours. A manufacturer with a proven track record demonstrates reliability and competence in delivering high-quality PCBs.

3. Quality Standards and Certifications:

Quality is paramount when it comes to PCB manufacturing. Ensure that the manufacturer adheres to recognized quality standards and holds relevant certifications such as ISO 9001 or IPC (Association Connecting Electronics Industries) standards. These certifications indicate that the manufacturer follows rigorous quality control processes, ensuring the production of reliable and durable PCBs.

4. Manufacturing Capabilities:

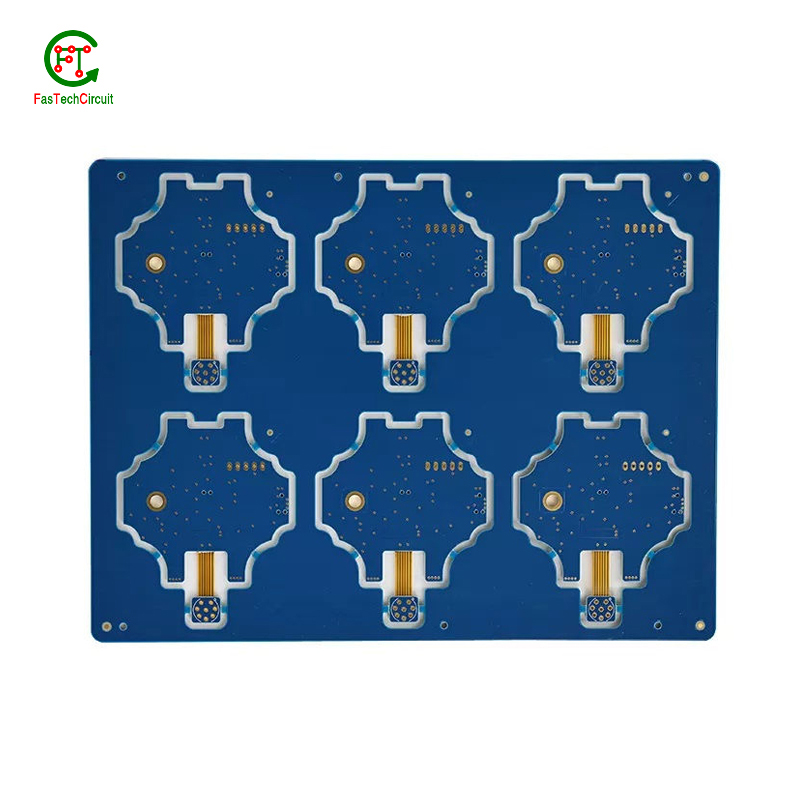

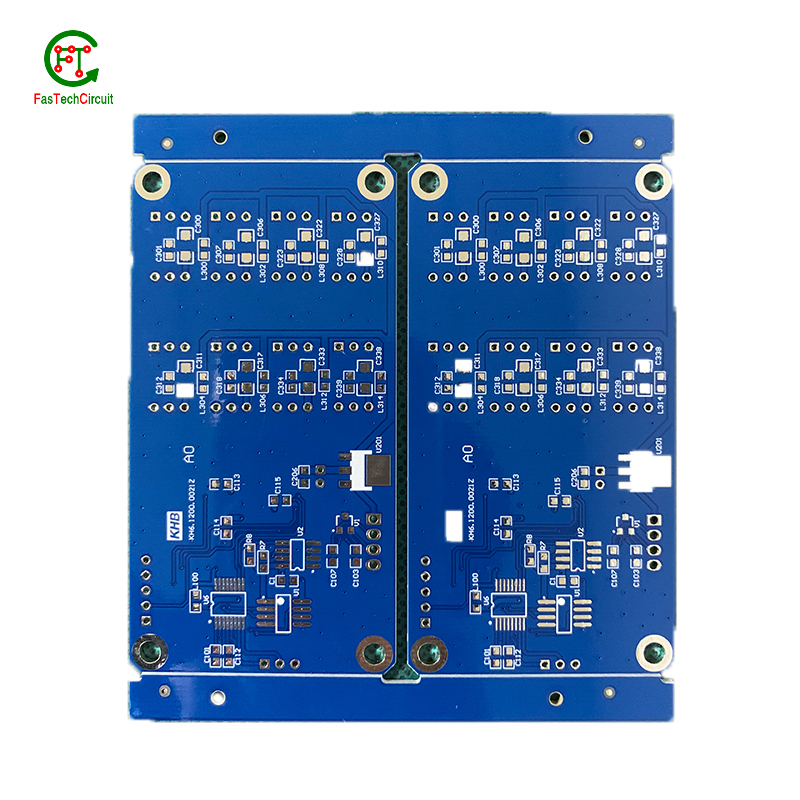

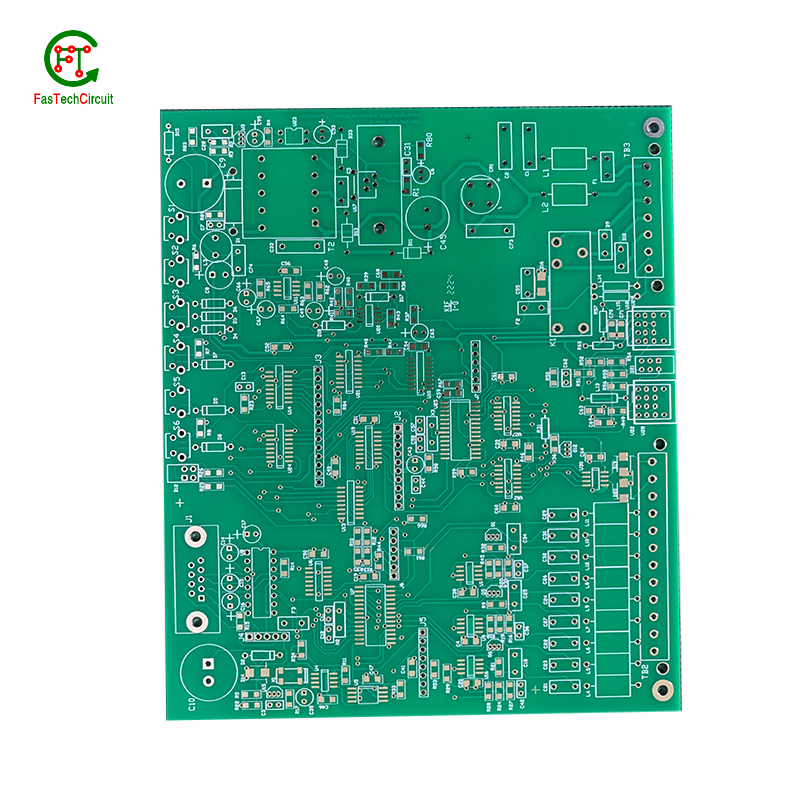

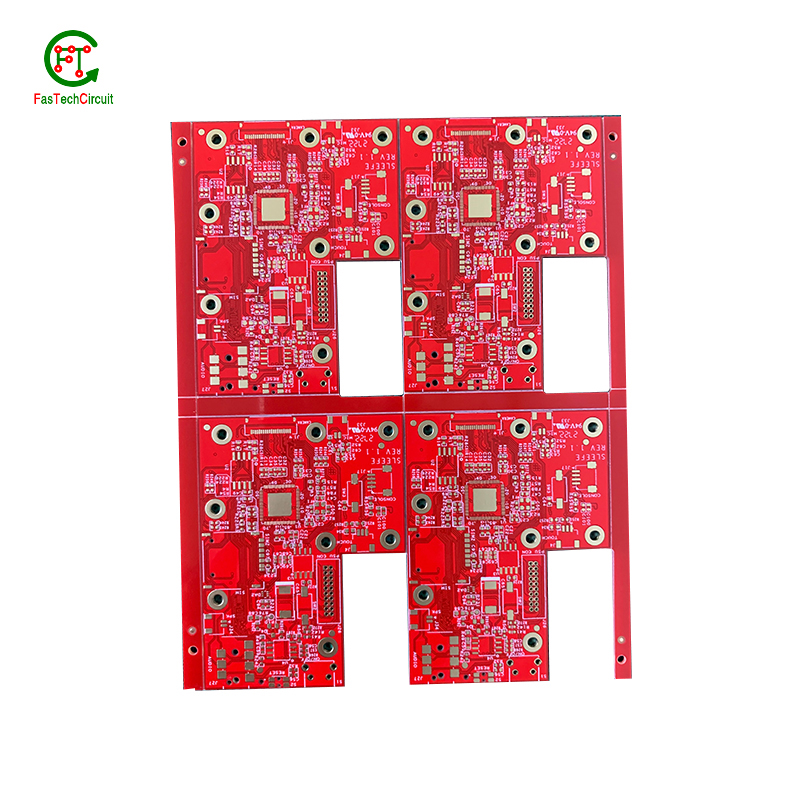

Evaluate the manufacturer's manufacturing capabilities to determine if they align with your project requirements. Consider factors such as the range of PCB materials available, manufacturing processes (surface mount technology, through-hole, or mixed technology), and the ability to handle specialized requirements like flexible or rigid-flex PCBs. Additionally, assess their production capacity and turnaround time to ensure they can meet your project deadlines.

5. Prototyping and Testing Services:

Prototyping and testing play a crucial role in the PCB development process. Choose a manufacturer that offers prototyping services to validate your design before moving to full-scale production. Additionally, inquire about their testing procedures to ensure that the manufactured PCBs undergo rigorous inspection, functional testing, and quality assurance measures.

6. Supply Chain Management:

Efficient supply chain management is essential for timely delivery and cost-effective production. Inquire about the manufacturer's sourcing practices, component procurement, and inventory management capabilities. A reliable manufacturer will have established relationships with reputable suppliers, ensuring a steady supply of high-quality components for your PCBs.

7. Technical Support and Customer Service:

Consider the level of technical support and customer service provided by the manufacturer. A responsive and knowledgeable technical support team can assist you throughout the design, manufacturing, and assembly process, helping to address any queries or issues that may arise. Clear communication channels and prompt customer service contribute to a smooth and successful collaboration.

8. Cost and Pricing Structure:

While cost should not be the sole determining factor, it is crucial to consider the manufacturer's pricing structure and overall affordability. Request detailed quotations that include all relevant costs such as tooling, setup fees, prototype charges, and volume production costs. Beware of manufacturers offering significantly lower prices, as this may compromise quality and reliability.

9. Reviews and References:

Research customer reviews, testimonials, and references to gain insights into the manufacturer's reputation and customer satisfaction level. Reviews can provide valuable information about the manufacturer's reliability, communication, product quality, and adherence to deadlines. Don't hesitate to reach out to existing customers to get firsthand feedback about their experiences with the manufacturer.

10. Intellectual Property Protection:

Protecting intellectual property rights is very important for choosing a PCB board manufacturer. Before working with a manufacturer, make sure they have clear intellectual property protection policies and practices in place to ensure your designs and confidential information are properly protected. This may include signing a non-disclosure or non-compete agreement that restricts manufacturers from using your designs outside of the project. Also, learn about the manufacturer's attitude and history toward intellectual property, including any incidents involving infringement or theft of intellectual property. Choosing a manufacturer with a strong reputation for intellectual property protection will ensure that your project is properly protected from unauthorized use or disclosure.

Selecting the right PCB board manufacturer is crucial as their expertise and capabilities will directly affect the success of your project. An excellent manufacturer will have rich experience and a professional team, able to provide customized solutions according to customer needs. They actively communicate with customers, provide technical support, and ensure on-time delivery of products. At the same time, excellent PCB board manufacturers also focus on quality management and continuous improvement. They adopt strict quality control measures, carry out inspection and testing at each manufacturing stage to ensure that the produced PCB boards meet the standards and specifications.

To sum up, choosing a suitable PCB board manufacturer is the key to ensure the success of the project. By evaluating their expertise, range of services, quality management, and customer support, you can find a partner that can meet your needs and deliver high-quality PCB boards.

RELATED NEWS

pcb board manufacturing How To Contact US

PCB from 1 to 30 layers, HDI, Heavy Copper, Rigid-flex board with "pcb board manufacturing One-Stop" service.