How to optimize power distribution in PCB design

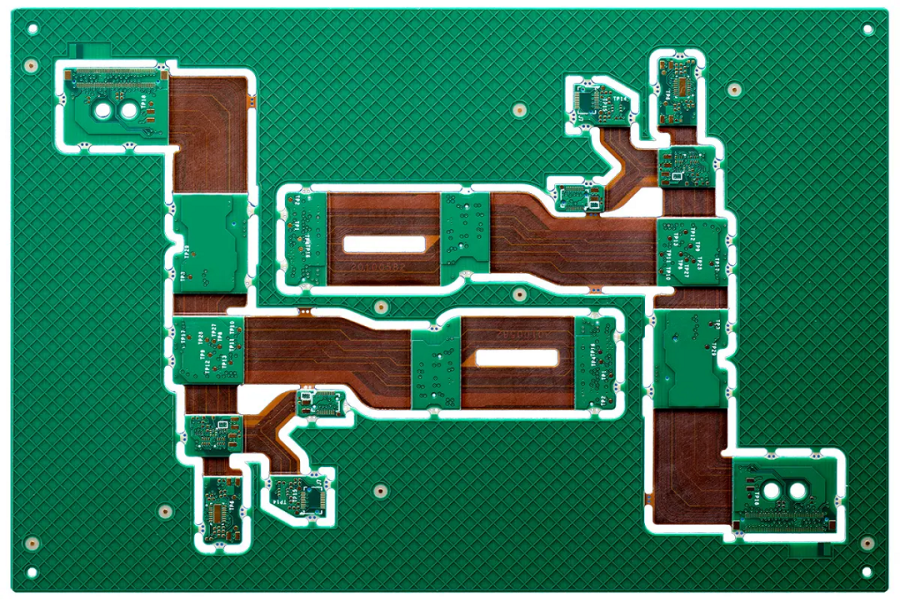

flexible pcb is usually made of fiberglass, plastic and other materials. It has good insulation properties and can effectively avoid short circuits between circuit components.

Demystifying the PCB manufacturing process: from layout to board making

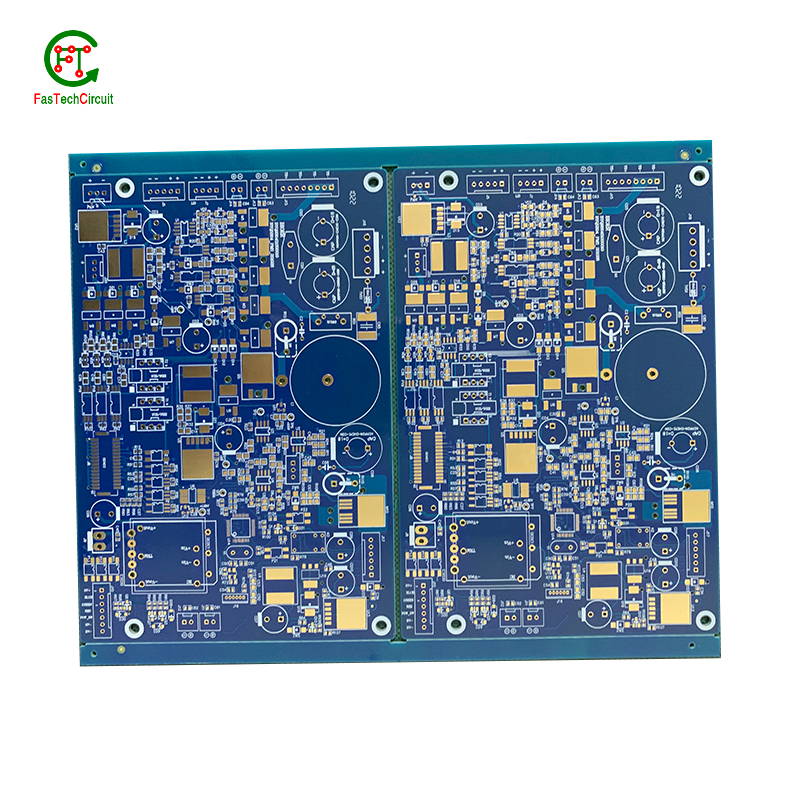

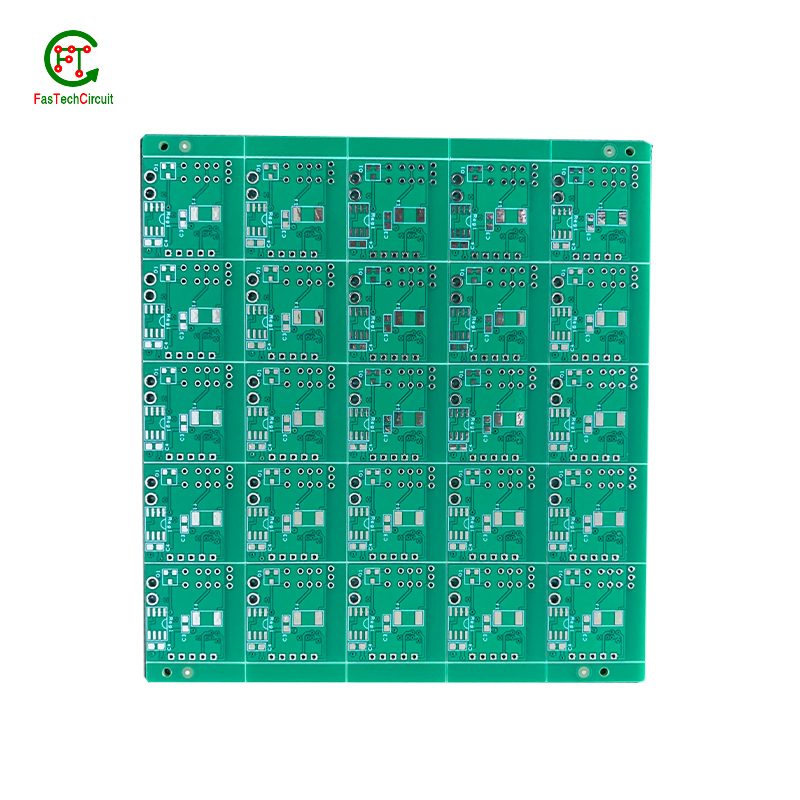

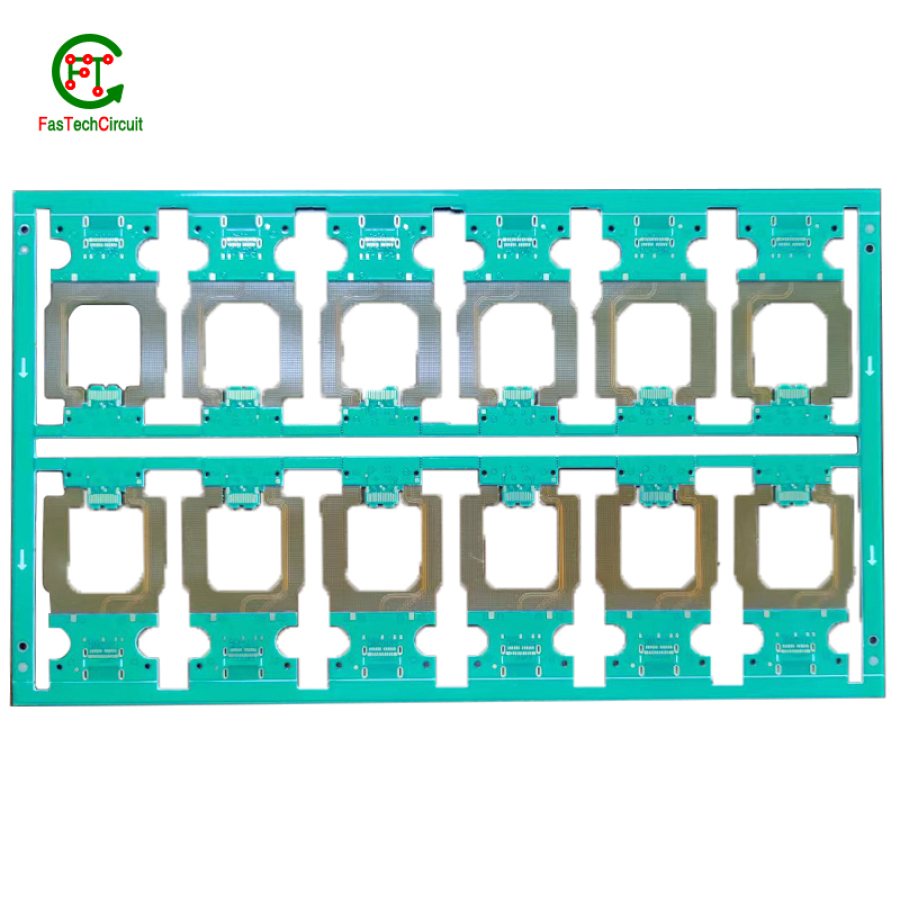

Our PCB products are available in a wide range of multi-layer configurations, allowing for complex circuit designs and enabling greater functionality in electronic devices.

By utilizing advanced manufacturing techniques and high-density component placement, our PCB products are able to achieve compact and lightweight designs, saving valuable space in electronic devices.

PCB--An Ultimate FAQ Guide.

2.How much voltage can PCB products withstand?

3.What is the difference between PCB FasTechCircuit vs PCB ASUS vs PCB MSI

4.About PCB raw materials

5.Does PCB comply with ROHS standards?

6.About PCB inventory

7.About PCB MOQ

8.What is the operating temperature of PCB?

9.Do PCB products have self-healing properties?

10.About the scale of PCB factory

11.What materials are used in this PCB product?

12.Are PCB products waterproof?

13.About PCB raw material procurement system

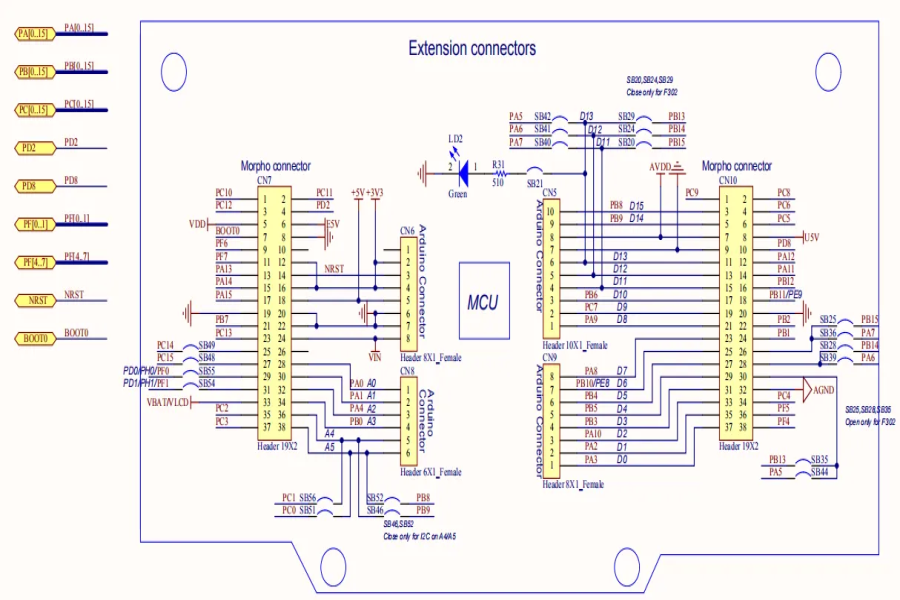

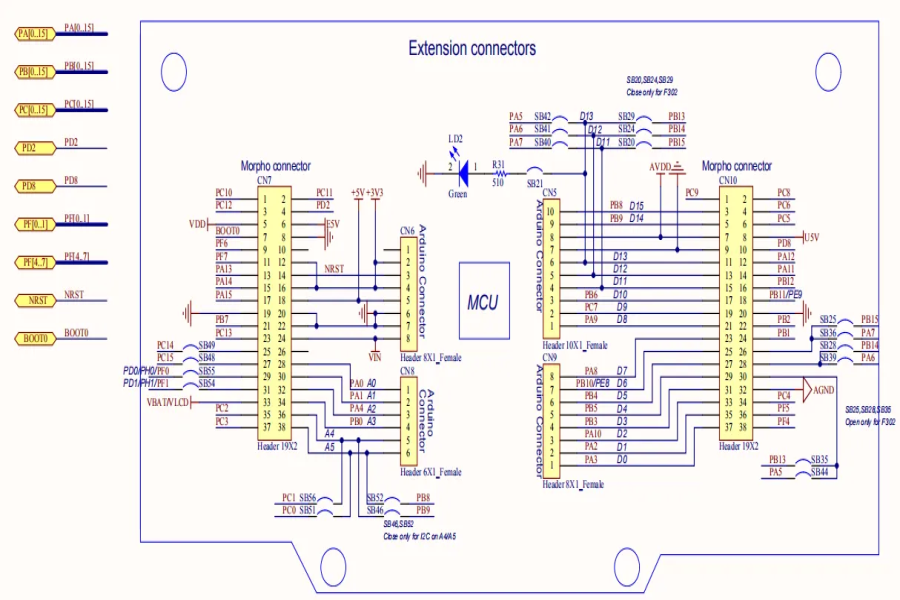

14.What is the difference between PCB FasTechCircuit vs PCB Biostar vs PCB EVGA

15.About PCB overseas warehouse

16.About PCB customization services

17.Does the PCB have special anti-seismic design?

18.About PCB technology

19.What is the thickness of the PCB product?

20.What are the electrical characteristics of PCB?

21.About the development history of PCB factory

22.About PCB warranty

1.Does PCB have special flame retardant treatment?

PCB (Printed Circuit Board) products can undergo special flame retardant treatments to enhance their fire resistance and safety characteristics. These treatments typically involve applying flame-retardant materials or coatings to the PCB to reduce the risk of combustion and the spread of fire. Flame retardant PCBs are commonly used in applications where safety is a critical concern, such as in automotive electronics, aerospace, and industrial equipment. The flame retardant treatment is designed to meet specific safety standards and regulations, ensuring that PCBs can withstand exposure to high temperatures and flames without contributing to a fire hazard. The flame retardant treatment is an important feature for applications where fire safety is paramount.

2.How much voltage can PCB products withstand?

The voltage that PCB (Printed Circuit Board) products can withstand varies depending on several factors, including the design, materials, and intended application. PCBs are typically designed to withstand voltages ranging from a few volts to several hundred volts. Low-power electronic devices may have PCBs that can handle lower voltages, while high-power applications, such as power distribution or industrial equipment, may require PCBs designed to withstand higher voltages. Designers consider factors like insulation, spacing, and dielectric strength when determining the voltage tolerance of a PCB to ensure safe and reliable operation within its specified limits.

3.What is the difference between PCB FasTechCircuit vs PCB ASUS vs PCB MSI

The choice between these manufacturers depends on the specific requirements of your project. PCB FasTechCircuit might be suitable for rapid prototyping, while PCB ASUS and PCB MSI are trusted choices for high-quality components in gaming and consumer electronics. Ultimately, the decision should be based on your project's needs and goals.

4.About PCB raw materials

PCB (Printed Circuit Board) raw materials refer to the base materials used in the manufacturing of electronic circuit boards. These materials typically include copper-clad laminates, solder mask, silkscreen, and various types of coatings and films. The selection of high-quality raw materials is crucial for ensuring the functionality, durability and reliability of PCBs, which are the backbone of electronic devices. Different applications require different types of raw materials, such as high-speed signal transmission, thermal management, and environmental protection. With the constant advancement of technology, the demand for more innovative and sustainable PCB raw materials continues to rise, driving the development of the electronics industry towards a more efficient and eco-friendly future.

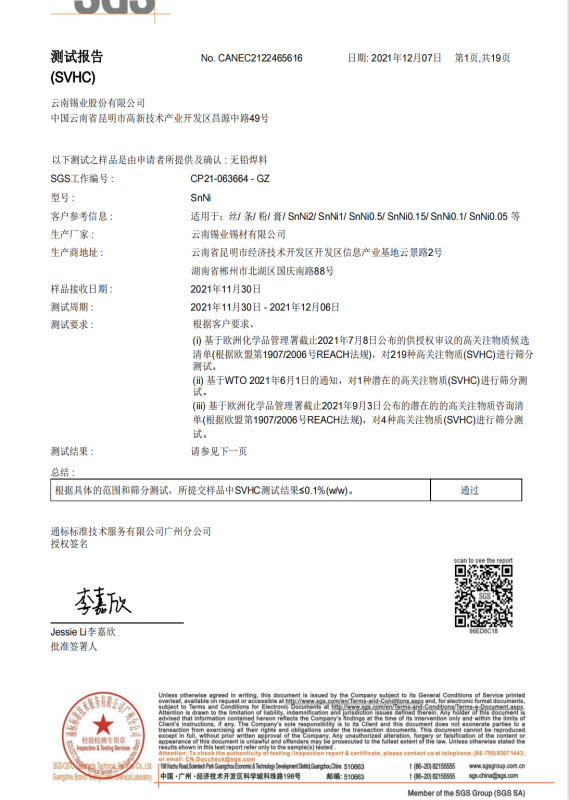

5.Does PCB comply with ROHS standards?

Many PCB (Printed Circuit Board) manufacturers and products aim to comply with RoHS (Restriction of Hazardous Substances) standards. RoHS is a regulation that restricts the use of certain hazardous materials, such as lead, mercury, and cadmium, in electronic and electrical equipment. Compliance with RoHS standards is crucial for environmental and safety reasons, as it helps reduce the use of harmful substances in electronics and their potential impact on health and the environment. However, RoHS compliance can vary between manufacturers and specific PCB products, so it's essential to verify compliance with the relevant regulations and standards for a particular PCB product.

6.About PCB inventory

PCB inventory, or printed circuit board inventory, refers to the collection of all available PCBs (printed circuit boards) in stock for a particular company or organization. These PCBs are crucial components in the production of electronic devices and serve as the foundation for the electrical connections between various components. Maintaining an efficient and well-managed PCB inventory is essential for companies to meet the demand for their products, reduce production costs, and stay competitive in the market. Regular inventory checks, tracking of usage, and proper storage and handling of PCBs are key factors in managing a successful PCB inventory.

7.About PCB MOQ

The minimum order quantity (MOQ) for printed circuit boards (PCBs) refers to the minimum number of boards that must be purchased in a single order. It is typically set by PCB manufacturers to ensure cost effectiveness and efficiency in production. The MOQ may vary depending on factors such as board size, layers, materials, and technology. It is important for companies or individuals to understand the MOQ before placing an order to avoid unnecessary costs and delays in production.

8.What is the operating temperature of PCB?

The operating temperature of a PCB (Printed Circuit Board) can vary depending on its design, materials, and intended application. PCBs are typically specified with an operating temperature range that indicates the temperatures at which they can safely and reliably function. Common temperature ranges for standard PCBs in electronic devices are -40°C to 85°C or 0°C to 70°C. However, for specialized applications, such as industrial or automotive electronics, PCBs may have wider operating temperature ranges, extending from -40°C to 125°C or higher. The choice of temperature range depends on the intended application and environmental conditions in which the PCB will be used, ensuring that it can withstand the required temperature extremes without degradation in performance.

9.Do PCB products have self-healing properties?

PCB (Printed Circuit Board) products do not possess self-healing properties. Self-healing is a property associated with certain materials or components that can repair or regenerate when damaged, such as self-healing polymers. PCBs are typically constructed from rigid materials like fiberglass or epoxy, which do not have self-healing capabilities. Therefore, if a PCB is damaged or experiences a fault, it typically requires manual repair or replacement by a skilled technician or engineer to restore its functionality. PCBs are designed for reliable electrical connections but do not have the ability to self-repair when damaged.

10.About the scale of PCB factory

The scale of a PCB factory refers to its size and production capacity. It may vary greatly depending on the company's resources and operations. Typically, a PCB factory will have a large and well-equipped manufacturing facility, with specialized equipment and machinery to produce circuit boards in large quantities. The factory may also have a sizeable workforce, including engineers, technicians, and workers, who are trained and experienced in PCB production. The scale of the factory also plays an essential role in meeting the demands of clients and keeping up with the rapid advancements in technology. A larger and more advanced PCB factory can provide a wider range of services and offer faster production times, making them more competitive in the market. Overall, the scale of a PCB factory reflects its capabilities and success in meeting the growing demands of the electronics industry.

11.What materials are used in this PCB product?

The PCB (Printed Circuit Board) product utilizes a variety of materials in its construction to ensure efficient and reliable electronic connections. These materials typically include a non-conductive substrate (often made of fiberglass or other materials), a copper layer for electrical conductivity, solder mask for protection, and various components like resistors, capacitors, and integrated circuits. The specific materials and their quality play a crucial role in the performance and durability of the PCB, making it a critical component in electronic devices and systems.

12.Are PCB products waterproof?

PCB (Printed Circuit Board) products are not inherently waterproof, but they can be made water-resistant or waterproof by applying specific protective measures during the design and manufacturing process. Water-resistant PCBs are often coated with conformal coatings or encapsulated in waterproof housings to shield them from moisture and environmental factors. The degree of waterproofing can vary, with some PCBs designed to withstand exposure to water and others being more water-resistant. The level of protection depends on the intended application and the environmental conditions in which the PCB will operate. Waterproofing is crucial for applications where PCBs may be exposed to moisture, such as in outdoor electronics, automotive systems, and marine devices.

13.About PCB raw material procurement system

The PCB raw material procurement system is a process that involves the acquisition of necessary materials for the production of printed circuit boards. This system is essential in ensuring that the right materials are sourced in a timely and cost-effective manner to meet production demands. It involves sourcing materials from suppliers, negotiating prices, and monitoring inventory levels to maintain an efficient supply chain. A well-managed PCB raw material procurement system is crucial for maintaining the quality and efficiency of PCB production.

14.What is the difference between PCB FasTechCircuit vs PCB Biostar vs PCB EVGA

The choice between these manufacturers should be based on your specific project requirements. PCB FasTechCircuit is ideal for fast prototyping, while PCB Biostar and PCB EVGA are trusted options for high-quality components in computer hardware, with EVGA specifically known for its gaming-oriented graphics cards. Your decision should align with the goals and needs of your project.

15.About PCB overseas warehouse

A PCB overseas warehouse is a storage facility strategically located in a different country than the manufacturer's main facility, allowing for easy shipment and delivery of printed circuit boards (PCBs) to international customers. This provides numerous benefits including faster shipping times, reduced shipping costs, and improved customer service. These warehouses serve as a key component in the global supply chain of PCBs, facilitating efficient and timely distribution of products to meet the demands of a global market.

16.About PCB customization services

PCB customization services involve creating personalized printed circuit boards (PCBs) to meet specific design and functionality requirements. This process includes collaborating with the client to understand their unique needs and customizing the PCB layout, material, and components accordingly. Through PCB customization services, clients can obtain tailor-made solutions for their specific applications, ensuring high-quality and efficient performance. These services are essential for industries such as automotive, aerospace, and telecommunications, where precision and reliability are crucial. With the help of experienced professionals and advanced technologies, PCB customization services offer a cost-effective and timely solution for businesses seeking customized electronic components.

17.Does the PCB have special anti-seismic design?

PCB (Printed Circuit Board) products typically do not have special anti-seismic designs as their primary function is to provide electrical connections and support for electronic components. Anti-seismic considerations are generally addressed at the system level in applications like industrial equipment, automotive electronics, or aerospace systems, where the entire system's design may incorporate anti-seismic measures to ensure stability and functionality during mechanical stress or vibrations. While PCBs themselves are not designed for anti-seismic purposes, they are integrated into systems that may have such protection in place to prevent damage or malfunction during seismic events.

18.About PCB technology

PCB technology, also known as Printed Circuit Board technology, is a fundamental aspect of modern electronics. It involves designing and manufacturing electronic circuits and interconnecting components using conductive pathways, or traces, on a non-conductive substrate. This technology has revolutionized the electronic industry and has enabled the creation of highly efficient and compact electronic devices, from smartphones to computers and medical equipment. PCB technology continues to advance with the demand for smaller, faster, and more complex electronic devices, making it a crucial component in the development of new technologies.

19.What is the thickness of the PCB product?

The thickness of a PCB (Printed Circuit Board) product can vary based on its design and intended application. PCBs are available in a range of thicknesses, typically measured in millimeters (mm) or mils (1 mil = 0.001 inches). Standard PCB thicknesses often include 0.8mm, 1.6mm, and 2.0mm, but custom thicknesses can be specified to meet specific requirements. Thicker PCBs provide greater mechanical rigidity and heat dissipation, while thinner ones are suitable for applications with space constraints. The choice of thickness depends on the PCB's function and the design needs of the electronic system it will be a part of.

20.What are the electrical characteristics of PCB?

The electrical characteristics of PCB (Printed Circuit Board) are vital for its performance in electronic systems. These characteristics include impedance, dielectric constant (Dk), crosstalk, signal integrity, capacitance, inductance, voltage and current handling, frequency response, and high-frequency performance. PCBs are designed to maintain controlled impedance, minimize signal interference, and handle specific voltage and current levels, ensuring their reliability and functionality in various electronic applications. The choice of materials and design considerations plays a significant role in achieving the desired electrical characteristics for PCBs.

21.About the development history of PCB factory

The development of PCB factories can be traced back to the early 20th century when the first commercial prototype of a printed circuit board was created. Since then, the demand for PCBs has continuously increased due to the rapid growth of technology and the need for more efficient and compact electronic devices. In the 1950s, industry giants such as IBM and RCA began using PCBs in their electronic products, leading to the mass production of PCBs in the 1960s. The 1970s saw the introduction of computer-aided design and manufacturing technology, making the production of PCBs faster and more cost-effective. In the 1980s, surface mount technology revolutionized PCB production, making it possible to create smaller and more complex boards. The 1990s saw the rise of offshore PCB manufacturing, with China becoming a major player in the industry. Today, PCB factories continue to innovate and evolve, utilizing advanced technology and implementing sustainable practices to meet the growing demands of the electronics industry.

22.About PCB warranty

PCB warranty refers to the guarantee provided by manufacturers for printed circuit boards (PCBs). It ensures that the PCBs are free from defects in materials and workmanship for a specific period of time. This warranty is important as it can protect customers from potential losses caused by product defects and provides assurance of quality and reliability. Customers should pay attention to the terms and conditions of the warranty when purchasing PCBs to fully understand their rights and responsibilities in case of any issues with the product.

RELATED NEWS

pcb board manufacturing How To Contact US

PCB from 1 to 30 layers, HDI, Heavy Copper, Rigid-flex board with "pcb board manufacturing One-Stop" service.