Understanding the basics of PCB technology

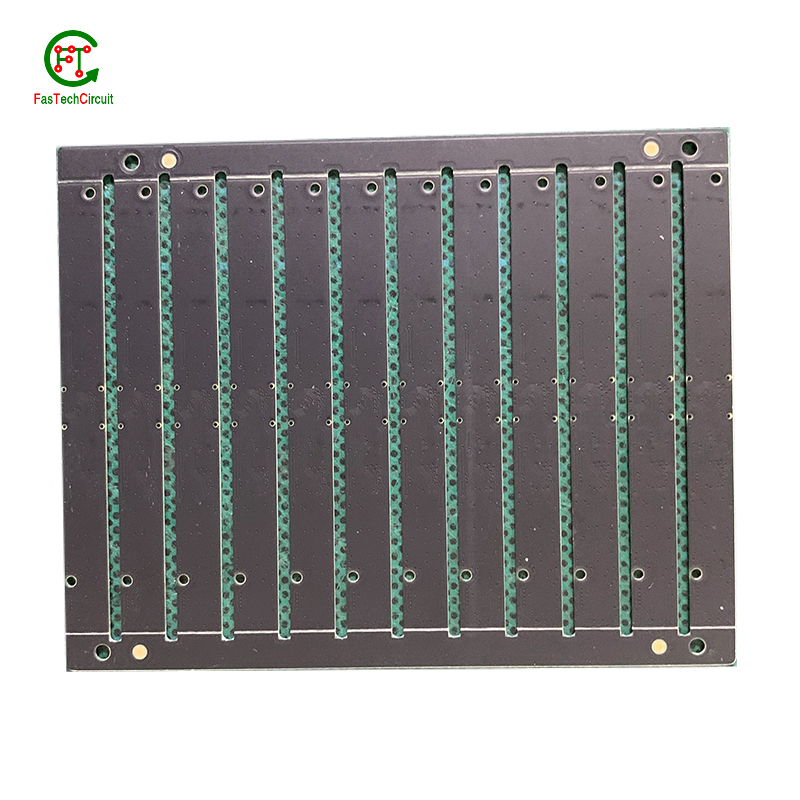

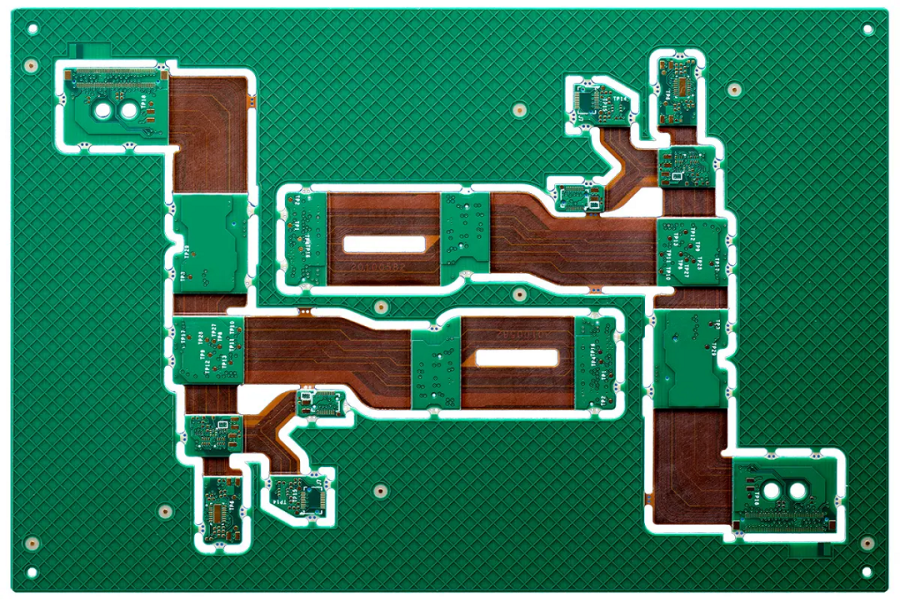

4 layer pcb is a printed circuit board that uses printing technology to connect circuit components and wires in the circuit diagram to the board to support and fix electronic components.

Challenges and Solutions: Common Problems in PCB Design

Our PCB products are designed and manufactured to ensure high reliability under various operating conditions, minimizing the risk of failure and downtime.

We are committed to using environmentally friendly materials and production processes in the manufacturing of our PCB products, reducing our carbon footprint and promoting sustainability.

PCB--An Ultimate FAQ Guide.

2.Does the PCB have special anti-seismic design?

3.About PCB raw material procurement system

4.Does the PCB have a special anti-theft design?

5.About PCB quality system

6.About PCB production capacity

7.Does the PCB have special anti-corrosion treatment?

8.About PCB technology

9.Do PCB products use environmentally friendly materials?

10.About the development history of PCB factory

11.About the development history of PCB factory

12.About PCB origin

13.About PCB customization services

14.About PCB patent

15.What are the electrical characteristics of PCB?

16.Does PCB have the ability to resist electromagnetic interference?

17.About the scale of PCB factory

18.About PCB technology

19.Do PCB products have anti-static functions?

20.What is the processing accuracy of PCB products?

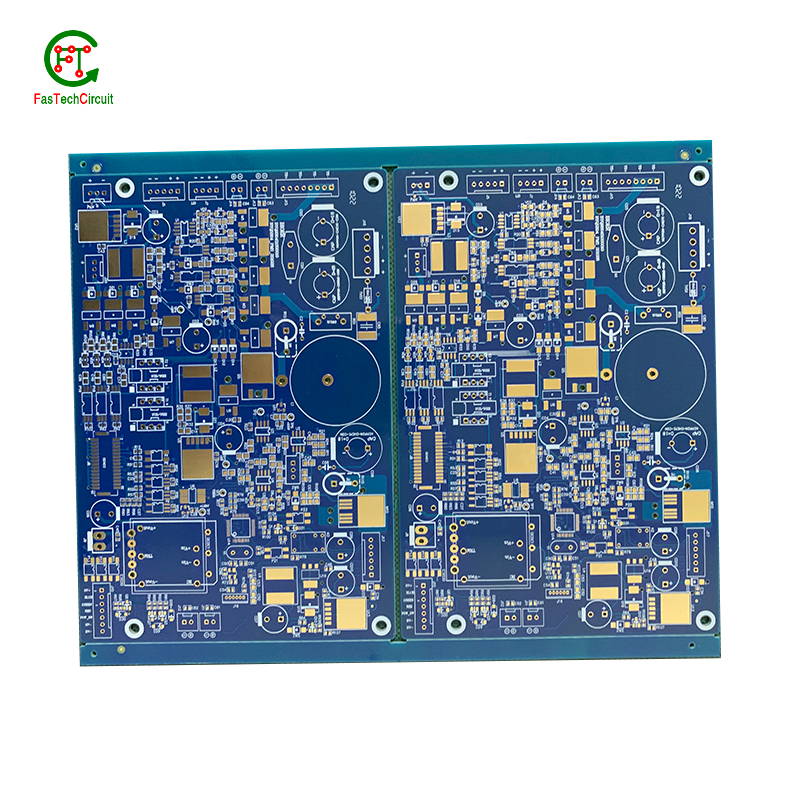

1.What is the surface treatment of PCB?

Common surface treatment methods include HASL (Hot Air Solder Leveling), ENIG (Electroless Nickel Immersion Gold), OSP (Organic Solderability Preservatives), and immersion tin or silver. The choice of treatment method depends on the specific requirements of the PCB design and its intended application.

2.Does the PCB have special anti-seismic design?

PCB (Printed Circuit Board) products typically do not have special anti-seismic designs as their primary function is to provide electrical connections and support for electronic components. Anti-seismic considerations are generally addressed at the system level in applications like industrial equipment, automotive electronics, or aerospace systems, where the entire system's design may incorporate anti-seismic measures to ensure stability and functionality during mechanical stress or vibrations. While PCBs themselves are not designed for anti-seismic purposes, they are integrated into systems that may have such protection in place to prevent damage or malfunction during seismic events.

3.About PCB raw material procurement system

The PCB raw material procurement system is a process that involves the acquisition of necessary materials for the production of printed circuit boards. This system is essential in ensuring that the right materials are sourced in a timely and cost-effective manner to meet production demands. It involves sourcing materials from suppliers, negotiating prices, and monitoring inventory levels to maintain an efficient supply chain. A well-managed PCB raw material procurement system is crucial for maintaining the quality and efficiency of PCB production.

4.Does the PCB have a special anti-theft design?

PCB (Printed Circuit Board) products typically do not have a special anti-theft design themselves. Anti-theft features are usually implemented at the level of the entire electronic system or device in which the PCB is incorporated. These features may include encryption, secure access control, or tamper-evident packaging to prevent unauthorized access or use of the device. While the PCB may play a role in security by facilitating secure connections or encryption features, its primary function is to provide electrical connectivity within electronic devices. Anti-theft measures are usually implemented at the system level, not at the PCB level.

5.About PCB quality system

The PCB quality system is a set of processes and procedures for ensuring that printed circuit boards meet the required quality standards. It encompasses various aspects such as design, fabrication, assembly, and testing, to ensure consistent and reliable performance of the PCBs. The system involves rigorous quality control measures, continuous improvement efforts, and strict adherence to industry standards and regulations. This comprehensive approach to PCB quality management is crucial for achieving high quality products and maintaining customer satisfaction.

6.About PCB production capacity

PCB production capacity refers to the amount and ability of a PCB (Printed Circuit Board) manufacturer to produce electronic circuit boards in a given period of time. This includes the company's production capabilities, resources, and efficiency in producing PCBs. The capacity of a PCB manufacturer is an important consideration for businesses and industries that rely on PCBs for their electronic devices, as it directly impacts the supply and turnaround time for these crucial components. With the constant demand for smaller, faster, and more complex electronic devices, there is a growing need for PCB production capacity to keep up with the industry's evolving requirements. Therefore, manufacturers are continuously investing in technology and expanding their production capabilities to meet the demands of the market.

7.Does the PCB have special anti-corrosion treatment?

PCB (Printed Circuit Board) products can undergo special anti-corrosion treatments to enhance their durability and resistance to environmental factors. Anti-corrosion treatments typically involve the application of conformal coatings, which create a protective layer over the PCB to shield it from moisture, humidity, and corrosive elements. These coatings act as a barrier against oxidation and chemical corrosion, preserving the integrity of the PCB components and connections. The choice to apply anti-corrosion treatment depends on the specific application and the potential exposure to corrosive agents, ensuring that the PCB remains reliable and functional in challenging conditions.

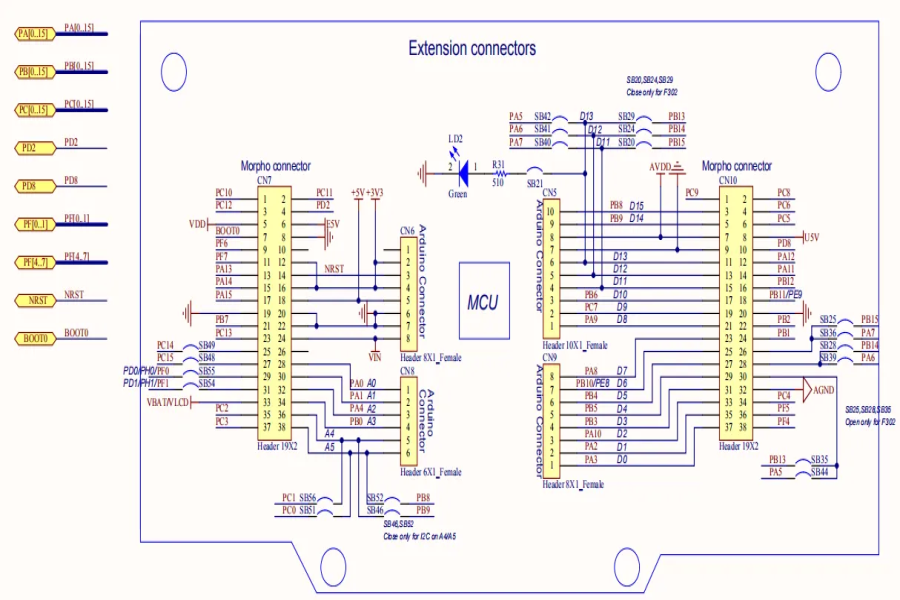

8.About PCB technology

PCB technology, also known as printed circuit board technology, refers to the process of designing, manufacturing and assembling electronic circuit boards used in various electronic devices. This technology involves the use of specialized software for design, advanced manufacturing techniques such as surface mount technology and through-hole technology, and various testing methods to ensure the functionality and reliability of the PCBs. It plays a crucial role in the development and production of electronic devices, making it one of the fundamental technologies in the modern electronics industry.

9.Do PCB products use environmentally friendly materials?

PCB (Printed Circuit Board) products can be manufactured using environmentally friendly materials and processes, depending on the manufacturer's practices and the specific requirements of the application. Environmentally friendly PCBs may incorporate lead-free solder materials, halogen-free substrates, and other eco-friendly alternatives. In many regions, there are regulations and standards, such as RoHS (Restriction of Hazardous Substances) directives, which require the reduction or elimination of hazardous materials in electronics, including PCBs. Manufacturers often aim to meet these environmental standards by using eco-friendly materials and processes in their PCB production. However, the extent to which a PCB product is environmentally friendly depends on the manufacturer's practices and adherence to such regulations.

10.About the development history of PCB factory

The development of PCB factories can be traced back to the early 20th century when the technology for producing printed circuit boards was first invented. Over the years, with the advancements in electronics and manufacturing processes, the demand for PCBs grew rapidly. This led to the establishment of more specialized and efficient PCB factories, which played a crucial role in the development of modern electronics. With the introduction of more sophisticated machinery and techniques, these factories were able to mass produce high-quality PCBs at a faster pace, meeting the growing demand from various industries. Today, PCB factories continue to evolve and innovate, adopting new technologies such as automation and AI to streamline processes and produce higher quality and more complex circuit boards for the ever-expanding electronics market.

11.About the development history of PCB factory

The development of PCB factories can be traced back to the early 20th century when the first commercial prototype of a printed circuit board was created. Since then, the demand for PCBs has continuously increased due to the rapid growth of technology and the need for more efficient and compact electronic devices. In the 1950s, industry giants such as IBM and RCA began using PCBs in their electronic products, leading to the mass production of PCBs in the 1960s. The 1970s saw the introduction of computer-aided design and manufacturing technology, making the production of PCBs faster and more cost-effective. In the 1980s, surface mount technology revolutionized PCB production, making it possible to create smaller and more complex boards. The 1990s saw the rise of offshore PCB manufacturing, with China becoming a major player in the industry. Today, PCB factories continue to innovate and evolve, utilizing advanced technology and implementing sustainable practices to meet the growing demands of the electronics industry.

12.About PCB origin

PCB, short for Printed Circuit Board, is one of the essential components in electronic devices. It serves as a foundation and support for electronic components, allowing them to be connected and work together. The origin of PCB can be traced back to the early 20th century when people found a need to create a more efficient and reliable way to connect, mount, and organize electronic components. Over time, with the development of technology and manufacturing processes, PCB has become an integral part of modern electronic devices, making our daily lives more convenient and connected. Today, PCBs are widely used in various industries, from consumer electronics to medical equipment, highlighting their critical role and contribution to the advancement of technology.

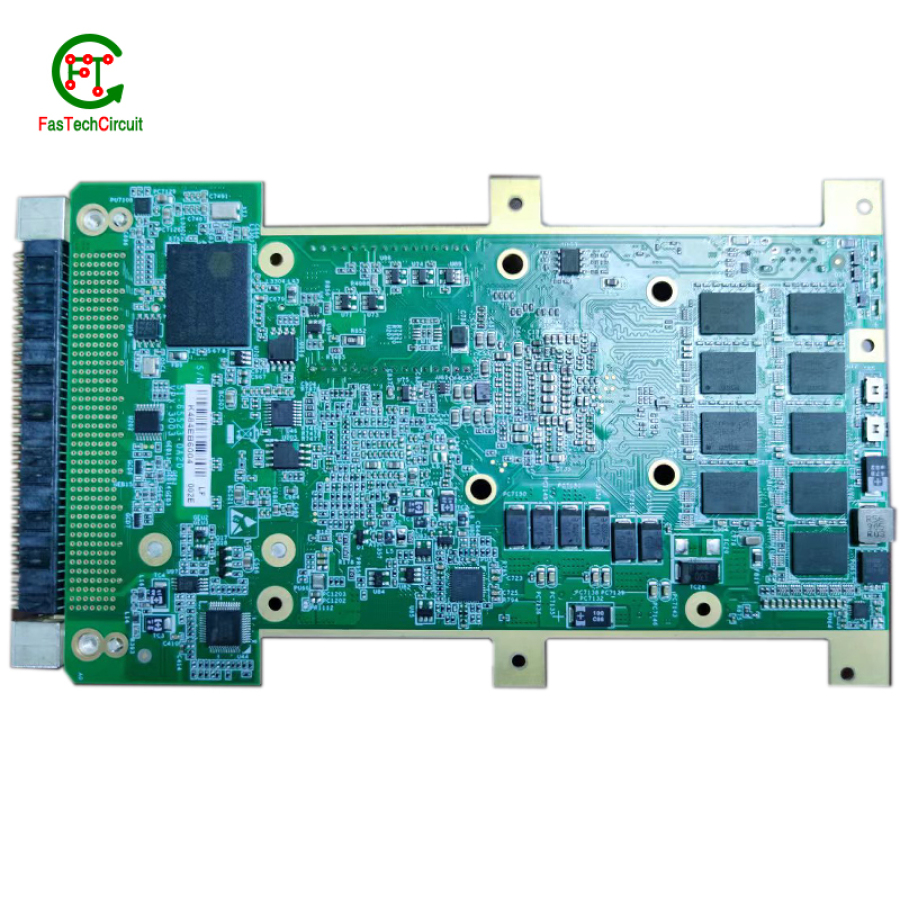

13.About PCB customization services

PCB customization services involve creating personalized printed circuit boards (PCBs) to meet specific design and functionality requirements. This process includes collaborating with the client to understand their unique needs and customizing the PCB layout, material, and components accordingly. Through PCB customization services, clients can obtain tailor-made solutions for their specific applications, ensuring high-quality and efficient performance. These services are essential for industries such as automotive, aerospace, and telecommunications, where precision and reliability are crucial. With the help of experienced professionals and advanced technologies, PCB customization services offer a cost-effective and timely solution for businesses seeking customized electronic components.

14.About PCB patent

PCB patent refers to the legal protection granted to the design, technology, or invention related to printed circuit boards (PCBs). These patents not only protect the intellectual property of PCB manufacturers and designers, but also encourage innovation and development in the electronic industry. With the increasing demand for smaller and more advanced devices, PCB patents play a crucial role in safeguarding the rights of inventors and promoting the growth of the PCB market. However, obtaining a PCB patent can be a complex and lengthy process, involving multiple legal requirements and thorough examination. The enforcement of PCB patents also requires strict adherence to patent laws and regulations to protect against infringements. Overall, PCB patents are essential for fostering innovation and ensuring fair competition in the ever-evolving world of technology.

15.What are the electrical characteristics of PCB?

The electrical characteristics of PCB (Printed Circuit Board) are vital for its performance in electronic systems. These characteristics include impedance, dielectric constant (Dk), crosstalk, signal integrity, capacitance, inductance, voltage and current handling, frequency response, and high-frequency performance. PCBs are designed to maintain controlled impedance, minimize signal interference, and handle specific voltage and current levels, ensuring their reliability and functionality in various electronic applications. The choice of materials and design considerations plays a significant role in achieving the desired electrical characteristics for PCBs.

16.Does PCB have the ability to resist electromagnetic interference?

PCB (Printed Circuit Board) products can be designed to resist electromagnetic interference (EMI) through various methods and features. EMI shielding, grounded planes, and controlled impedance routing are some common techniques used to mitigate the impact of EMI. PCB design and layout play a crucial role in minimizing EMI susceptibility and emissions. Additionally, the selection of materials and components can influence the PCB's EMI resistance. Proper grounding, signal isolation, and use of EMI shielding materials can help ensure that PCBs perform well in EMI-prone environments. The level of EMI resistance depends on the design and materials used, making it an important consideration in applications where EMI can affect electronic performance.

17.About the scale of PCB factory

A PCB factory, also known as a printed circuit board factory, is a manufacturing facility that specializes in the production of printed circuit boards. These are used in a wide range of electronic devices, from smartphones and laptops to cars and airplanes. These factories vary in scale, with some producing small volumes for niche markets, while others are large operations that mass-produce PCBs for mainstream electronics companies. The scale of a PCB factory can be measured by its annual production output, the number of employees, and the size of its production facility. The larger the scale of a PCB factory, the more advanced and complex its production processes are likely to be, allowing it to produce high-quality boards in large quantities.

18.About PCB technology

PCB technology, also known as Printed Circuit Board technology, is a fundamental aspect of modern electronics. It involves designing and manufacturing electronic circuits and interconnecting components using conductive pathways, or traces, on a non-conductive substrate. This technology has revolutionized the electronic industry and has enabled the creation of highly efficient and compact electronic devices, from smartphones to computers and medical equipment. PCB technology continues to advance with the demand for smaller, faster, and more complex electronic devices, making it a crucial component in the development of new technologies.

19.Do PCB products have anti-static functions?

PCB (Printed Circuit Board) products themselves do not typically have inherent anti-static functions. However, anti-static precautions are essential during the manufacturing and handling of PCBs. Static electricity can potentially damage sensitive electronic components on a PCB. To mitigate this risk, anti-static measures such as using anti-static workstations, wearing anti-static garments, and using anti-static tools and packaging materials are employed when working with PCBs. These precautions help prevent electrostatic discharge (ESD) and protect the integrity of the components and the PCB itself, ensuring that the final product functions reliably in electronic systems.

20.What is the processing accuracy of PCB products?

The processing accuracy of PCB (Printed Circuit Board) products is a critical aspect of their quality. It involves ensuring that the dimensions, traces, holes, and other features of the PCB are fabricated with precision. The accuracy is typically specified in terms of tolerances for various parameters, including trace width, hole diameter, and overall dimensions. Common processing accuracy standards for PCBs include a minimum trace width and spacing, as well as specific tolerances for holes and cutouts. Achieving high processing accuracy is essential to ensure that the PCB functions as intended and that components can be soldered onto it without issues. The specific processing accuracy requirements can vary based on the PCB's design and application.

RELATED NEWS

pcb board manufacturing How To Contact US

PCB from 1 to 30 layers, HDI, Heavy Copper, Rigid-flex board with "pcb board manufacturing One-Stop" service.