What are the key steps involved in the PCBA assembly process and how do they ensure the quality and functionality of electronic devices?

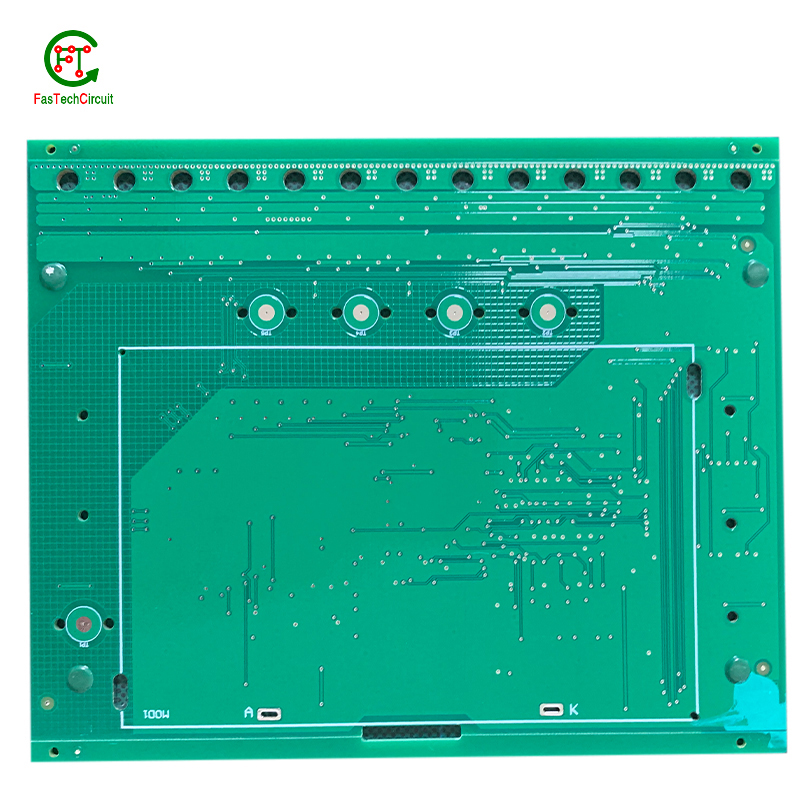

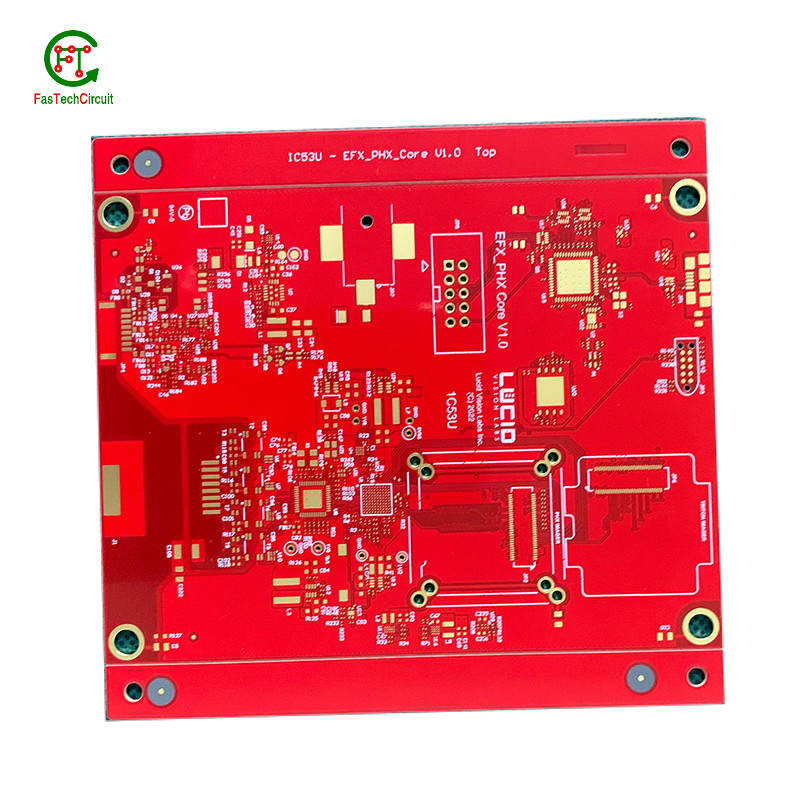

The PCBA (Printed Circuit Board Assembly) process is a crucial step in the manufacturing of electronic devices. It involves the assembly of electronic components onto a printed circuit board (PCB) to create a functional electronic device. The PCBA process consists of several key steps, each of which plays a vital role in ensuring the quality and functionality of the final product. In this article, FasTechCircuit will explore these key steps and their significance in achieving high-quality PCBA.

Hot Tags: About FasTechCircuit ,More products

1. Component Placement:

Component placement is the process of accurately positioning electronic components onto the PCB. This can be done manually or with the help of automated pick-and-place machines. The placement of components must be precise to ensure proper electrical connectivity and functional integrity.

Automated component placement machines use vision systems and robotic arms to pick components from reels or trays and place them onto the PCB. This ensures high accuracy and efficiency in component placement.

2. Solder Paste Application:

Solder paste is a mixture of solder alloy particles and flux that facilitates the soldering process. It is applied to specific areas of the PCB where components will be placed.

The solder paste is applied using a stencil, which is aligned with the PCB and then a squeegee is used to spread the paste over the stencil, depositing it onto the appropriate areas of the PCB. This ensures the precise application of solder paste, which is essential for proper soldering.

3. Reflow Soldering:

Reflow soldering is the process of melting the solder paste and bonding the components to the PCB. This is typically done in a reflow oven, where the PCB is subjected to controlled heating and cooling cycles.

During reflow soldering, the temperature is raised to a level where the solder paste melts and creates a secure bond between the components and the PCB. The temperature is then gradually lowered to solidify the solder joints, ensuring their integrity and reliability.

4. Inspection:

Inspection is a critical step in the PCBA process to ensure the quality and functionality of the assembled PCB. It involves various methods to detect and rectify any defects or issues.

Visual inspection is performed to check for any visible defects, such as misalignment, solder bridging, or missing components. Automated optical inspection (AOI) systems use cameras and algorithms to detect defects more accurately and efficiently.

In-circuit testing (ICT) is another common method used to verify the electrical connectivity and functionality of the assembled PCB. Test probes are used to measure voltages, currents, and resistances at various points on the board.

Functional testing involves testing the PCB in its operating state to ensure that it performs as intended. This may include checking inputs and outputs, running specific software or firmware, and verifying the overall functionality of the electronic device.

5. Cleaning:

After the soldering process, the PCB may be cleaned to remove any residues or contaminants that can affect its performance and reliability.

Cleaning is typically done using specialized cleaning agents and equipment to ensure that the PCB is free from flux residues, solder balls, or other contaminants. This ensures the long-term reliability and functionality of the electronic device.

6. Final Inspection and Packaging:

Once the PCBA process is completed, a final inspection is performed to ensure that all quality standards and customer specifications are met.

The inspected and approved PCBAs are then packaged and prepared for shipment. This may include placing them in antistatic bags, adding labels or documentation, and organizing them for transportation.

By following these key steps, the PCBA process ensures the quality and functionality of electronic devices. Accurate component placement, precise solder paste application, controlled reflow soldering, thorough inspection, proper cleaning, and final inspection all contribute to the overall quality and reliability of the assembled PCBs. These steps help to identify and rectify any defects or issues, ensuring that the electronic devices meet the required specifications and perform as intended.

RELATED NEWS

pcb board manufacturing How To Contact US

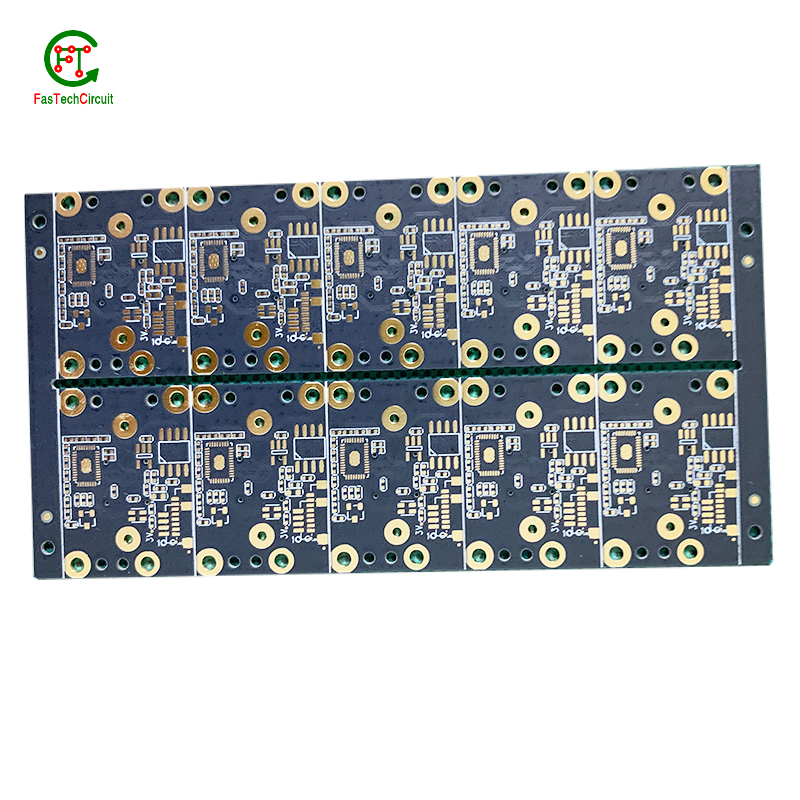

PCB from 1 to 30 layers, HDI, Heavy Copper, Rigid-flex board with "pcb board manufacturing One-Stop" service.