How does the use of advanced technologies and automation in PCB assembly improve efficiency, accuracy, and reliability in the production of electronic devices?

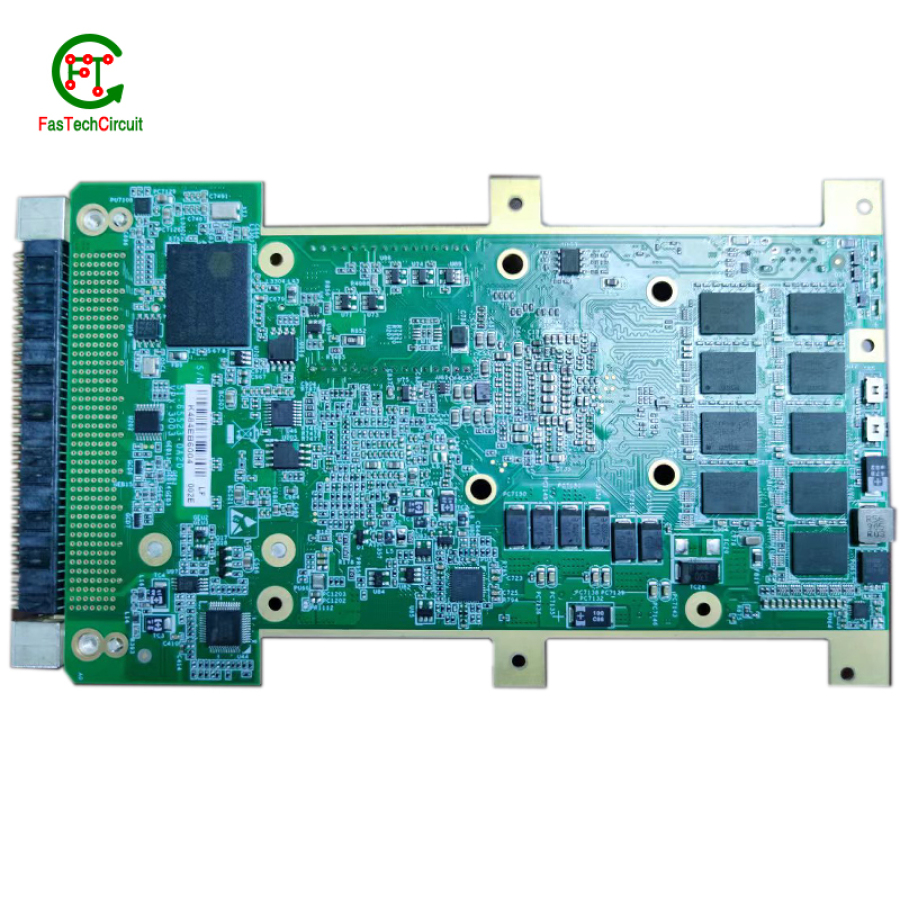

The use of advanced technologies and automation in PCB (Printed Circuit Board) assembly has revolutionized the manufacturing process of electronic devices, leading to improved efficiency, accuracy, and reliability. In this article, FasTechCircuit will explore how the integration of advanced technologies and automation has transformed PCB assembly and its impact on the production of electronic devices.

Hot Tags: About FasTechCircuit ,More products

1. Enhanced Efficiency:

Faster Production: Advanced technologies and automation enable faster production cycles by reducing the time required for manual tasks. Automated machines and robotic systems can perform tasks such as component placement, soldering, and testing at a much higher speed than human operators, resulting in increased productivity and shorter lead times.

Continuous Operation: Automation allows for continuous operation of PCB assembly lines, minimizing downtime and maximizing production output. Automated machines can work 24/7 without the need for breaks or shifts, ensuring a consistent and efficient production process.

Streamlined Workflow: Advanced technologies and automation streamline the workflow of PCB assembly. Automated systems can be programmed to perform sequential tasks without interruption, eliminating bottlenecks and optimizing the overall production process. This results in a more efficient and synchronized assembly line.

2. Improved Accuracy:

Precise Component Placement: Automated machines equipped with vision systems and precision robotics ensure accurate component placement on PCBs. Vision systems can detect the exact position and orientation of components, while precision robotics provide precise alignment and placement, minimizing errors and improving the overall accuracy of the assembly process.

Consistent Soldering Quality: Automated soldering machines utilize controlled heating and soldering techniques, ensuring consistent soldering quality across all PCBs. This eliminates human errors and inconsistencies in soldering, resulting in improved reliability and performance of electronic devices.

Error Detection and Correction: Advanced technologies and automation allow for real-time error detection and correction during the assembly process. Vision systems and automated inspection equipment can identify defects, such as misplaced components or soldering issues, and trigger immediate corrective actions. This prevents faulty products from progressing further in the assembly line, reducing waste and ensuring high-quality end products.

3. Enhanced Reliability:

Reduced Human Error: Automation minimizes the reliance on manual labor, reducing the chances of human error in PCB assembly. Automated machines are programmed to perform tasks with precision and consistency, eliminating errors caused by fatigue, distraction, or lack of skill. This leads to improved reliability and fewer defects in the final products.

Improved Quality Control: Advanced technologies enable comprehensive quality control measures throughout the PCB assembly process. Automated inspection systems can detect defects at various stages, including component placement, soldering, and electrical testing. This ensures that only high-quality PCBs proceed to the next production stage, resulting in more reliable electronic devices.

Traceability and Data Analysis: Automation allows for the collection and analysis of data at every stage of PCB assembly. This enables traceability of components and processes, making it easier to identify and rectify any issues or defects. Data analysis also helps in identifying trends, optimizing production parameters, and continuously improving the assembly process, further enhancing the reliability of electronic devices.

In conclusion, the use of advanced technologies and automation in PCB assembly has significantly improved the efficiency, accuracy, and reliability of the production of electronic devices. The integration of automated machines, precision robotics, vision systems, and data analysis has led to faster production cycles, precise component placement, improved quality control, and reduced human errors. These advancements have not only increased the productivity and competitiveness of PCB assembly but have also resulted in higher quality and more reliable electronic devices for consumers.

RELATED NEWS

pcb board manufacturing How To Contact US

PCB from 1 to 30 layers, HDI, Heavy Copper, Rigid-flex board with "pcb board manufacturing One-Stop" service.