The impact of substrate thickness on PCB performance

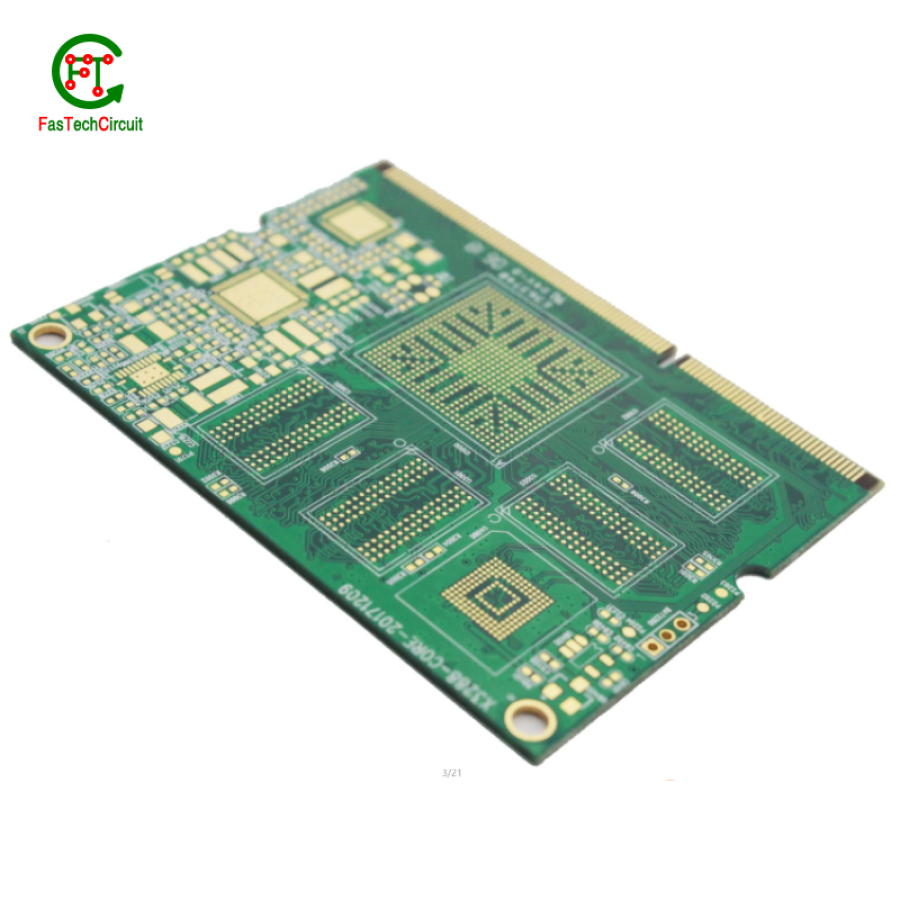

HIGH SPEED PCB is usually made of fiberglass, plastic and other materials. It has good insulation properties and can effectively avoid short circuits between circuit components.

current situation and prospects of PCB manufacturing

We are committed to using environmentally friendly materials and production processes in the manufacturing of our PCB products, reducing our carbon footprint and promoting sustainability.

By utilizing advanced manufacturing techniques and high-density component placement, our PCB products are able to achieve compact and lightweight designs, saving valuable space in electronic devices.

PCB--An Ultimate FAQ Guide.

2.About PCB production capacity

3.About PCB inventory

4.What is the surface treatment of PCB?

5.About PCB R&D capabilities

6.About PCB warranty

7.About PCB warranty

8.About PCB production equipment

9.Do PCB products have anti-corrosion capabilities?

10.About the scale of PCB factory

11.About PCB raw material procurement system

12.About PCB raw materials

13.About PCB customization services

14.About the development history of PCB factory

15.What is the difference between PCB FasTechCircuit vs PCB Colorful vs PCB Zotac

16.Does PCB have special flame retardant treatment?

17.Does the PCB product have the function of preventing short circuit?

18.About PCB production capacity

19.Do PCB products have radiation anti-interference capabilities?

20.Do PCB products have anti-static functions?

21.About PCB R&D capabilities

22.About PCB raw material procurement system

23.Does the PCB have special anti-corrosion treatment?

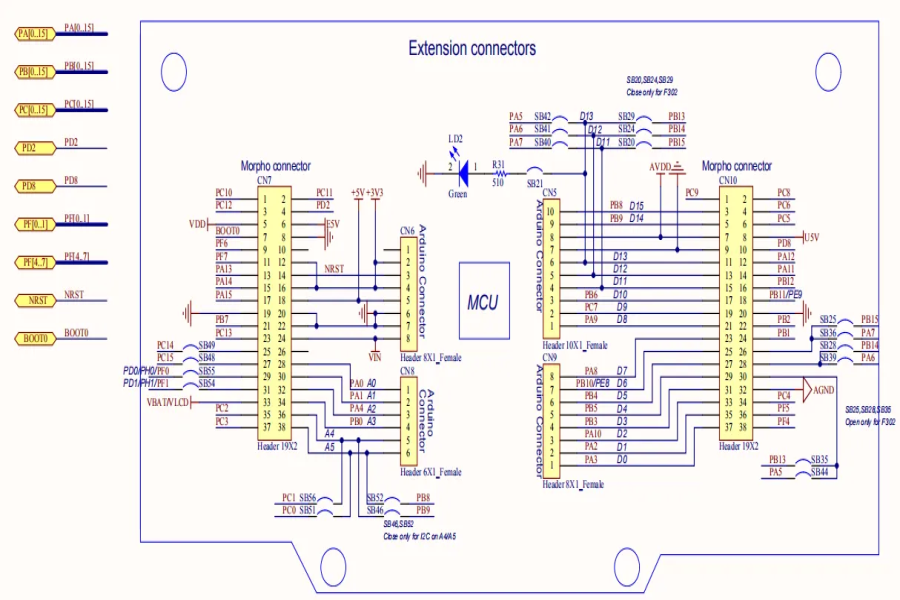

1.Does the PCB support high-speed signal transmission?

PCB (Printed Circuit Board) products can be designed to support high-speed signal transmission, and their performance in this regard depends on several factors. To ensure effective high-speed signal transmission, PCBs may incorporate features such as controlled impedance traces, reduced crosstalk, and signal integrity optimization. Design considerations include trace length matching, layer stackup, and the selection of appropriate materials. PCBs used in applications like data centers, high-speed networking, and advanced electronics often undergo meticulous design and testing to ensure they meet the requirements for high-speed signal integrity and transmission.

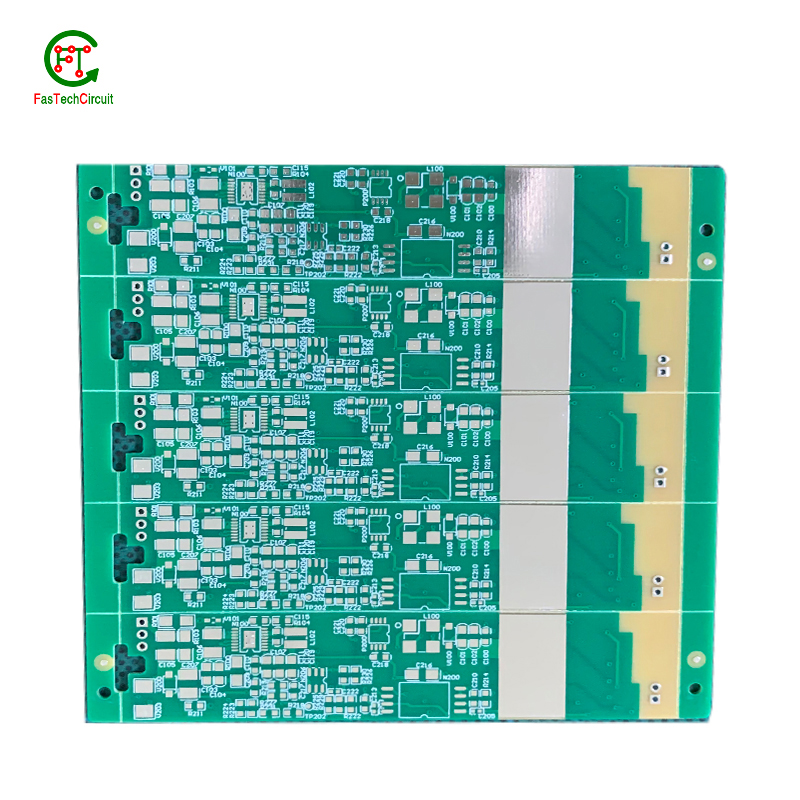

2.About PCB production capacity

PCB production capacity refers to the maximum quantity of printed circuit boards (PCBs) that a manufacturer is able to produce within a given timeframe. This not only includes the physical space and equipment available for production, but also considers factors such as production time, manpower, and efficiency. A high production capacity allows for a larger volume of PCBs to be manufactured, meeting the demands of customers and addressing the growing market for electronic devices. Advances in technology and process optimization have continually increased PCB production capacity, allowing for more efficient and cost-effective production processes.

3.About PCB inventory

PCB inventory is an essential aspect of electronic manufacturing industry, which refers to the storage and management of printed circuit boards (PCBs) used in various electronic devices. PCB inventory helps companies maintain a steady supply of circuit boards for production, repair, and custom-made projects. It is crucial for companies to keep track of their PCB inventory to ensure timely production and avoid delays in delivery. Furthermore, efficient management of PCB inventory can help companies reduce costs and eliminate the risk of excess or shortage of materials. With the continuous advancement of technology, effective management of PCB inventory is becoming increasingly important for companies to stay competitive in the market.

4.What is the surface treatment of PCB?

Common surface treatment methods include HASL (Hot Air Solder Leveling), ENIG (Electroless Nickel Immersion Gold), OSP (Organic Solderability Preservatives), and immersion tin or silver. The choice of treatment method depends on the specific requirements of the PCB design and its intended application.

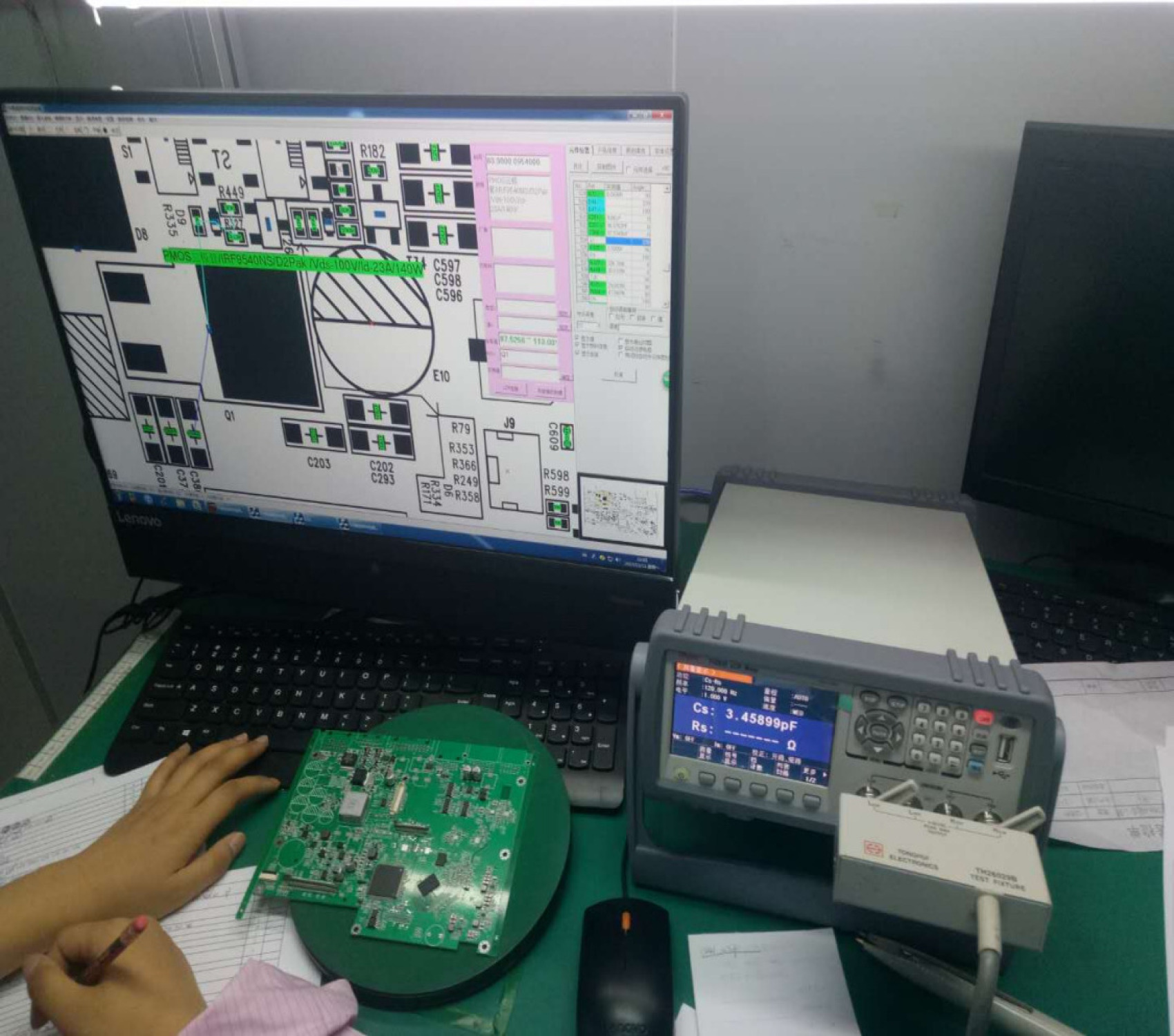

5.About PCB R&D capabilities

PCB R&D capabilities refer to a company's ability to research, develop, and innovate new printed circuit board technologies and processes. These capabilities include the expertise and resources to design, prototype, test, and manufacture high-quality PCBs that meet the ever-evolving needs and demands of the industry. With strong PCB R&D capabilities, a company can stay ahead of the competition and continuously improve its products to meet the latest standards and requirements. This often requires a team of skilled engineers, state-of-the-art equipment, and a culture of continuous improvement and innovation. Companies with strong PCB R&D capabilities are essential for the advancement of technologies in various industries, including electronics, telecommunications, automotive, and aerospace.

6.About PCB warranty

PCB warranty refers to the guarantee provided by manufacturers for printed circuit boards (PCBs). It ensures that the PCBs are free from defects in materials and workmanship for a specific period of time. This warranty is important as it can protect customers from potential losses caused by product defects and provides assurance of quality and reliability. Customers should pay attention to the terms and conditions of the warranty when purchasing PCBs to fully understand their rights and responsibilities in case of any issues with the product.

7.About PCB warranty

The PCB warranty provides assurance for customers that their purchased circuit boards are free from defects and will function as intended within a specified time frame. This warranty ensures that customers receive high-quality products and can have peace of mind when using them for their electronic applications. It typically covers repair or replacement of faulty boards, offering protection and support to customers, thereby building trust and confidence in the manufacturer's products.

8.About PCB production equipment

PCB (Printed Circuit Board) production equipment is an essential component in the manufacturing process of electronic devices. It includes various machines and tools used to fabricate, assemble, and test printed circuit boards, which are the foundation of all electronic devices. These equipment typically include drills, routers, plating machines, soldering machines, inspection systems, and more. With the advancement of technology, PCB production equipment has become more sophisticated and efficient, allowing for higher precision and faster production times. As electronic devices continue to evolve and become more intricate, the demand for advanced PCB production equipment will only continue to grow.

9.Do PCB products have anti-corrosion capabilities?

PCB (Printed Circuit Board) products can incorporate anti-corrosion capabilities, primarily through the choice of materials and surface treatments. Corrosion protection is vital, especially in environments with high humidity or exposure to corrosive agents. PCBs can be manufactured with materials that are resistant to corrosion, such as specific laminates and coatings. Surface treatments like ENIG (Electroless Nickel Immersion Gold) or OSP (Organic Solderability Preservatives) also provide a level of corrosion resistance. The extent of anti-corrosion capabilities depends on the design and materials used, ensuring the PCB's longevity and reliability, even in challenging conditions.

10.About the scale of PCB factory

A PCB factory, also known as a printed circuit board factory, is a manufacturing facility that specializes in the production of printed circuit boards. These are used in a wide range of electronic devices, from smartphones and laptops to cars and airplanes. These factories vary in scale, with some producing small volumes for niche markets, while others are large operations that mass-produce PCBs for mainstream electronics companies. The scale of a PCB factory can be measured by its annual production output, the number of employees, and the size of its production facility. The larger the scale of a PCB factory, the more advanced and complex its production processes are likely to be, allowing it to produce high-quality boards in large quantities.

11.About PCB raw material procurement system

The PCB raw material procurement system is a process that involves the acquisition of necessary materials for the production of printed circuit boards. This system is essential in ensuring that the right materials are sourced in a timely and cost-effective manner to meet production demands. It involves sourcing materials from suppliers, negotiating prices, and monitoring inventory levels to maintain an efficient supply chain. A well-managed PCB raw material procurement system is crucial for maintaining the quality and efficiency of PCB production.

12.About PCB raw materials

PCB (Printed Circuit Board) raw materials refer to the base materials used in the manufacturing of electronic circuit boards. These materials typically include copper-clad laminates, solder mask, silkscreen, and various types of coatings and films. The selection of high-quality raw materials is crucial for ensuring the functionality, durability and reliability of PCBs, which are the backbone of electronic devices. Different applications require different types of raw materials, such as high-speed signal transmission, thermal management, and environmental protection. With the constant advancement of technology, the demand for more innovative and sustainable PCB raw materials continues to rise, driving the development of the electronics industry towards a more efficient and eco-friendly future.

13.About PCB customization services

PCB customization services refer to the process of designing and producing customized printed circuit boards according to the specific needs and requirements of a customer. This service allows for the creation of unique and tailored PCBs that can meet the exact specifications of a project or product. Through collaboration with PCB manufacturers, customers can customize various aspects such as size, shape, number of layers, materials, and layout to achieve the desired functionality and performance. These services are essential for industries such as electronics, automotive, aerospace, and medical devices that require specialized PCBs for their products. With PCB customization services, companies can ensure high-quality and efficient production of their electronic devices.

14.About the development history of PCB factory

The development of PCB factories can be traced back to the early 20th century when the technology for producing printed circuit boards was first invented. Over the years, with the advancements in electronics and manufacturing processes, the demand for PCBs grew rapidly. This led to the establishment of more specialized and efficient PCB factories, which played a crucial role in the development of modern electronics. With the introduction of more sophisticated machinery and techniques, these factories were able to mass produce high-quality PCBs at a faster pace, meeting the growing demand from various industries. Today, PCB factories continue to evolve and innovate, adopting new technologies such as automation and AI to streamline processes and produce higher quality and more complex circuit boards for the ever-expanding electronics market.

15.What is the difference between PCB FasTechCircuit vs PCB Colorful vs PCB Zotac

The choice between these manufacturers should be based on your specific project requirements. PCB FasTechCircuit is suitable for rapid prototyping, while PCB Colorful and PCB Zotac are trusted options for high-quality components in computer hardware, with a specific emphasis on gaming and graphics cards. Your decision should align with the goals and needs of your project.

16.Does PCB have special flame retardant treatment?

PCB (Printed Circuit Board) products can undergo special flame retardant treatments to enhance their fire resistance and safety characteristics. These treatments typically involve applying flame-retardant materials or coatings to the PCB to reduce the risk of combustion and the spread of fire. Flame retardant PCBs are commonly used in applications where safety is a critical concern, such as in automotive electronics, aerospace, and industrial equipment. The flame retardant treatment is designed to meet specific safety standards and regulations, ensuring that PCBs can withstand exposure to high temperatures and flames without contributing to a fire hazard. The flame retardant treatment is an important feature for applications where fire safety is paramount.

17.Does the PCB product have the function of preventing short circuit?

PCB (Printed Circuit Board) products are designed with features and measures to prevent short circuits. These measures include the careful routing of traces to avoid unintentional connections, the use of insulating materials to separate conductive layers, and the application of solder masks to protect copper traces. Additionally, the design and manufacturing processes of PCBs aim to minimize the risk of short circuits. However, the effectiveness of short-circuit prevention depends on the quality of design, manufacturing, and adherence to best practices. PCBs are an essential component in ensuring that electrical connections are made safely and reliably without causing short circuits in electronic systems.

18.About PCB production capacity

PCB production capacity refers to the amount and ability of a PCB (Printed Circuit Board) manufacturer to produce electronic circuit boards in a given period of time. This includes the company's production capabilities, resources, and efficiency in producing PCBs. The capacity of a PCB manufacturer is an important consideration for businesses and industries that rely on PCBs for their electronic devices, as it directly impacts the supply and turnaround time for these crucial components. With the constant demand for smaller, faster, and more complex electronic devices, there is a growing need for PCB production capacity to keep up with the industry's evolving requirements. Therefore, manufacturers are continuously investing in technology and expanding their production capabilities to meet the demands of the market.

19.Do PCB products have radiation anti-interference capabilities?

PCB (Printed Circuit Board) products can be designed with radiation anti-interference capabilities to reduce the risk of electromagnetic interference (EMI) and improve the overall performance of electronic systems. Various techniques are employed to minimize EMI, including proper grounding, signal routing, shielding, and the use of filtering components. Additionally, some PCBs may incorporate specialized designs to mitigate radiation and reduce interference with other electronic components. These anti-interference measures are essential in applications where EMI can disrupt signal integrity and affect the functionality of sensitive electronic devices, ensuring that PCB products operate reliably in the presence of electromagnetic radiation.

20.Do PCB products have anti-static functions?

PCB (Printed Circuit Board) products themselves do not typically have inherent anti-static functions. However, anti-static precautions are essential during the manufacturing and handling of PCBs. Static electricity can potentially damage sensitive electronic components on a PCB. To mitigate this risk, anti-static measures such as using anti-static workstations, wearing anti-static garments, and using anti-static tools and packaging materials are employed when working with PCBs. These precautions help prevent electrostatic discharge (ESD) and protect the integrity of the components and the PCB itself, ensuring that the final product functions reliably in electronic systems.

21.About PCB R&D capabilities

PCB is an integral component in electronic devices, and its development requires advanced research and development capabilities. With continuous innovation and technological advancements, PCB R&D capabilities have greatly improved. These capabilities include design and layout, material selection, prototyping, testing, and production optimization. Through rigorous research and collaboration with various industries, PCB manufacturers are able to meet the constantly evolving demands and provide efficient and reliable solutions for electronic devices.

22.About PCB raw material procurement system

The PCB raw material procurement system is a crucial aspect of the production process for printed circuit boards. It involves the sourcing and acquisition of all necessary materials, such as copper foil, laminate sheets, solder mask, and components, needed for the manufacturing of PCBs. This system requires efficient coordination between suppliers and the PCB manufacturer to ensure timely delivery and high-quality materials. Additionally, proper management of inventory levels and cost control are essential components of the procurement system to ensure smooth and cost-effective production of PCBs.

23.Does the PCB have special anti-corrosion treatment?

PCB (Printed Circuit Board) products can undergo special anti-corrosion treatments to enhance their durability and resistance to environmental factors. Anti-corrosion treatments typically involve the application of conformal coatings, which create a protective layer over the PCB to shield it from moisture, humidity, and corrosive elements. These coatings act as a barrier against oxidation and chemical corrosion, preserving the integrity of the PCB components and connections. The choice to apply anti-corrosion treatment depends on the specific application and the potential exposure to corrosive agents, ensuring that the PCB remains reliable and functional in challenging conditions.

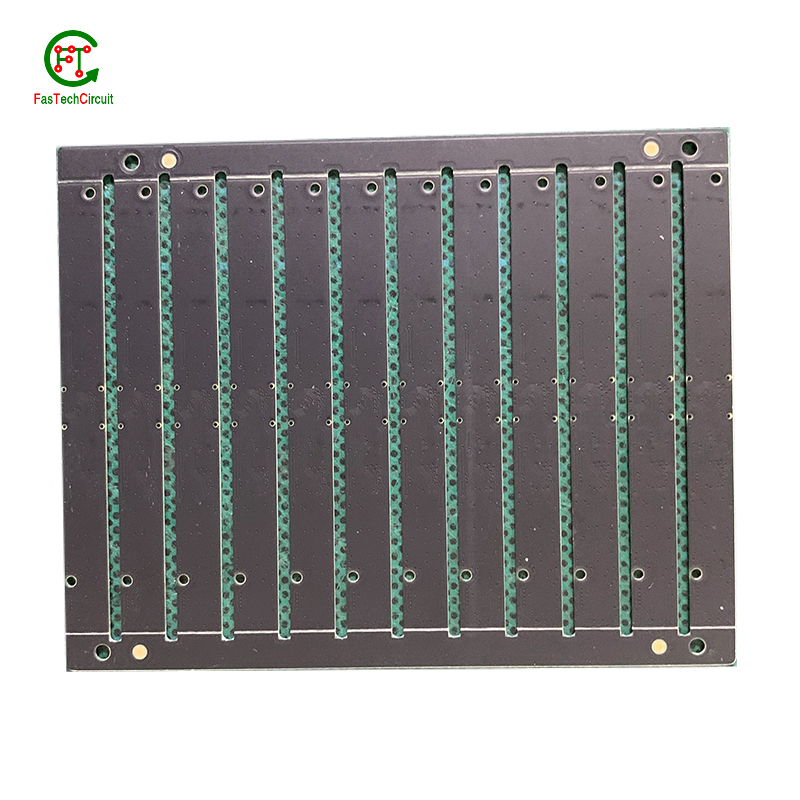

RELATED NEWS

pcb board manufacturing How To Contact US

PCB from 1 to 30 layers, HDI, Heavy Copper, Rigid-flex board with "pcb board manufacturing One-Stop" service.