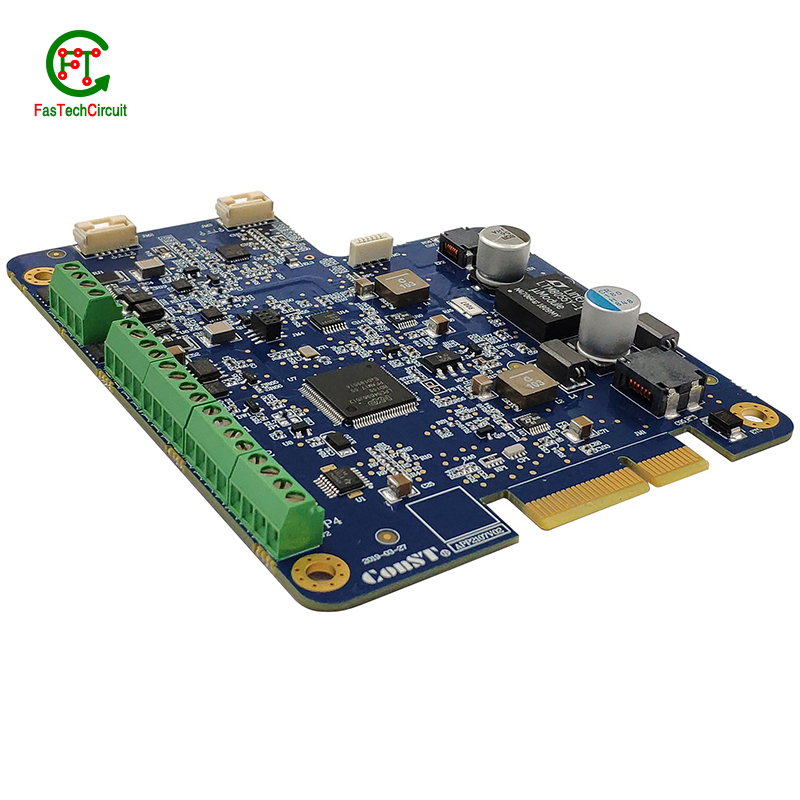

pcba supplier

PCBA suppliers are a very important part of the electronics manufacturing industry, and the circuit board assembly services they provide play a vital role in the manufacture of modern electronic devices. As a PCBA supplier, FasTechCircuit will analyze and discuss from the definition, classification, industry status, market demand and development trend of PCBA.

1. Definition and classification of PCBA suppliers

PCBA, or Printed Circuit Board Assembly, is called printed circuit board assembly in Chinese. It is the process of mounting various electronic components on circuit boards that have completed circuit design and PCB manufacturing, and finally form electronic products. PCBA suppliers are companies or individuals specialized in PCBA manufacturing and assembly. Their main business includes PCB design, component procurement, SMT (surface mount), DIP (plug-in) and other circuit board assembly services.

According to different business scope and service content, PCBA suppliers can be divided into the following categories:

(1). Full-process PCBA supplier: This type of supplier can provide one-stop services from circuit design, PCB manufacturing to component procurement, circuit board assembly, testing, etc. Its advantage is that it can provide a full range of technical support and products Quality assurance, but its disadvantage is that the cost is relatively high.

(2). Single service PCBA supplier: This type of supplier only provides a single service such as circuit board assembly or testing, which has the advantage of lower cost, but due to its limited service scope, its technical support and quality assurance are relatively insufficient.

(3). ODM/OEM supplier: This type of supplier is usually an enterprise engaged in the manufacture of electronic products, and its main business is to provide customers with ODM (Original Design Manufacturing) or OEM (Original Equipment Manufacturing) services, that is, according to the needs of customers and design requirements for product manufacturing and assembly.

2. Industry Status of PCBA Suppliers

With the continuous development and popularity of the global electronics industry, the market demand for PCBA suppliers is also increasing. At present, PCBA suppliers are mainly distributed in Asia, Europe and North America. Among them, China, as one of the largest electronics manufacturing bases in the world, ranks among the top in the world in terms of the number and market share of its PCBA suppliers. According to statistics, there are currently more than 20,000 PCBA suppliers in China, and their market share is about 40% of the global total.

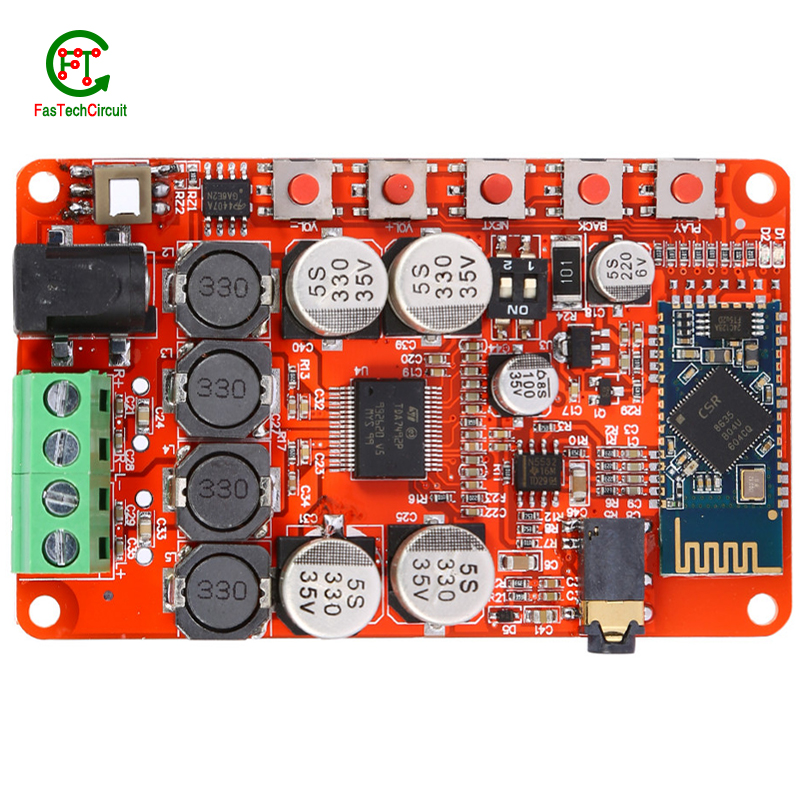

In addition, with the continuous advancement of technology and the continuous popularization of electronic products, the status and role of PCBA suppliers in the industry are becoming more and more important. At present, the main customers of PCBA suppliers include manufacturers of various electronic equipment such as computers, mobile phones, digital cameras, drones, and smart homes. At the same time, with the continuous development and application of emerging technologies such as the Internet of Things, artificial intelligence, and 5G, the market demand for PCBA suppliers will further expand.

3. Market demand and development trend of PCBA suppliers

With the rapid development of the electronics industry, the market demand for PCBA suppliers is also increasing rapidly. At present, the market demand of PCBA suppliers mainly focuses on the following aspects:

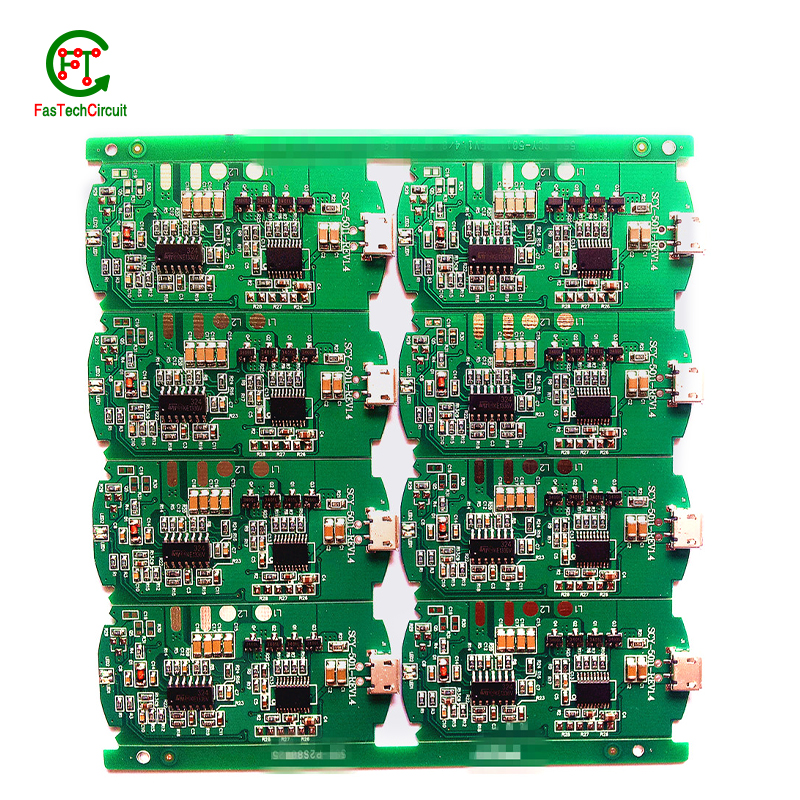

(1). Production of high-quality and high-performance circuit boards: With the continuous upgrading of electronic products, customers have higher and higher requirements for the quality and performance of circuit boards. Therefore, PCBA suppliers need to continuously improve their production processes and technical levels. To meet the needs of customers.

(2). Low-cost, high-efficiency production mode: As the market competition of electronic products is becoming more and more fierce, PCBA suppliers need to continuously improve their production efficiency and reduce costs to ensure their advantages in market competition.

(3). Provide all-round and one-stop service: With the continuous increase of customer demand, PCBA suppliers need to provide more comprehensive and professional services to meet customer needs and requirements. For example, providing one-stop service from design to manufacturing, providing after-sales support, etc.

(4). Continuous innovation and expansion of new business areas: With the continuous emergence of emerging technologies, PCBA suppliers need to continuously expand their business areas to meet market demand and customer needs. For example, expand smart home, Internet of Things, artificial intelligence and other fields.

PCBA suppliers are a very important part of the electronics manufacturing industry, and their market demands and development trends are constantly changing and developing. Therefore, PCBA suppliers need to continuously improve their technical level and service quality to meet the needs of the market and customers. At the same time, PCBA suppliers need to actively expand new business areas to adapt to the rapid development of the industry.

RELATED NEWS

pcb board manufacturing How To Contact US

PCB from 1 to 30 layers, HDI, Heavy Copper, Rigid-flex board with "pcb board manufacturing One-Stop" service.