Selecting the appropriate copper thickness for your PCB

eft pcb is usually made of fiberglass, plastic and other materials. It has good insulation properties and can effectively avoid short circuits between circuit components.

PCB design trends for the future

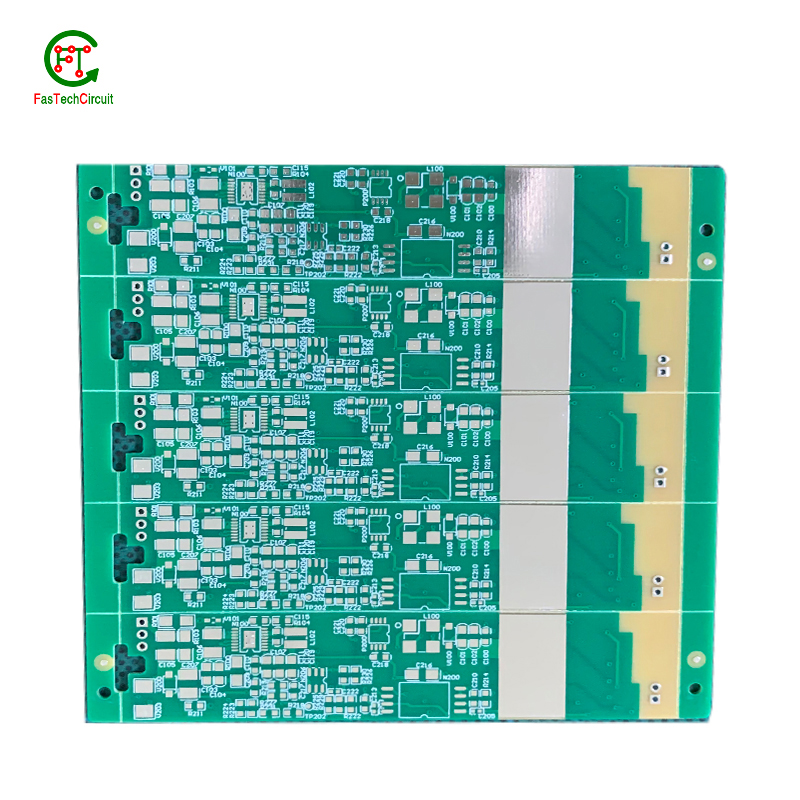

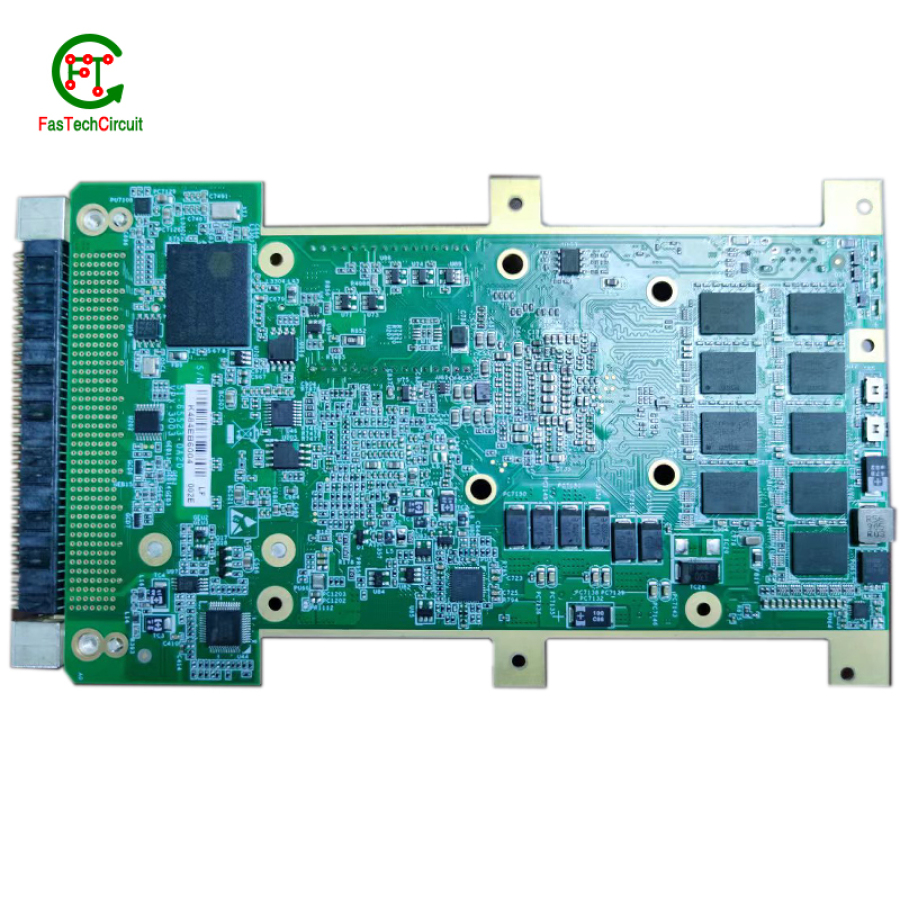

Our PCB products are available in a wide range of multi-layer configurations, allowing for complex circuit designs and enabling greater functionality in electronic devices.

Our PCB products are designed and manufactured to ensure high reliability under various operating conditions, minimizing the risk of failure and downtime.

PCB--An Ultimate FAQ Guide.

2.About PCB customization services

3.Do PCB products use environmentally friendly materials?

4.About PCB inventory

5.Is this PCB product single-sided or double-sided?

6.About PCB delivery date

7.About PCB production skills training

8.About PCB raw material procurement system

9.Does PCB comply with ROHS standards?

10.About PCB raw materials

11.About the development history of PCB factory

12.What is the difference between PCB FasTechCircuit vs PCB ASRock vs PCB Gigabyte

13.About PCB production capacity

14.About PCB origin

15.Does the PCB have special anti-seismic design?

16.How much voltage can PCB products withstand?

17.About PCB quality system

18.About PCB payment method

19.About PCB production equipment

1.Do PCB products have assembly functions?

PCB (Printed Circuit Board) products do not inherently have assembly functions themselves but are designed to support the assembly of electronic components. PCBs serve as the foundational platform for mounting and interconnecting various electronic parts, such as resistors, capacitors, integrated circuits, and connectors. The assembly of these components onto the PCB is a critical part of the manufacturing process of electronic devices. The design of the PCB includes features like component footprints, solder pads, and traces to facilitate the precise placement and soldering of components. While PCBs are not responsible for the assembly process, their design is tailored to enable the efficient and reliable assembly of electronic components.

2.About PCB customization services

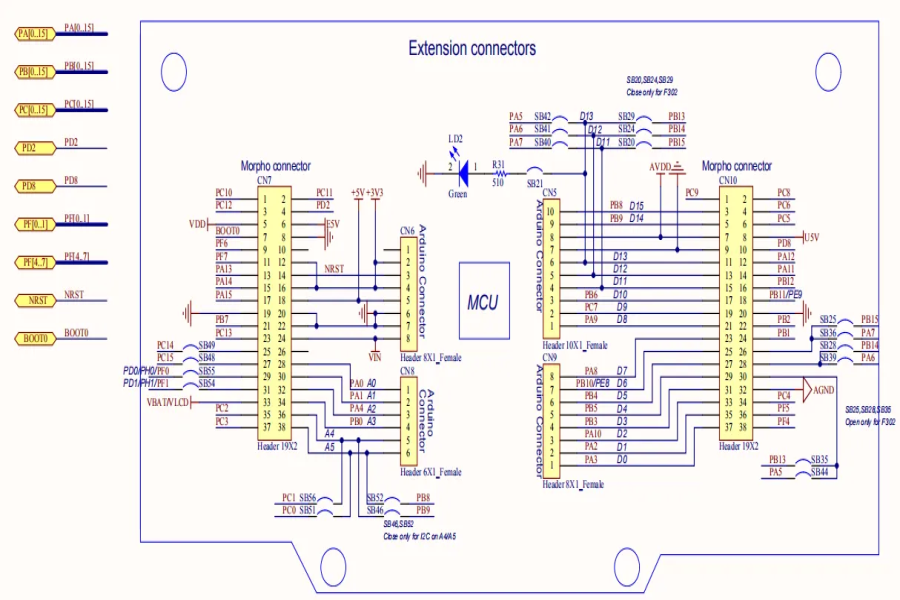

PCB customization services refer to the process of designing and producing customized printed circuit boards according to the specific needs and requirements of a customer. This service allows for the creation of unique and tailored PCBs that can meet the exact specifications of a project or product. Through collaboration with PCB manufacturers, customers can customize various aspects such as size, shape, number of layers, materials, and layout to achieve the desired functionality and performance. These services are essential for industries such as electronics, automotive, aerospace, and medical devices that require specialized PCBs for their products. With PCB customization services, companies can ensure high-quality and efficient production of their electronic devices.

3.Do PCB products use environmentally friendly materials?

PCB (Printed Circuit Board) products can be manufactured using environmentally friendly materials and processes, depending on the manufacturer's practices and the specific requirements of the application. Environmentally friendly PCBs may incorporate lead-free solder materials, halogen-free substrates, and other eco-friendly alternatives. In many regions, there are regulations and standards, such as RoHS (Restriction of Hazardous Substances) directives, which require the reduction or elimination of hazardous materials in electronics, including PCBs. Manufacturers often aim to meet these environmental standards by using eco-friendly materials and processes in their PCB production. However, the extent to which a PCB product is environmentally friendly depends on the manufacturer's practices and adherence to such regulations.

4.About PCB inventory

PCB inventory, or printed circuit board inventory, refers to the collection of all available PCBs (printed circuit boards) in stock for a particular company or organization. These PCBs are crucial components in the production of electronic devices and serve as the foundation for the electrical connections between various components. Maintaining an efficient and well-managed PCB inventory is essential for companies to meet the demand for their products, reduce production costs, and stay competitive in the market. Regular inventory checks, tracking of usage, and proper storage and handling of PCBs are key factors in managing a successful PCB inventory.

5.Is this PCB product single-sided or double-sided?

This PCB (Printed Circuit Board) product can be configured as either single-sided or double-sided, depending on the specific application and design requirements. Single-sided PCBs have circuitry on one side of the board, while double-sided PCBs feature electrical connections on both sides. The choice between single-sided and double-sided PCBs is made based on factors like the complexity of the circuit, space constraints, and cost considerations. This flexibility in design allows the PCB product to adapt to a variety of electronic applications, ensuring it can meet the needs of different projects and devices.

6.About PCB delivery date

The PCB (Printed Circuit Board) delivery date refers to the estimated time or deadline for the production and shipment of the circuit boards. This date is an important factor for customers who rely on the timely delivery of their ordered PCBs to meet their project or production deadlines. The delivery date is influenced by various factors such as the complexity of the PCB design, the materials used, and the production capacity of the manufacturer. It is essential for both the customer and the manufacturer to communicate effectively and set realistic delivery dates to ensure a smooth and efficient production process. Adhering to the delivery date is crucial for customer satisfaction and maintaining a good reputation in the market. Timely delivery not only showcases the reliability and efficiency of the manufacturer but also helps customers stay on schedule with their projects and plans.

7.About PCB production skills training

PCB production skills training is designed to provide individuals with the necessary knowledge and techniques for manufacturing high-quality printed circuit boards (PCBs). Through this training, participants will learn about the different types of PCBs, the process of PCB production, and the latest industry standards and techniques. This training will equip individuals with the skills to handle various equipment and tools used in PCB production, as well as to troubleshoot and resolve any issues that may arise during the process. Ultimately, the goal of this training is to foster a competent and skilled workforce capable of producing reliable and efficient PCBs for a variety of electronic devices.

8.About PCB raw material procurement system

The PCB raw material procurement system is a crucial aspect of the production process for printed circuit boards. It involves the sourcing and acquisition of all necessary materials, such as copper foil, laminate sheets, solder mask, and components, needed for the manufacturing of PCBs. This system requires efficient coordination between suppliers and the PCB manufacturer to ensure timely delivery and high-quality materials. Additionally, proper management of inventory levels and cost control are essential components of the procurement system to ensure smooth and cost-effective production of PCBs.

9.Does PCB comply with ROHS standards?

Many PCB (Printed Circuit Board) manufacturers and products aim to comply with RoHS (Restriction of Hazardous Substances) standards. RoHS is a regulation that restricts the use of certain hazardous materials, such as lead, mercury, and cadmium, in electronic and electrical equipment. Compliance with RoHS standards is crucial for environmental and safety reasons, as it helps reduce the use of harmful substances in electronics and their potential impact on health and the environment. However, RoHS compliance can vary between manufacturers and specific PCB products, so it's essential to verify compliance with the relevant regulations and standards for a particular PCB product.

10.About PCB raw materials

PCB (Printed Circuit Board) raw materials refer to the base materials used in the manufacturing of electronic circuit boards. These materials typically include copper-clad laminates, solder mask, silkscreen, and various types of coatings and films. The selection of high-quality raw materials is crucial for ensuring the functionality, durability and reliability of PCBs, which are the backbone of electronic devices. Different applications require different types of raw materials, such as high-speed signal transmission, thermal management, and environmental protection. With the constant advancement of technology, the demand for more innovative and sustainable PCB raw materials continues to rise, driving the development of the electronics industry towards a more efficient and eco-friendly future.

11.About the development history of PCB factory

The development of PCB factories can be traced back to the early 20th century when the first commercial prototype of a printed circuit board was created. Since then, the demand for PCBs has continuously increased due to the rapid growth of technology and the need for more efficient and compact electronic devices. In the 1950s, industry giants such as IBM and RCA began using PCBs in their electronic products, leading to the mass production of PCBs in the 1960s. The 1970s saw the introduction of computer-aided design and manufacturing technology, making the production of PCBs faster and more cost-effective. In the 1980s, surface mount technology revolutionized PCB production, making it possible to create smaller and more complex boards. The 1990s saw the rise of offshore PCB manufacturing, with China becoming a major player in the industry. Today, PCB factories continue to innovate and evolve, utilizing advanced technology and implementing sustainable practices to meet the growing demands of the electronics industry.

12.What is the difference between PCB FasTechCircuit vs PCB ASRock vs PCB Gigabyte

The choice between these manufacturers should be based on your specific project requirements. PCB FasTechCircuit is suitable for fast prototyping, while PCB ASRock and PCB Gigabyte are trusted options for high-quality components in computer hardware. Your decision should align with the objectives and needs of your project.

13.About PCB production capacity

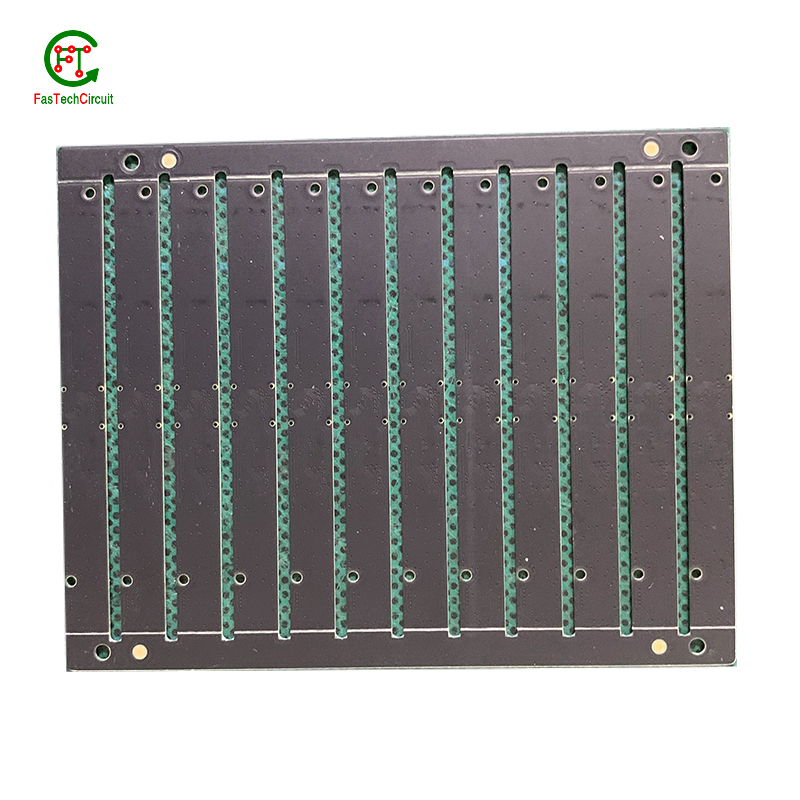

PCB production capacity refers to the maximum quantity of printed circuit boards (PCBs) that a manufacturer is able to produce within a given timeframe. This not only includes the physical space and equipment available for production, but also considers factors such as production time, manpower, and efficiency. A high production capacity allows for a larger volume of PCBs to be manufactured, meeting the demands of customers and addressing the growing market for electronic devices. Advances in technology and process optimization have continually increased PCB production capacity, allowing for more efficient and cost-effective production processes.

14.About PCB origin

PCB, short for Printed Circuit Board, is one of the essential components in electronic devices. It serves as a foundation and support for electronic components, allowing them to be connected and work together. The origin of PCB can be traced back to the early 20th century when people found a need to create a more efficient and reliable way to connect, mount, and organize electronic components. Over time, with the development of technology and manufacturing processes, PCB has become an integral part of modern electronic devices, making our daily lives more convenient and connected. Today, PCBs are widely used in various industries, from consumer electronics to medical equipment, highlighting their critical role and contribution to the advancement of technology.

15.Does the PCB have special anti-seismic design?

PCB (Printed Circuit Board) products typically do not have special anti-seismic designs as their primary function is to provide electrical connections and support for electronic components. Anti-seismic considerations are generally addressed at the system level in applications like industrial equipment, automotive electronics, or aerospace systems, where the entire system's design may incorporate anti-seismic measures to ensure stability and functionality during mechanical stress or vibrations. While PCBs themselves are not designed for anti-seismic purposes, they are integrated into systems that may have such protection in place to prevent damage or malfunction during seismic events.

16.How much voltage can PCB products withstand?

The voltage that PCB (Printed Circuit Board) products can withstand varies depending on several factors, including the design, materials, and intended application. PCBs are typically designed to withstand voltages ranging from a few volts to several hundred volts. Low-power electronic devices may have PCBs that can handle lower voltages, while high-power applications, such as power distribution or industrial equipment, may require PCBs designed to withstand higher voltages. Designers consider factors like insulation, spacing, and dielectric strength when determining the voltage tolerance of a PCB to ensure safe and reliable operation within its specified limits.

17.About PCB quality system

The PCB quality system is a comprehensive and structured approach to ensuring the quality of printed circuit boards. It encompasses various processes and procedures, from design and manufacturing to testing and inspection, to ensure that the final product meets the required standards and specifications. By implementing a robust quality system, manufacturers can achieve consistent and reliable quality, reduce defects and errors, and ultimately deliver high-quality PCBs that meet the expectations of their customers. This system is crucial in the electronics industry, as PCBs are integral components in most electronic devices and their quality can greatly impact the performance and reliability of these devices.

18.About PCB payment method

The PCB (Printed Circuit Board) payment method is a type of electronic payment method that utilizes a pre-printed circuit board with integrated circuits to process transactions. This method allows users to make secure payments using electronic cards, such as credit or debit cards, by simply inserting or swiping the card into a terminal. PCB payment systems are widely used in retail, hospitality, and other industries, providing a fast and efficient way to process transactions and reduce the risk of fraud. With the rise of technology, PCB payments are becoming increasingly popular due to their convenience, security, and ease of use.

19.About PCB production equipment

Printed Circuit Board (PCB) production equipment refers to a set of machinery and tools used in the manufacturing process of PCBs. These equipment include machines for etching, drilling, plating, soldering, and testing of printed circuit boards. They are crucial for automating and streamlining the production process, ensuring the efficiency and accuracy of PCB manufacturing. With the continuous advancements in technology, the PCB production equipment has also evolved, becoming more advanced and sophisticated, allowing for the production of high-quality and complex PCBs. This equipment is essential in the electronics industry, as it enables the efficient production of electronic devices that are vital to our daily lives.

RELATED NEWS

pcb board manufacturing How To Contact US

PCB from 1 to 30 layers, HDI, Heavy Copper, Rigid-flex board with "pcb board manufacturing One-Stop" service.