What is the process of PCB fabrication and assembly?

1. High Quality and Reliability

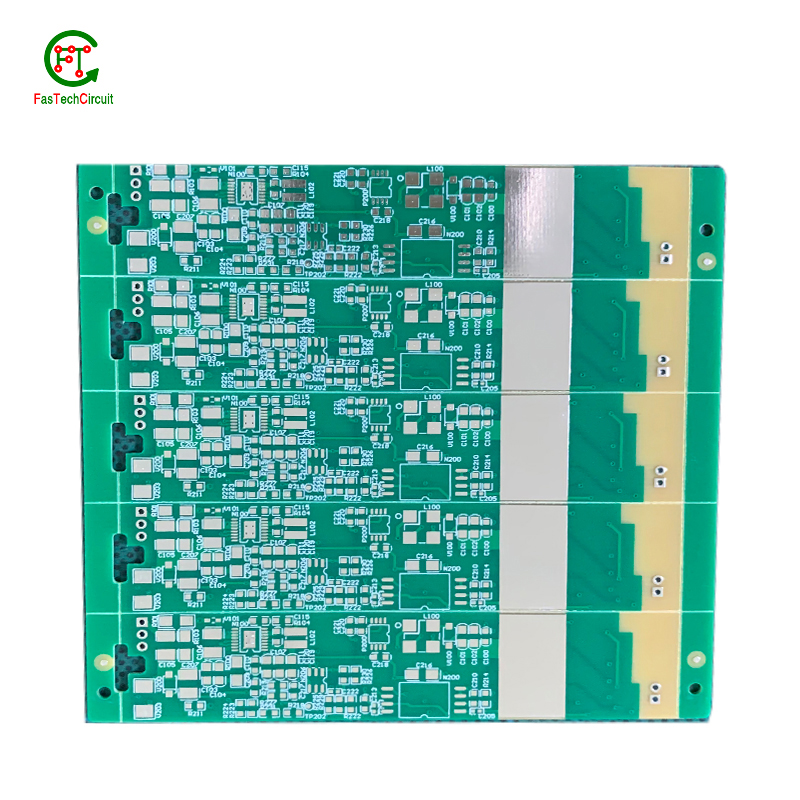

One of the major advantages of PCB assembly is its high-quality and reliability. With the use of advanced manufacturing processes, precise equipment, and strict quality control measures, PCB assembly products are built to withstand various environmental conditions and have a longer lifespan. This ensures that the devices will function reliably and consistently, meeting the expectations of customers.

2. Increased Efficiency

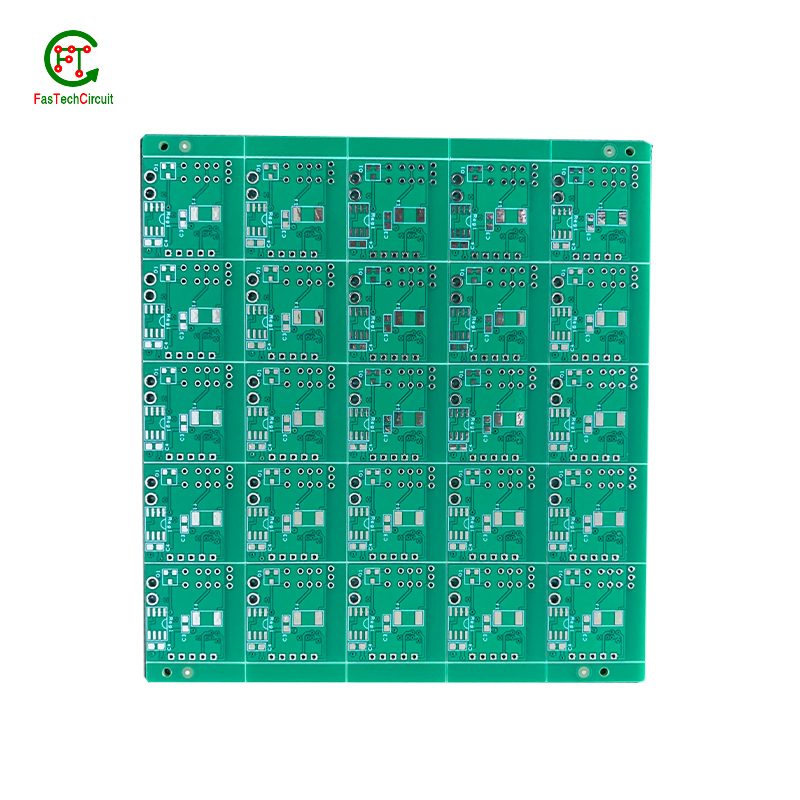

Compared to traditional manual assembly methods, PCB assembly has significantly increased efficiency. The use of automated equipment, such as pick and place machines and soldering machines, has greatly improved the speed and accuracy of assembly. This results in a quicker turnaround time and increased productivity, allowing for larger quantities of PCBs to be produced in a shorter amount of time.

3. Cost-Effectiveness

PCB assembly offers a cost-effective solution for electronic device production. The use of automated equipment reduces the need for manual labor, resulting in lower labor costs. Additionally, the use of high-quality materials and efficient processes leads to fewer defective products, reducing the cost of rework or replacement.

4. Miniaturization

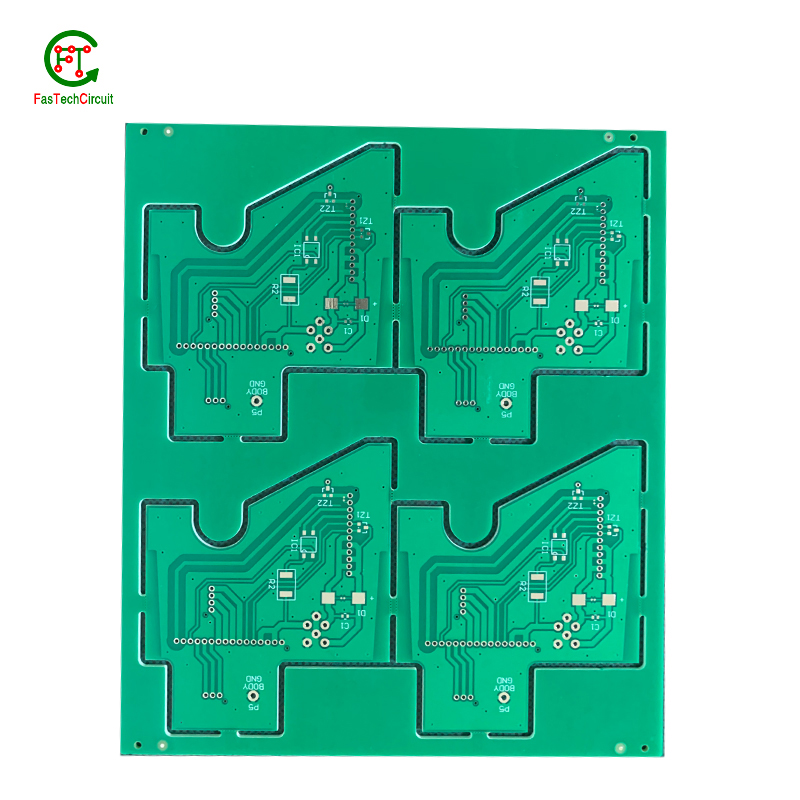

PCB assembly allows for miniaturization of electronic devices. The use of smaller components and sophisticated placement techniques enables the production of compact and lightweight devices without compromising their functionality. This is particularly beneficial for portable devices, as it makes them more convenient and user-friendly.

5. Customization

Another advantage of PCB assembly is that it allows for customization. Electronic devices can be designed and assembled according to specific requirements, such as size, shape, and functionality. This flexibility is especially beneficial for industries that require tailor-made products to meet their unique needs.

In comparison, traditional methods of manufacturing electronic devices, such as hand soldering, may result in lower quality, longer production times, and higher costs. PCB assembly offers significant advantages in terms of quality, efficiency, cost-effectiveness, miniaturization, and customization, making it the preferred method of electronic device production. With its continued advancements and innovations, we can expect PCB assembly to play a crucial role in the future of the electronics industry.

PCB assembly is crucial in the electronics industry as it enables the production of complex and compact electronic devices. This process also allows for easy and efficient repairs and upgrades to electronic products, making them more sustainable and cost-effective.

The demand for smaller and more powerful consumer electronics has increased the importance of efficient and effective PCB assembly. This process involves utilizing surface mount technology (SMT) and through-hole assembly methods to create compact and high-performance electronic products. With the use of automated equipment, the assembly process has become faster and more precise, enabling the production of a large number of products in a shorter period of time.

PCB assembly is the process of assembling electronic components onto printed circuit boards (PCBs). It plays a critical role in the production of various electronic devices, from household appliances to advanced industrial equipment. However, as technology advances and the demand for higher quality products increases, there are often concerns and questions regarding the PCB assembly process. In this FQA (Frequently Asked Questions) section, we will address some commonly asked questions to provide a better understanding of PCB assembly.

2.What is PCB standards?

3.What is PCB layout?

4.What is the standard for PCB assembly?

5.Why is PCB poor?

6.What is the raw material of PCB assembly?

1.Which country made PCB?

PCB (Printed Circuit Board) technology was first developed and patented by Austrian engineer Paul Eisler in 1936. However, the first commercial use of PCBs was in the United States in the 1950s. Today, PCBs are manufactured in many countries around the world, including China, Japan, South Korea, Taiwan, Germany, and the United States.

2.What is PCB standards?

PCB standards refer to a set of guidelines and specifications that define the design, manufacturing, and testing requirements for printed circuit boards (PCBs). These standards ensure that PCBs are produced consistently and meet certain quality and performance criteria. They cover various aspects of PCB production, including materials, layout, trace width and spacing, hole sizes, solder mask, and testing methods. Adhering to PCB standards helps to ensure the reliability, functionality, and safety of electronic devices that use PCBs. Some common PCB standards include IPC-2221, IPC-A-600, and UL 796.

3.What is PCB layout?

PCB layout, also known as printed circuit board layout, is the process of arranging electronic components and their connections on a printed circuit board (PCB). It involves designing the physical layout of the PCB, including the placement of components, routing of electrical connections, and placement of other elements such as power and ground planes, signal traces, and mounting holes. The goal of PCB layout is to create a functional and efficient circuit board that meets the electrical and mechanical requirements of the electronic device it will be used in. This process is typically done using specialized software and requires knowledge of electronics, circuit design, and manufacturing processes.

4.What is the standard for PCB assembly?

The standard for PCB assembly is IPC-A-610, which is published by the Association Connecting Electronics Industries (IPC). This standard outlines the acceptability criteria for electronic assemblies, including PCBs, and covers topics such as component placement, soldering, cleanliness, and other quality requirements. It is widely used in the electronics industry to ensure consistent and high-quality PCB assembly processes.

5.Why is PCB poor?

There are a few reasons why PCB (Printed Circuit Board) may be considered poor: 1. Cost: PCBs can be expensive to manufacture, especially for small quantities or complex designs. This can make them less accessible for smaller companies or individuals. 2. Complexity: PCBs can be difficult to design and manufacture, especially for more complex circuits. This can lead to errors or defects in the final product. 3. Fragility: PCBs are made of thin layers of materials and can be easily damaged if mishandled or exposed to extreme conditions. This can make them less reliable and require frequent replacements. 4. Environmental impact: The production of PCBs involves the use of toxic chemicals and materials, which can have a negative impact on the environment if not properly disposed of. 5. Limited flexibility: PCBs are rigid and cannot be easily bent or shaped, making them less suitable for certain applications that require flexibility. 6. Limited customization: Once a PCB is manufactured, it is difficult to make changes or modifications to the design. This can be a disadvantage for products that require frequent updates or changes. 7. Limited scalability: PCBs are designed for specific applications and may not be easily scalable for different sizes or configurations. This can limit their use in different products or industries.

6.What is the raw material of PCB assembly?

The raw material of PCB assembly includes: 1. Copper-clad laminate (CCL): This is the base material of the PCB, which is made of layers of fiberglass cloth and epoxy resin with a thin layer of copper on one or both sides. 2. Copper foil: This is the thin layer of copper that is laminated onto the CCL to create the conductive traces and pads on the PCB. 3. Solder mask: This is a layer of polymer resin that is applied over the copper traces to protect them from oxidation and to prevent solder from flowing onto unwanted areas during the assembly process. 4. Silk screen: This is a layer of ink that is applied over the solder mask to add labels, symbols, and other markings to the PCB. 5. Solder paste: This is a mixture of solder alloy particles and flux that is used to attach electronic components to the PCB. 6. Electronic components: These include resistors, capacitors, diodes, transistors, integrated circuits, and other electronic devices that are mounted onto the PCB. 7. Adhesives: These are used to bond components to the PCB and to hold the layers of the PCB together. 8. Flux: This is a chemical substance that is used to clean and prepare the surfaces of the PCB and components for soldering. 9. Solder: This is a metal alloy that is melted and used to create electrical connections between components and the PCB. 10. Lead-free materials: In some cases, lead-free materials may be used in the PCB assembly process to comply with environmental regulations. These materials include lead-free solder, lead-free components, and lead-free flux.

RELATED NEWS

pcb board manufacturing How To Contact US

PCB from 1 to 30 layers, HDI, Heavy Copper, Rigid-flex board with "pcb board manufacturing One-Stop" service.