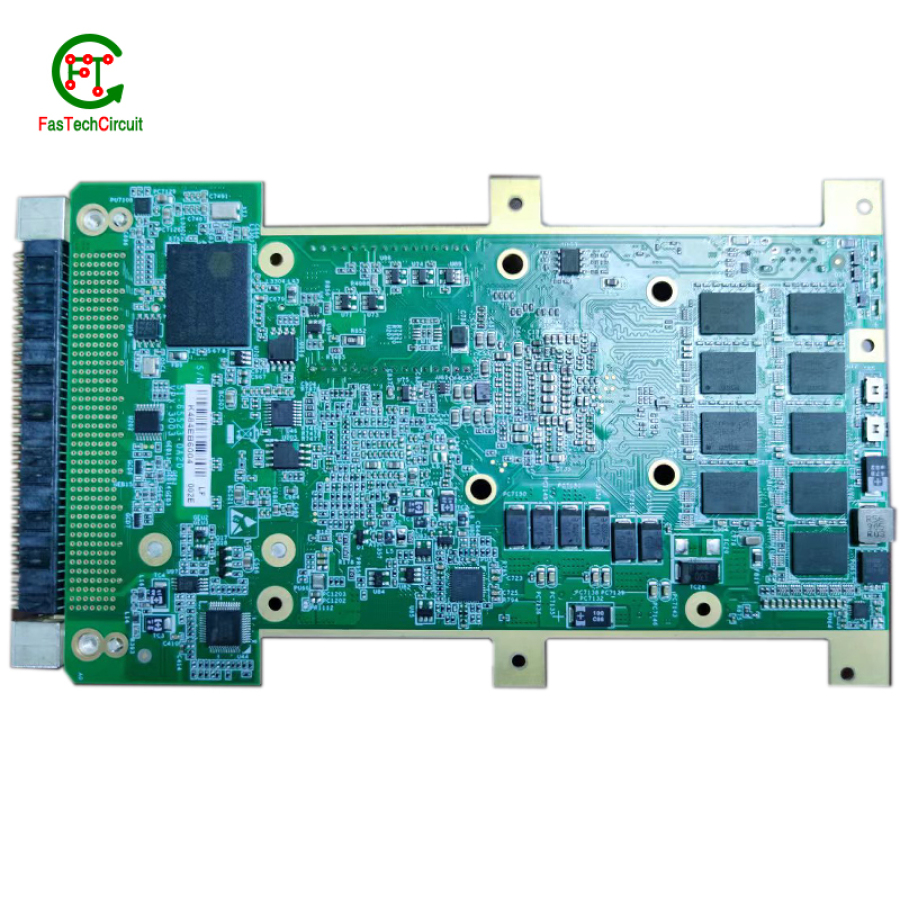

fast pcb

With the continuous development of information technology, the application range of electronic products is becoming wider and wider. As the core component of electronic products, the manufacturing technology of circuit boards is also constantly improving. Among them, FasTechCircuit is a PCB and PCBA supplier in more than 50 countries and more than 4,000 customers. Its rapid circuit board manufacturing technology is one of the emerging technologies in the circuit board industry in recent years. important link in manufacturing.

1. The development history of fast circuit board manufacturing technology

Fast circuit board manufacturing technology originated in the late 1960s, when electronics manufacturing companies in the United States and Europe began to explore the use of photosensitive resin plates, copper foil and chemical etching to manufacture circuit boards. With the continuous development of computer and automation technology, rapid circuit board manufacturing technology has been developed rapidly. In the 1980s, fast circuit board manufacturing technology has become an important technology in the circuit board industry, which can meet the needs of fast and efficient production.

2.Second, the principle of fast circuit board manufacturing technology

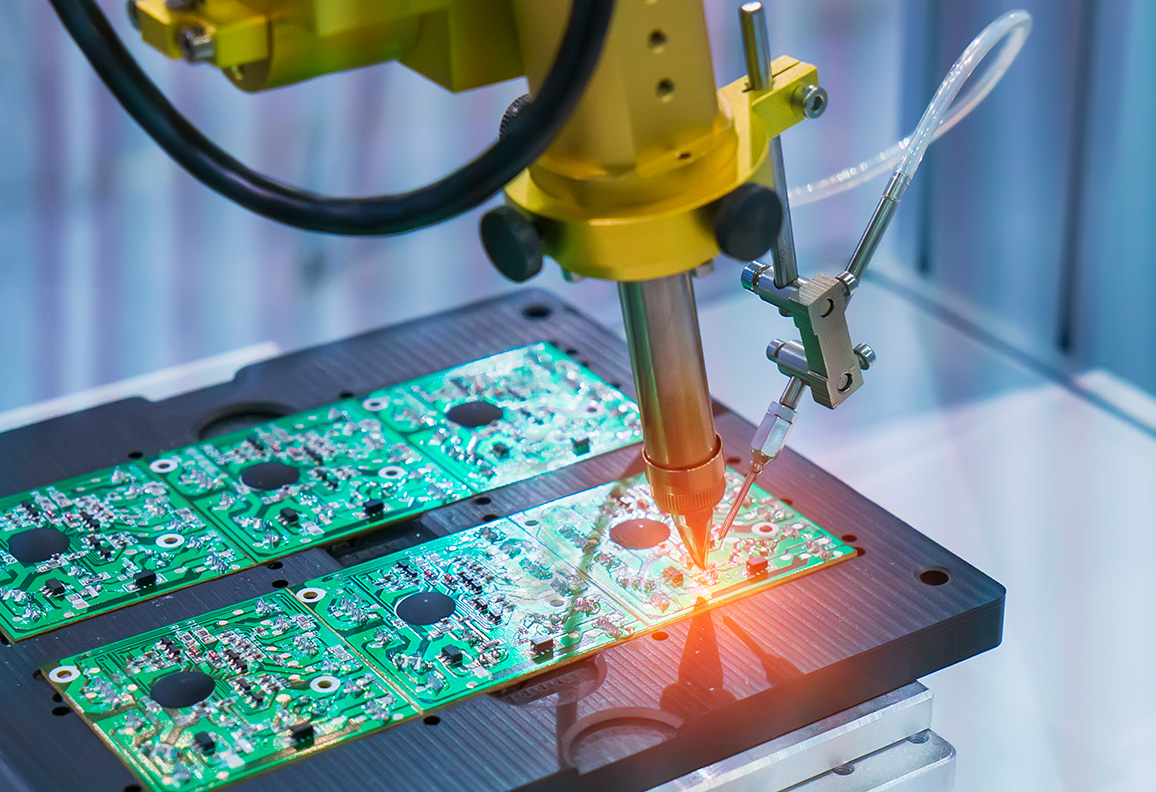

Rapid circuit board manufacturing technology adopts advanced computer-aided design (CAD) and computer-aided manufacturing (CAM) technology, through the steps of circuit board CAD drawing, circuit board CAM processing, circuit board molding and circuit board printing, etc., to realize the rapid manufacturing of circuits board purpose.

The main steps of rapid circuit board manufacturing technology include:

(1). Circuit board CAD drawing: use computer software to design and draw circuit boards, including circuit board circuit diagrams, dimensions, apertures, copper foil thickness and other parameters.

(2). Circuit board CAM processing: According to the circuit board drawing drawn by CAD, the photoplotter or laser plotter is controlled by computer program to make photosensitive resin board and copper foil covering.

(3). Circuit board forming: According to the circuit board drawing drawn by CAD, the copper foil and photosensitive resin board are made into the required circuit board shape through chemical etching or mechanical processing.

(4). Circuit board printing: The computer program controls the circuit board printing machine for printing, and prints the logo, text, graphics, etc. of the circuit board.

3. Advantages of fast circuit board manufacturing technology

Compared with traditional circuit board manufacturing technology, rapid circuit board manufacturing technology has the following advantages:

(1). Fast: Rapid circuit board manufacturing technology adopts advanced CAD and CAM technology, which can quickly produce circuit boards and improve production efficiency and production speed.

(2). High efficiency: Fast circuit board manufacturing technology can realize automatic production, reduce the possibility of manual operation and error, and improve production efficiency.

(3). Low cost: Fast circuit board manufacturing technology adopts low-cost processes such as photosensitive resin board and chemical etching, which can save production costs and improve the competitiveness of enterprises.

(4). High precision: Rapid circuit board manufacturing technology adopts advanced CAD and CAM technology, which can realize high-precision circuit board manufacturing and improve the quality and reliability of circuit boards.

4. Application fields of fast circuit board manufacturing technology

Rapid circuit board manufacturing technology has been widely used in the field of electronic product manufacturing, such as:

(1). Communication equipment: The circuit boards in communication equipment such as mobile phones, routers, and switches all adopt fast circuit board manufacturing technology to meet the requirements of high-speed communication.

(2). Computer equipment: Circuit boards such as motherboards and graphics cards in computer equipment such as notebook computers and desktop computers also use fast circuit board manufacturing technology to meet the needs of high-performance computing.

(3). Home appliances: The circuit boards in TVs, DVDs, audio and other home appliances also use fast circuit board manufacturing technology to meet the requirements of product miniaturization and multi-function.

5.Five, the development trend of fast circuit board manufacturing technology

In the future, rapid circuit board manufacturing technology will also face the following development trends:

(1). High density: With the miniaturization and high performance of electronic products, fast circuit board manufacturing technology will pay more attention to realizing high density of circuit boards and improving the performance and reliability of circuit boards.

(2). High speed: With the continuous development of communication technology, fast circuit board manufacturing technology will pay more attention to realizing high speed of circuit board and improving the performance and speed of communication equipment.

(3). Multi-layering: With the multi-functionalization of electronic products, rapid circuit board manufacturing technology will pay more attention to realizing the multi-layering of circuit boards and improving the functions and performance of circuit boards.

(4). Greening: With the continuous improvement of environmental protection awareness, rapid circuit board manufacturing technology will pay more attention to realizing the greening of circuit boards and reducing environmental pollution.

Rapid circuit board manufacturing technology is an important link in the manufacture of electronic products, and has the advantages of rapidity, high efficiency, and low cost. In the future, with the development of electronic products and technological progress, fast circuit board manufacturing technology will also continue to improve and develop, becoming an important technology in electronic product manufacturing.

RELATED NEWS

pcb board manufacturing How To Contact US

PCB from 1 to 30 layers, HDI, Heavy Copper, Rigid-flex board with "pcb board manufacturing One-Stop" service.