What is PCBA and how does it play a crucial role in electronic device manufacturing?

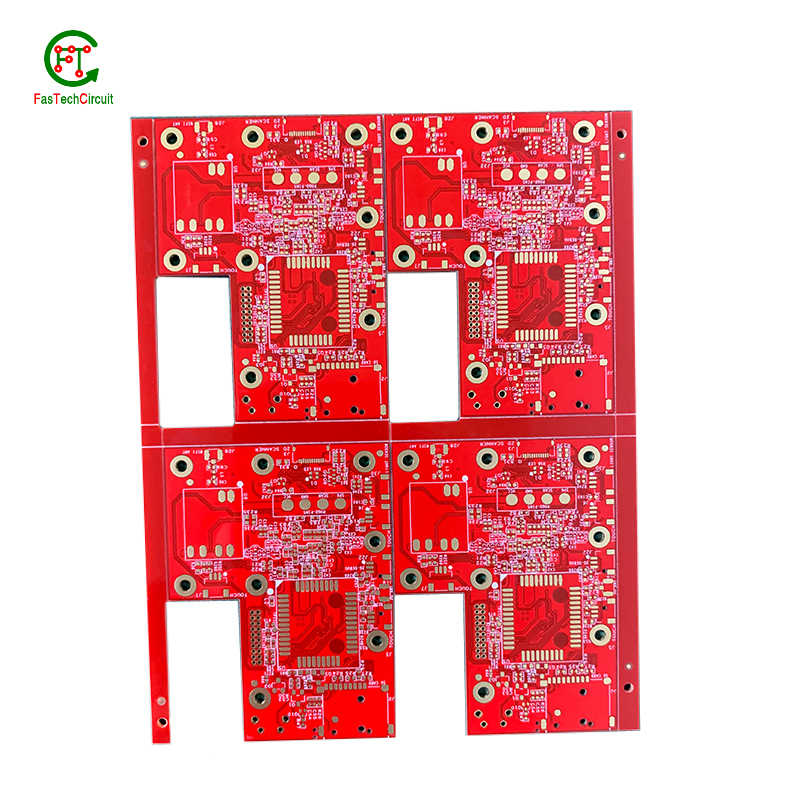

PCBA, which stands for Printed Circuit Board Assembly, is a vital process in electronic device manufacturing. It involves the assembly of electronic components onto a printed circuit board (PCB) to create a functional electronic device. PCBA plays a crucial role in the overall manufacturing process and contributes significantly to the quality, functionality, and reliability of electronic devices. In this article, FasTechCircuit will explore what PCBA is and its importance in electronic device manufacturing.

What is PCBA?

Hot Tags: About FasTechCircuit ,More products

PCBA refers to the process of soldering electronic components, such as resistors, capacitors, integrated circuits, and connectors, onto a PCB. The PCB acts as a supportive base for these components and provides electrical connectivity between them. The PCBA process involves various steps, including component placement, soldering, inspection, and testing, to ensure the proper functioning of the assembled electronic device.

Importance of PCBA in Electronic Device Manufacturing

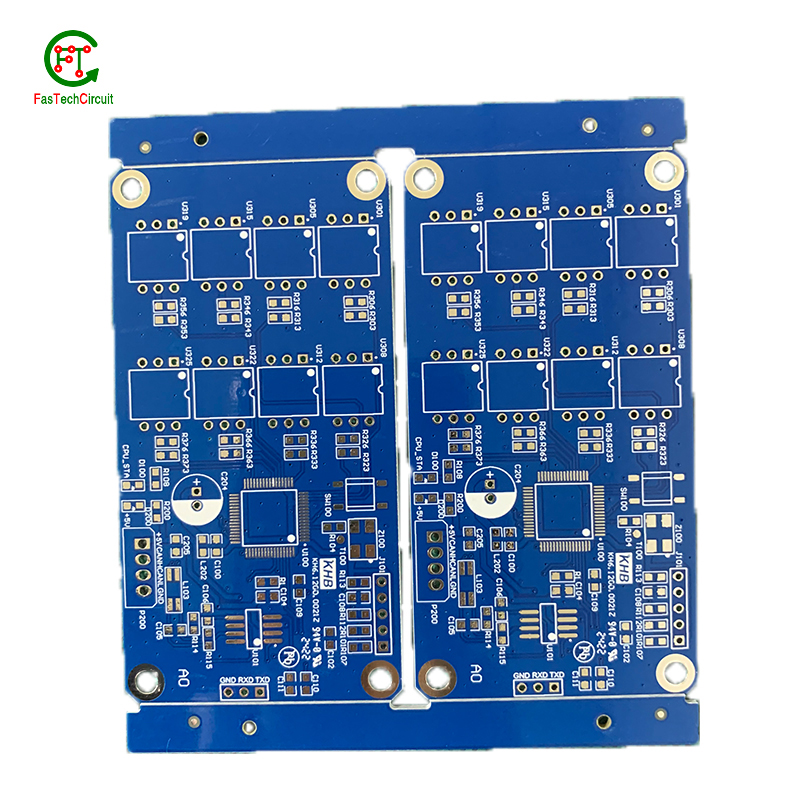

1. Electrical Connectivity: The PCBA process is crucial for establishing electrical connections between the components on the PCB. The PCB acts as a platform where different electrical components are mounted and interconnected through conductive traces. These traces provide pathways for the flow of electrical signals, enabling the device to perform its intended functions.

2. Component Integration: PCBA allows for the integration of various electronic components onto a single PCB. This integration reduces the space required for electronic circuits, making the devices compact and lightweight. By assembling multiple components onto a single PCB, the overall size of the electronic device is reduced, making it more portable and convenient for users.

3. Signal Integrity: The PCBA process plays a significant role in maintaining the signal integrity of electronic devices. Proper soldering techniques and careful component placement ensure that electrical signals can flow smoothly without interference or signal loss. This is especially crucial for high-speed digital circuits, where even minor signal distortions can result in data errors or malfunctioning.

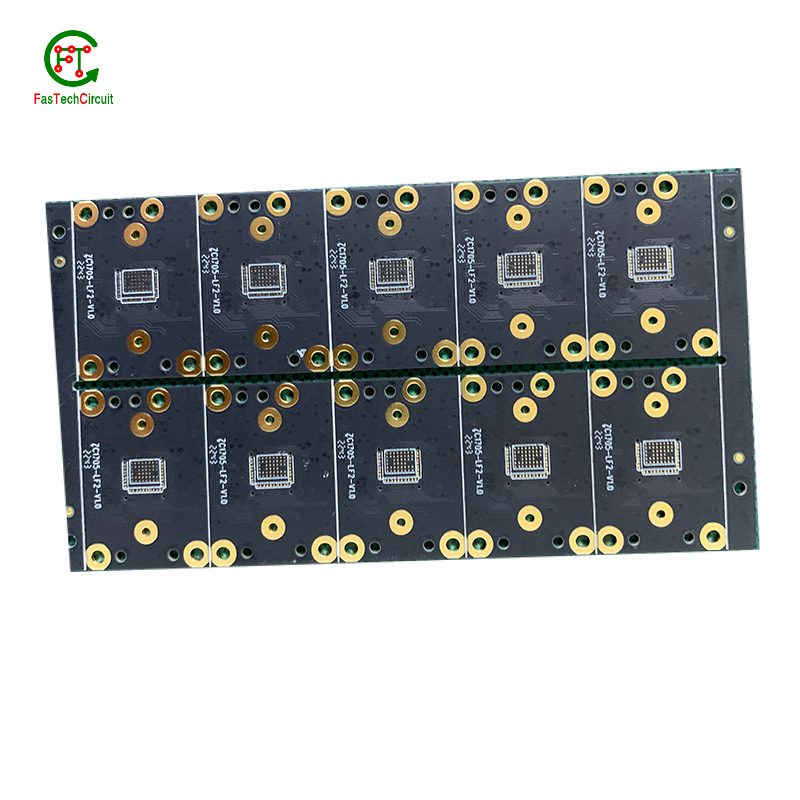

4. Manufacturing Efficiency: PCBA allows for efficient and streamlined manufacturing processes. By automating component placement and soldering processes, manufacturers can achieve high levels of precision, consistency, and speed in assembly. This leads to increased productivity, reduced labor costs, and faster time-to-market for electronic devices.

5. Quality Control: The PCBA process includes thorough inspection and testing procedures to ensure the quality and reliability of the assembled electronic devices. Visual inspections, automated optical inspections, and in-circuit testing are performed to detect and rectify any defects or issues. These quality control measures help to minimize the chances of faulty devices reaching the market, enhancing customer satisfaction and brand reputation.

6. Repair and Upgradability: PCBA allows for easier repair and upgradability of electronic devices. In case of component failures or the need for upgrades, faulty components can be replaced or additional components can be added to the PCB. This flexibility in repair and upgradability extends the lifespan of electronic devices and reduces electronic waste.

7. Cost-Effective Manufacturing: PCBA enables cost-effective manufacturing by optimizing production processes, reducing material waste, and utilizing automated assembly techniques. By automating repetitive tasks and minimizing human error, manufacturers can achieve higher yields and lower production costs. This cost-effectiveness translates into competitive pricing for electronic devices in the market.

In conclusion, PCBA is a crucial process in electronic device manufacturing. It enables the assembly of electronic components onto a PCB, ensuring electrical connectivity, integration, signal integrity, manufacturing efficiency, quality control, repairability, upgradability, and cost-effectiveness. PCBA plays a significant role in ensuring the quality, functionality, and reliability of electronic devices, ultimately contributing to customer satisfaction and the success of electronic device manufacturers.

RELATED NEWS

pcb board manufacturing How To Contact US

PCB from 1 to 30 layers, HDI, Heavy Copper, Rigid-flex board with "pcb board manufacturing One-Stop" service.