Overcoming challenges in designing for high-density routing

pcb assembling is usually made of fiberglass, plastic and other materials. It has good insulation properties and can effectively avoid short circuits between circuit components.

Optimizing PCB layout: the key to improving circuit performance

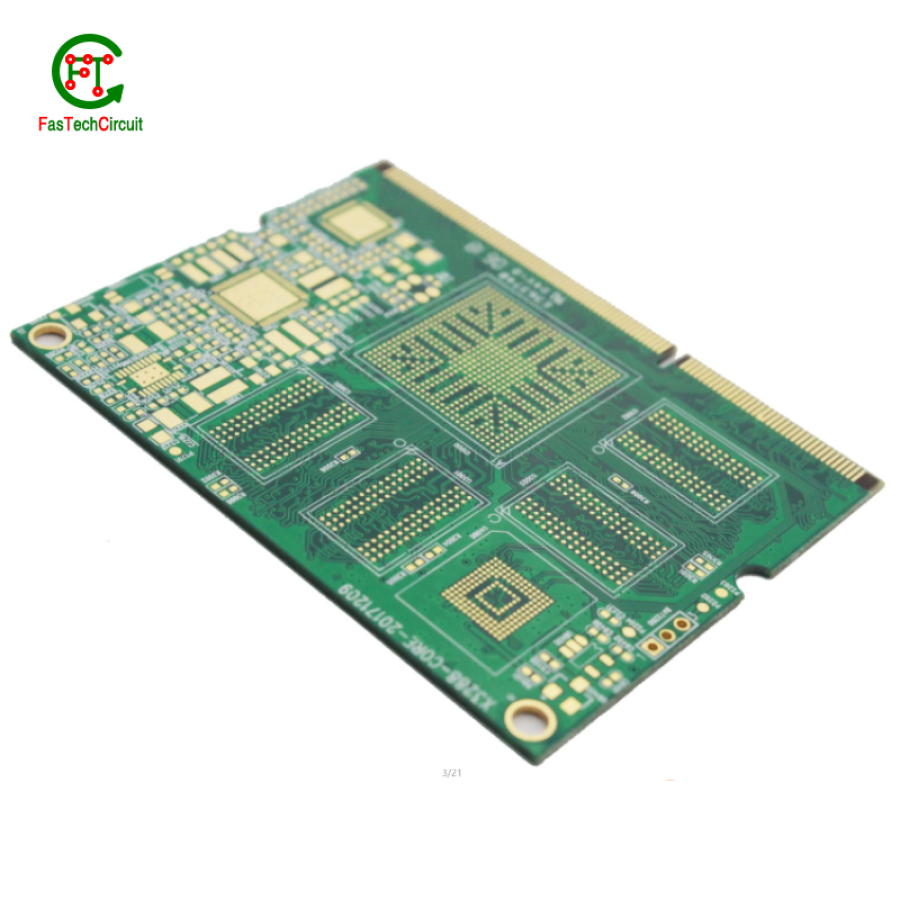

Our PCB products are designed to support high-speed signal transmission, allowing for faster data transfer rates and improved overall system performance.

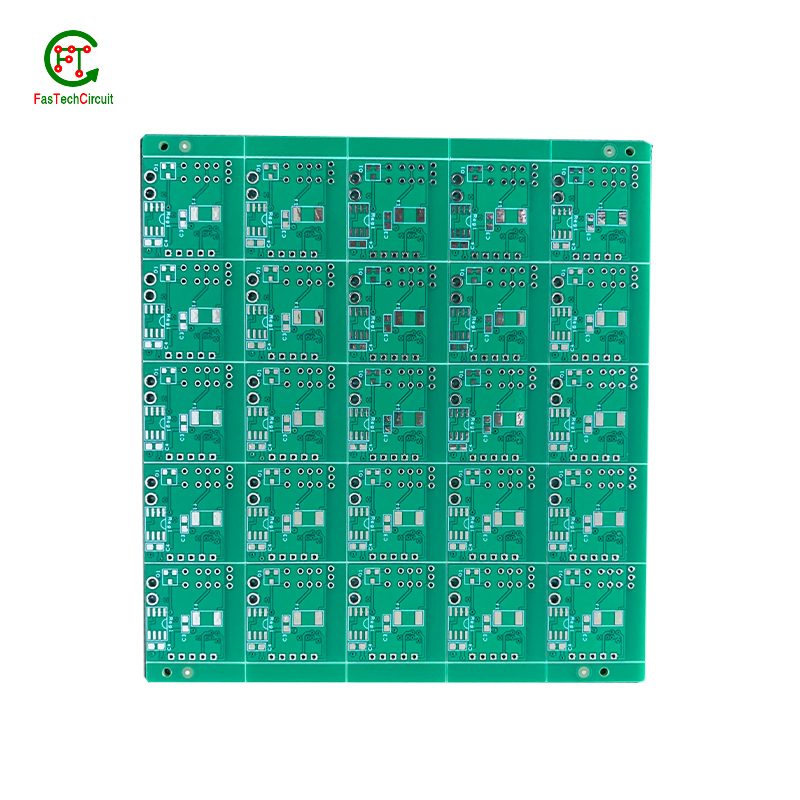

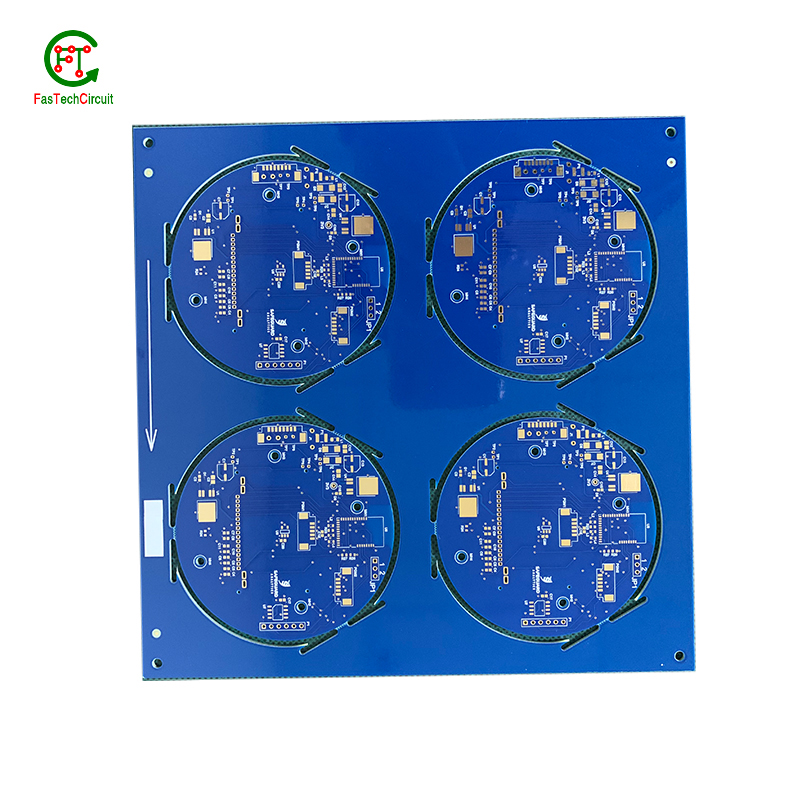

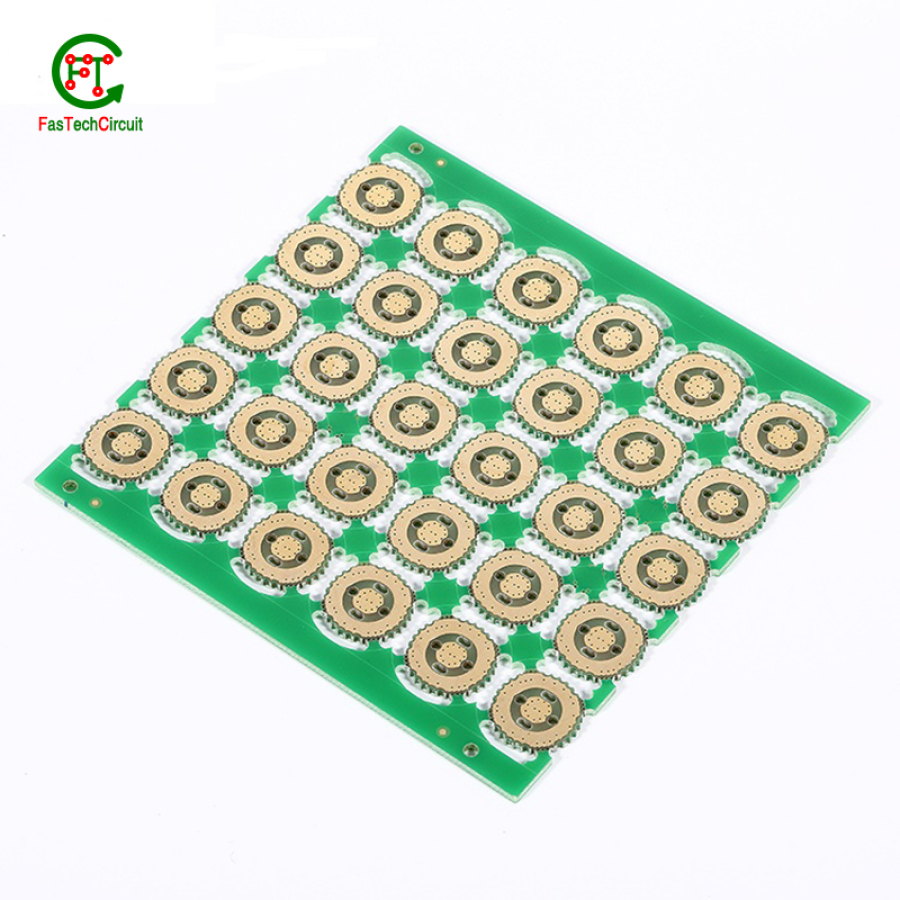

By utilizing advanced manufacturing techniques and high-density component placement, our PCB products are able to achieve compact and lightweight designs, saving valuable space in electronic devices.

PCB--An Ultimate FAQ Guide.

2.How many layers of circuits does a PCB product have?

3.About PCB production management system

4.How is the circuit layout of PCB products designed?

5.Are PCB products waterproof?

6.What electronic components can this PCB product support?

7.Is this PCB product single-sided or double-sided?

8.What is the thickness of the PCB product?

9.How long is the service life of PCB products?

10.Is the PCB UL certified?

11.About the development history of PCB factory

12.Do PCB products use environmentally friendly materials?

13.About PCB origin

14.What materials are used in this PCB product?

15.About PCB warranty

16.About PCB patent

17.About PCB quality system

18.Does the PCB have radio frequency shielding properties?

19.What are the dimensions of PCB products?

20.How much voltage can PCB products withstand?

21.About PCB raw material procurement system

1.What is the operating temperature of PCB?

The operating temperature of a PCB (Printed Circuit Board) can vary depending on its design, materials, and intended application. PCBs are typically specified with an operating temperature range that indicates the temperatures at which they can safely and reliably function. Common temperature ranges for standard PCBs in electronic devices are -40°C to 85°C or 0°C to 70°C. However, for specialized applications, such as industrial or automotive electronics, PCBs may have wider operating temperature ranges, extending from -40°C to 125°C or higher. The choice of temperature range depends on the intended application and environmental conditions in which the PCB will be used, ensuring that it can withstand the required temperature extremes without degradation in performance.

2.How many layers of circuits does a PCB product have?

The number of layers in a PCB (Printed Circuit Board) product can vary widely and is determined by the complexity of the electronic circuit it serves. PCBs can have a single layer (single-sided), two layers (double-sided), or multiple layers, often referred to as multilayer PCBs. Multilayer PCBs can have three or more layers, with some advanced designs featuring more than 20 layers. The choice of the number of layers depends on the specific requirements of the electronic system, including the complexity of the circuit, the need for signal integrity, and space constraints. Multilayer PCBs are commonly used in complex electronic devices, such as smartphones, computers, and industrial equipment, where they provide the necessary space for intricate circuits and connections.

3.About PCB production management system

The PCB production management system is an advanced and comprehensive software solution designed to streamline and optimize the production process of printed circuit boards. This system offers a centralized platform for tracking, managing and monitoring all stages of the production cycle, from design and material procurement to assembly and testing. By implementing this system, PCB manufacturers can increase efficiency, reduce errors and boost productivity. It also provides real-time visibility into production progress, inventory levels, and quality control, allowing for better decision-making and quicker response to any issues that may arise. With its user-friendly interface and powerful features, the PCB production management system is a valuable tool for modern production facilities seeking to stay competitive in the ever-evolving electronics industry.

4.How is the circuit layout of PCB products designed?

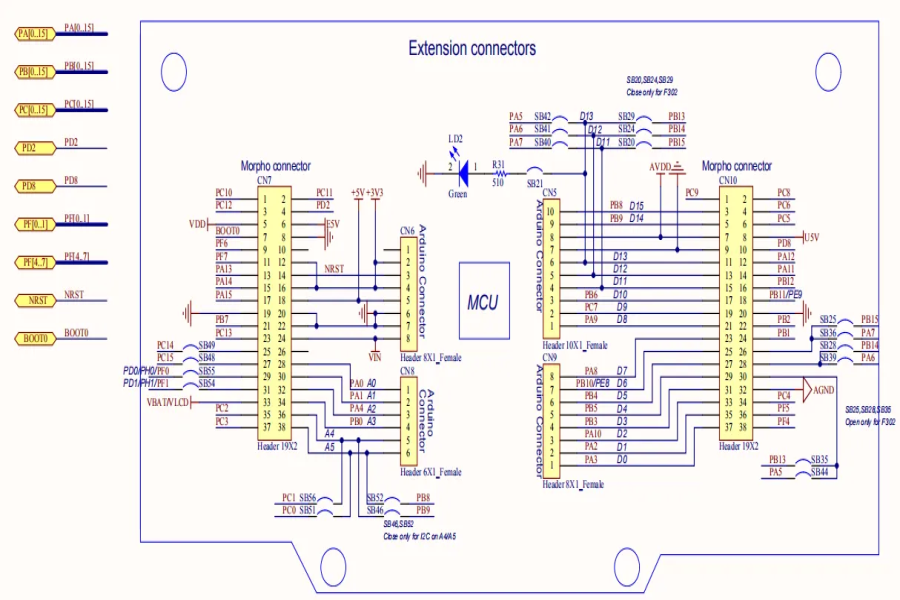

The design of the circuit layout for PCB (Printed Circuit Board) products is a meticulous process that involves the placement and interconnection of electronic components to create a functional circuit. Designers use specialized software to arrange components on the board, optimize signal flow, and ensure efficient use of space. Factors like component placement, signal traces, power distribution, and signal integrity are considered during the design process. The goal is to create an organized and efficient layout that minimizes signal interference, maximizes functionality, and meets the specific requirements of the electronic system. The final circuit layout is a critical aspect of PCB design, ensuring the reliable performance of the electronic device or system.

5.Are PCB products waterproof?

PCB (Printed Circuit Board) products are not inherently waterproof, but they can be made water-resistant or waterproof by applying specific protective measures during the design and manufacturing process. Water-resistant PCBs are often coated with conformal coatings or encapsulated in waterproof housings to shield them from moisture and environmental factors. The degree of waterproofing can vary, with some PCBs designed to withstand exposure to water and others being more water-resistant. The level of protection depends on the intended application and the environmental conditions in which the PCB will operate. Waterproofing is crucial for applications where PCBs may be exposed to moisture, such as in outdoor electronics, automotive systems, and marine devices.

6.What electronic components can this PCB product support?

The capabilities of this PCB (Printed Circuit Board) product extend to supporting a wide array of electronic components. These components include but are not limited to integrated circuits (ICs), microcontrollers, resistors, capacitors, diodes, transistors, connectors, and various sensors. The PCB's design and layout are tailored to accommodate these components and establish electrical connections between them. This versatility enables the PCB to be used in a broad spectrum of electronic devices and systems, where it acts as the central hub for component integration and electrical functionality.

7.Is this PCB product single-sided or double-sided?

This PCB (Printed Circuit Board) product can be configured as either single-sided or double-sided, depending on the specific application and design requirements. Single-sided PCBs have circuitry on one side of the board, while double-sided PCBs feature electrical connections on both sides. The choice between single-sided and double-sided PCBs is made based on factors like the complexity of the circuit, space constraints, and cost considerations. This flexibility in design allows the PCB product to adapt to a variety of electronic applications, ensuring it can meet the needs of different projects and devices.

8.What is the thickness of the PCB product?

The thickness of a PCB (Printed Circuit Board) product can vary based on its design and intended application. PCBs are available in a range of thicknesses, typically measured in millimeters (mm) or mils (1 mil = 0.001 inches). Standard PCB thicknesses often include 0.8mm, 1.6mm, and 2.0mm, but custom thicknesses can be specified to meet specific requirements. Thicker PCBs provide greater mechanical rigidity and heat dissipation, while thinner ones are suitable for applications with space constraints. The choice of thickness depends on the PCB's function and the design needs of the electronic system it will be a part of.

9.How long is the service life of PCB products?

The service life of PCB (Printed Circuit Board) products can vary significantly depending on several factors, including the quality of materials, manufacturing processes, and the conditions under which the PCB is used. In many cases, well-designed and properly manufactured PCBs can have a service life of several years to decades. High-quality materials and careful assembly can contribute to longer-lasting PCBs. However, environmental factors, temperature extremes, humidity, and the level of wear and tear can impact the service life. For critical applications, extended service life is essential, and durability is a key consideration in the PCB's design and manufacturing process. Regular maintenance and proper handling can also help extend the life of PCB products.

10.Is the PCB UL certified?

UL (Underwriters Laboratories) certification is typically not associated with individual PCB (Printed Circuit Board) products. Instead, UL certification is generally applied to the end-use electronic equipment or devices in which PCBs are integrated. UL certification ensures that the entire electronic system complies with safety and performance standards. The PCB itself is just one component of the larger system. While PCB manufacturers may use materials and processes that meet UL requirements, the certification process focuses on the overall safety and performance of the complete electronic product, which includes the PCB. Therefore, PCBs are not UL certified on their own, but they contribute to the overall compliance of the electronic equipment in which they are used.

11.About the development history of PCB factory

The development of PCB factories can be traced back to the early 20th century when the technology for producing printed circuit boards was first invented. Over the years, with the advancements in electronics and manufacturing processes, the demand for PCBs grew rapidly. This led to the establishment of more specialized and efficient PCB factories, which played a crucial role in the development of modern electronics. With the introduction of more sophisticated machinery and techniques, these factories were able to mass produce high-quality PCBs at a faster pace, meeting the growing demand from various industries. Today, PCB factories continue to evolve and innovate, adopting new technologies such as automation and AI to streamline processes and produce higher quality and more complex circuit boards for the ever-expanding electronics market.

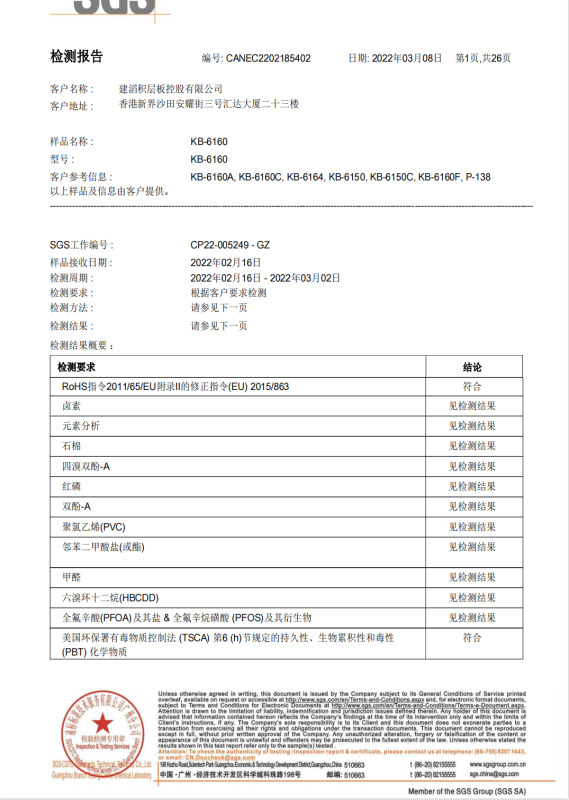

12.Do PCB products use environmentally friendly materials?

PCB (Printed Circuit Board) products can be manufactured using environmentally friendly materials and processes, depending on the manufacturer's practices and the specific requirements of the application. Environmentally friendly PCBs may incorporate lead-free solder materials, halogen-free substrates, and other eco-friendly alternatives. In many regions, there are regulations and standards, such as RoHS (Restriction of Hazardous Substances) directives, which require the reduction or elimination of hazardous materials in electronics, including PCBs. Manufacturers often aim to meet these environmental standards by using eco-friendly materials and processes in their PCB production. However, the extent to which a PCB product is environmentally friendly depends on the manufacturer's practices and adherence to such regulations.

13.About PCB origin

PCB, short for Printed Circuit Board, is one of the essential components in electronic devices. It serves as a foundation and support for electronic components, allowing them to be connected and work together. The origin of PCB can be traced back to the early 20th century when people found a need to create a more efficient and reliable way to connect, mount, and organize electronic components. Over time, with the development of technology and manufacturing processes, PCB has become an integral part of modern electronic devices, making our daily lives more convenient and connected. Today, PCBs are widely used in various industries, from consumer electronics to medical equipment, highlighting their critical role and contribution to the advancement of technology.

14.What materials are used in this PCB product?

The PCB (Printed Circuit Board) product utilizes a variety of materials in its construction to ensure efficient and reliable electronic connections. These materials typically include a non-conductive substrate (often made of fiberglass or other materials), a copper layer for electrical conductivity, solder mask for protection, and various components like resistors, capacitors, and integrated circuits. The specific materials and their quality play a crucial role in the performance and durability of the PCB, making it a critical component in electronic devices and systems.

15.About PCB warranty

PCB warranty refers to the guarantee provided by manufacturers for printed circuit boards (PCBs). It ensures that the PCBs are free from defects in materials and workmanship for a specific period of time. This warranty is important as it can protect customers from potential losses caused by product defects and provides assurance of quality and reliability. Customers should pay attention to the terms and conditions of the warranty when purchasing PCBs to fully understand their rights and responsibilities in case of any issues with the product.

16.About PCB patent

PCB patent refers to the legal protection granted to the design, technology, or invention related to printed circuit boards (PCBs). These patents not only protect the intellectual property of PCB manufacturers and designers, but also encourage innovation and development in the electronic industry. With the increasing demand for smaller and more advanced devices, PCB patents play a crucial role in safeguarding the rights of inventors and promoting the growth of the PCB market. However, obtaining a PCB patent can be a complex and lengthy process, involving multiple legal requirements and thorough examination. The enforcement of PCB patents also requires strict adherence to patent laws and regulations to protect against infringements. Overall, PCB patents are essential for fostering innovation and ensuring fair competition in the ever-evolving world of technology.

17.About PCB quality system

The PCB quality system is a comprehensive and structured approach to ensuring the quality of printed circuit boards. It encompasses various processes and procedures, from design and manufacturing to testing and inspection, to ensure that the final product meets the required standards and specifications. By implementing a robust quality system, manufacturers can achieve consistent and reliable quality, reduce defects and errors, and ultimately deliver high-quality PCBs that meet the expectations of their customers. This system is crucial in the electronics industry, as PCBs are integral components in most electronic devices and their quality can greatly impact the performance and reliability of these devices.

18.Does the PCB have radio frequency shielding properties?

PCB (Printed Circuit Board) products can be designed with radio frequency (RF) shielding properties, but this depends on the specific design requirements of the application. RF shielding is typically achieved through the use of shielding materials, such as metal cans or shields, placed over sensitive components or sections of the PCB. These shields are designed to block or attenuate electromagnetic interference at RF frequencies. The shielding effectiveness of a PCB is determined by its design, materials, and the presence of shielding components. PCBs themselves may not inherently have RF shielding properties, but they are a part of the overall system design that incorporates RF shielding when necessary to protect against interference.

19.What are the dimensions of PCB products?

The dimensions of PCB (Printed Circuit Board) products can vary widely depending on the specific application and requirements. PCBs come in various sizes and shapes to accommodate different electronic devices and systems. They can range from small and compact boards used in mobile phones or wearables to larger and more intricate boards found in computers, industrial equipment, or automotive systems. The dimensions are tailored to fit the intended space within the electronic device and to support the necessary components and connections. As a result, PCBs are available in a diverse range of sizes and configurations to meet the unique needs of various applications.

20.How much voltage can PCB products withstand?

The voltage that PCB (Printed Circuit Board) products can withstand varies depending on several factors, including the design, materials, and intended application. PCBs are typically designed to withstand voltages ranging from a few volts to several hundred volts. Low-power electronic devices may have PCBs that can handle lower voltages, while high-power applications, such as power distribution or industrial equipment, may require PCBs designed to withstand higher voltages. Designers consider factors like insulation, spacing, and dielectric strength when determining the voltage tolerance of a PCB to ensure safe and reliable operation within its specified limits.

21.About PCB raw material procurement system

The PCB raw material procurement system is a crucial aspect of the production process for printed circuit boards. It involves the sourcing and acquisition of all necessary materials, such as copper foil, laminate sheets, solder mask, and components, needed for the manufacturing of PCBs. This system requires efficient coordination between suppliers and the PCB manufacturer to ensure timely delivery and high-quality materials. Additionally, proper management of inventory levels and cost control are essential components of the procurement system to ensure smooth and cost-effective production of PCBs.

TAG: PCB, PCBA, HIGH SPEED PCB, MULTILAYER PCB

RELATED NEWS

pcb board manufacturing How To Contact US

PCB from 1 to 30 layers, HDI, Heavy Copper, Rigid-flex board with "pcb board manufacturing One-Stop" service.