144 bga 11x11 pcb layout art

Our geographical location enables us to offer competitive prices because in Shenzhen, we have abundant parts resources and convenient transportation. Our products are widely used in consumer electronics, telecommunications, medical, petroleum and other industries. All our products comply with international quality standards and our customers come from different markets around the world. For example Tanzania,Angola,Jamaica,Swaziland,Spain etc.

| Base Material | FR-4/CEM-1/CEM-3/Polyimild/PTFE/Rogers |

| Board Thickness | 0.2-5mm |

| Model Number | Custom PCB & PCB Assembly |

| Type | Aluminum PCB |

| Brand Name | FC |

| Copper Thickness | 0.5-2mil(9-44um) |

| Min. Hole Size | 0.1mm(4mil)for HDI / 0.15mm(6mil) |

| Min. Line Width | 0.075mm/0.075mm(3mil/3mil) |

| Min. Line Spacing | 0.003'' |

| Surface Finishing | HASL/OSP/Ag/ENIG/ENEPIG/Immersion silver/Tin |

| Board Size | Custom |

| Model Number | Customized |

| Base Material | FR4 Aluminum CEM-1 94V0 |

| Surface Finishing | HASLENIG OSP |

| Number of layer | 1-14layer |

| Other service | Components purchasing and assem |

| ly Solder mask | White Black Green Blue,Red,etc. |

| Dsign service | Available |

| Testing | Function testing |

| Certificate | RoHS, ISO/TS16949, ISO9001 |

| Name | High Quality led light aluminum pcb printed circuit board |

| Packaging Details | Vaccum package and standard carton outside High Quality led light aluminum pcb printed circuit board |

| Supply Ability | 49944 Square Meter/Square Meters per Month |

| Quantity (pieces) | > 19958 |

| Lead time (days) | 14 |

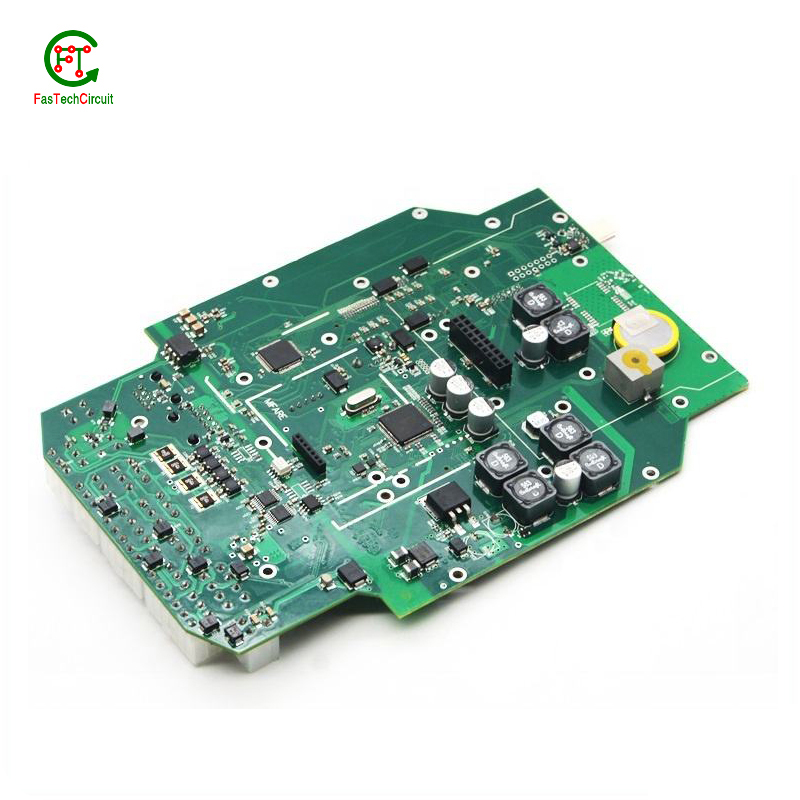

144 bga 11x11 pcb layout art bearings FAQs Guide Welcome to our state-of-the-art PCB (Printed Circuit Board) products. We are proud to offer a comprehensive range of high-quality and versatile PCB solutions to meet the constantly evolving needs of the modern electronics industry.Our PCBs are expertly designed and manufactured using the latest technology and advanced techniques, ensuring reliability, durability, and exceptional performance for a wide range of applications. We understand the importance of precision and attention to detail in the production of PCBs and we are committed to meeting stringent quality standards.

2.What materials are used to make a 144 bga 11x11 pcb layout art?

3.How are 144 bga 11x11 pcb layout art used in medical devices?

4.How does a 144 bga 11x11 pcb layout art work?

5.Can a 144 bga 11x11 pcb layout art be used for both power and signal transmission?

6.How are 144 bga 11x11 pcb layout arts protected from moisture and humidity?

7.What is the difference between a diode and a capacitor?

8.Can 144 bga 11x11 pcb layout arts be used in high-frequency applications?

9.What does 144 bga 11x11 pcb layout art stand for?

10.What are the advantages of using a 144 bga 11x11 pcb layout art?

11.What type of solder is used for 144 bga 11x11 pcb layout art assembly?

12.What is embedded 144 bga 11x11 pcb layout art technology?

13.Can 144 bga 11x11 pcb layout arts be used in automotive applications?

14.What are the benefits of using surface mount technology (SMT) for 144 bga 11x11 pcb layout art?

15.What is the role of silkscreen on a 144 bga 11x11 pcb layout art?

16.What is the purpose of a 144 bga 11x11 pcb layout art?

17.How are components selected for a 144 bga 11x11 pcb layout art design?

18.How are holes drilled into a 144 bga 11x11 pcb layout art?

1.What is the purpose of a ground plane on a 144 bga 11x11 pcb layout art?

I have a comprehensive after -sales service system, which can pay attention to market trends in time and adjust our strategy in a timely manner.

A decoupling capacitor is an essential component on a PCB (Printed Circuit Board) which is used to reduce or eliminate high frequency noise between different components. It acts as a buffer between the power supply and other circuit components, by storing electrical charge and then releasing it when there is a sudden change in the supply voltage. This helps to stabilize the power supply, providing a steady and noise-free flow of electricity to the circuit. Furthermore, decoupling capacitors also help to filter out any unwanted signals that may cause interference or disruptions in the proper functioning of the circuit.

2.What materials are used to make a 144 bga 11x11 pcb layout art?

We have advanced production equipment and technology to meet the needs of customers, and can provide customers with high quality, low priced 144 bga 11x11 pcb layout art products.

A PCB, or printed circuit board, is typically made of a non-conductive material such as fiberglass or composite epoxy resin. This material acts as a base for a thin layer of copper foil, which is then etched to create the desired circuit pattern. Other common materials used in the production of PCBs include solder mask, a polymer layer used to insulate and protect the copper traces, and silkscreen, which is used to label and identify the different components on the PCB. In addition, various electronic components such as resistors, capacitors, and diodes are also mounted onto the PCB to form a functional electronic circuit. Other potential materials used in the production of PCBs include metal core, ceramics, and conductive ink, depending on the specific design and requirements of the circuit.

3.How are 144 bga 11x11 pcb layout art used in medical devices?

Printed Circuit Boards (PCBs) are essential components used in a wide range of medical devices, playing a crucial role in both diagnostic and treatment equipment. These devices require reliable and precise circuitry to accurately collect and process data, deliver therapies, and regulate medical procedures. PCBs are used in equipment such as MRI machines, pacemakers, defibrillators, and monitors, where their small size and high density make them ideal for compact and portable designs. In addition, PCBs are also used in medical implants, enabling a safe and secure connection between the device and the body. With their advanced technology, PCBs continue to be an integral part of the medical industry, ensuring the effectiveness and success of various medical procedures and treatments.

4.How does a 144 bga 11x11 pcb layout art work?

We maintain a stable growth through reasonable capital operations, focus on industry development trends and cutting -edge technologies, and focus on product quality and safety performance.

A PCB (Printed Circuit Board) is a thin board made of non-conductive material, such as fiberglass or plastic, with conductive pathways etched or printed onto its surface. These pathways, also known as traces, are used to connect electronic components on the board, such as resistors, capacitors, and integrated circuits.

The PCB works by providing a platform for the components to be mounted and connected in a specific circuit configuration. The traces on the board act as wires, allowing electricity to flow between the components and creating a complete circuit.

The process of creating a PCB involves several steps, including designing the circuit layout, printing or etching the traces onto the board, and attaching the components using soldering techniques. Once the components are attached, the board is tested to ensure that all connections are correct and functioning properly.

When a PCB is connected to a power source, electricity flows through the traces, powering the components and allowing them to perform their intended functions. The traces also act as a pathway for signals to travel between components, allowing for communication and data transfer within the circuit.

PCBs are used in a wide range of electronic devices, from simple household appliances to complex computer systems. They provide a compact and efficient way to connect and control electronic components, making them an essential part of modern technology.

5.Can a 144 bga 11x11 pcb layout art be used for both power and signal transmission?

Yes, a PCB (printed circuit board) can be used for both power and signal transmission. This is commonly seen in electronic devices such as computers, smartphones, and other electronic devices. The PCB acts as a platform for connecting various components and circuits, including power sources and signal pathways. The power and signal traces on the PCB are designed to handle different levels of current and voltage to ensure efficient transmission and prevent interference between the two. However, it is important to properly design and layout the PCB to ensure proper separation and isolation of power and signal traces to avoid any potential issues.

6.How are 144 bga 11x11 pcb layout arts protected from moisture and humidity?

PCB (Printed Circuit Boards) are susceptible to damage from moisture and humidity, which can result in malfunction or even complete failure of electronic devices. Therefore, it is necessary to take measures to protect PCBs from these elements.

One way to protect PCBs from moisture is by using a conformal coating. This is a thin layer of protective material that is applied to the surface of the PCB. It acts as a barrier, preventing moisture from coming into contact with the sensitive components on the board.

Another method is to use moisture-resistant materials for the PCB itself. This can include using moisture-resistant coatings or laminates for the board, as well as corrosion-resistant materials for the conductors and connectors.

In addition to these preventive measures, PCBs can also be stored in controlled environments with low humidity levels. This can help to minimize the amount of moisture that comes into contact with the boards, reducing the risk of damage.

Regular maintenance and periodic testing can also help to ensure the continued protection of PCBs from moisture and humidity. By taking these precautions, electronic devices can maintain their functionality and reliability, even in environments with high humidity levels.

7.What is the difference between a diode and a capacitor?

We have a first -class management team, and we pay attention to teamwork to achieve common goals.

A diode is an electronic component that allows current to flow in only one direction. It has two terminals, an anode and a cathode, and works by allowing current to flow from the anode to the cathode, but not in the reverse direction.

A capacitor, on the other hand, is an electronic component that stores electrical energy in an electric field. It has two conductive plates separated by an insulating material, and when a voltage is applied, one plate accumulates a positive charge and the other accumulates a negative charge. This allows the capacitor to store energy and release it when needed.

8.Can 144 bga 11x11 pcb layout arts be used in high-frequency applications?

Our mission is to provide customers with the best solutions for 144 bga 11x11 pcb layout art.

Yes, PCBs (printed circuit boards) can be used in high-frequency applications. However, the design and construction of the PCB must be carefully considered to ensure optimal performance at high frequencies. This includes using specialized materials, such as high-frequency laminates, and implementing proper grounding and shielding techniques. Additionally, the layout and routing of the PCB must be optimized to minimize signal loss and interference.

9.What does 144 bga 11x11 pcb layout art stand for?

We attach importance to the innovation ability and team spirit of employees, have advanced R & D facilities and laboratories, and have a good quality management system.

PCB stands for Printed Circuit Board.

10.What are the advantages of using a 144 bga 11x11 pcb layout art?

We are centered on customers and always pay attention to customers' needs for 144 bga 11x11 pcb layout art products.

There are several advantages of using a PCB (Printed Circuit Board). Firstly, a PCB provides a compact and organized layout for electronic components, which makes it easier for technicians to troubleshoot and repair any issues. Secondly, it reduces the chances of loose connections and short circuits, which can be a major safety concern. Thirdly, PCBs are cost-effective and can be easily mass-produced, making them a popular choice for large-scale production. Additionally, they offer durability and stability, ensuring long-lasting performance. Finally, PCBs also allow for easy integration of new components, making it easier to upgrade or modify the electronic devices.

11.What type of solder is used for 144 bga 11x11 pcb layout art assembly?

The most commonly used solder for PCB assembly is a lead-free solder, specifically a tin-silver-copper (SnAgCu) alloy. This type of solder is preferred due to its high melting point, good wetting properties, and compatibility with surface mount technology (SMT) components. Other types of solder that may be used include tin-lead (SnPb) solder and lead-free alternatives such as tin-copper (SnCu) and tin-bismuth (SnBi) alloys. The specific type of solder used may vary depending on the application and industry standards.

12.What is embedded 144 bga 11x11 pcb layout art technology?

Our products & services cover a wide range of areas and meet the needs of different fields.

Embedded PCB technology refers to the integration of electronic components directly onto a printed circuit board (PCB) during the manufacturing process. This allows for a more compact and efficient design, as well as improved reliability and performance. The components are embedded within the layers of the PCB, rather than being mounted on the surface, resulting in a more streamlined and durable product. This technology is commonly used in applications such as smartphones, tablets, and other portable electronic devices.

13.Can 144 bga 11x11 pcb layout arts be used in automotive applications?

Yes, PCBs (printed circuit boards) can be used in automotive applications. They are commonly used in various electronic systems in vehicles, such as engine control units, infotainment systems, and safety systems. PCBs offer a compact and reliable way to connect and control electronic components in vehicles. They are also designed to withstand harsh environmental conditions, such as temperature fluctuations, vibrations, and moisture, making them suitable for use in automotive applications.

14.What are the benefits of using surface mount technology (SMT) for 144 bga 11x11 pcb layout art?

We focus on innovation and continuous improvement to maintain a competitive advantage.

Surface mount technology (SMT) is a popular method for assembling printed circuit boards (PCBs) that offers numerous benefits over traditional through-hole components. Firstly, SMT components are smaller and more compact, allowing for greater PCB density and reducing the overall size of the board. This makes SMT ideal for increasingly miniaturized electronics, such as smartphones and wearables. Additionally, SMT components are typically cheaper and easier to manufacture, leading to cost savings in both materials and labor. SMT also allows for automated assembly, resulting in faster and more efficient production processes. Furthermore, the smaller size of SMT components leads to improved electrical performance due to decreased parasitic effects and shorter signal paths. This makes SMT ideal for high-frequency applications.

15.What is the role of silkscreen on a 144 bga 11x11 pcb layout art?

Being one of the top 144 bga 11x11 pcb layout art manufacturers in China, We attach great importance to this detail.

Silkscreen, also known as legend or nomenclature, is a vital component of a printed circuit board (PCB). It is the layer of text and symbols that are printed on the surface of the PCB to provide essential information for component placement and identification. The silkscreen plays a crucial role in the manufacturing process of PCBs, as it helps to ensure the accuracy and functionality of the final product. By indicating component locations, values, and reference designators, the silkscreen serves as a guide for the assembly and soldering of electronic components. Additionally, it also provides important information for maintenance and troubleshooting purposes.

16.What is the purpose of a 144 bga 11x11 pcb layout art?

We pay attention to the transformation of intellectual property protection and innovation achievements. Your OEM or ODM order design we have a complete confidentiality system.

A PCB (Printed Circuit Board) is a flat board made of non-conductive material, such as fiberglass, with conductive pathways etched or printed onto it. The main purpose of a PCB is to provide a platform for electronic components to be mounted and connected together to form a functioning electronic circuit. It serves as a physical support for the components and provides a means for them to communicate with each other through the conductive pathways. PCBs are used in a wide range of electronic devices, from simple household appliances to complex computer systems, and are essential for the proper functioning and reliability of these devices. They also allow for easier and more efficient production of electronic devices, as the components can be mounted and connected in a standardized and automated manner.

17.How are components selected for a 144 bga 11x11 pcb layout art design?

We pay attention to employee development and benefits, and provide a good working environment in order to improve the efficiency of employees and improve the quality management of 144 bga 11x11 pcb layout art products.

A power rating for a PCB, or Printed Circuit Board, is a measure of the maximum amount of power the board is able to safely handle. This rating takes into account the overall design and materials used in the creation of the PCB, as well as the environment in which it will be used. It is an important consideration in electronics and circuit design as exceeding the power rating can lead to overheating and potential damage to the board and connected components. Properly understanding and adhering to the power rating of a PCB is crucial for ensuring safe and efficient operation of electronic devices.

18.How are holes drilled into a 144 bga 11x11 pcb layout art?

We actively participate in the 144 bga 11x11 pcb layout art industry associations and organization activities. The corporate social responsibility performed well, and the focus of brand building and promotion.

Drilling holes into printed circuit boards (PCBs) is a critical part of the PCB manufacturing process. These holes are used for mounting electronic components and for creating electrical connections between different layers of the board. There are two main methods for drilling holes into a PCB – mechanical drilling and laser drilling. Mechanical drilling involves using a high speed drill bit to physically drill through the board, while laser drilling uses a high-powered laser to vaporize the material and create the holes. Both methods have their own advantages and are often used in combination to achieve the desired hole sizes and precision. Regardless of the method, the holes are carefully planned and executed to ensure the successful production of a high-quality PCB.

RELATED PRODUCTS & SERVICE

pcb board manufacturing How To Contact US

PCB from 1 to 30 layers, HDI, Heavy Copper, Rigid-flex board with "pcb board manufacturing One-Stop" service.