Prototype Printed Circuit power Bank PCB Circuit multilayer PCB manufacturer with WIFI Welding Making Machine Inverter

Categories: All Products,pcb board manufacturing,PCB assembly

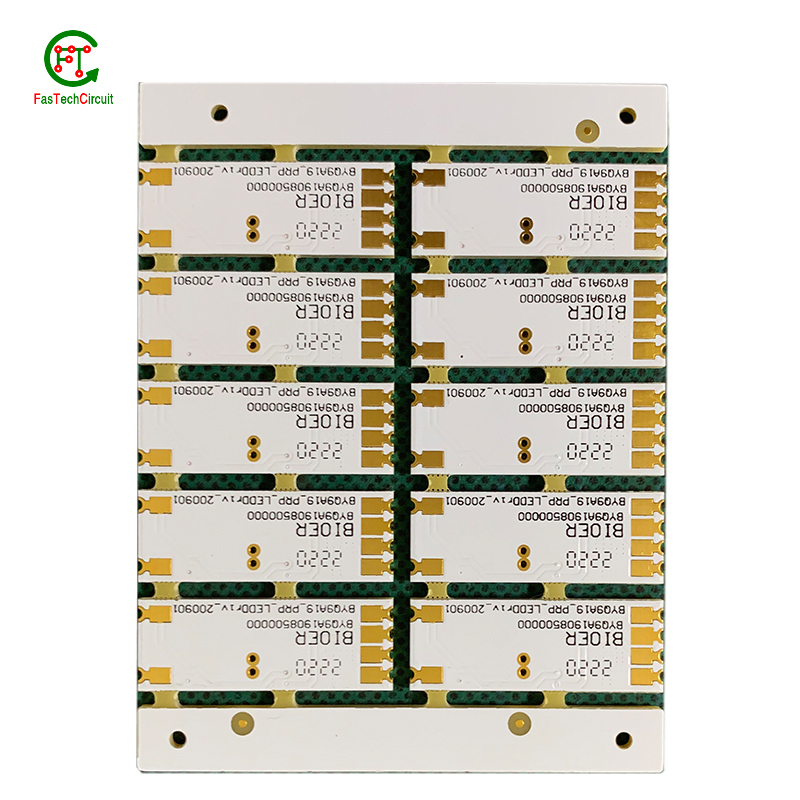

| Part number | White PCB from Germany |

| Layer count | 1 |

| Material | Aluminum |

| Thickness | 1.0mm |

| Copper | 1 OZ |

| Treatment | ENIG |

| Solder mask | White |

| Silkscreen | Black |

| Shape | V CUT |

| Application | LCD, LED |

| Min trace width | 6mil |

| Min trace gap | 6 mil |

| Boare size | 165 x 122 mm |

| Trademark | FasTechCircuit |

| HS code | 8534009000 |

Tags:PCB,PCBA,HIGH SPEED PCB,MULTILAYER PCB,HDI PCB BOARD,RIGID-FLEX PCB,PCB ASSEMBLY,IMPEDANCE PCB,STANDARD PCB,SPECIAL PCB,FPC

Categories: All Products,pcb

Since 2003

FasTechCircuit devotes to technology innovation and to be an outstanding world-class one-stop hardware solution provider.

We were found in 2003, who is a one-stop-shop that can provide PCB reverse design + PCB manufacturing + Component Sourcing + PCB assembly + Final Product Function Testing.

We has cooperated with 5000+enterprises from over 40+ conuntries, our products are widely used in communications, industrial control, semiconductors, power and energy,

medical equipment, automotive electronics....

FasTechCircuit shaped the international network of marketing and technique, offering good service in electronic industry.

FAQ:

1.Common PCB Design Mistakes and How to Avoid Them?

Common PCB design errors can have serious impacts on the performance and reliability of electronic devices. To avoid these mistakes, engineers should pay special attention to the following aspects. First of all, unreasonable wiring layout may cause signal interference and electromagnetic compatibility problems, so the crossover and interference of signal lines should be avoided. Secondly, failure to consider thermal management may cause components to overheat, so component layout and heat dissipation measures need to be properly arranged. Additionally, neglecting ground plane design can lead to ground return problems, so the integrity of the ground plane should be ensured. Finally, unreasonable component selection and packaging may also lead to manufacturing problems and unstable performance, so appropriate components should be selected based on specific needs and the packaging should be designed carefully. By focusing on these aspects, engineers can avoid common PCB design mistakes and ensure board reliability and performance.

2.The Impact of EMI on PCB Performance and Solutions for Mitigation?

Electromagnetic interference (EMI) has a significant impact on PCB performance, potentially causing signal interference, performance degradation, and wireless communication issues. To mitigate the effects of EMI, design engineers need to adopt a series of solutions. First of all, reasonable layout and wiring design can reduce the crossover and interference between signal lines and reduce the probability of EMI occurrence. Secondly, choosing appropriate shielding materials and methods, such as adding shielding covers, using shielding layers, etc., can effectively isolate and reduce the radiation of EMI sources. In addition, through reasonable ground plane design and differential signal transmission, the spread of electromagnetic interference can be reduced. In addition, the use of filters and suppression circuits can also effectively reduce EMI. By combining these solutions, engineers can significantly improve PCB performance, reduce the negative impact of electromagnetic interference on electronic equipment, and improve its reliability and stability.

3.Troubleshooting Short Circuits: A Guide to Identifying and Fixing PCB Issues?

Troubleshooting short circuit problems is a critical task in PCB design and repair because it can cause circuit failure, damage components, and even compromise device safety. To troubleshoot a short circuit problem, you first need to use a test tool such as a multi-meter or thermal imager to determine the location of the short circuit. Next, carefully examine the PCB routing, solder joints, and spacing between components to identify possible causes of short circuits. Repairing a short typically involves patching the damaged trace, correcting a soldering error, replacing the damaged component, or isolating the short with an isolation barrier. Finally, test the repaired PCB to make sure the problem has been resolved. By following these steps, engineers can quickly and accurately identify and repair short circuit issues in PCB, ensuring proper board operation and reliability.

4.Advanced PCB Manufacturing Techniques: Ensuring Precision and Quality?

Advanced PCB manufacturing technology is crucial to ensure accuracy and quality. The adoption of these technologies can significantly improve the performance and reliability of printed circuit boards. An important technology is precision welding and assembly, including surface mount technology and welding robots, which help ensure components are installed correctly and connected reliably. Another key aspect is high-density interconnect technology, such as micro-line width and spacing, blind via and buried via designs, to meet the needs of modern electronic devices for smaller, lighter and more compact circuit boards. High-quality printing and photolithography techniques are also important factors in ensuring circuit accuracy. In addition, advanced inspection and testing technologies, such as automated optical inspection and X-ray inspection, can be used to ensure the accuracy of the manufacturing process, thereby reducing defects and failures. Combining these technologies, PCB manufacturers can provide highly precise and high-quality circuit boards to meet the growing needs of the electronics industry.

5.The Role of PCB in the Internet of Things (IoT) Revolution?

Advanced PCB manufacturing technology is crucial to ensure accuracy and quality. The adoption of these technologies can significantly improve the performance and reliability of printed circuit boards. An important technology is precision welding and assembly, including surface mount technology and welding robots, which help ensure components are installed correctly and connected reliably. Another key aspect is high-density interconnect technology, such as micro-line width and spacing, blind via and buried via designs, to meet the needs of modern electronic devices for smaller, lighter and more compact circuit boards. High-quality printing and photolithography techniques are also important factors in ensuring circuit accuracy. In addition, advanced inspection and testing technologies, such as automated optical inspection and X-ray inspection, can be used to ensure the accuracy of the manufacturing process, thereby reducing defects and failures. Combining these technologies, PCB manufacturers can provide highly precise and high-quality circuit boards to meet the growing needs of the electronics industry.

RELATED PRODUCTS & SERVICE

pcb board manufacturing How To Contact US

PCB from 1 to 30 layers, HDI, Heavy Copper, Rigid-flex board with "pcb board manufacturing One-Stop" service.