94v0 led pcb board

Our geographical location enables us to offer competitive prices because in Shenzhen, we have abundant parts resources and convenient transportation. Our products are widely used in consumer electronics, telecommunications, medical, petroleum and other industries. All our products comply with international quality standards and our customers come from different markets around the world. For example Spratly Islands,Rwanda,Reunion,Lithuania etc.

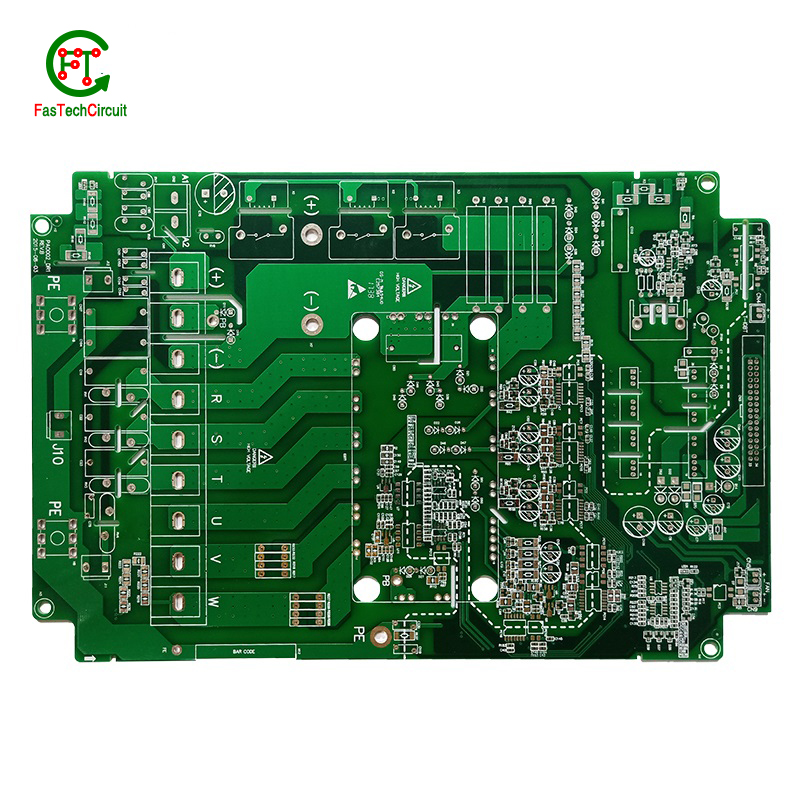

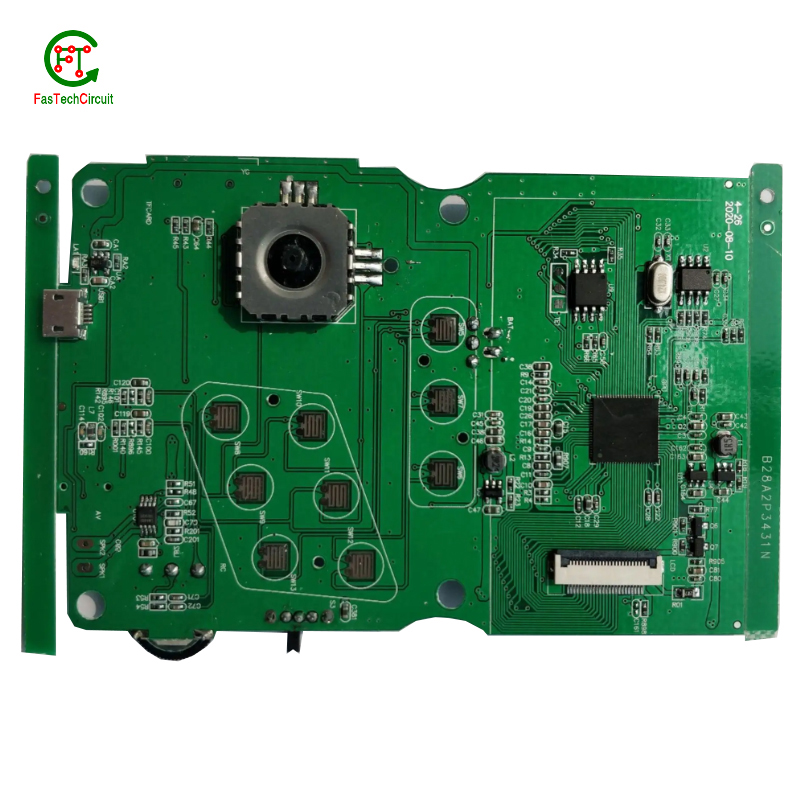

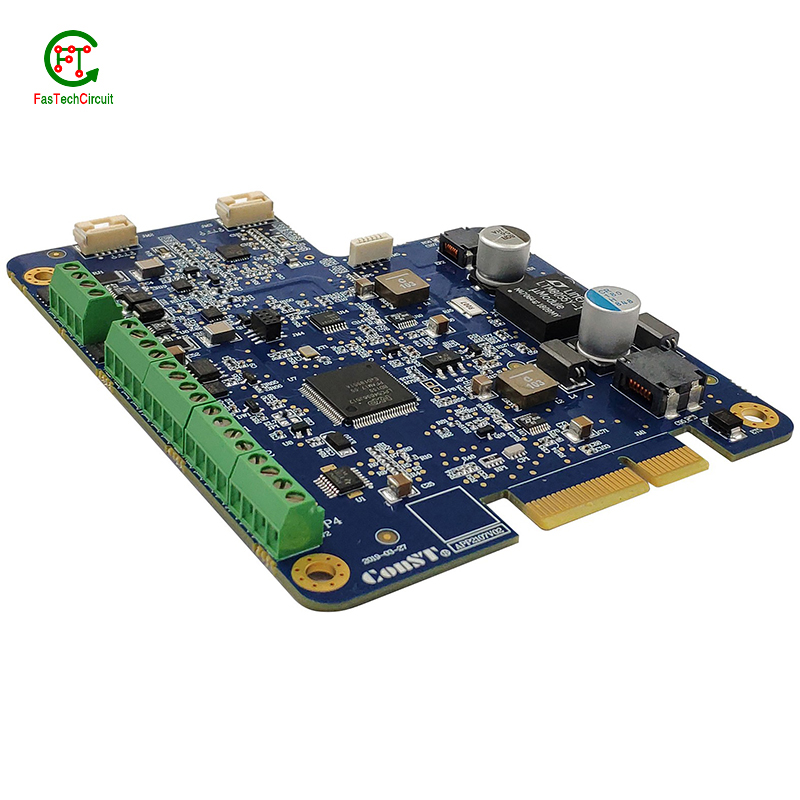

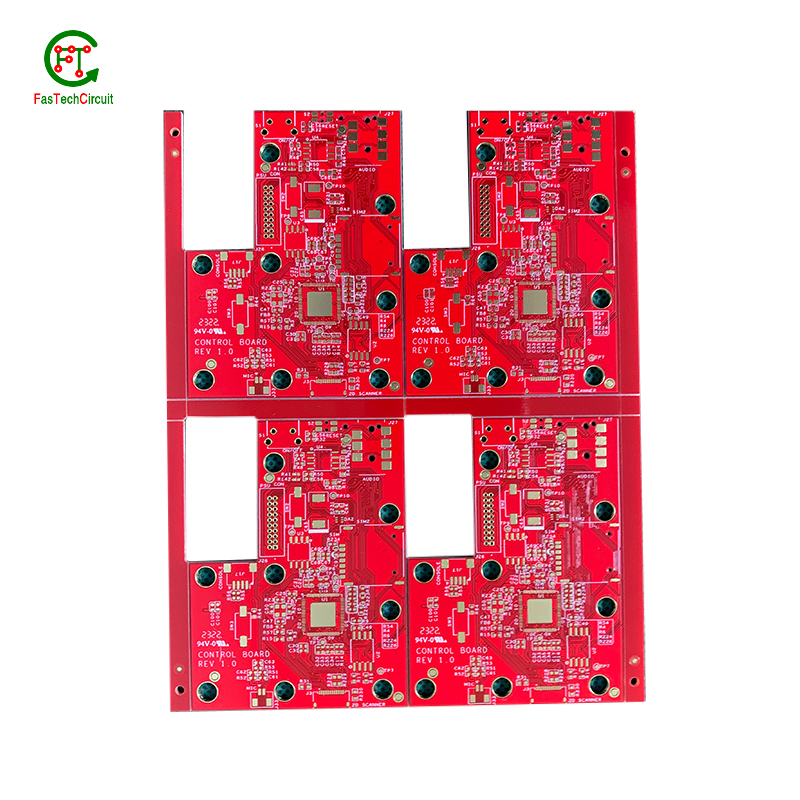

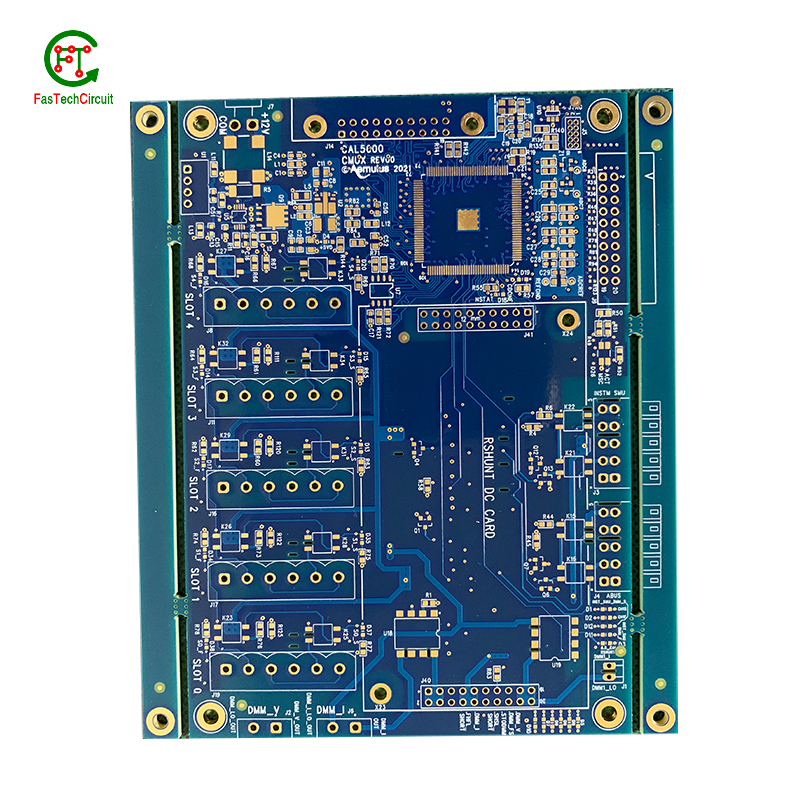

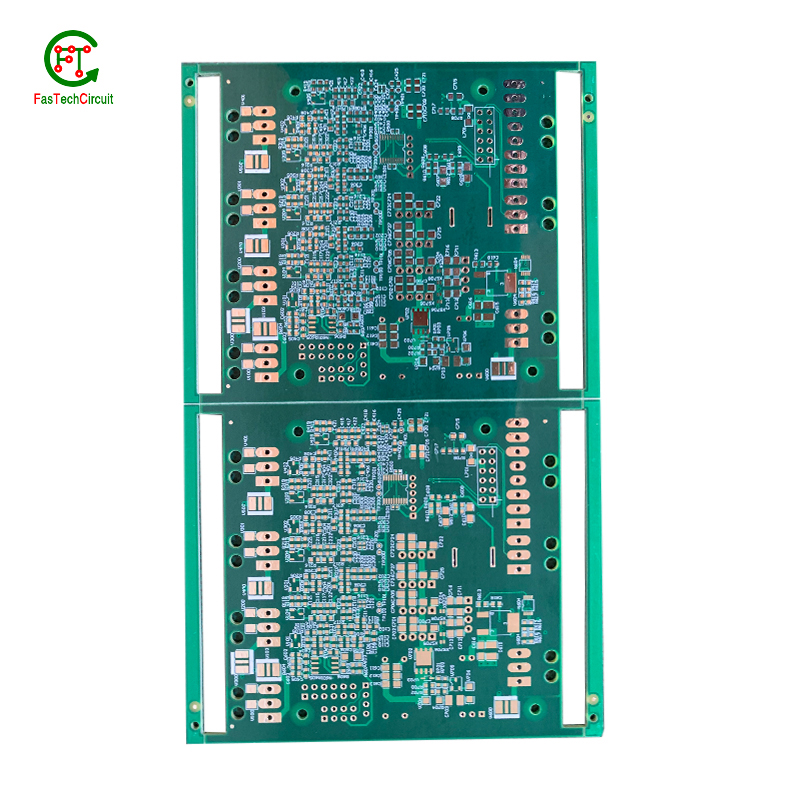

| Number of Layers | 4 layer |

| Base Material | gold sinking |

| Board Thickness | 2.3MM |

| Board Size | 347M*599MM |

| Model Number | 4 layer pcb |

| Type | pcb |

| Place of Origin | Original |

| Brand Name | Original |

| Copper Thickness | 3OZ |

| Min. Hole Size | custom made |

| Min. Line Width | custom made |

| Min. Line Spacing | custom made |

| Surface Finishing | custom made |

| Impedance control | +/- 2% |

| Warpage | less than 1% |

| Packaging Details | New and Original, factory sealed packing, it will be pack in one of these packing type: Tube, Tray, Tape and Reel, Tape and Box, Bulk packing, Bag and etc. Please kindly contact us for more details. |

| Supply Ability | 6731 Piece/Pieces per Week |

| Quantity (pieces) | > 11495 |

| Lead time (days) | 6 |

94v0 led pcb board bearings FAQs Guide Welcome to our state-of-the-art PCB (Printed Circuit Board) products. We are proud to offer a comprehensive range of high-quality and versatile PCB solutions to meet the constantly evolving needs of the modern electronics industry.Our PCBs are expertly designed and manufactured using the latest technology and advanced techniques, ensuring reliability, durability, and exceptional performance for a wide range of applications. We understand the importance of precision and attention to detail in the production of PCBs and we are committed to meeting stringent quality standards.

2.Can a 94v0 led pcb board be used for both power and signal transmission?

3.What are the benefits of using surface mount technology (SMT) for 94v0 led pcb board?

4.What is the process of etching a 94v0 led pcb board?

5.What is the maximum operating temperature of a 94v0 led pcb board?

6.Can a 94v0 led pcb board be used with both through-hole and surface mount components?

7.What materials are used to make a 94v0 led pcb board?

8.How are 94v0 led pcb boards manufactured?

9.What does 94v0 led pcb board stand for?

10.What is the minimum trace width and spacing on a 94v0 led pcb board?

11.How are signal traces routed on a 94v0 led pcb board?

12.What software is used for 94v0 led pcb board design?

13.What is the role of silkscreen on a 94v0 led pcb board?

14.What is the difference between an analog and a digital signal on a 94v0 led pcb board?

15.How are 94v0 led pcb boards protected from moisture and humidity?

16.What is the difference between a copper pour and a trace on a 94v0 led pcb board?

17.What is the lifespan of a 94v0 led pcb board under harsh environmental conditions?

1.What is the role of a data sheet in 94v0 led pcb board design?

A data sheet is an essential tool for PCB design, providing vital information and specifications for all of the components used in the design process. It contains detailed technical data, such as dimensions, electrical ratings, and performance characteristics, that allow designers to make informed decisions when selecting and placing components on a PCB. By referencing the data sheet, designers can ensure that each component is properly integrated into the overall design, following any necessary guidelines or restrictions. Additionally, data sheets also provide necessary information for the layout and routing of traces on the PCB, ensuring that the design can meet required performance specifications.

2.Can a 94v0 led pcb board be used for both power and signal transmission?

Yes, a PCB (printed circuit board) can be used for both power and signal transmission. This is commonly seen in electronic devices such as computers, smartphones, and other electronic devices. The PCB acts as a platform for connecting various components and circuits, including power sources and signal pathways. The power and signal traces on the PCB are designed to handle different levels of current and voltage to ensure efficient transmission and prevent interference between the two. However, it is important to properly design and layout the PCB to ensure proper separation and isolation of power and signal traces to avoid any potential issues.

3.What are the benefits of using surface mount technology (SMT) for 94v0 led pcb board?

We focus on innovation and continuous improvement to maintain a competitive advantage.

Surface mount technology (SMT) is a popular method for assembling printed circuit boards (PCBs) that offers numerous benefits over traditional through-hole components. Firstly, SMT components are smaller and more compact, allowing for greater PCB density and reducing the overall size of the board. This makes SMT ideal for increasingly miniaturized electronics, such as smartphones and wearables. Additionally, SMT components are typically cheaper and easier to manufacture, leading to cost savings in both materials and labor. SMT also allows for automated assembly, resulting in faster and more efficient production processes. Furthermore, the smaller size of SMT components leads to improved electrical performance due to decreased parasitic effects and shorter signal paths. This makes SMT ideal for high-frequency applications.

4.What is the process of etching a 94v0 led pcb board?

We have flexible production capacity. Whether you are large orders or small orders, you can produce and release goods in a timely manner to meet customer needs.

PCB (Printed Circuit Board) etching is the process of creating a circuit pattern on a copper-clad board by using chemical etchants to selectively remove the unwanted copper. The process begins by transferring the circuit design onto a copper-clad board using various methods such as printing or photolithography. Next, the board is coated with a resist material, which protects the areas of copper that will eventually become the circuit traces. The board is then placed in an etching solution, typically a mixture of acid and water, which dissolves the unprotected copper. Once the desired circuit pattern is etched into the board, the resist material is removed, and the board is cleaned and inspected for any imperfections. PCB etching is a crucial step in the manufacturing of PCBs, as it creates the necessary conductive pathways for electronic components to be mounted and interconnected, making it an essential process in the production of electronic devices.

5.What is the maximum operating temperature of a 94v0 led pcb board?

We have a professional team that is committed to the innovation and development of 94v0 led pcb board.

The maximum operating temperature of a PCB (printed circuit board) can vary depending on the materials and components used in its construction. Generally, the maximum operating temperature for a standard FR4 PCB is around 130-140 degrees Celsius. However, specialized materials such as high-temperature laminates or ceramic substrates can withstand higher temperatures up to 200-250 degrees Celsius. The maximum operating temperature of a PCB should always be determined by the manufacturer's specifications and guidelines.

6.Can a 94v0 led pcb board be used with both through-hole and surface mount components?

We continue to improve 94v0 led pcb board products and processes to improve efficiency.

Yes, a PCB (printed circuit board) can be designed to accommodate both through-hole and surface mount components. This is known as a mixed-technology PCB. The PCB will have both through-hole and surface mount pads and traces, allowing for the placement and soldering of both types of components. This type of PCB is commonly used in electronic devices that require a combination of through-hole and surface mount components for functionality.

7.What materials are used to make a 94v0 led pcb board?

We have advanced production equipment and technology to meet the needs of customers, and can provide customers with high quality, low priced 94v0 led pcb board products.

A PCB, or printed circuit board, is typically made of a non-conductive material such as fiberglass or composite epoxy resin. This material acts as a base for a thin layer of copper foil, which is then etched to create the desired circuit pattern. Other common materials used in the production of PCBs include solder mask, a polymer layer used to insulate and protect the copper traces, and silkscreen, which is used to label and identify the different components on the PCB. In addition, various electronic components such as resistors, capacitors, and diodes are also mounted onto the PCB to form a functional electronic circuit. Other potential materials used in the production of PCBs include metal core, ceramics, and conductive ink, depending on the specific design and requirements of the circuit.

8.How are 94v0 led pcb boards manufactured?

We have the leading technology and innovation capabilities, and attach importance to employee training and development, and provide promotion opportunities.

PCB are manufactured through a series of steps starting with designing the circuit layout. Once the design is finalized, the layout is printed on a special type of paper known as the “artwork”. This artwork is then transferred onto a copper-coated laminate board through a process called etching. The excess copper is removed, leaving behind the desired circuit pattern. The board is then drilled to create holes for components to be inserted. The next step involves adding a thin layer of solder mask to protect the circuit and adding a thin layer of copper to create traces. Finally, the components are added using a specialized machine, and the board goes through a series of tests to ensure proper functionality. Once the tests are passed, the board is cut and separated into individual PCBs for use in various electronic devices.

9.What does 94v0 led pcb board stand for?

We attach importance to the innovation ability and team spirit of employees, have advanced R & D facilities and laboratories, and have a good quality management system.

PCB stands for Printed Circuit Board.

10.What is the minimum trace width and spacing on a 94v0 led pcb board?

We operate our 94v0 led pcb board business with integrity and honesty.

The minimum trace width and spacing on a PCB can vary depending on the manufacturing process and the specific requirements of the design. However, a common industry standard for minimum trace width and spacing is 0.006 inches (0.1524 mm). This is typically used for standard PCBs with a 1 oz copper weight. For more complex designs or higher copper weights, the minimum trace width and spacing may need to be increased to ensure proper functionality and reliability. It is important to consult with the PCB manufacturer and follow their guidelines for minimum trace width and spacing to ensure a successful design.

11.How are signal traces routed on a 94v0 led pcb board?

Signal traces are an essential element of a PCB, responsible for carrying electronic signals between components and ensuring proper communication and functionality of the circuit. To route these traces, designers use specialized software to determine the most efficient and optimal path for each signal, taking into account factors such as signal integrity, trace length, and potential interference. This process involves careful planning, as well as techniques such as vias, ground and power planes, and differential pairs to minimize noise and maintain signal integrity.

12.What software is used for 94v0 led pcb board design?

Our 94v0 led pcb board products have competitive and differentiated advantages, and actively promote digital transformation and innovation.

Some popular software used for PCB design include:

1. Altium Designer

2. Eagle PCB

3. KiCad

4. OrCAD

5. PADS

6. Proteus

7. DipTrace

8. EasyEDA

9. CircuitMaker

10. DesignSpark PCB

13.What is the role of silkscreen on a 94v0 led pcb board?

Being one of the top 94v0 led pcb board manufacturers in China, We attach great importance to this detail.

Silkscreen, also known as legend or nomenclature, is a vital component of a printed circuit board (PCB). It is the layer of text and symbols that are printed on the surface of the PCB to provide essential information for component placement and identification. The silkscreen plays a crucial role in the manufacturing process of PCBs, as it helps to ensure the accuracy and functionality of the final product. By indicating component locations, values, and reference designators, the silkscreen serves as a guide for the assembly and soldering of electronic components. Additionally, it also provides important information for maintenance and troubleshooting purposes.

14.What is the difference between an analog and a digital signal on a 94v0 led pcb board?

An analog signal is a continuous signal that varies in amplitude and frequency over time. It can take on any value within a given range and is typically represented by a smooth, continuous waveform. Analog signals are used to transmit information such as audio, video, and sensor data.

A digital signal, on the other hand, is a discrete signal that can only take on a limited number of values. It is represented by a series of binary digits (0s and 1s) and can only have two states: on or off. Digital signals are used to transmit information in the form of data and are commonly used in digital electronics such as computers and smartphones.

On a PCB, the main difference between analog and digital signals lies in the way they are processed and transmitted. Analog signals require specialized components such as amplifiers and filters to maintain their integrity, while digital signals can be processed and transmitted using digital logic circuits. Additionally, analog signals are more susceptible to noise and interference, while digital signals are more immune to these factors.

15.How are 94v0 led pcb boards protected from moisture and humidity?

PCB (Printed Circuit Boards) are susceptible to damage from moisture and humidity, which can result in malfunction or even complete failure of electronic devices. Therefore, it is necessary to take measures to protect PCBs from these elements.

One way to protect PCBs from moisture is by using a conformal coating. This is a thin layer of protective material that is applied to the surface of the PCB. It acts as a barrier, preventing moisture from coming into contact with the sensitive components on the board.

Another method is to use moisture-resistant materials for the PCB itself. This can include using moisture-resistant coatings or laminates for the board, as well as corrosion-resistant materials for the conductors and connectors.

In addition to these preventive measures, PCBs can also be stored in controlled environments with low humidity levels. This can help to minimize the amount of moisture that comes into contact with the boards, reducing the risk of damage.

Regular maintenance and periodic testing can also help to ensure the continued protection of PCBs from moisture and humidity. By taking these precautions, electronic devices can maintain their functionality and reliability, even in environments with high humidity levels.

16.What is the difference between a copper pour and a trace on a 94v0 led pcb board?

We adhere to the principle of quality first and have a complete production quality management system and quality inspection process.

A copper pour and a trace are two common electronic components that are found on a printed circuit board (PCB). A copper pour is a large area of copper that is used to connect multiple components or ground signals together on a PCB. This creates a solid and low resistance pathway for signals to flow. On the other hand, a trace is a thin line of copper used to connect individual components on a PCB. It carries a specific signal from one component to another. Unlike a copper pour, a trace can be designed to carry a specific current and have a specific width to meet the requirements of the circuit.

17.What is the lifespan of a 94v0 led pcb board under harsh environmental conditions?

The lifespan of a PCB (printed circuit board) under harsh environmental conditions can vary greatly depending on the specific conditions and the quality of the PCB. In general, a well-designed and high-quality PCB can last for 10-20 years under harsh conditions such as extreme temperatures, humidity, and exposure to chemicals or vibrations. However, if the PCB is not properly designed or manufactured, its lifespan can be significantly shorter, potentially lasting only a few years or even months. Factors such as the type of materials used, the thickness of the copper traces, and the quality of the solder joints can also affect the lifespan of a PCB under harsh environmental conditions. Regular maintenance and proper handling can also help extend the lifespan of a PCB.

RELATED PRODUCTS & SERVICE

pcb board manufacturing How To Contact US

PCB from 1 to 30 layers, HDI, Heavy Copper, Rigid-flex board with "pcb board manufacturing One-Stop" service.