Rogers RO4350B RF Printed Circuit Board

Model : Rogers RO4350B High Frequency Board

Material: Rogers RO4350B

Layer: 2 layers

DK :3.48

Dielectric Thickness : 1 524mm

Thermal Conductivity : 0.69w/m.k

Volume Resistivity : 1.2*1010

Surface Resistivity : 5.7*109

Finished Thickness: 1 .6MM

Copper Thickness : Base 0.50Z,Finished 10Z

Surface Treatment : Immersion Gold

Trace / Space : 4mil/4mil

Rogers ro4350b high frequency PCB

Ro4350b is a patented hydrocarbon resin system / ceramic fller reinforced by woven glass cloth. Its electrical properties are very close to PTFE / woven glass cloth material, and its machinability is

similar to that of epoxy resin / glass cloth material.

The ro4350b can use the standard epoxy/ glass cloth processing technology, while providing strictly controlled permitivity and loss at a fraction of the price of traditional microwave materials. There

is no need for special through-hole pretreatment or operation procedures like PTFE based microwave materials.

Ro4350b material has passed UL 94V-0 fire rating for active equipment and high voltage RF design.

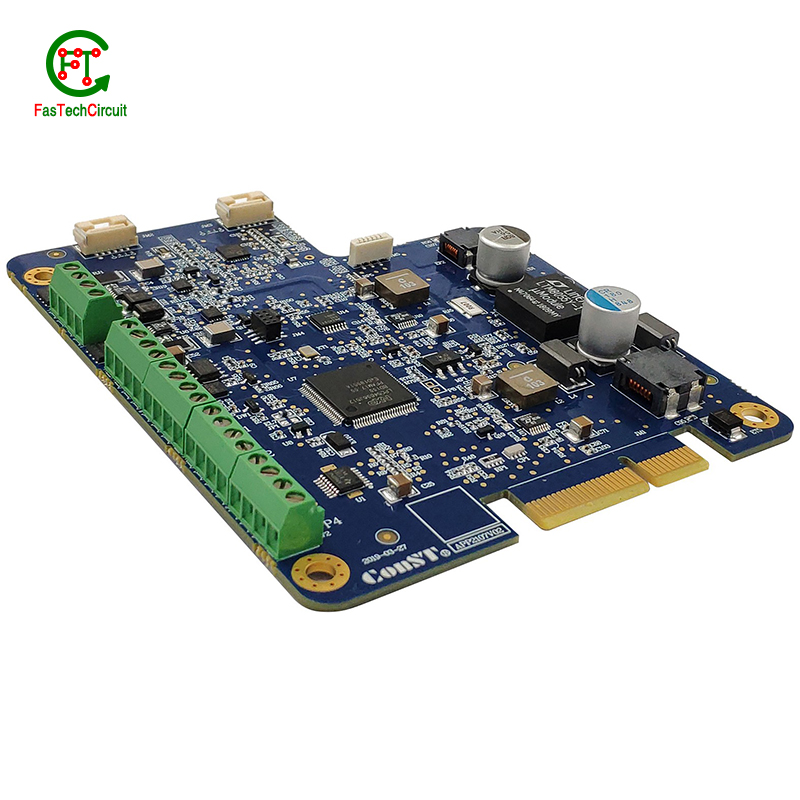

Real Project display:

Rogers RO4350B Advantages:

1. Low DF

2. Low DK fluctuates with temperature

3. Low Z axis thermal expansion cefficient

4. Low internal expansion coefficient

5. Low DK tolerance

6. Stable electrical characteristics at different frequencies

7. Easy for mass production and muti-layer mixing of FR4, high cost perormance

Typical aplcations:Cellular base station antenna and power amplifer, Microwave point to point connection (P2P). Automotive radar and sensors, Radio frequency identifcation (RFID) tags, LNB for live satellite

RF/Microwave PCB application

PCB printed circuit boards with radio frequency(RF PCBs) are an increasingly used technique within the PCB industry.

--RF PCB with a high frequency with works above 100 MHz.

--Microwave PCB with works above 2 GHz radio frequency.

RF-pcb's are used in different applications such as remote controls(wireless controls)security,smartphones,sensors etc.

New technologies make more and more use of these RF aplications.

This asks for a manufacturing according to high quality standards and choosing the right RF materials depending on the application.

It is important that one knows the properties of the various materials.Choosing the right material is perhaps the most critical decision in the production process of the RF PCB.

RELATED PRODUCTS & SERVICE

pcb board manufacturing How To Contact US

PCB from 1 to 30 layers, HDI, Heavy Copper, Rigid-flex board with "pcb board manufacturing One-Stop" service.