1800 layout pcb

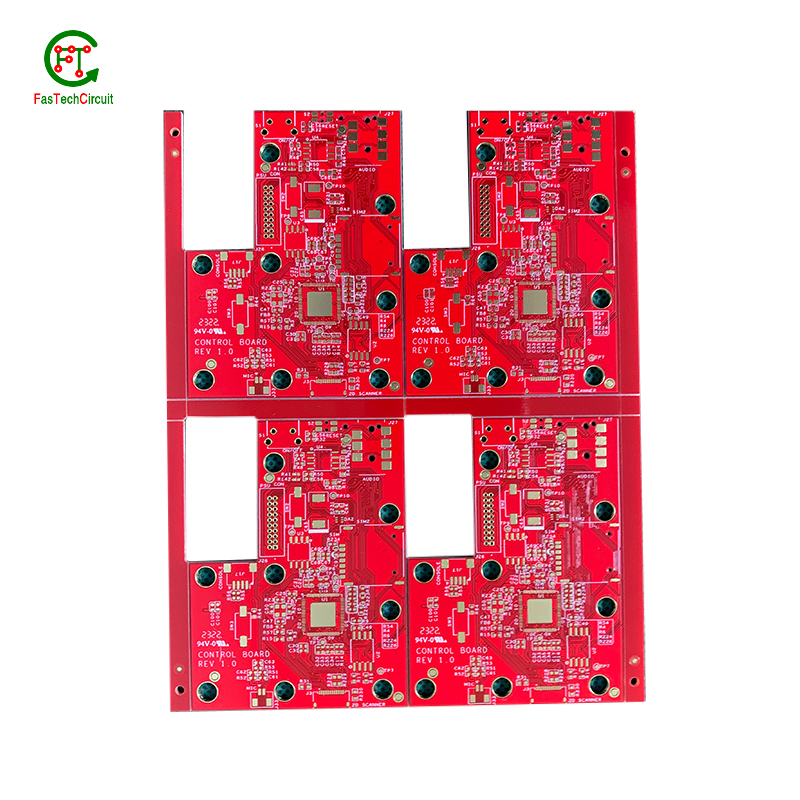

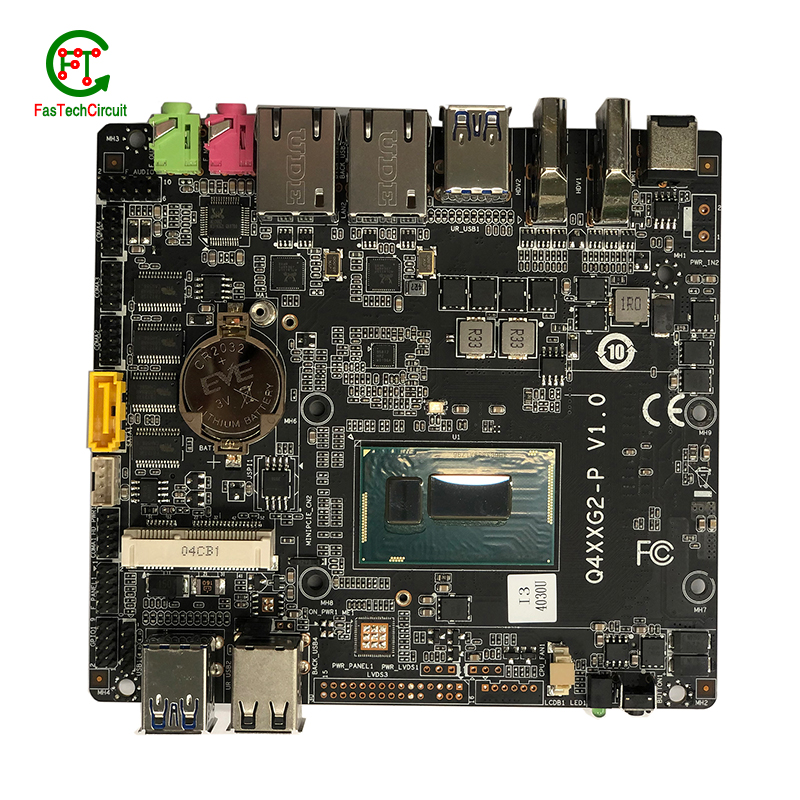

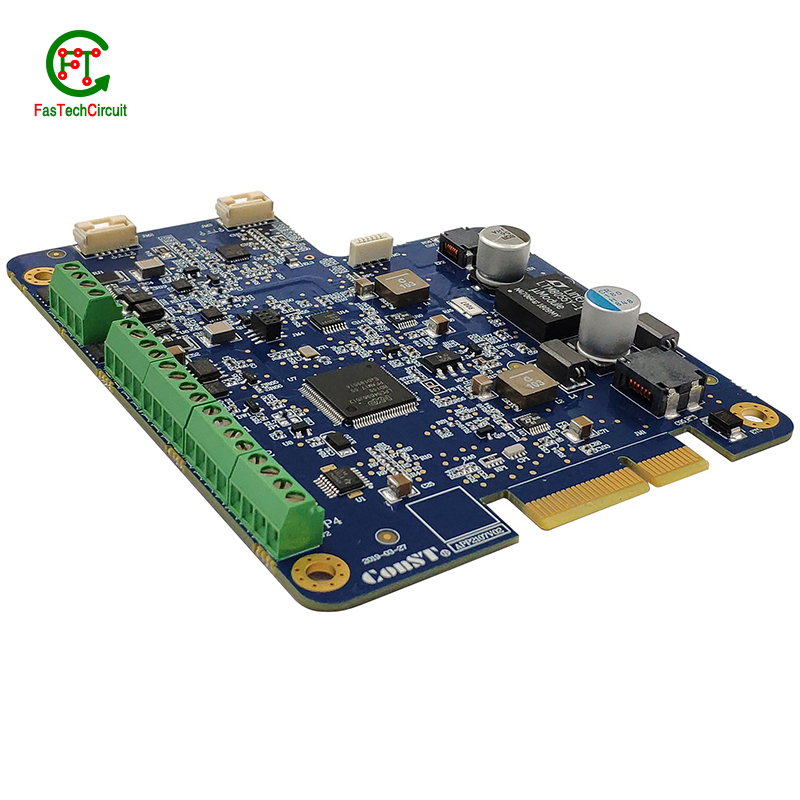

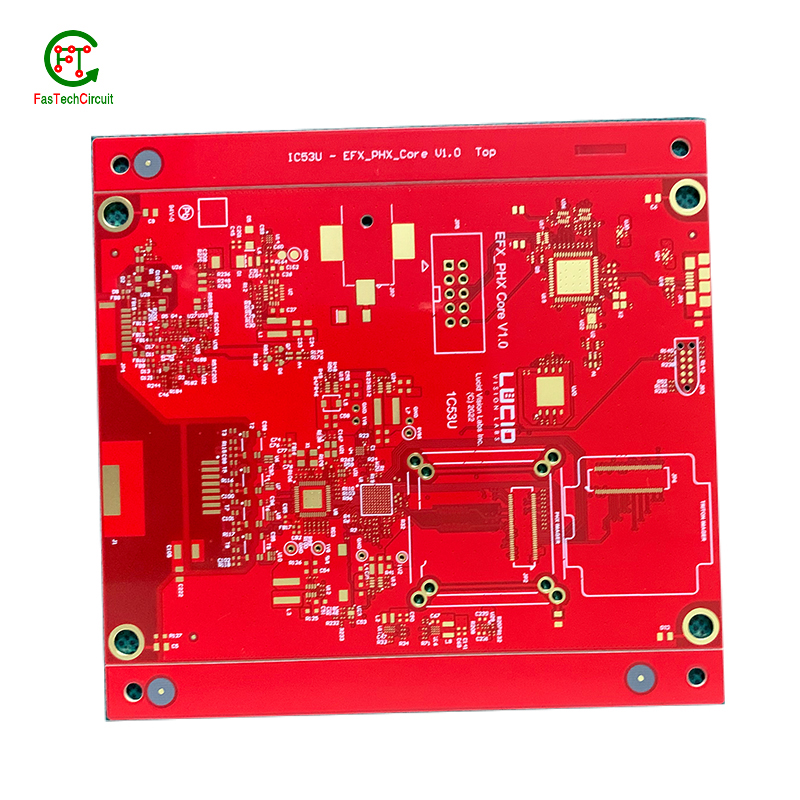

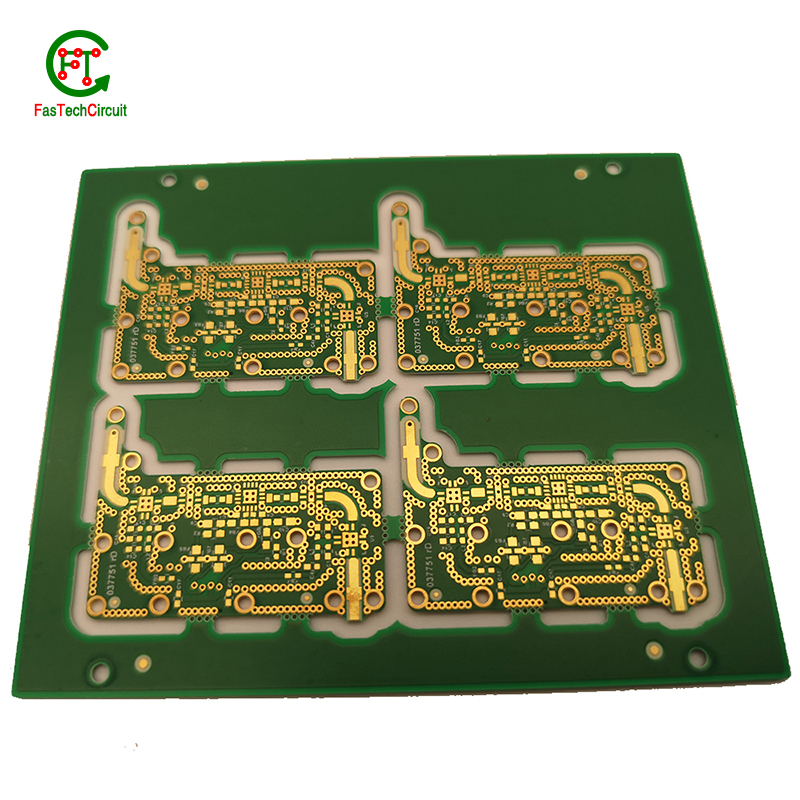

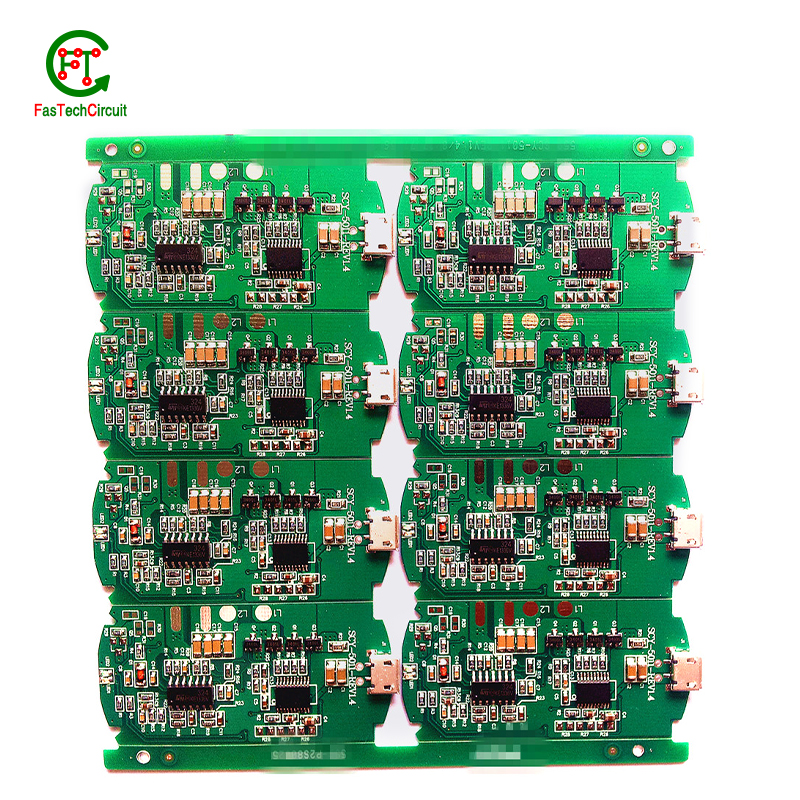

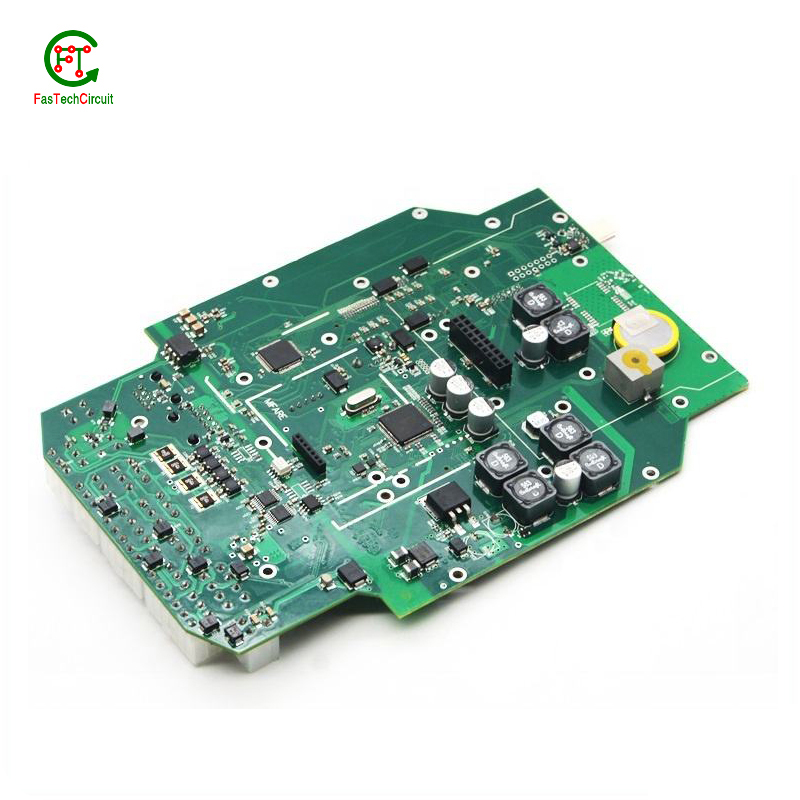

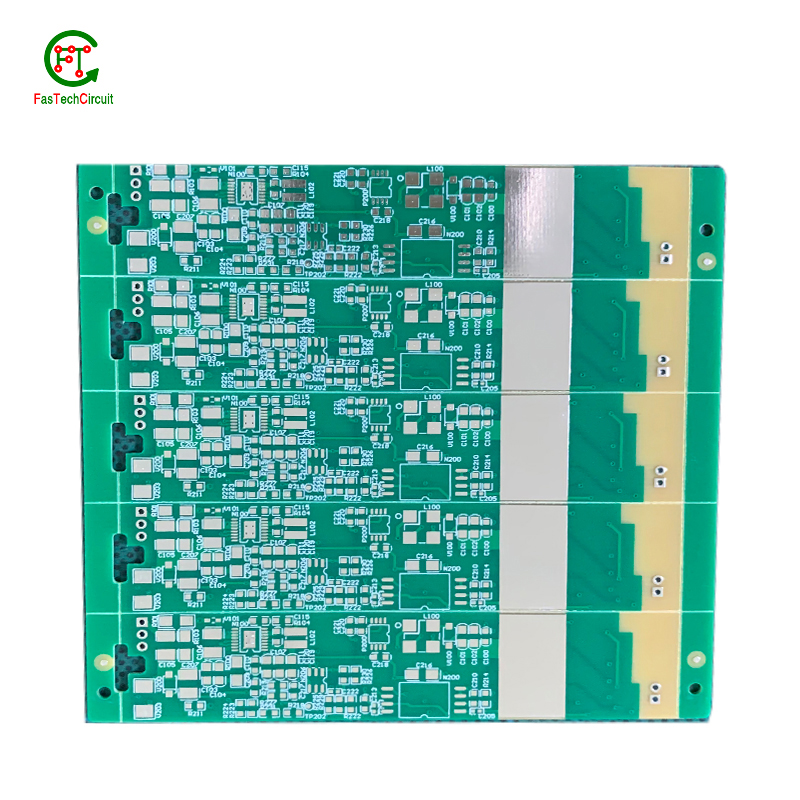

As a professional PCB manufacturer, our product range includes single-sided boards, double-sided boards, multi-layer boards, rigid-flexible connection boards, high-frequency boards, blind through boards, buried via boards, etc. At the same time, we also provide a variety of surface treatment processes, such as HASL, ENIG, OSP, metal spraying, etc., to meet the different needs of customers. We can provide one-stop OEM service with price advantage and fast delivery!

Our products are widely used in consumer electronics, communication equipment, industrial control, automotive electronics and other fields, and enjoy a high reputation in domestic and foreign markets. Our team has rich PCB manufacturing experience and professional skills and can provide customers with customized products and solutions. At the same time, we are also committed to continuously launching competitive and innovative products to meet the changing needs of customers. All our products comply with international quality standards and our customers come from different markets around the world. For example $keyworRd{4} etc.

| Model Number | customized PCBA |

| Type | pcba |

| Place of Origin | Guangdong, China |

| Brand Name | none |

| Copper Thickness | 1 oz |

| Supplier Type | OEM |

| Application | Electronics Device |

| Service | One-step Service |

| Layer | 1-44layers |

| Solder mask color | Blue.green.red.black.white.etc |

| Testing Service | 100% |

| Component size | 0201-1150mm |

| Component max height | 34mm |

| Min lead pitch | 0.3mm |

| Min BGA ball pitch | 0.4mm |

| Max PCB size | 436x502mm |

| Packaging Details | Vacuum package for bare PCB and ESD package for PCBA Printed Circuit Board Factory FPC Board PCBA Companies PCBA Assembly |

| Supply Ability | 41219 Piece/Pieces per Week |

| Quantity (pieces) | > 894 |

| Lead time (days) | 8 |

1800 layout pcb bearings FAQs Guide Welcome to our state-of-the-art PCB (Printed Circuit Board) products. We are proud to offer a comprehensive range of high-quality and versatile PCB solutions to meet the constantly evolving needs of the modern electronics industry.Our PCBs are expertly designed and manufactured using the latest technology and advanced techniques, ensuring reliability, durability, and exceptional performance for a wide range of applications. We understand the importance of precision and attention to detail in the production of PCBs and we are committed to meeting stringent quality standards.

2.What type of material is used for the silkscreen on a 1800 layout pcb?

3.How are 1800 layout pcbs protected from moisture and humidity?

4.How are 1800 layout pcbs designed?

5.What is the purpose of a 1800 layout pcb?

6.What are the advantages of using a 1800 layout pcb?

7.What is the role of silkscreen on a 1800 layout pcb?

8.What is embedded 1800 layout pcb technology?

9.Can 1800 layout pcbs be used in high voltage applications?

10.What are the most common uses for 1800 layout pcb?

11.What materials are used to make a 1800 layout pcb?

12.How are 1800 layout pcbs tested for quality control?

13.Can 1800 layout pcbs be used in high-frequency applications?

1.What is the difference between an analog and a digital signal on a 1800 layout pcb?

An analog signal is a continuous signal that varies in amplitude and frequency over time. It can take on any value within a given range and is typically represented by a smooth, continuous waveform. Analog signals are used to transmit information such as audio, video, and sensor data.

A digital signal, on the other hand, is a discrete signal that can only take on a limited number of values. It is represented by a series of binary digits (0s and 1s) and can only have two states: on or off. Digital signals are used to transmit information in the form of data and are commonly used in digital electronics such as computers and smartphones.

On a PCB, the main difference between analog and digital signals lies in the way they are processed and transmitted. Analog signals require specialized components such as amplifiers and filters to maintain their integrity, while digital signals can be processed and transmitted using digital logic circuits. Additionally, analog signals are more susceptible to noise and interference, while digital signals are more immune to these factors.

2.What type of material is used for the silkscreen on a 1800 layout pcb?

We have a wide range of 1800 layout pcb customer groups and establishes long -term cooperative relationships with partners. The countries we provide services include .

The material used for the silkscreen on a PCB is typically a white or black ink made of epoxy or acrylic. It is applied using a screen printing process and is cured at high temperatures to ensure durability and resistance to chemicals and solvents.

3.How are 1800 layout pcbs protected from moisture and humidity?

PCB (Printed Circuit Boards) are susceptible to damage from moisture and humidity, which can result in malfunction or even complete failure of electronic devices. Therefore, it is necessary to take measures to protect PCBs from these elements.

One way to protect PCBs from moisture is by using a conformal coating. This is a thin layer of protective material that is applied to the surface of the PCB. It acts as a barrier, preventing moisture from coming into contact with the sensitive components on the board.

Another method is to use moisture-resistant materials for the PCB itself. This can include using moisture-resistant coatings or laminates for the board, as well as corrosion-resistant materials for the conductors and connectors.

In addition to these preventive measures, PCBs can also be stored in controlled environments with low humidity levels. This can help to minimize the amount of moisture that comes into contact with the boards, reducing the risk of damage.

Regular maintenance and periodic testing can also help to ensure the continued protection of PCBs from moisture and humidity. By taking these precautions, electronic devices can maintain their functionality and reliability, even in environments with high humidity levels.

4.How are 1800 layout pcbs designed?

We should perform well in market competition, and the prices of 1800 layout pcb products have a great competitive advantage.

Printed Circuit Boards, commonly known as PCBs, are an essential part of modern-day technology. They serve as the foundation for electronic devices and are crucial to their functionality. The process of designing a PCB involves several stages, starting with creating a schematic diagram that outlines the connections between various electronic components. This is followed by placement and routing, where the physical layout of the board is determined and traces are added to connect the components. PCB designers use advanced software to optimize the layout and ensure that it meets the necessary electrical and mechanical requirements. Once the design is finalized, manufacturers can use the design files to produce the PCB. Designing a PCB requires a combination of technical knowledge, creativity, and attention to detail to create a functional and efficient circuit board for a specific application.

5.What is the purpose of a 1800 layout pcb?

We pay attention to the transformation of intellectual property protection and innovation achievements. Your OEM or ODM order design we have a complete confidentiality system.

A PCB (Printed Circuit Board) is a flat board made of non-conductive material, such as fiberglass, with conductive pathways etched or printed onto it. The main purpose of a PCB is to provide a platform for electronic components to be mounted and connected together to form a functioning electronic circuit. It serves as a physical support for the components and provides a means for them to communicate with each other through the conductive pathways. PCBs are used in a wide range of electronic devices, from simple household appliances to complex computer systems, and are essential for the proper functioning and reliability of these devices. They also allow for easier and more efficient production of electronic devices, as the components can be mounted and connected in a standardized and automated manner.

6.What are the advantages of using a 1800 layout pcb?

We are centered on customers and always pay attention to customers' needs for 1800 layout pcb products.

There are several advantages of using a PCB (Printed Circuit Board). Firstly, a PCB provides a compact and organized layout for electronic components, which makes it easier for technicians to troubleshoot and repair any issues. Secondly, it reduces the chances of loose connections and short circuits, which can be a major safety concern. Thirdly, PCBs are cost-effective and can be easily mass-produced, making them a popular choice for large-scale production. Additionally, they offer durability and stability, ensuring long-lasting performance. Finally, PCBs also allow for easy integration of new components, making it easier to upgrade or modify the electronic devices.

7.What is the role of silkscreen on a 1800 layout pcb?

Being one of the top 1800 layout pcb manufacturers in China, We attach great importance to this detail.

Silkscreen, also known as legend or nomenclature, is a vital component of a printed circuit board (PCB). It is the layer of text and symbols that are printed on the surface of the PCB to provide essential information for component placement and identification. The silkscreen plays a crucial role in the manufacturing process of PCBs, as it helps to ensure the accuracy and functionality of the final product. By indicating component locations, values, and reference designators, the silkscreen serves as a guide for the assembly and soldering of electronic components. Additionally, it also provides important information for maintenance and troubleshooting purposes.

8.What is embedded 1800 layout pcb technology?

Our products & services cover a wide range of areas and meet the needs of different fields.

Embedded PCB technology refers to the integration of electronic components directly onto a printed circuit board (PCB) during the manufacturing process. This allows for a more compact and efficient design, as well as improved reliability and performance. The components are embedded within the layers of the PCB, rather than being mounted on the surface, resulting in a more streamlined and durable product. This technology is commonly used in applications such as smartphones, tablets, and other portable electronic devices.

9.Can 1800 layout pcbs be used in high voltage applications?

We have advantages in marketing and channel expansion. Suppliers have established good cooperative relations, continuously improved workflows, improved efficiency and productivity, and provided customers with high -quality products and services.

Yes, PCBs (printed circuit boards) can be used in high voltage applications. However, the design and construction of the PCB must be carefully considered to ensure it can withstand the high voltage without causing damage or malfunction. This may include using specialized materials, increasing the spacing between components, and implementing proper insulation and grounding techniques. It is important to consult with a qualified engineer or designer when using PCBs in high voltage applications to ensure safety and reliability.

10.What are the most common uses for 1800 layout pcb?

We enjoy high authority and influence in the industry and continue to innovate products and service models.

Printed circuit boards, or PCBs, are widely used in electronic devices and equipment. They are used in everything from smartphones and computers to household appliances and automotive systems. PCBs are essential components for connecting electrical and electronic components together, providing a robust and reliable platform for digital and analog signals to pass through. Common uses for PCBs include controlling and powering electronic devices, storing and processing data, and providing a means of communication between components. They are also used in various industrial and commercial applications, such as automation and control systems, medical equipment, and aerospace technology. PCBs offer a cost-effective and efficient solution for creating complex electronic circuits, making them a crucial component in modern technology.

11.What materials are used to make a 1800 layout pcb?

We have advanced production equipment and technology to meet the needs of customers, and can provide customers with high quality, low priced 1800 layout pcb products.

A PCB, or printed circuit board, is typically made of a non-conductive material such as fiberglass or composite epoxy resin. This material acts as a base for a thin layer of copper foil, which is then etched to create the desired circuit pattern. Other common materials used in the production of PCBs include solder mask, a polymer layer used to insulate and protect the copper traces, and silkscreen, which is used to label and identify the different components on the PCB. In addition, various electronic components such as resistors, capacitors, and diodes are also mounted onto the PCB to form a functional electronic circuit. Other potential materials used in the production of PCBs include metal core, ceramics, and conductive ink, depending on the specific design and requirements of the circuit.

12.How are 1800 layout pcbs tested for quality control?

We have broad development space in domestic and foreign markets. 1800 layout pcb have great advantages in terms of price, quality, and delivery date.

PCB (Printed Circuit Board) testing is a critical step in the quality control process of electronic products. It ensures that all components and connections on the board are functioning correctly and that the PCB meets the required standards and specifications.

The testing process typically starts with a visual inspection to identify any visible defects, such as incorrect soldering or damaged components. Next, electrical testing is conducted to check the functionality of each individual component and the overall circuit.

One common method of testing is the use of a test fixture, which applies signals to the PCB and checks for correct responses. Other methods include automated optical inspection (AOI) and in-circuit testing (ICT).

Once the initial testing is completed, the PCB may undergo environmental testing to simulate real-life conditions and ensure its reliability and durability. This includes temperature and humidity cycling, vibration and shock testing, and more.

13.Can 1800 layout pcbs be used in high-frequency applications?

Our mission is to provide customers with the best solutions for 1800 layout pcb.

Yes, PCBs (printed circuit boards) can be used in high-frequency applications. However, the design and construction of the PCB must be carefully considered to ensure optimal performance at high frequencies. This includes using specialized materials, such as high-frequency laminates, and implementing proper grounding and shielding techniques. Additionally, the layout and routing of the PCB must be optimized to minimize signal loss and interference.

RELATED PRODUCTS & SERVICE

pcb board manufacturing How To Contact US

PCB from 1 to 30 layers, HDI, Heavy Copper, Rigid-flex board with "pcb board manufacturing One-Stop" service.