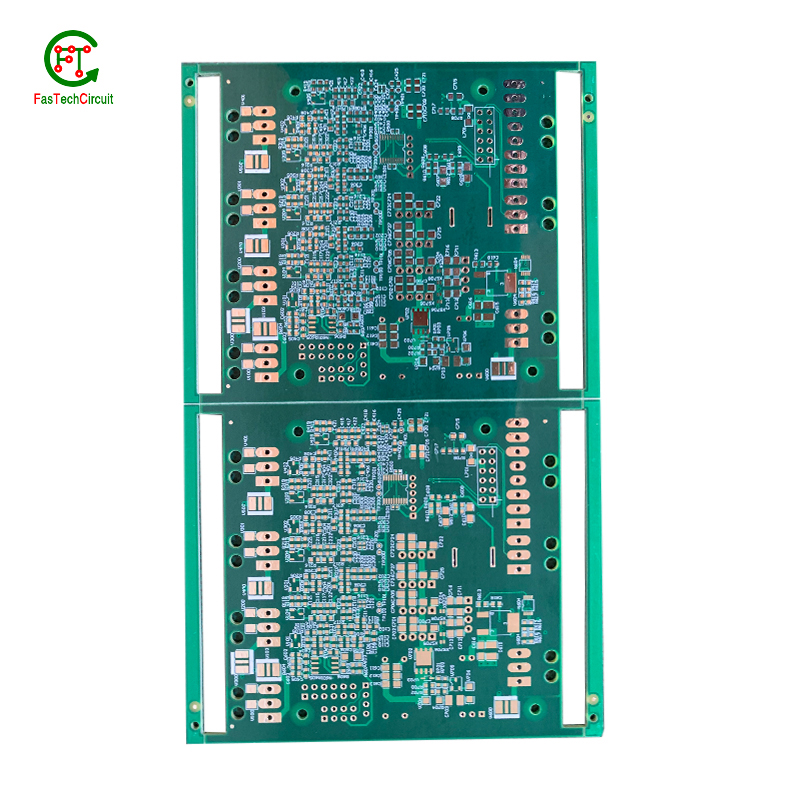

25g ethernet pcb design

| Model Number | customized PCBA |

| Type | pcba |

| Place of Origin | Guangdong, China |

| Brand Name | none |

| Copper Thickness | 1 oz |

| Supplier Type | OEM |

| Application | Electronics Device |

| Service | One-step Service |

| Layer | 1-40layers |

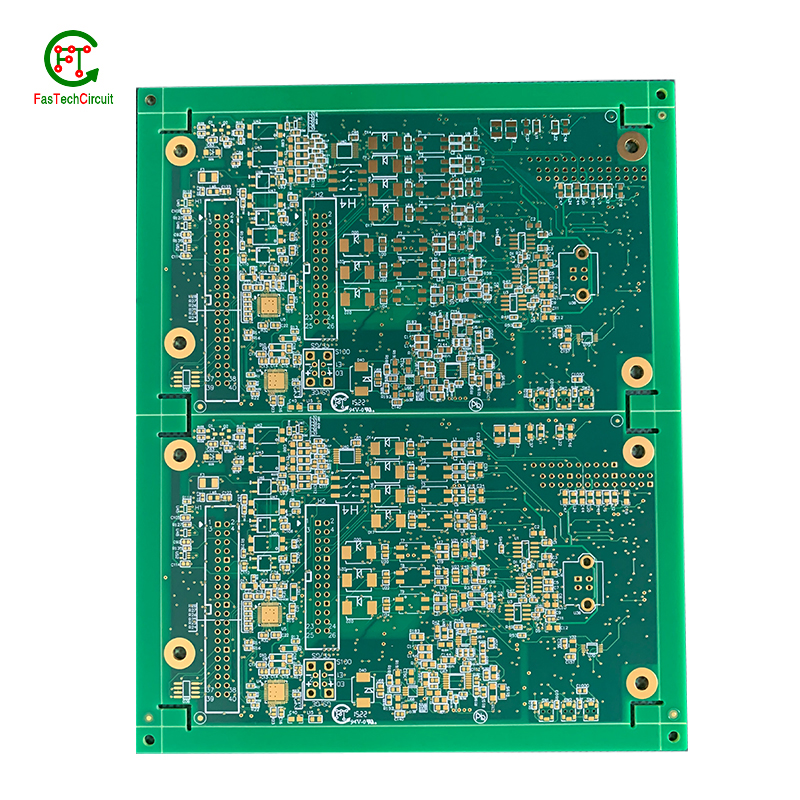

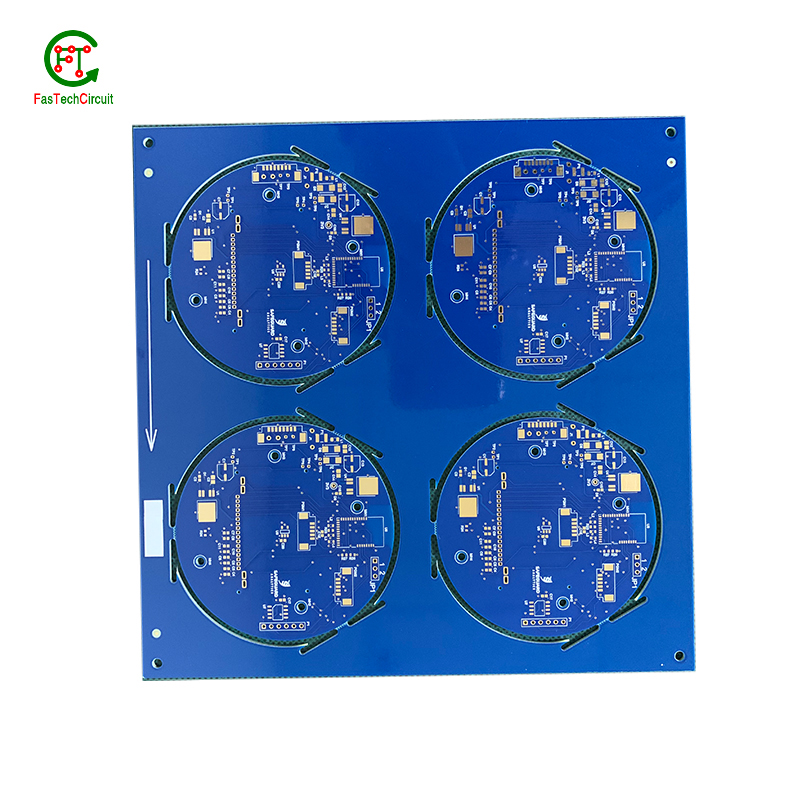

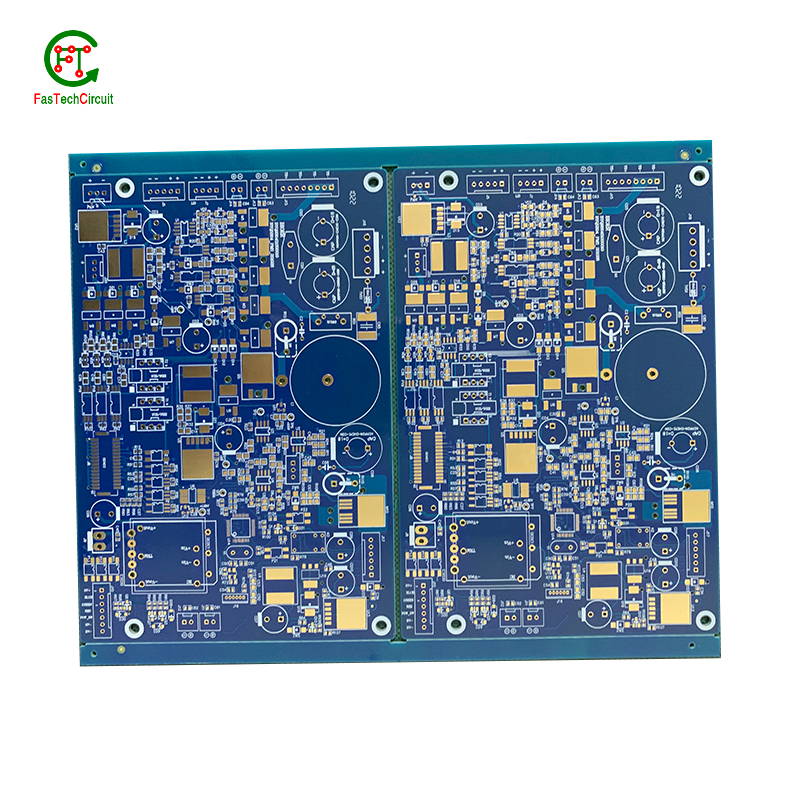

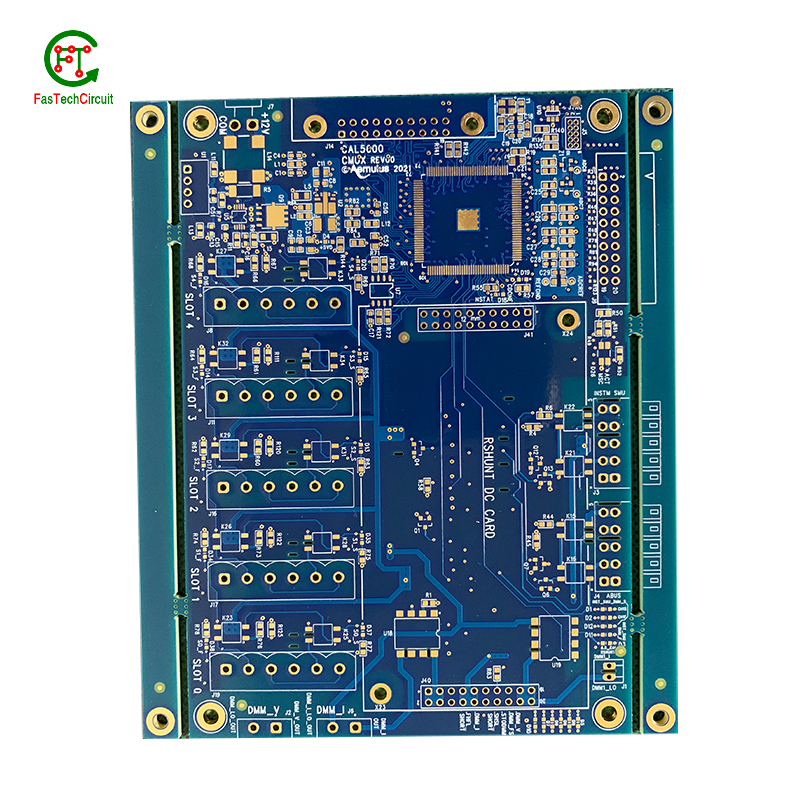

| Solder mask color | Blue.green.red.black.white.etc |

| Testing Service | 100% |

| Component size | 0201-1155mm |

| Component max height | 22mm |

| Min lead pitch | 0.1mm |

| Min BGA ball pitch | 0.4mm |

| Max PCB size | 508x454mm |

| Packaging Details | Vacuum package for bare PCB and ESD package for PCBA Printed Circuit Board Factory FPC Board PCBA Companies PCBA Assembly |

| Supply Ability | 55936 Piece/Pieces per Week |

| Quantity (pieces) | > 886 |

| Lead time (days) | 14 |

25g ethernet pcb design bearings FAQs Guide Welcome to our state-of-the-art PCB (Printed Circuit Board) products. We are proud to offer a comprehensive range of high-quality and versatile PCB solutions to meet the constantly evolving needs of the modern electronics industry.Our PCBs are expertly designed and manufactured using the latest technology and advanced techniques, ensuring reliability, durability, and exceptional performance for a wide range of applications. We understand the importance of precision and attention to detail in the production of PCBs and we are committed to meeting stringent quality standards.

2.What is the difference between single-sided, double-sided, and multi-layer 25g ethernet pcb design?

3.How are components attached to a 25g ethernet pcb design?

4.What is a through-hole component?

5.How does a 25g ethernet pcb design work?

6.What is the difference between a copper pour and a trace on a 25g ethernet pcb design?

7.How are signal traces routed on a 25g ethernet pcb design?

8.What does 25g ethernet pcb design stand for?

9.What is the role of a data sheet in 25g ethernet pcb design design?

10.What is the typical lifespan of a 25g ethernet pcb design?

11.How is a 25g ethernet pcb design tested for functionality?

12.What is the lifespan of a 25g ethernet pcb design under harsh environmental conditions?

13.What are the benefits of using surface mount technology (SMT) for 25g ethernet pcb design?

14.What is the purpose of a ground plane on a 25g ethernet pcb design?

15.How are components selected for a 25g ethernet pcb design design?

16.What is embedded 25g ethernet pcb design technology?

17.What is the difference between a gold-plated and a tin-plated 25g ethernet pcb design?

18.What is the minimum thickness of a 25g ethernet pcb design?

1.What are some common 25g ethernet pcb design layout guidelines?

We should have a stable supply chain and logistics capabilities, and provide customers with high -quality, low -priced 25g ethernet pcb design products.

Thermal considerations play a crucial role in the design of printed circuit boards (PCBs). The concept of heat management is critical as excessive heat can lead to reduced performance and potential damage to the electronic components on the board. This is why thermal considerations are carefully taken into account during PCB design. Designers must carefully consider factors such as the size, placement, and orientation of components on the board to ensure efficient heat dissipation. They also need to factor in the type and thickness of the board material, as well as incorporate proper ventilation and heat sinks to prevent overheating. By carefully considering these thermal aspects during the design process, the resulting PCBs can perform optimally and have a longer lifespan.

2.What is the difference between single-sided, double-sided, and multi-layer 25g ethernet pcb design?

We have established a good reputation and reliable partnerships within the 25g ethernet pcb design industry.

Single-sided PCB (Printed Circuit Board) is a type of PCB that has components and traces on only one side of the board. The other side is usually used for soldering and mounting the board onto a larger circuit.

Double-sided PCB is a type of PCB that has components and traces on both sides of the board. The traces on both sides are connected through vias, which are small holes drilled through the board and plated with metal to create an electrical connection.

Multi-layer PCB is a type of PCB that has multiple layers of conductive material and insulating material sandwiched together. The layers are connected through vias, allowing for more complex and compact circuit designs. Multi-layer PCBs are used in more advanced and high-performance electronic devices.

3.How are components attached to a 25g ethernet pcb design?

We adhere to the principle of integrity and transparency, and establish long -term relationships with partners, and we attach great importance to this detail.

eads or pins of the component and melting solder onto them, whicComponents are attached to a PCB (printed circuit board) through a process called soldering. This involves heating the metal lh then solidifies and creates a strong electrical and mechanical connection between the component and the PCB. There are two main methods of soldering components onto a PCB:

1. Through-hole soldering: This method involves inserting the leads or pins of the component through pre-drilled holes on the PCB and soldering them on the opposite side of the board. This method is commonly used for larger components such as resistors, capacitors, and integrated circuits.

2. Surface mount soldering: This method involves soldering the component directly onto the surface of the PCB, without the need for pre-drilled holes. This is done using specialized equipment such as a soldering iron or a reflow oven. Surface mount components are smaller in size and are commonly used for more complex and compact electronic devices.

4.What is a through-hole component?

We focus on providing high 25g ethernet pcb design quality products and services.

A through-hole component is an electronic component that has leads or pins that are inserted into holes on a printed circuit board (PCB) and then soldered to the opposite side of the board. This type of component is typically larger and more robust than surface mount components, and is often used for high-power or high-voltage applications. Through-hole components are also easier to replace or repair compared to surface mount components.

5.How does a 25g ethernet pcb design work?

We maintain a stable growth through reasonable capital operations, focus on industry development trends and cutting -edge technologies, and focus on product quality and safety performance.

A PCB (Printed Circuit Board) is a thin board made of non-conductive material, such as fiberglass or plastic, with conductive pathways etched or printed onto its surface. These pathways, also known as traces, are used to connect electronic components on the board, such as resistors, capacitors, and integrated circuits.

The PCB works by providing a platform for the components to be mounted and connected in a specific circuit configuration. The traces on the board act as wires, allowing electricity to flow between the components and creating a complete circuit.

The process of creating a PCB involves several steps, including designing the circuit layout, printing or etching the traces onto the board, and attaching the components using soldering techniques. Once the components are attached, the board is tested to ensure that all connections are correct and functioning properly.

When a PCB is connected to a power source, electricity flows through the traces, powering the components and allowing them to perform their intended functions. The traces also act as a pathway for signals to travel between components, allowing for communication and data transfer within the circuit.

PCBs are used in a wide range of electronic devices, from simple household appliances to complex computer systems. They provide a compact and efficient way to connect and control electronic components, making them an essential part of modern technology.

6.What is the difference between a copper pour and a trace on a 25g ethernet pcb design?

We adhere to the principle of quality first and have a complete production quality management system and quality inspection process.

A copper pour and a trace are two common electronic components that are found on a printed circuit board (PCB). A copper pour is a large area of copper that is used to connect multiple components or ground signals together on a PCB. This creates a solid and low resistance pathway for signals to flow. On the other hand, a trace is a thin line of copper used to connect individual components on a PCB. It carries a specific signal from one component to another. Unlike a copper pour, a trace can be designed to carry a specific current and have a specific width to meet the requirements of the circuit.

7.How are signal traces routed on a 25g ethernet pcb design?

Signal traces are an essential element of a PCB, responsible for carrying electronic signals between components and ensuring proper communication and functionality of the circuit. To route these traces, designers use specialized software to determine the most efficient and optimal path for each signal, taking into account factors such as signal integrity, trace length, and potential interference. This process involves careful planning, as well as techniques such as vias, ground and power planes, and differential pairs to minimize noise and maintain signal integrity.

8.What does 25g ethernet pcb design stand for?

We attach importance to the innovation ability and team spirit of employees, have advanced R & D facilities and laboratories, and have a good quality management system.

PCB stands for Printed Circuit Board.

9.What is the role of a data sheet in 25g ethernet pcb design design?

A data sheet is an essential tool for PCB design, providing vital information and specifications for all of the components used in the design process. It contains detailed technical data, such as dimensions, electrical ratings, and performance characteristics, that allow designers to make informed decisions when selecting and placing components on a PCB. By referencing the data sheet, designers can ensure that each component is properly integrated into the overall design, following any necessary guidelines or restrictions. Additionally, data sheets also provide necessary information for the layout and routing of traces on the PCB, ensuring that the design can meet required performance specifications.

10.What is the typical lifespan of a 25g ethernet pcb design?

25g ethernet pcb design is not a product only, but also can help you comes to money-making.

The typical lifespan of a PCB (printed circuit board) can vary greatly depending on various factors such as the quality of materials used, environmental conditions, and usage. In general, a well-designed and properly manufactured PCB can last for 10-20 years or more. However, some PCBs may fail prematurely due to factors such as corrosion, thermal stress, or mechanical damage. Regular maintenance and proper handling can also extend the lifespan of a PCB.

11.How is a 25g ethernet pcb design tested for functionality?

A PCB, or Printed Circuit Board, is tested for functionality to ensure that all components and connections on the board are working correctly. This is important in order to detect any potential manufacturing or design defects that could compromise the board's performance. To test a PCB, a range of diagnostic tools and techniques are used including visual inspection, automated testing software, and specialized equipment such as oscilloscopes and multimeters. Experienced technicians also use their knowledge and expertise to troubleshoot and identify any issues with the board. Through this rigorous testing process, any faults or failures are identified and resolved before the PCB is released for production, ensuring that it meets the desired functionality and performance standards.

12.What is the lifespan of a 25g ethernet pcb design under harsh environmental conditions?

The lifespan of a PCB (printed circuit board) under harsh environmental conditions can vary greatly depending on the specific conditions and the quality of the PCB. In general, a well-designed and high-quality PCB can last for 10-20 years under harsh conditions such as extreme temperatures, humidity, and exposure to chemicals or vibrations. However, if the PCB is not properly designed or manufactured, its lifespan can be significantly shorter, potentially lasting only a few years or even months. Factors such as the type of materials used, the thickness of the copper traces, and the quality of the solder joints can also affect the lifespan of a PCB under harsh environmental conditions. Regular maintenance and proper handling can also help extend the lifespan of a PCB.

13.What are the benefits of using surface mount technology (SMT) for 25g ethernet pcb design?

We focus on innovation and continuous improvement to maintain a competitive advantage.

Surface mount technology (SMT) is a popular method for assembling printed circuit boards (PCBs) that offers numerous benefits over traditional through-hole components. Firstly, SMT components are smaller and more compact, allowing for greater PCB density and reducing the overall size of the board. This makes SMT ideal for increasingly miniaturized electronics, such as smartphones and wearables. Additionally, SMT components are typically cheaper and easier to manufacture, leading to cost savings in both materials and labor. SMT also allows for automated assembly, resulting in faster and more efficient production processes. Furthermore, the smaller size of SMT components leads to improved electrical performance due to decreased parasitic effects and shorter signal paths. This makes SMT ideal for high-frequency applications.

14.What is the purpose of a ground plane on a 25g ethernet pcb design?

I have a comprehensive after -sales service system, which can pay attention to market trends in time and adjust our strategy in a timely manner.

A decoupling capacitor is an essential component on a PCB (Printed Circuit Board) which is used to reduce or eliminate high frequency noise between different components. It acts as a buffer between the power supply and other circuit components, by storing electrical charge and then releasing it when there is a sudden change in the supply voltage. This helps to stabilize the power supply, providing a steady and noise-free flow of electricity to the circuit. Furthermore, decoupling capacitors also help to filter out any unwanted signals that may cause interference or disruptions in the proper functioning of the circuit.

15.How are components selected for a 25g ethernet pcb design design?

We pay attention to employee development and benefits, and provide a good working environment in order to improve the efficiency of employees and improve the quality management of 25g ethernet pcb design products.

A power rating for a PCB, or Printed Circuit Board, is a measure of the maximum amount of power the board is able to safely handle. This rating takes into account the overall design and materials used in the creation of the PCB, as well as the environment in which it will be used. It is an important consideration in electronics and circuit design as exceeding the power rating can lead to overheating and potential damage to the board and connected components. Properly understanding and adhering to the power rating of a PCB is crucial for ensuring safe and efficient operation of electronic devices.

16.What is embedded 25g ethernet pcb design technology?

Our products & services cover a wide range of areas and meet the needs of different fields.

Embedded PCB technology refers to the integration of electronic components directly onto a printed circuit board (PCB) during the manufacturing process. This allows for a more compact and efficient design, as well as improved reliability and performance. The components are embedded within the layers of the PCB, rather than being mounted on the surface, resulting in a more streamlined and durable product. This technology is commonly used in applications such as smartphones, tablets, and other portable electronic devices.

17.What is the difference between a gold-plated and a tin-plated 25g ethernet pcb design?

A gold-plated PCB (Printed Circuit Board) is a type of PCB that has a thin layer of gold coating on its surface. This layer is added through a process called electroplating and is commonly used to protect the PCB components from corrosion and increase the conductivity. On the other hand, a tin-plated PCB has a layer of tin coating on its surface, which is also applied through electroplating. Unlike gold plating, tin plating is mainly used to prevent oxidization and improve solderability.

18.What is the minimum thickness of a 25g ethernet pcb design?

We are committed to providing personalized solutions and established long -term strategic cooperative relationships with customers.

The minimum thickness of a PCB (printed circuit board) can vary depending on the materials and manufacturing processes used. However, the standard minimum thickness for a single-sided PCB is 0.6mm (0.024 inches) and for a double-sided PCB it is 0.8mm (0.032 inches). Thinner PCBs can be made, but they may be more fragile and have limitations on the components and circuitry that can be used.

RELATED PRODUCTS & SERVICE

pcb board manufacturing How To Contact US

PCB from 1 to 30 layers, HDI, Heavy Copper, Rigid-flex board with "pcb board manufacturing One-Stop" service.