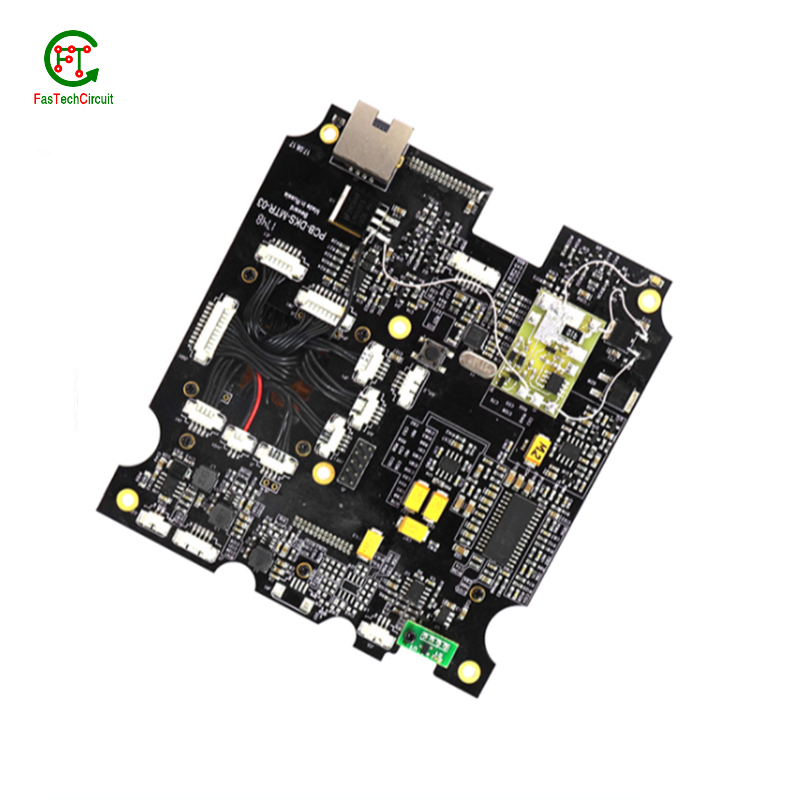

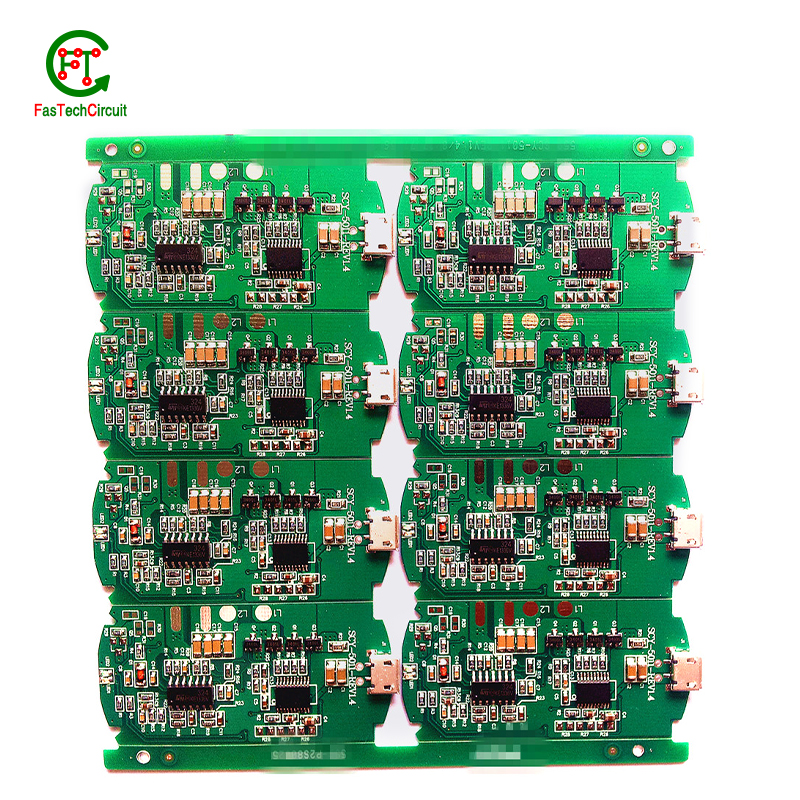

2 ghz oscillator vco circuit pcb

We have 20 QC auditors with three years of experience who use advanced testing equipment such as AOI, BGA X-ray and PCB E-test to ensure that all our products comply with IECQ-HSPM QC 080000, CE, UL and RoHS Certification. All our products comply with international quality standards and our customers come from different markets around the world. For example Cocos (Keeling) Islands,Bahrain,Liechtenstein,Navassa Island,Israel,Bahamas, The etc.

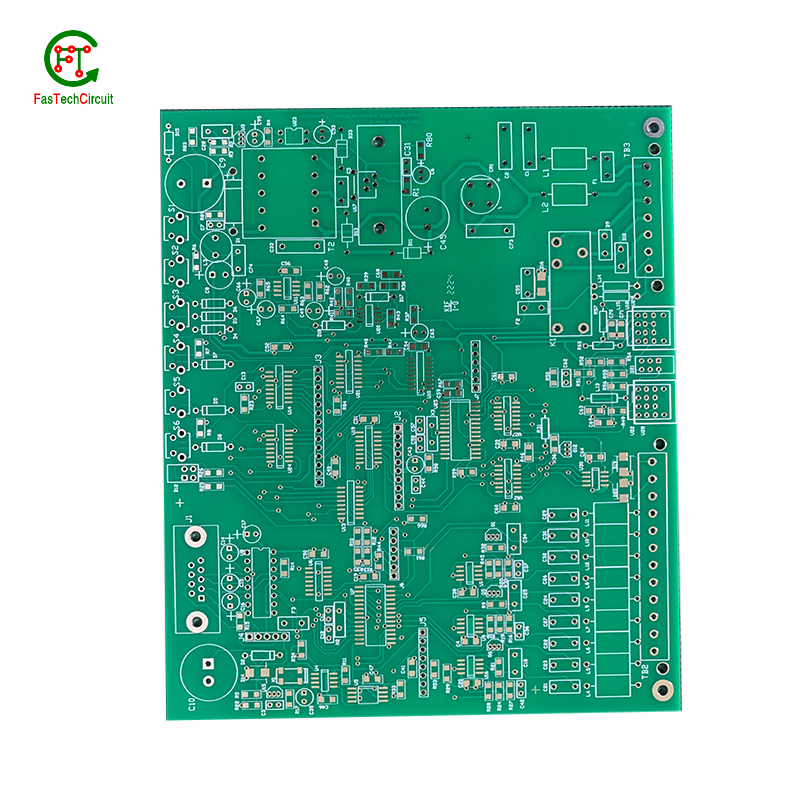

| Number of Layers | 4 layer |

| Base Material | gold sinking |

| Board Thickness | 1.5MM |

| Board Size | 251M*611MM |

| Model Number | 4 layer pcb |

| Type | pcb |

| Place of Origin | Original |

| Brand Name | Original |

| Copper Thickness | 3OZ |

| Min. Hole Size | custom made |

| Min. Line Width | custom made |

| Min. Line Spacing | custom made |

| Surface Finishing | custom made |

| Impedance control | +/- 8% |

| Warpage | less than 1% |

| Packaging Details | New and Original, factory sealed packing, it will be pack in one of these packing type: Tube, Tray, Tape and Reel, Tape and Box, Bulk packing, Bag and etc. Please kindly contact us for more details. |

| Supply Ability | 5590 Piece/Pieces per Week |

| Quantity (pieces) | > 14217 |

| Lead time (days) | 5 |

2 ghz oscillator vco circuit pcb bearings FAQs Guide Welcome to our state-of-the-art PCB (Printed Circuit Board) products. We are proud to offer a comprehensive range of high-quality and versatile PCB solutions to meet the constantly evolving needs of the modern electronics industry.Our PCBs are expertly designed and manufactured using the latest technology and advanced techniques, ensuring reliability, durability, and exceptional performance for a wide range of applications. We understand the importance of precision and attention to detail in the production of PCBs and we are committed to meeting stringent quality standards.

2.How are signal integrity issues addressed in 2 ghz oscillator vco circuit pcb design?

3.What are the main components of a 2 ghz oscillator vco circuit pcb?

4.Can 2 ghz oscillator vco circuit pcbs be used in automotive applications?

5.What is the difference between a copper pour and a trace on a 2 ghz oscillator vco circuit pcb?

6.How are 2 ghz oscillator vco circuit pcbs protected from moisture and humidity?

7.What is the future outlook for 2 ghz oscillator vco circuit pcb technology?

8.What is the role of vias on a 2 ghz oscillator vco circuit pcb?

9.Are 2 ghz oscillator vco circuit pcb recyclable?

10.How are high-frequency signals handled on a 2 ghz oscillator vco circuit pcb?

11.What is the maximum size of a 2 ghz oscillator vco circuit pcb?

12.How are power and ground planes connected on a 2 ghz oscillator vco circuit pcb?

13.What is the power rating for a 2 ghz oscillator vco circuit pcb?

14.What are some common problems that can occur with 2 ghz oscillator vco circuit pcb?

15.How does a 2 ghz oscillator vco circuit pcb work?

16.How are components selected for a 2 ghz oscillator vco circuit pcb design?

17.What does 2 ghz oscillator vco circuit pcb stand for?

18.Can 2 ghz oscillator vco circuit pcbs be customized?

1.What is the purpose of a solder mask on a 2 ghz oscillator vco circuit pcb?

We have a good reputation and image in the industry. The quality and price advantage of 2 ghz oscillator vco circuit pcb products is an important factor in our hard overseas market.

A solder mask is a thin layer of protective material applied to a printed circuit board (PCB) to prevent solder from bridging between conductive traces, pads, or vias during the soldering process. It also helps to protect the PCB from environmental factors such as moisture, dust, and corrosion. Additionally, the solder mask can provide insulation between conductive traces, reducing the risk of short circuits. It also helps to improve the overall appearance of the PCB by providing a uniform and professional finish.

2.How are signal integrity issues addressed in 2 ghz oscillator vco circuit pcb design?

We focus on our customers' needs and strive to meet their expectations, so we take this very seriously.

Signal integrity issues are a common concern in PCB design, as they can greatly affect the performance and reliability of electronic systems. These issues arise from high-speed signal transmissions on the board, which can result in degraded signals, data errors, and even system failures. In order to address these issues, PCB designers must consider various factors such as layout, routing, and component placement to ensure proper signal integrity. This involves implementing signal protection measures such as controlled impedance routing, signal shielding, and minimizing signal crosstalk. Additionally, designers may use simulation and analysis tools to identify and resolve any potential signal integrity problems before the PCB goes into production. By carefully addressing signal integrity issues in the design phase, PCBs can achieve optimal performance and functionality.

3.What are the main components of a 2 ghz oscillator vco circuit pcb?

We continuously upgrade our skills and knowledge to adapt to changing 2 ghz oscillator vco circuit pcb market needs.

A typical PCB consists of several vital components, including a substrate material, copper traces, solder mask, silk screen, and plated through-holes. The substrate material acts as the base and provides mechanical support for the board. Copper traces, usually made of thin lines of copper foil, serve as the conductive paths for transmitting electrical signals. The solder mask, applied as a protective layer, prevents accidental short circuits and corrosion. Silk screen, a layer of ink-based labeling, aids in component identification. Lastly, plated through-holes enable electrical connection between different layers of the PCB board. These components work together to form a fully functioning PCB.

4.Can 2 ghz oscillator vco circuit pcbs be used in automotive applications?

Yes, PCBs (printed circuit boards) can be used in automotive applications. They are commonly used in various electronic systems in vehicles, such as engine control units, infotainment systems, and safety systems. PCBs offer a compact and reliable way to connect and control electronic components in vehicles. They are also designed to withstand harsh environmental conditions, such as temperature fluctuations, vibrations, and moisture, making them suitable for use in automotive applications.

5.What is the difference between a copper pour and a trace on a 2 ghz oscillator vco circuit pcb?

We adhere to the principle of quality first and have a complete production quality management system and quality inspection process.

A copper pour and a trace are two common electronic components that are found on a printed circuit board (PCB). A copper pour is a large area of copper that is used to connect multiple components or ground signals together on a PCB. This creates a solid and low resistance pathway for signals to flow. On the other hand, a trace is a thin line of copper used to connect individual components on a PCB. It carries a specific signal from one component to another. Unlike a copper pour, a trace can be designed to carry a specific current and have a specific width to meet the requirements of the circuit.

6.How are 2 ghz oscillator vco circuit pcbs protected from moisture and humidity?

PCB (Printed Circuit Boards) are susceptible to damage from moisture and humidity, which can result in malfunction or even complete failure of electronic devices. Therefore, it is necessary to take measures to protect PCBs from these elements.

One way to protect PCBs from moisture is by using a conformal coating. This is a thin layer of protective material that is applied to the surface of the PCB. It acts as a barrier, preventing moisture from coming into contact with the sensitive components on the board.

Another method is to use moisture-resistant materials for the PCB itself. This can include using moisture-resistant coatings or laminates for the board, as well as corrosion-resistant materials for the conductors and connectors.

In addition to these preventive measures, PCBs can also be stored in controlled environments with low humidity levels. This can help to minimize the amount of moisture that comes into contact with the boards, reducing the risk of damage.

Regular maintenance and periodic testing can also help to ensure the continued protection of PCBs from moisture and humidity. By taking these precautions, electronic devices can maintain their functionality and reliability, even in environments with high humidity levels.

7.What is the future outlook for 2 ghz oscillator vco circuit pcb technology?

Printed Circuit Boards, or PCBs, have been a vital component in electronic devices for decades. They serve as the foundation for the electrical connections and components that make our devices function properly. As technology continues to advance, so does the demand for smaller, faster, and more efficient PCBs. With the rise of IoT and smart devices, the future outlook for PCB technology is promising. It is expected that PCBs will become even more compact and complex, utilizing advanced materials and techniques such as 3D printing and flexible substrates. This will not only improve the performance of electronic devices, but also make them more durable and cost-effective. Furthermore, as sustainability becomes a growing concern, eco-friendly PCB materials and manufacturing processes are being developed to reduce environmental impact. With these advancements, it is safe to say that the future of PCB technology is bright and full of endless possibilities.

8.What is the role of vias on a 2 ghz oscillator vco circuit pcb?

Our company has many years of 2 ghz oscillator vco circuit pcb experience and expertise.

Vias play a crucial role in connecting different layers of a printed circuit board (PCB). These small, plated holes act as conductive paths, allowing signals and power to pass through the board and reach various components. Vias are also essential for routing traces from one layer to another, optimizing the layout and reducing the size and complexity of the board. Additionally, vias provide structural support and improve thermal management by facilitating heat dissipation.

9.Are 2 ghz oscillator vco circuit pcb recyclable?

We have been working hard to improve service quality and meet customer needs.

Yes, PCBs (printed circuit boards) are recyclable. They can be broken down and the individual components can be reused or repurposed. However, the recycling process can be complex and requires specialized equipment and techniques. It is important to properly dispose of PCBs to prevent environmental contamination and health hazards.

10.How are high-frequency signals handled on a 2 ghz oscillator vco circuit pcb?

High-frequency signals are typically handled with great care and precision on a PCB to ensure optimal performance. This involves using high-quality materials, such as high-speed laminates and low-loss dielectrics, to minimize signal loss and interference. Additionally, designers must carefully consider the trace routing and placement of components on the PCB to minimize signal reflections and keep the signal path as short and direct as possible. Specialized techniques, like controlled impedance and shielding, may also be used to further improve signal integrity.

11.What is the maximum size of a 2 ghz oscillator vco circuit pcb?

We pay attention to the introduction and training of talents, scientifically regulate the management system, and focus on cultural construction and team cohesion.

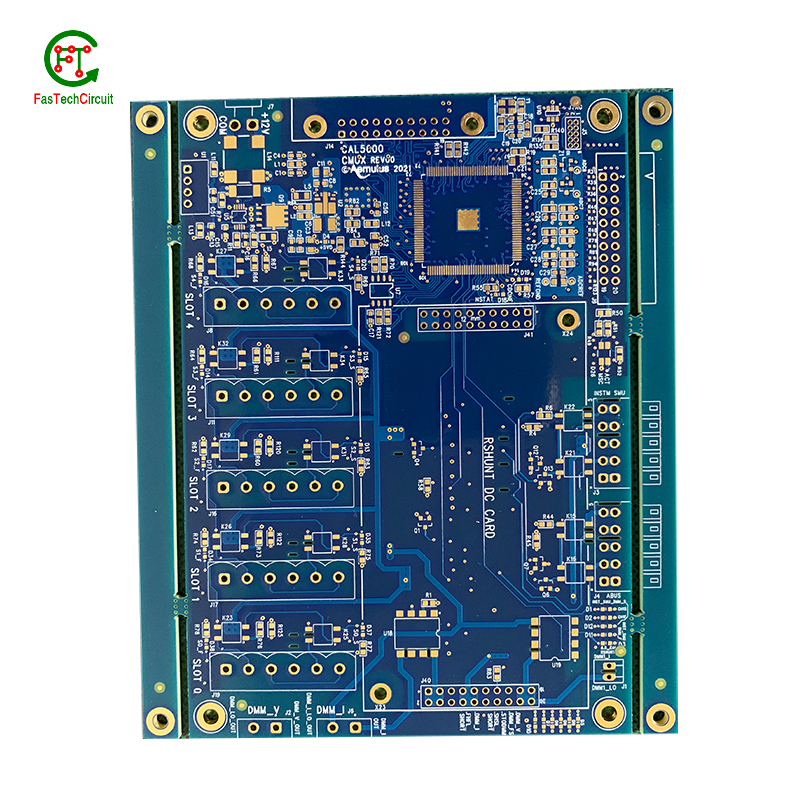

The maximum size of a PCB (printed circuit board) can vary depending on the manufacturer and theircapabilities. However, the industry standard maximum size for a single PCB panel is typically around 18 inches by 24 inches (457 mm by 610 mm). Larger PCBs can be created by combining multiple panels together. Some manufacturers may also have the capability to create custom-sized PCBs that exceed the industry standard maximum size.

12.How are power and ground planes connected on a 2 ghz oscillator vco circuit pcb?

Power and ground planes are typically connected on a PCB through vias, which are small holes drilled through the layers of the PCB. These vias are filled with conductive material, such as copper, and allow for the flow of current between the power and ground planes. The vias are strategically placed throughout the PCB to ensure a low impedance connection between the power and ground planes. Additionally, traces or copper pours can also be used to connect the power and ground planes on different layers of the PCB.

13.What is the power rating for a 2 ghz oscillator vco circuit pcb?

We maintain a certain amount of R&D investment every year and continuously improve operational efficiency to provide better services to our cooperative customers.

The power rating for a PCB (printed circuit board) can vary greatly depending on its size, design, and intended use. Generally, the power rating for a PCB is determined by the maximum amount of current it can safely handle without overheating or causing damage. This can range from a few milliamps for small, low-power circuits to several amps for larger, high-power circuits. It is important to consult the manufacturer's specifications or consult with an engineer to determine the specific power rating for a particular PCB.

14.What are some common problems that can occur with 2 ghz oscillator vco circuit pcb?

Our 2 ghz oscillator vco circuit pcb products undergo strict quality control to ensure customer satisfaction.

PCB (printed circuit boards) are an integral part of electronic devices, serving as the foundation for electrical connections and components. However, like any other technology, there are certain issues that may arise with PCB. One common problem is damage to the board due to excessive heat, as electronic components generate heat and if the PCB is not properly designed or ventilated, it can lead to malfunctions or even permanent damage. Another issue is poor soldering, which can result in weak connections or no connection at all. This can be caused by inadequate equipment or inexperience in the assembly process. Additionally, PCB can also suffer from corrosion over time, especially in high humidity environments, affecting its performance and reliability. It is important to address these problems early on to prevent further damage and ensure the functionality of electronic devices. Regular maintenance, proper design and assembly techniques, and use of quality materials can help prevent these common issues with PCB.

15.How does a 2 ghz oscillator vco circuit pcb work?

We maintain a stable growth through reasonable capital operations, focus on industry development trends and cutting -edge technologies, and focus on product quality and safety performance.

A PCB (Printed Circuit Board) is a thin board made of non-conductive material, such as fiberglass or plastic, with conductive pathways etched or printed onto its surface. These pathways, also known as traces, are used to connect electronic components on the board, such as resistors, capacitors, and integrated circuits.

The PCB works by providing a platform for the components to be mounted and connected in a specific circuit configuration. The traces on the board act as wires, allowing electricity to flow between the components and creating a complete circuit.

The process of creating a PCB involves several steps, including designing the circuit layout, printing or etching the traces onto the board, and attaching the components using soldering techniques. Once the components are attached, the board is tested to ensure that all connections are correct and functioning properly.

When a PCB is connected to a power source, electricity flows through the traces, powering the components and allowing them to perform their intended functions. The traces also act as a pathway for signals to travel between components, allowing for communication and data transfer within the circuit.

PCBs are used in a wide range of electronic devices, from simple household appliances to complex computer systems. They provide a compact and efficient way to connect and control electronic components, making them an essential part of modern technology.

16.How are components selected for a 2 ghz oscillator vco circuit pcb design?

We pay attention to employee development and benefits, and provide a good working environment in order to improve the efficiency of employees and improve the quality management of 2 ghz oscillator vco circuit pcb products.

A power rating for a PCB, or Printed Circuit Board, is a measure of the maximum amount of power the board is able to safely handle. This rating takes into account the overall design and materials used in the creation of the PCB, as well as the environment in which it will be used. It is an important consideration in electronics and circuit design as exceeding the power rating can lead to overheating and potential damage to the board and connected components. Properly understanding and adhering to the power rating of a PCB is crucial for ensuring safe and efficient operation of electronic devices.

17.What does 2 ghz oscillator vco circuit pcb stand for?

We attach importance to the innovation ability and team spirit of employees, have advanced R & D facilities and laboratories, and have a good quality management system.

PCB stands for Printed Circuit Board.

18.Can 2 ghz oscillator vco circuit pcbs be customized?

We should enjoy a good reputation in the industry, and we can increase the added value of the products of cooperative customers through technological innovation.

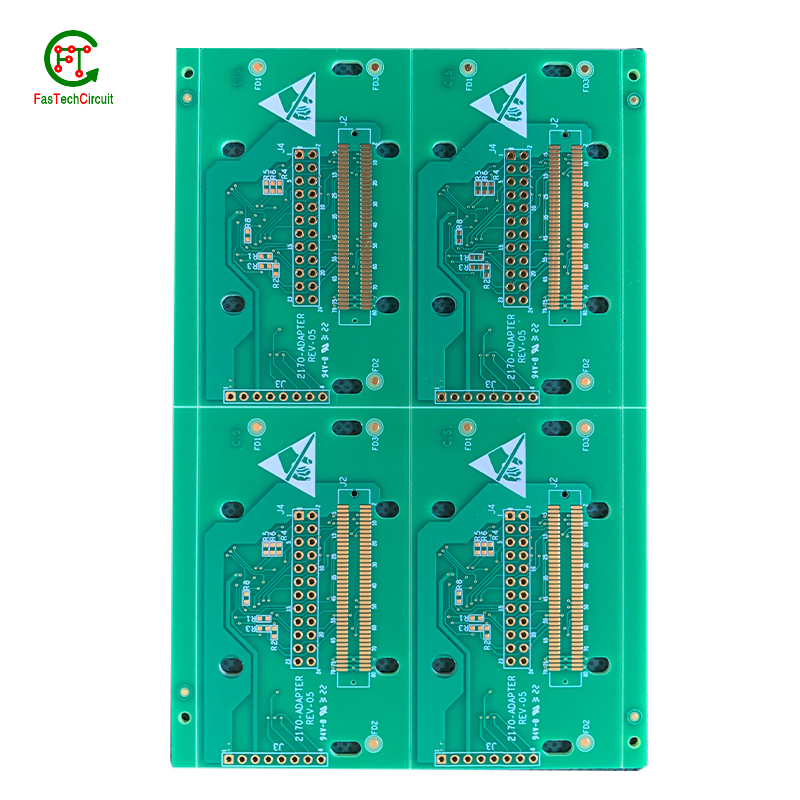

Yes, PCBs (printed circuit boards) can be customized to meet specific design requirements. This can include changes to the size, shape, number of layers, and placement of components on the board. Customization can also involve the use of specialized materials, finishes, and manufacturing processes to meet specific performance or environmental requirements. PCB manufacturers often offer design services to help customers create custom PCBs that meet their unique needs.

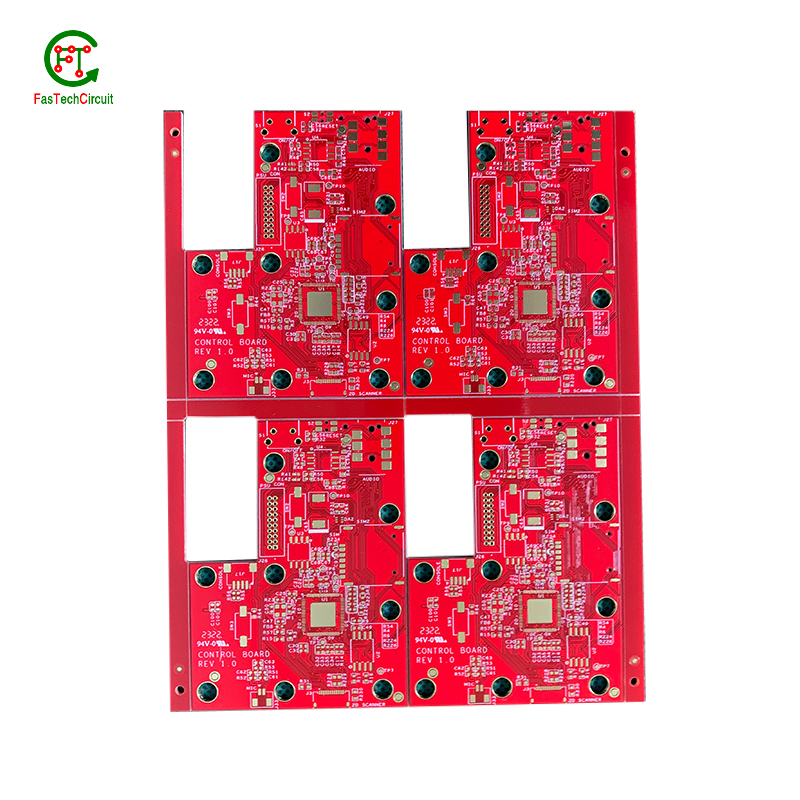

RELATED PRODUCTS & SERVICE

pcb board manufacturing How To Contact US

PCB from 1 to 30 layers, HDI, Heavy Copper, Rigid-flex board with "pcb board manufacturing One-Stop" service.