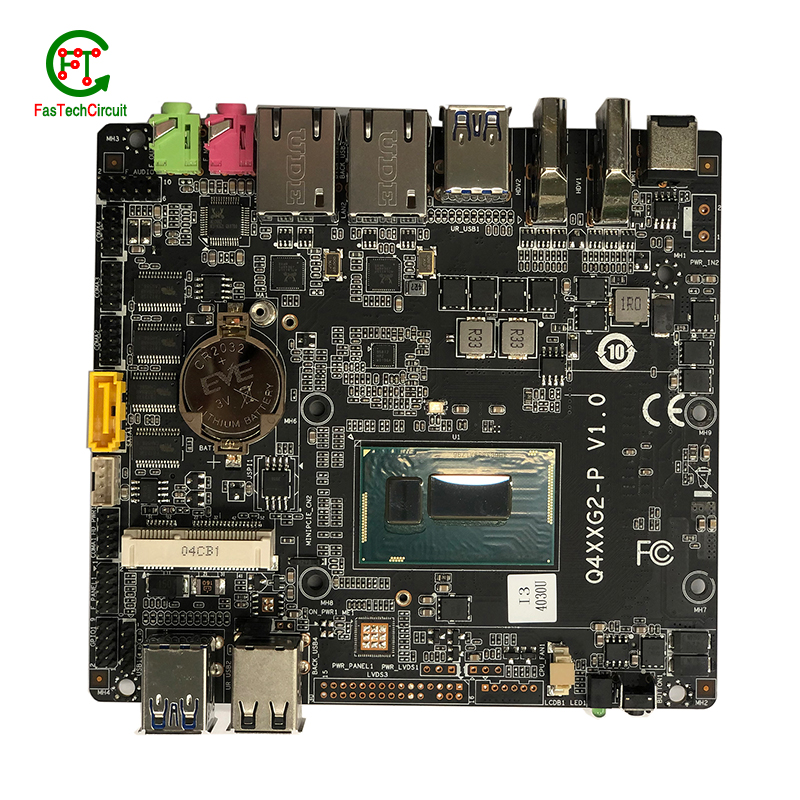

94v0 fr4 pcb assembly service

We can provide one-stop OEM service, and we constantly improve ourselves to keep up with international development levels. Since its establishment, we have passed ISO9001:2000, UL, TS16949:2002, ISO14001:2004 and other certifications. The purpose of our company is that quality and integrity are the lifeline! We strictly control quality to meet customers' needs, and our products are exported to more than 40 countries including North America, Europe, and Nauru,Wallis and Futuna,Ireland.

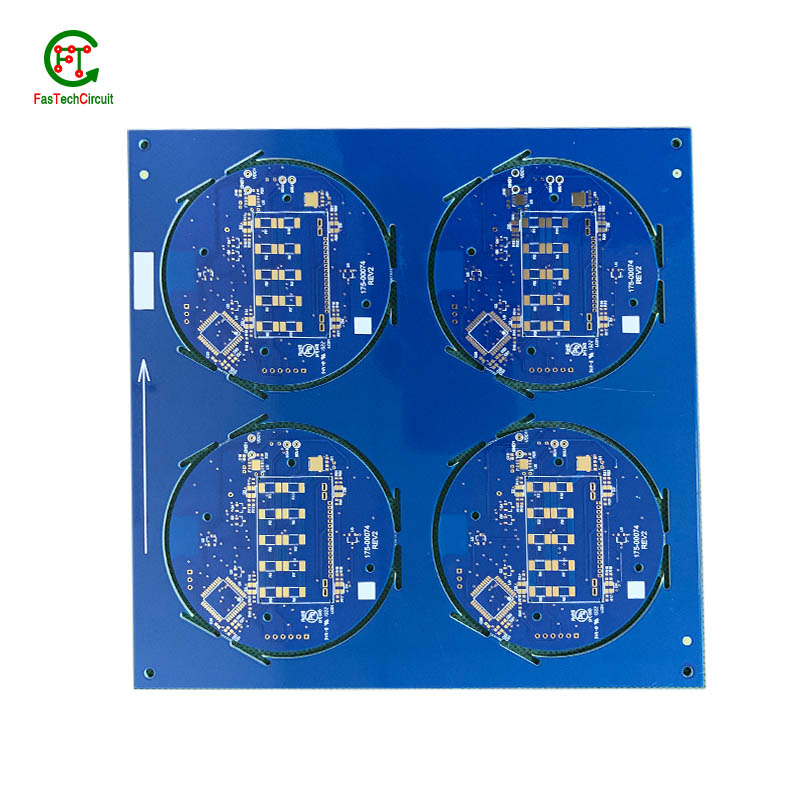

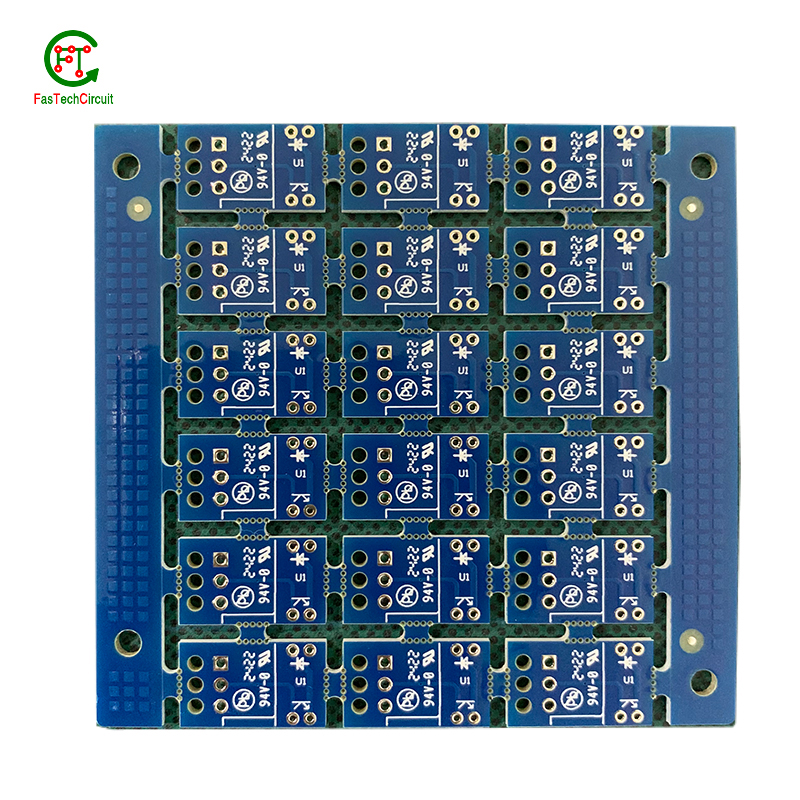

| Number of Layers | 4 layer |

| Base Material | gold sinking |

| Board Thickness | 2.7MM |

| Board Size | 315M*621MM |

| Model Number | 4 layer pcb |

| Type | pcb |

| Place of Origin | Original |

| Brand Name | Original |

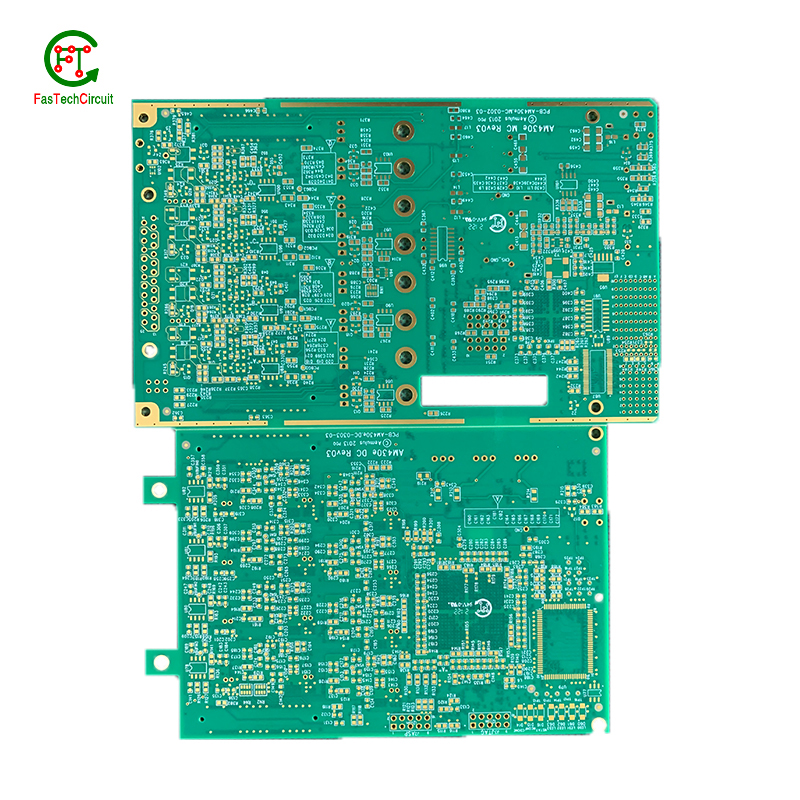

| Copper Thickness | 3OZ |

| Min. Hole Size | custom made |

| Min. Line Width | custom made |

| Min. Line Spacing | custom made |

| Surface Finishing | custom made |

| Impedance control | +/- 3% |

| Warpage | less than 1% |

| Packaging Details | New and Original, factory sealed packing, it will be pack in one of these packing type: Tube, Tray, Tape and Reel, Tape and Box, Bulk packing, Bag and etc. Please kindly contact us for more details. |

| Supply Ability | 9214 Piece/Pieces per Week |

| Quantity (pieces) | > 12767 |

| Lead time (days) | 14 |

94v0 fr4 pcb assembly service bearings FAQs Guide Welcome to our state-of-the-art PCB (Printed Circuit Board) products. We are proud to offer a comprehensive range of high-quality and versatile PCB solutions to meet the constantly evolving needs of the modern electronics industry.Our PCBs are expertly designed and manufactured using the latest technology and advanced techniques, ensuring reliability, durability, and exceptional performance for a wide range of applications. We understand the importance of precision and attention to detail in the production of PCBs and we are committed to meeting stringent quality standards.

2.What is the purpose of a solder mask on a 94v0 fr4 pcb assembly service?

3.Can 94v0 fr4 pcb assembly services be used in high-frequency applications?

4.What is the difference between single-sided, double-sided, and multi-layer 94v0 fr4 pcb assembly service?

5.How are 94v0 fr4 pcb assembly services protected from moisture and humidity?

6.What is the difference between an analog and a digital signal on a 94v0 fr4 pcb assembly service?

7.What are some common problems that can occur with 94v0 fr4 pcb assembly service?

8.What is the minimum thickness of a 94v0 fr4 pcb assembly service?

9.What is the lifespan of a 94v0 fr4 pcb assembly service under harsh environmental conditions?

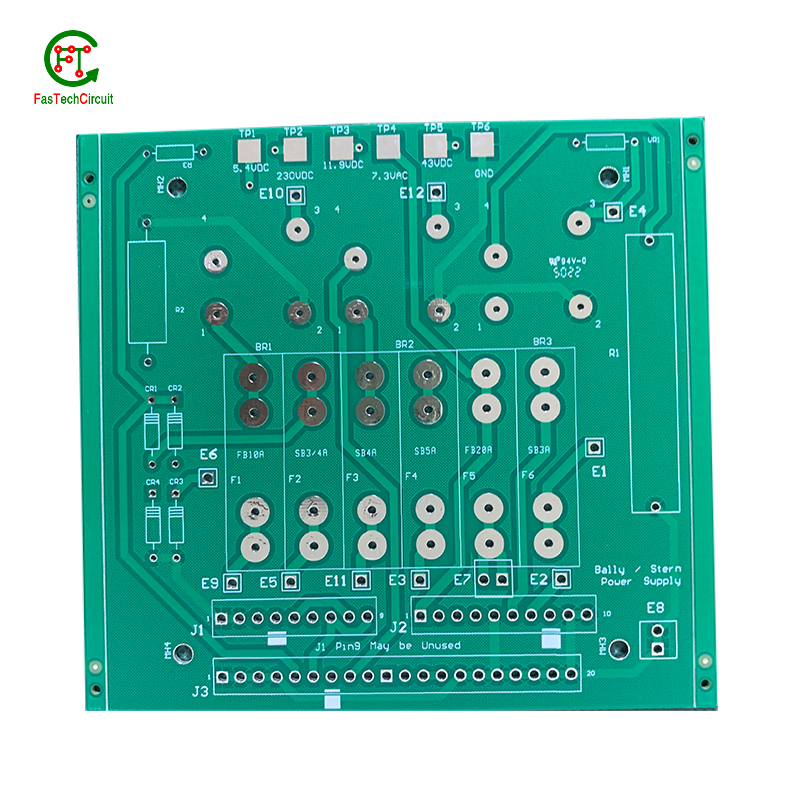

10.What types of 94v0 fr4 pcb assembly services are there?

11.What is the function of a resistor on a 94v0 fr4 pcb assembly service?

12.What is the role of a data sheet in 94v0 fr4 pcb assembly service design?

13.What is noise coupling and how can it be prevented on a 94v0 fr4 pcb assembly service?

14.What is the function of a decoupling capacitor on a 94v0 fr4 pcb assembly service?

1.What is the standard thickness for copper used in 94v0 fr4 pcb assembly services?

The standard thickness for copper used in PCBs is 1 ounce (oz) or 35 micrometers (µm). However, thicker copper layers such as 2 oz or 3 oz can also be used for higher current carrying capacity or better heat dissipation. The thickness of copper used in a PCB is determined by the design requirements and the intended use of the board.

2.What is the purpose of a solder mask on a 94v0 fr4 pcb assembly service?

We have a good reputation and image in the industry. The quality and price advantage of 94v0 fr4 pcb assembly service products is an important factor in our hard overseas market.

A solder mask is a thin layer of protective material applied to a printed circuit board (PCB) to prevent solder from bridging between conductive traces, pads, or vias during the soldering process. It also helps to protect the PCB from environmental factors such as moisture, dust, and corrosion. Additionally, the solder mask can provide insulation between conductive traces, reducing the risk of short circuits. It also helps to improve the overall appearance of the PCB by providing a uniform and professional finish.

3.Can 94v0 fr4 pcb assembly services be used in high-frequency applications?

Our mission is to provide customers with the best solutions for 94v0 fr4 pcb assembly service.

Yes, PCBs (printed circuit boards) can be used in high-frequency applications. However, the design and construction of the PCB must be carefully considered to ensure optimal performance at high frequencies. This includes using specialized materials, such as high-frequency laminates, and implementing proper grounding and shielding techniques. Additionally, the layout and routing of the PCB must be optimized to minimize signal loss and interference.

4.What is the difference between single-sided, double-sided, and multi-layer 94v0 fr4 pcb assembly service?

We have established a good reputation and reliable partnerships within the 94v0 fr4 pcb assembly service industry.

Single-sided PCB (Printed Circuit Board) is a type of PCB that has components and traces on only one side of the board. The other side is usually used for soldering and mounting the board onto a larger circuit.

Double-sided PCB is a type of PCB that has components and traces on both sides of the board. The traces on both sides are connected through vias, which are small holes drilled through the board and plated with metal to create an electrical connection.

Multi-layer PCB is a type of PCB that has multiple layers of conductive material and insulating material sandwiched together. The layers are connected through vias, allowing for more complex and compact circuit designs. Multi-layer PCBs are used in more advanced and high-performance electronic devices.

5.How are 94v0 fr4 pcb assembly services protected from moisture and humidity?

PCB (Printed Circuit Boards) are susceptible to damage from moisture and humidity, which can result in malfunction or even complete failure of electronic devices. Therefore, it is necessary to take measures to protect PCBs from these elements.

One way to protect PCBs from moisture is by using a conformal coating. This is a thin layer of protective material that is applied to the surface of the PCB. It acts as a barrier, preventing moisture from coming into contact with the sensitive components on the board.

Another method is to use moisture-resistant materials for the PCB itself. This can include using moisture-resistant coatings or laminates for the board, as well as corrosion-resistant materials for the conductors and connectors.

In addition to these preventive measures, PCBs can also be stored in controlled environments with low humidity levels. This can help to minimize the amount of moisture that comes into contact with the boards, reducing the risk of damage.

Regular maintenance and periodic testing can also help to ensure the continued protection of PCBs from moisture and humidity. By taking these precautions, electronic devices can maintain their functionality and reliability, even in environments with high humidity levels.

6.What is the difference between an analog and a digital signal on a 94v0 fr4 pcb assembly service?

An analog signal is a continuous signal that varies in amplitude and frequency over time. It can take on any value within a given range and is typically represented by a smooth, continuous waveform. Analog signals are used to transmit information such as audio, video, and sensor data.

A digital signal, on the other hand, is a discrete signal that can only take on a limited number of values. It is represented by a series of binary digits (0s and 1s) and can only have two states: on or off. Digital signals are used to transmit information in the form of data and are commonly used in digital electronics such as computers and smartphones.

On a PCB, the main difference between analog and digital signals lies in the way they are processed and transmitted. Analog signals require specialized components such as amplifiers and filters to maintain their integrity, while digital signals can be processed and transmitted using digital logic circuits. Additionally, analog signals are more susceptible to noise and interference, while digital signals are more immune to these factors.

7.What are some common problems that can occur with 94v0 fr4 pcb assembly service?

Our 94v0 fr4 pcb assembly service products undergo strict quality control to ensure customer satisfaction.

PCB (printed circuit boards) are an integral part of electronic devices, serving as the foundation for electrical connections and components. However, like any other technology, there are certain issues that may arise with PCB. One common problem is damage to the board due to excessive heat, as electronic components generate heat and if the PCB is not properly designed or ventilated, it can lead to malfunctions or even permanent damage. Another issue is poor soldering, which can result in weak connections or no connection at all. This can be caused by inadequate equipment or inexperience in the assembly process. Additionally, PCB can also suffer from corrosion over time, especially in high humidity environments, affecting its performance and reliability. It is important to address these problems early on to prevent further damage and ensure the functionality of electronic devices. Regular maintenance, proper design and assembly techniques, and use of quality materials can help prevent these common issues with PCB.

8.What is the minimum thickness of a 94v0 fr4 pcb assembly service?

We are committed to providing personalized solutions and established long -term strategic cooperative relationships with customers.

The minimum thickness of a PCB (printed circuit board) can vary depending on the materials and manufacturing processes used. However, the standard minimum thickness for a single-sided PCB is 0.6mm (0.024 inches) and for a double-sided PCB it is 0.8mm (0.032 inches). Thinner PCBs can be made, but they may be more fragile and have limitations on the components and circuitry that can be used.

9.What is the lifespan of a 94v0 fr4 pcb assembly service under harsh environmental conditions?

The lifespan of a PCB (printed circuit board) under harsh environmental conditions can vary greatly depending on the specific conditions and the quality of the PCB. In general, a well-designed and high-quality PCB can last for 10-20 years under harsh conditions such as extreme temperatures, humidity, and exposure to chemicals or vibrations. However, if the PCB is not properly designed or manufactured, its lifespan can be significantly shorter, potentially lasting only a few years or even months. Factors such as the type of materials used, the thickness of the copper traces, and the quality of the solder joints can also affect the lifespan of a PCB under harsh environmental conditions. Regular maintenance and proper handling can also help extend the lifespan of a PCB.

10.What types of 94v0 fr4 pcb assembly services are there?

As one of the 94v0 fr4 pcb assembly service market leaders, we are known for innovation and reliability.

There are several types of PCBs, including single-sided, double-sided, multi-layer, and flexible PCBs. Single-sided PCBs have components mounted on one side and conductive traces on the other. Double-sided PCBs have components mounted on both sides with conductive traces connecting them. Multi-layer PCBs have several layers of conductive traces and insulating material sandwiched together. Flexible PCBs are made from a flexible plastic material, allowing them to bend and twist for use in applications where traditional rigid PCBs are not suitable. Each type of PCB serves a different purpose and can be used in a variety of electronic devices and applications.

11.What is the function of a resistor on a 94v0 fr4 pcb assembly service?

We are a new 94v0 fr4 pcb assembly service manufacturer.

The ground plane on a printed circuit board (PCB) serves as a reference point for the electrical signals that flow throughout the circuit. It is typically a large area of copper that is connected to the negative terminal of the power supply and serves as a low-impedance return path for current. Its main purpose is to provide a stable and uniform ground connection for the components on the PCB, helping to reduce electromagnetic interference and ensuring proper signal grounding. Without a ground plane, the circuit may experience noise and other unwanted effects, potentially causing malfunctions or disruptions in its functionality. Therefore, the ground plane plays a crucial role in ensuring the overall performance and reliability of a PCB.

12.What is the role of a data sheet in 94v0 fr4 pcb assembly service design?

A data sheet is an essential tool for PCB design, providing vital information and specifications for all of the components used in the design process. It contains detailed technical data, such as dimensions, electrical ratings, and performance characteristics, that allow designers to make informed decisions when selecting and placing components on a PCB. By referencing the data sheet, designers can ensure that each component is properly integrated into the overall design, following any necessary guidelines or restrictions. Additionally, data sheets also provide necessary information for the layout and routing of traces on the PCB, ensuring that the design can meet required performance specifications.

13.What is noise coupling and how can it be prevented on a 94v0 fr4 pcb assembly service?

We are a professional 94v0 fr4 pcb assembly service company dedicated to providing high quality products and services.

Signal traces on a PCB (printed circuit board) are routes created to connect electronic components and allow for the transfer of electrical signals. These traces are typically made from copper and are carefully routed and designed to ensure efficient and reliable signal flow. The routing of signal traces is a critical aspect of PCB design and involves determining the best paths for the traces to minimize interference and optimize signal integrity. This is achieved through techniques such as controlled impedance routing, differential pair routing, and length-matching. Properly routing signal traces on a PCB is crucial for ensuring a functional and high-performance electronic circuit.

14.What is the function of a decoupling capacitor on a 94v0 fr4 pcb assembly service?

We have rich industry experience and professional knowledge, and have strong competitiveness in the market.

A decoupling capacitor is a type of capacitor that is used to reduce or eliminate noise and interference in electronic circuits. It is typically placed on a PCB (printed circuit board) near the power supply pins of an integrated circuit (IC) or other active component.

The main function of a decoupling capacitor is to provide a stable and clean power supply to the IC or other active component. This is achieved by filtering out high-frequency noise and voltage fluctuations that can be caused by other components on the PCB or external sources.

In addition, a decoupling capacitor also helps to prevent voltage drops and spikes that can occur when the IC or other component suddenly draws a large amount of current. This is especially important for sensitive components that require a stable power supply to function properly.

RELATED PRODUCTS & SERVICE

pcb board manufacturing How To Contact US

PCB from 1 to 30 layers, HDI, Heavy Copper, Rigid-flex board with "pcb board manufacturing One-Stop" service.