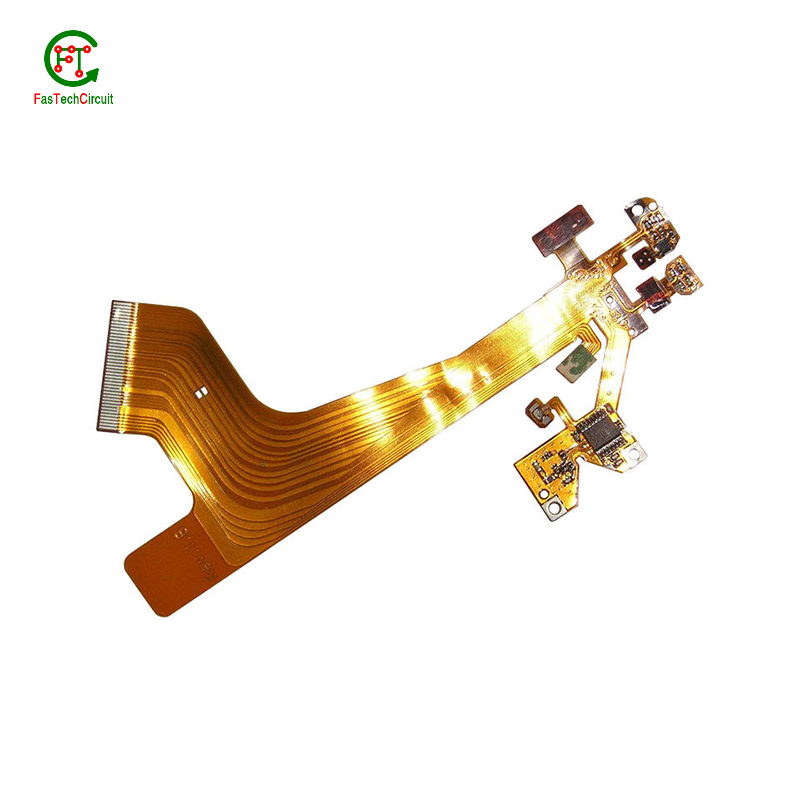

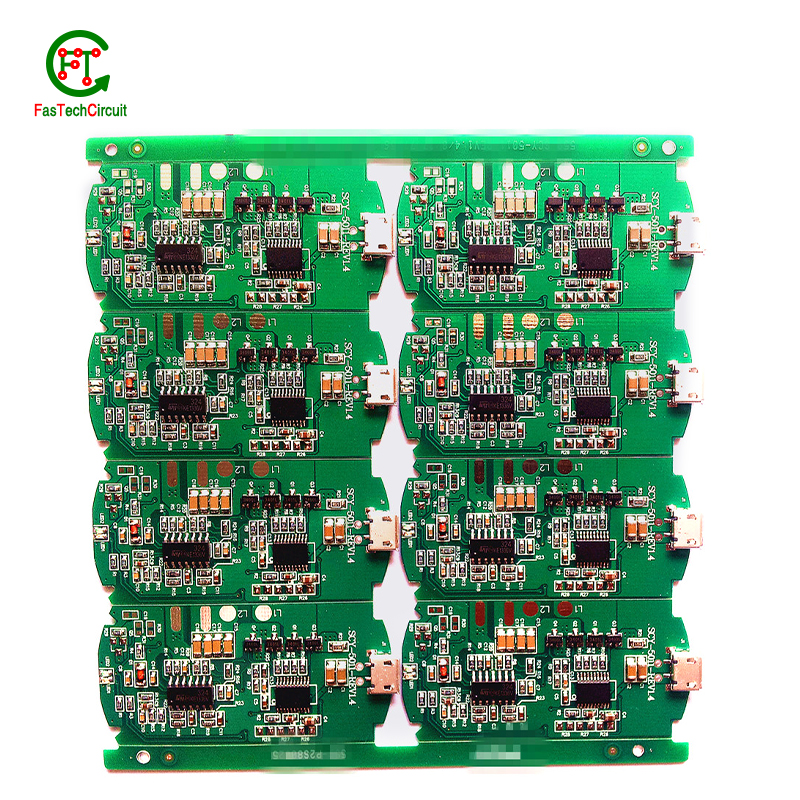

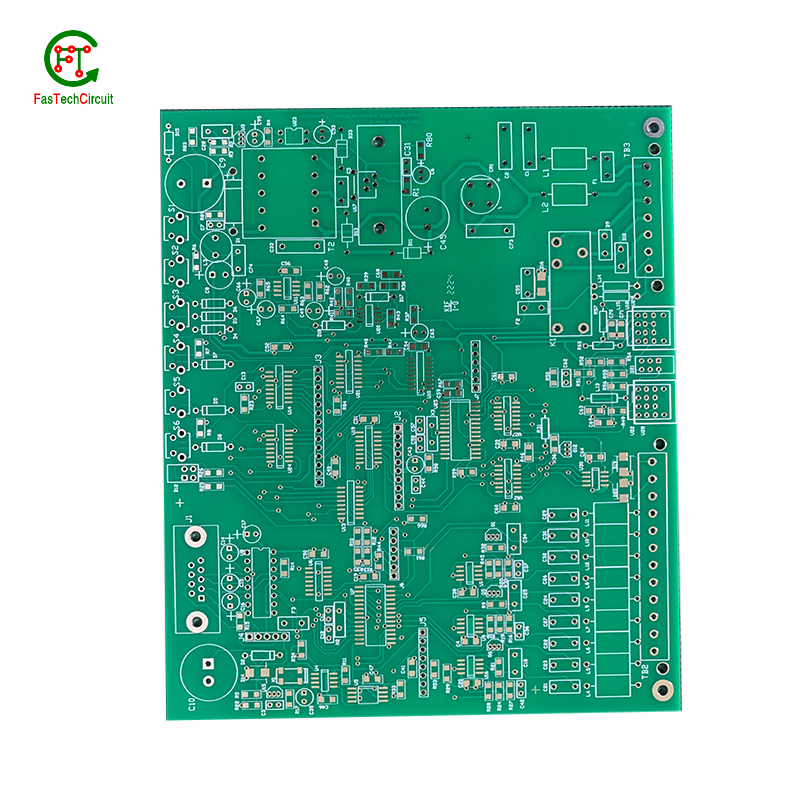

4558 ic subwoofer circuit pcb

Our customers mainly come from 50 regions around the world including Antigua and Barbuda,Ireland,Brazil,Malta,Pitcairn Islands. As an ISO9001 certified electronics assembly manufacturer, all projects we undertake are fully compliant with ROHS standards and quality assurance. Based on our engineering excellence and production capabilities in technology areas such as material analysis and storage, advanced equipment, reliability testing (AOI, X-RAY, ICT testing and functional testing), efficient SMT and THT assembly, we are recognized as a global leader in A PCBA supplier that more and more customers have trusted for a long time. Welcome to visit us for inspection at any time.

| Model Number | customized PCBA |

| Type | pcba |

| Place of Origin | Guangdong, China |

| Brand Name | none |

| Copper Thickness | 1 oz |

| Supplier Type | OEM |

| Application | Electronics Device |

| Service | One-step Service |

| Layer | 1-33layers |

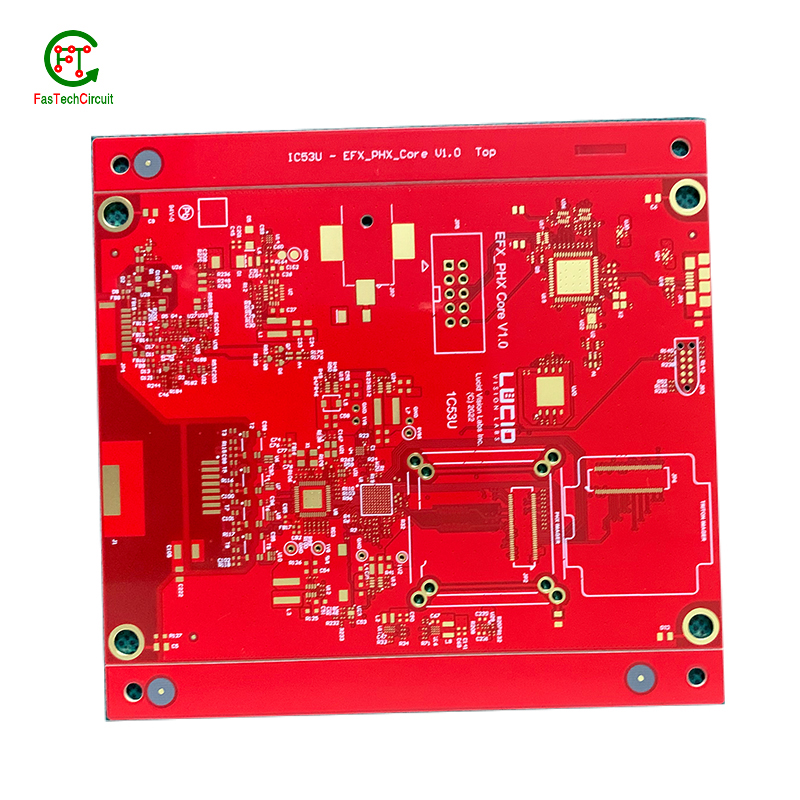

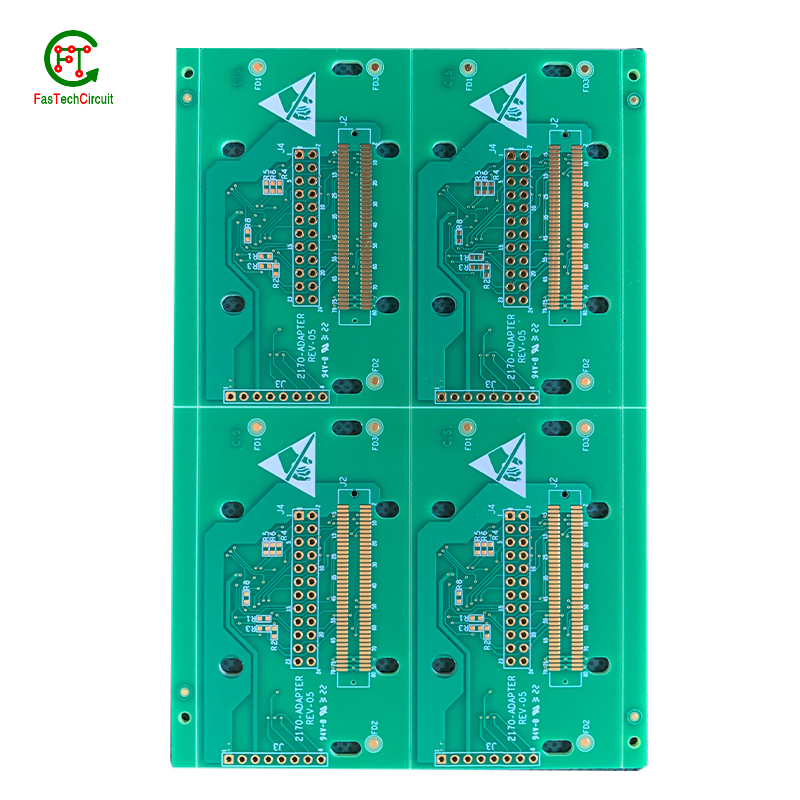

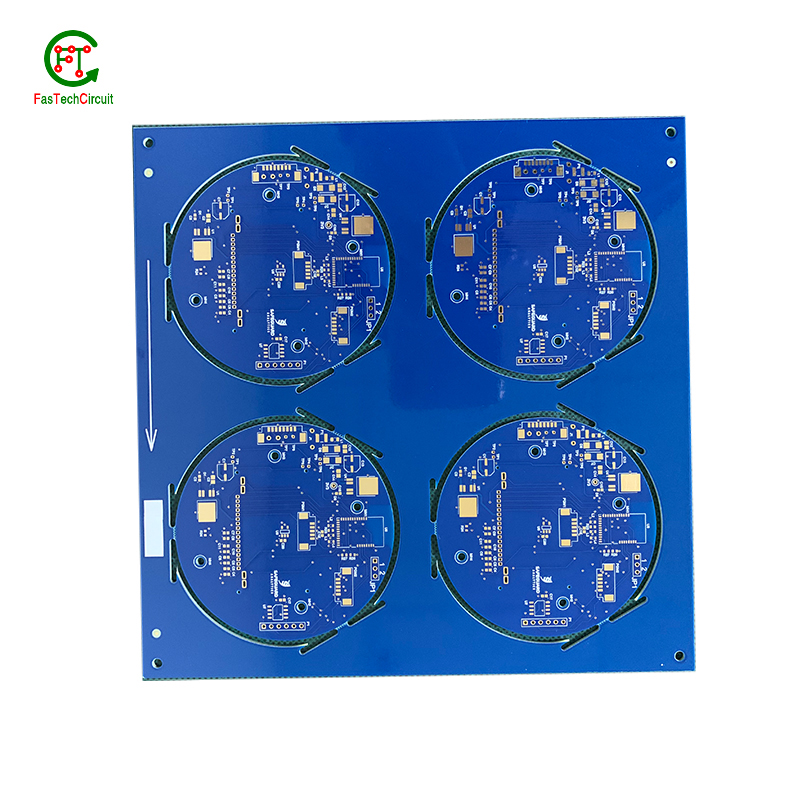

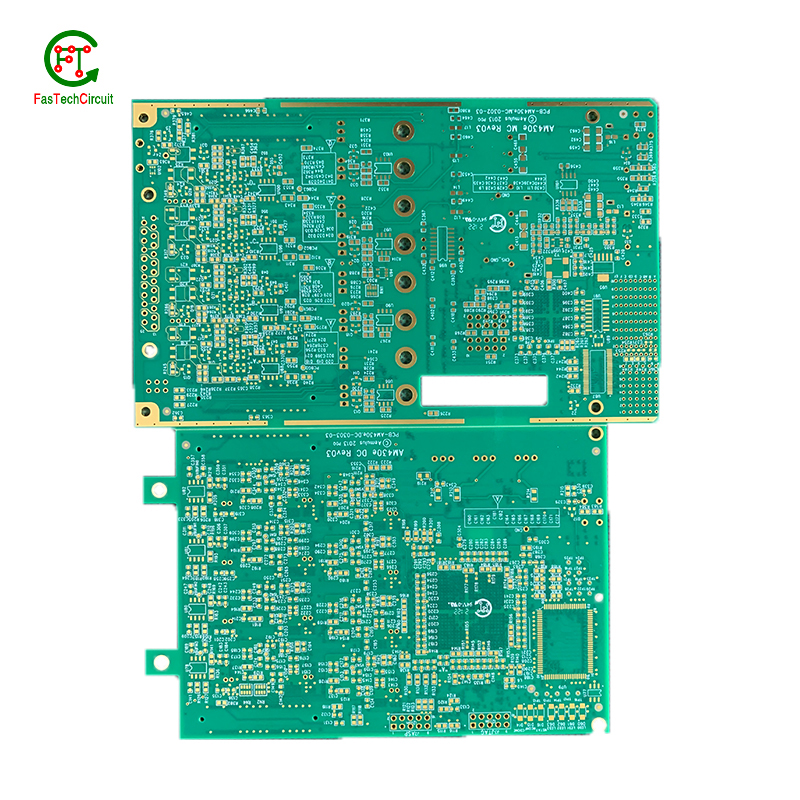

| Solder mask color | Blue.green.red.black.white.etc |

| Testing Service | 100% |

| Component size | 0201-1167mm |

| Component max height | 21mm |

| Min lead pitch | 0.4mm |

| Min BGA ball pitch | 0.2mm |

| Max PCB size | 592x532mm |

| Packaging Details | Vacuum package for bare PCB and ESD package for PCBA Printed Circuit Board Factory FPC Board PCBA Companies PCBA Assembly |

| Supply Ability | 44749 Piece/Pieces per Week |

| Quantity (pieces) | > 703 |

| Lead time (days) | 9 |

4558 ic subwoofer circuit pcb bearings FAQs Guide Welcome to our state-of-the-art PCB (Printed Circuit Board) products. We are proud to offer a comprehensive range of high-quality and versatile PCB solutions to meet the constantly evolving needs of the modern electronics industry.Our PCBs are expertly designed and manufactured using the latest technology and advanced techniques, ensuring reliability, durability, and exceptional performance for a wide range of applications. We understand the importance of precision and attention to detail in the production of PCBs and we are committed to meeting stringent quality standards.

2.What is the future outlook for 4558 ic subwoofer circuit pcb technology?

3.How are 4558 ic subwoofer circuit pcbs tested for quality control?

4.Can 4558 ic subwoofer circuit pcbs be used in high voltage applications?

5.Can 4558 ic subwoofer circuit pcbs be used for high-speed data transmission?

6.How are 4558 ic subwoofer circuit pcbs protected from environmental factors?

7.What is the difference between a diode and a capacitor?

8.What does 4558 ic subwoofer circuit pcb stand for?

9.What is the role of silkscreen on a 4558 ic subwoofer circuit pcb?

10.How are signal integrity issues addressed in 4558 ic subwoofer circuit pcb design?

11.What is the difference between single-sided, double-sided, and multi-layer 4558 ic subwoofer circuit pcb?

12.Can 4558 ic subwoofer circuit pcbs be customized?

13.Can a 4558 ic subwoofer circuit pcb be used for both power and signal transmission?

14.Can 4558 ic subwoofer circuit pcbs be used in high-frequency applications?

15.What is the difference between a gold-plated and a tin-plated 4558 ic subwoofer circuit pcb?

1.What is the role of automated optical inspection (AOI) in 4558 ic subwoofer circuit pcb production?

Automated optical inspection (AOI) plays a crucial role in the production of printed circuit boards (PCBs). It is a technology that uses advanced imaging techniques to detect and identify defects or errors on a PCB, such as missing components, incorrect placement, and faulty soldering. AOI has become an essential step in the production process as it helps manufacturers ensure the quality and reliability of their PCBs. By detecting and identifying defects at an early stage, AOI can significantly reduce the number of defects and increase the efficiency of the production process. Furthermore, AOI is able to perform inspections at a much faster rate and with higher accuracy compared to manual inspection, making it an indispensable tool for PCB production.

2.What is the future outlook for 4558 ic subwoofer circuit pcb technology?

Printed Circuit Boards, or PCBs, have been a vital component in electronic devices for decades. They serve as the foundation for the electrical connections and components that make our devices function properly. As technology continues to advance, so does the demand for smaller, faster, and more efficient PCBs. With the rise of IoT and smart devices, the future outlook for PCB technology is promising. It is expected that PCBs will become even more compact and complex, utilizing advanced materials and techniques such as 3D printing and flexible substrates. This will not only improve the performance of electronic devices, but also make them more durable and cost-effective. Furthermore, as sustainability becomes a growing concern, eco-friendly PCB materials and manufacturing processes are being developed to reduce environmental impact. With these advancements, it is safe to say that the future of PCB technology is bright and full of endless possibilities.

3.How are 4558 ic subwoofer circuit pcbs tested for quality control?

We have broad development space in domestic and foreign markets. 4558 ic subwoofer circuit pcb have great advantages in terms of price, quality, and delivery date.

PCB (Printed Circuit Board) testing is a critical step in the quality control process of electronic products. It ensures that all components and connections on the board are functioning correctly and that the PCB meets the required standards and specifications.

The testing process typically starts with a visual inspection to identify any visible defects, such as incorrect soldering or damaged components. Next, electrical testing is conducted to check the functionality of each individual component and the overall circuit.

One common method of testing is the use of a test fixture, which applies signals to the PCB and checks for correct responses. Other methods include automated optical inspection (AOI) and in-circuit testing (ICT).

Once the initial testing is completed, the PCB may undergo environmental testing to simulate real-life conditions and ensure its reliability and durability. This includes temperature and humidity cycling, vibration and shock testing, and more.

4.Can 4558 ic subwoofer circuit pcbs be used in high voltage applications?

We have advantages in marketing and channel expansion. Suppliers have established good cooperative relations, continuously improved workflows, improved efficiency and productivity, and provided customers with high -quality products and services.

Yes, PCBs (printed circuit boards) can be used in high voltage applications. However, the design and construction of the PCB must be carefully considered to ensure it can withstand the high voltage without causing damage or malfunction. This may include using specialized materials, increasing the spacing between components, and implementing proper insulation and grounding techniques. It is important to consult with a qualified engineer or designer when using PCBs in high voltage applications to ensure safety and reliability.

5.Can 4558 ic subwoofer circuit pcbs be used for high-speed data transmission?

Yes, PCBs (printed circuit boards) can be used for high-speed data transmission. PCBs are commonly used in electronic devices and systems to connect and route electrical signals between components. They are designed to have specific trace widths, lengths, and impedance to ensure efficient and reliable transmission of high-speed signals. Additionally, PCBs can be designed with specialized materials and techniques, such as controlled impedance and differential signaling, to further optimize their performance for high-speed data transmission.

6.How are 4558 ic subwoofer circuit pcbs protected from environmental factors?

We have established long-term and stable partnerships with our suppliers, so we have great advantages in price and cost and quality assurance.

PCBs, or printed circuit boards, are protected from environmental factors through the use of various techniques and materials. One method is to coat the PCB with a layer of conformal coating, which is a thin layer of protective material that covers the components and circuitry on the board. This coating can protect the PCB from moisture, dust, and other contaminants that could cause damage.

In addition to conformal coating, PCBs can also be protected through designing the layout of the board in a way that minimizes exposure to environmental factors. This includes placing sensitive components in areas that are less susceptible to moisture or temperature changes, as well as using specialized materials that are resistant to the effects of heat, humidity, and other environmental conditions.

7.What is the difference between a diode and a capacitor?

We have a first -class management team, and we pay attention to teamwork to achieve common goals.

A diode is an electronic component that allows current to flow in only one direction. It has two terminals, an anode and a cathode, and works by allowing current to flow from the anode to the cathode, but not in the reverse direction.

A capacitor, on the other hand, is an electronic component that stores electrical energy in an electric field. It has two conductive plates separated by an insulating material, and when a voltage is applied, one plate accumulates a positive charge and the other accumulates a negative charge. This allows the capacitor to store energy and release it when needed.

8.What does 4558 ic subwoofer circuit pcb stand for?

We attach importance to the innovation ability and team spirit of employees, have advanced R & D facilities and laboratories, and have a good quality management system.

PCB stands for Printed Circuit Board.

9.What is the role of silkscreen on a 4558 ic subwoofer circuit pcb?

Being one of the top 4558 ic subwoofer circuit pcb manufacturers in China, We attach great importance to this detail.

Silkscreen, also known as legend or nomenclature, is a vital component of a printed circuit board (PCB). It is the layer of text and symbols that are printed on the surface of the PCB to provide essential information for component placement and identification. The silkscreen plays a crucial role in the manufacturing process of PCBs, as it helps to ensure the accuracy and functionality of the final product. By indicating component locations, values, and reference designators, the silkscreen serves as a guide for the assembly and soldering of electronic components. Additionally, it also provides important information for maintenance and troubleshooting purposes.

10.How are signal integrity issues addressed in 4558 ic subwoofer circuit pcb design?

We focus on our customers' needs and strive to meet their expectations, so we take this very seriously.

Signal integrity issues are a common concern in PCB design, as they can greatly affect the performance and reliability of electronic systems. These issues arise from high-speed signal transmissions on the board, which can result in degraded signals, data errors, and even system failures. In order to address these issues, PCB designers must consider various factors such as layout, routing, and component placement to ensure proper signal integrity. This involves implementing signal protection measures such as controlled impedance routing, signal shielding, and minimizing signal crosstalk. Additionally, designers may use simulation and analysis tools to identify and resolve any potential signal integrity problems before the PCB goes into production. By carefully addressing signal integrity issues in the design phase, PCBs can achieve optimal performance and functionality.

11.What is the difference between single-sided, double-sided, and multi-layer 4558 ic subwoofer circuit pcb?

We have established a good reputation and reliable partnerships within the 4558 ic subwoofer circuit pcb industry.

Single-sided PCB (Printed Circuit Board) is a type of PCB that has components and traces on only one side of the board. The other side is usually used for soldering and mounting the board onto a larger circuit.

Double-sided PCB is a type of PCB that has components and traces on both sides of the board. The traces on both sides are connected through vias, which are small holes drilled through the board and plated with metal to create an electrical connection.

Multi-layer PCB is a type of PCB that has multiple layers of conductive material and insulating material sandwiched together. The layers are connected through vias, allowing for more complex and compact circuit designs. Multi-layer PCBs are used in more advanced and high-performance electronic devices.

12.Can 4558 ic subwoofer circuit pcbs be customized?

We should enjoy a good reputation in the industry, and we can increase the added value of the products of cooperative customers through technological innovation.

Yes, PCBs (printed circuit boards) can be customized to meet specific design requirements. This can include changes to the size, shape, number of layers, and placement of components on the board. Customization can also involve the use of specialized materials, finishes, and manufacturing processes to meet specific performance or environmental requirements. PCB manufacturers often offer design services to help customers create custom PCBs that meet their unique needs.

13.Can a 4558 ic subwoofer circuit pcb be used for both power and signal transmission?

Yes, a PCB (printed circuit board) can be used for both power and signal transmission. This is commonly seen in electronic devices such as computers, smartphones, and other electronic devices. The PCB acts as a platform for connecting various components and circuits, including power sources and signal pathways. The power and signal traces on the PCB are designed to handle different levels of current and voltage to ensure efficient transmission and prevent interference between the two. However, it is important to properly design and layout the PCB to ensure proper separation and isolation of power and signal traces to avoid any potential issues.

14.Can 4558 ic subwoofer circuit pcbs be used in high-frequency applications?

Our mission is to provide customers with the best solutions for 4558 ic subwoofer circuit pcb.

Yes, PCBs (printed circuit boards) can be used in high-frequency applications. However, the design and construction of the PCB must be carefully considered to ensure optimal performance at high frequencies. This includes using specialized materials, such as high-frequency laminates, and implementing proper grounding and shielding techniques. Additionally, the layout and routing of the PCB must be optimized to minimize signal loss and interference.

15.What is the difference between a gold-plated and a tin-plated 4558 ic subwoofer circuit pcb?

A gold-plated PCB (Printed Circuit Board) is a type of PCB that has a thin layer of gold coating on its surface. This layer is added through a process called electroplating and is commonly used to protect the PCB components from corrosion and increase the conductivity. On the other hand, a tin-plated PCB has a layer of tin coating on its surface, which is also applied through electroplating. Unlike gold plating, tin plating is mainly used to prevent oxidization and improve solderability.

RELATED PRODUCTS & SERVICE

pcb board manufacturing How To Contact US

PCB from 1 to 30 layers, HDI, Heavy Copper, Rigid-flex board with "pcb board manufacturing One-Stop" service.