a56-001 z60 pcb layout

In addition to basic PCB production, PCB manufacturers also provide customized services to meet customers' special needs. Customers can choose different materials, number of layers, thickness, line width and other parameters according to their own product needs. PCB manufacturers will produce according to customer requirements to ensure that the performance and quality of the product meet customer requirements.

In order to meet customers' needs for PCBs, we provide one-stop OEM services, and FasTechCircuit also has a complete quality control system. From raw material procurement to production and processing, to final finished product testing, FasTechCircuit strictly controls every process to ensure that product quality meets international standards. Our products are very popular in Svalbard,Madagascar,Bulgaria,Burkina Faso, the United States and Japan. Won high praise from customers.

| Base Material | FR-4/CEM-1/CEM-3/Polyimild/PTFE/Rogers |

| Board Thickness | 0.2-5mm |

| Model Number | Custom PCB & PCB Assembly |

| Type | Aluminum PCB |

| Brand Name | FC |

| Copper Thickness | 0.6-2mil(11-52um) |

| Min. Hole Size | 0.1mm(4mil)for HDI / 0.15mm(6mil) |

| Min. Line Width | 0.075mm/0.075mm(3mil/3mil) |

| Min. Line Spacing | 0.003'' |

| Surface Finishing | HASL/OSP/Ag/ENIG/ENEPIG/Immersion silver/Tin |

| Board Size | Custom |

| Model Number | Customized |

| Base Material | FR4 Aluminum CEM-1 94V0 |

| Surface Finishing | HASLENIG OSP |

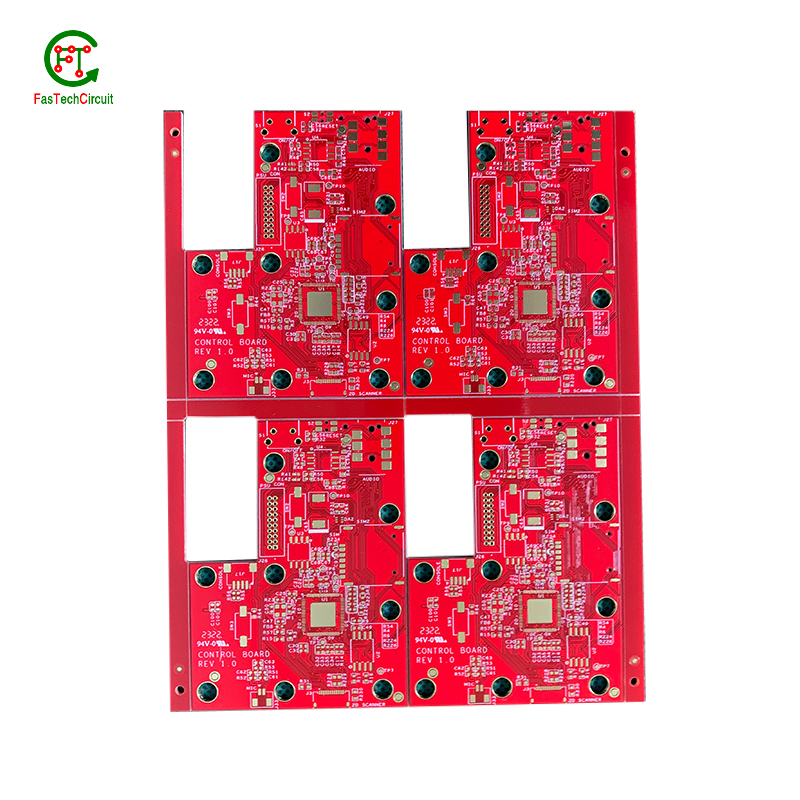

| Number of layer | 1-18layer |

| Other service | Components purchasing and assem |

| ly Solder mask | White Black Green Blue,Red,etc. |

| Dsign service | Available |

| Testing | Function testing |

| Certificate | RoHS, ISO/TS16949, ISO9001 |

| Name | High Quality led light aluminum pcb printed circuit board |

| Packaging Details | Vaccum package and standard carton outside High Quality led light aluminum pcb printed circuit board |

| Supply Ability | 57945 Square Meter/Square Meters per Month |

| Quantity (pieces) | > 15201 |

| Lead time (days) | 10 |

a56-001 z60 pcb layout bearings FAQs Guide Welcome to our state-of-the-art PCB (Printed Circuit Board) products. We are proud to offer a comprehensive range of high-quality and versatile PCB solutions to meet the constantly evolving needs of the modern electronics industry.Our PCBs are expertly designed and manufactured using the latest technology and advanced techniques, ensuring reliability, durability, and exceptional performance for a wide range of applications. We understand the importance of precision and attention to detail in the production of PCBs and we are committed to meeting stringent quality standards.

2.How are through-hole components soldered onto a a56-001 z60 pcb layout?

3.What is the typical lifespan of a a56-001 z60 pcb layout?

4.How are signal traces routed on a a56-001 z60 pcb layout?

5.How are components selected for a a56-001 z60 pcb layout design?

6.How are high-speed/high-frequency a56-001 z60 pcb layout tested and validated?

7.Can a56-001 z60 pcb layouts be used in high voltage applications?

8.Can a56-001 z60 pcb layouts be used in high-frequency applications?

9.Are a56-001 z60 pcb layout recyclable?

10.Can a a56-001 z60 pcb layout be repaired if damaged?

11.What is the lifespan of a a56-001 z60 pcb layout under harsh environmental conditions?

12.How are holes drilled into a a56-001 z60 pcb layout?

13.What is the role of a data sheet in a56-001 z60 pcb layout design?

14.What types of a56-001 z60 pcb layouts are there?

15.What materials are used to make a a56-001 z60 pcb layout?

16.What is the function of a decoupling capacitor on a a56-001 z60 pcb layout?

17.What is the purpose of a solder mask on a a56-001 z60 pcb layout?

18.What is the role of vias on a a56-001 z60 pcb layout?

1.What are the main components of a a56-001 z60 pcb layout?

We continuously upgrade our skills and knowledge to adapt to changing a56-001 z60 pcb layout market needs.

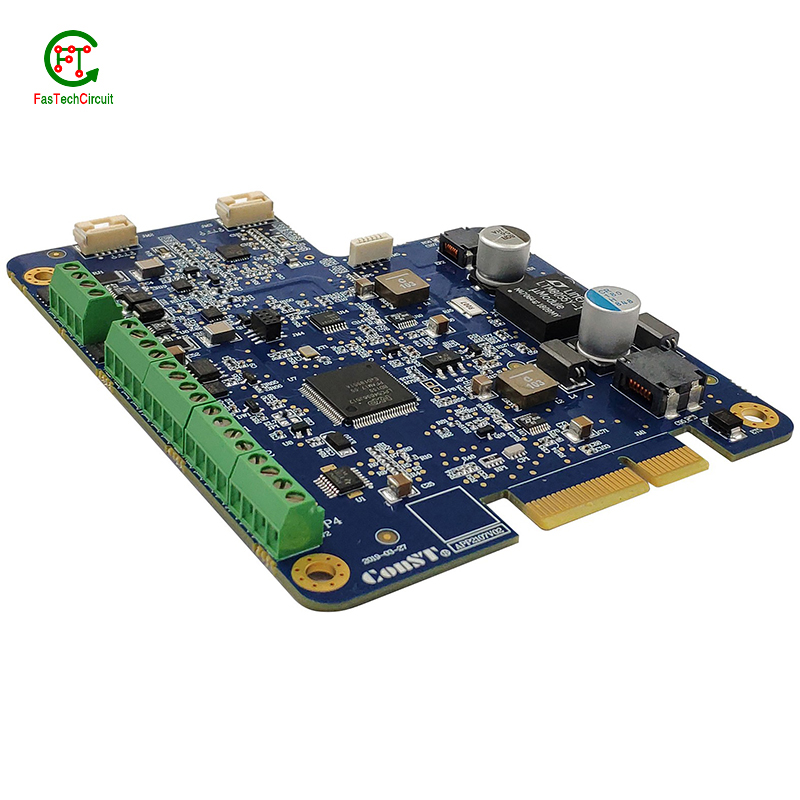

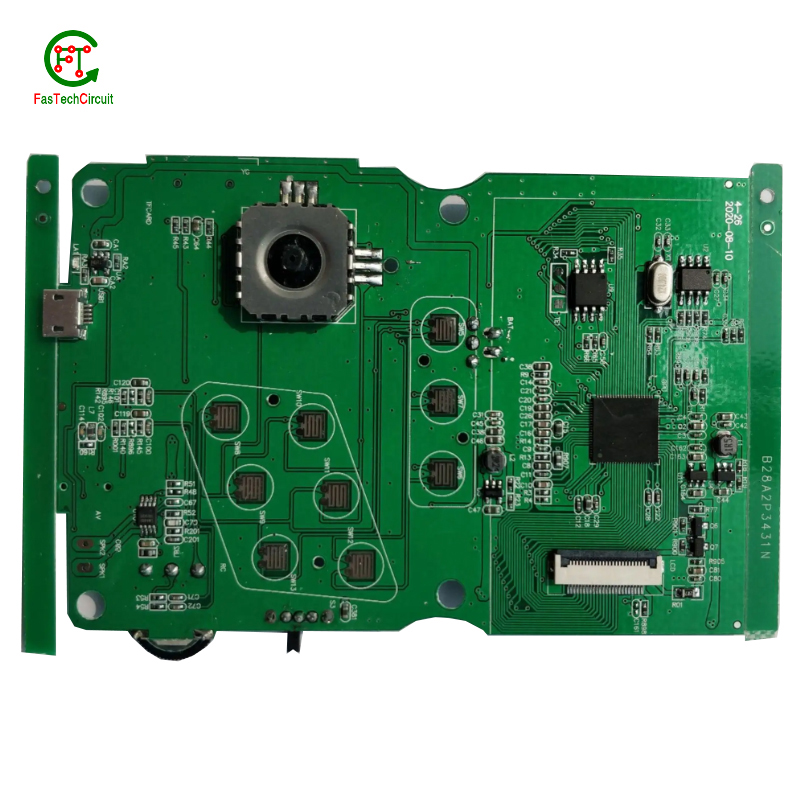

A typical PCB consists of several vital components, including a substrate material, copper traces, solder mask, silk screen, and plated through-holes. The substrate material acts as the base and provides mechanical support for the board. Copper traces, usually made of thin lines of copper foil, serve as the conductive paths for transmitting electrical signals. The solder mask, applied as a protective layer, prevents accidental short circuits and corrosion. Silk screen, a layer of ink-based labeling, aids in component identification. Lastly, plated through-holes enable electrical connection between different layers of the PCB board. These components work together to form a fully functioning PCB.

2.How are through-hole components soldered onto a a56-001 z60 pcb layout?

Through-hole components are soldered onto a printed circuit board (PCB) using a process called wave soldering. First, the PCB is fitted with all the necessary through-hole components, such as resistors, capacitors, and diodes. Then, the board is passed over a wave of molten solder, which flows through the holes in the PCB and creates a secure connection between the component and the board. The excess solder is removed and the board is inspected to ensure all components are properly soldered. This method of soldering provides a strong and reliable connection for through-hole components, making it a popular choice for electronic assembly.

3.What is the typical lifespan of a a56-001 z60 pcb layout?

a56-001 z60 pcb layout is not a product only, but also can help you comes to money-making.

The typical lifespan of a PCB (printed circuit board) can vary greatly depending on various factors such as the quality of materials used, environmental conditions, and usage. In general, a well-designed and properly manufactured PCB can last for 10-20 years or more. However, some PCBs may fail prematurely due to factors such as corrosion, thermal stress, or mechanical damage. Regular maintenance and proper handling can also extend the lifespan of a PCB.

4.How are signal traces routed on a a56-001 z60 pcb layout?

Signal traces are an essential element of a PCB, responsible for carrying electronic signals between components and ensuring proper communication and functionality of the circuit. To route these traces, designers use specialized software to determine the most efficient and optimal path for each signal, taking into account factors such as signal integrity, trace length, and potential interference. This process involves careful planning, as well as techniques such as vias, ground and power planes, and differential pairs to minimize noise and maintain signal integrity.

5.How are components selected for a a56-001 z60 pcb layout design?

We pay attention to employee development and benefits, and provide a good working environment in order to improve the efficiency of employees and improve the quality management of a56-001 z60 pcb layout products.

A power rating for a PCB, or Printed Circuit Board, is a measure of the maximum amount of power the board is able to safely handle. This rating takes into account the overall design and materials used in the creation of the PCB, as well as the environment in which it will be used. It is an important consideration in electronics and circuit design as exceeding the power rating can lead to overheating and potential damage to the board and connected components. Properly understanding and adhering to the power rating of a PCB is crucial for ensuring safe and efficient operation of electronic devices.

6.How are high-speed/high-frequency a56-001 z60 pcb layout tested and validated?

Testing and validation are essential steps in the production process of high-speed and high-frequency printed circuit boards (PCBs). These specialized types of PCBs are used in a wide range of industries, including telecommunications, aerospace, and automotive, and require precision and reliability in their performance.

The testing and validation process for high-speed/high-frequency PCBs involves several steps to ensure that the final product meets the required specifications. This starts with design simulation and analysis using specialized software to verify the layout and electrical characteristics of the PCB.

Once the design is confirmed, prototype PCBs are manufactured and subjected to various tests, including signal integrity and power integrity tests. These tests evaluate the electrical performance of the PCB, such as its ability to transmit signals at high speeds and maintain signal integrity.

In addition to electrical tests, environmental and mechanical tests are also performed to assess the durability and reliability of the PCB under different conditions, such as temperature changes and mechanical stress.

The final step in the testing and validation process is the inspection and analysis of the tested PCBs. This involves a detailed review of the test results and any necessary modifications to meet the required specifications.

7.Can a56-001 z60 pcb layouts be used in high voltage applications?

We have advantages in marketing and channel expansion. Suppliers have established good cooperative relations, continuously improved workflows, improved efficiency and productivity, and provided customers with high -quality products and services.

Yes, PCBs (printed circuit boards) can be used in high voltage applications. However, the design and construction of the PCB must be carefully considered to ensure it can withstand the high voltage without causing damage or malfunction. This may include using specialized materials, increasing the spacing between components, and implementing proper insulation and grounding techniques. It is important to consult with a qualified engineer or designer when using PCBs in high voltage applications to ensure safety and reliability.

8.Can a56-001 z60 pcb layouts be used in high-frequency applications?

Our mission is to provide customers with the best solutions for a56-001 z60 pcb layout.

Yes, PCBs (printed circuit boards) can be used in high-frequency applications. However, the design and construction of the PCB must be carefully considered to ensure optimal performance at high frequencies. This includes using specialized materials, such as high-frequency laminates, and implementing proper grounding and shielding techniques. Additionally, the layout and routing of the PCB must be optimized to minimize signal loss and interference.

9.Are a56-001 z60 pcb layout recyclable?

We have been working hard to improve service quality and meet customer needs.

Yes, PCBs (printed circuit boards) are recyclable. They can be broken down and the individual components can be reused or repurposed. However, the recycling process can be complex and requires specialized equipment and techniques. It is important to properly dispose of PCBs to prevent environmental contamination and health hazards.

10.Can a a56-001 z60 pcb layout be repaired if damaged?

We focus on teamwork and communication to achieve common goals, We attach great importance to this detail.

Yes, a PCB (printed circuit board) can be repaired if it is damaged. The extent of the damage and the complexity of the circuit will determine the difficulty and feasibility of the repair. Some common methods for repairing a damaged PCB include:

1. Soldering: If the damage is limited to a few components or traces, they can be replaced or repaired by soldering new components or wires onto the board.

2. Trace repair: If a trace (conductive pathway) on the PCB is damaged or broken, it can be repaired by using a conductive ink or wire to bridge the gap.

3. Component replacement: If a specific component on the PCB is damaged, it can be replaced with a new one. This requires identifying the damaged component and sourcing a replacement.

4. PCB rework: In some cases, the entire PCB may need to be reworked, which involves removing and replacing multiple components and traces.

11.What is the lifespan of a a56-001 z60 pcb layout under harsh environmental conditions?

The lifespan of a PCB (printed circuit board) under harsh environmental conditions can vary greatly depending on the specific conditions and the quality of the PCB. In general, a well-designed and high-quality PCB can last for 10-20 years under harsh conditions such as extreme temperatures, humidity, and exposure to chemicals or vibrations. However, if the PCB is not properly designed or manufactured, its lifespan can be significantly shorter, potentially lasting only a few years or even months. Factors such as the type of materials used, the thickness of the copper traces, and the quality of the solder joints can also affect the lifespan of a PCB under harsh environmental conditions. Regular maintenance and proper handling can also help extend the lifespan of a PCB.

12.How are holes drilled into a a56-001 z60 pcb layout?

We actively participate in the a56-001 z60 pcb layout industry associations and organization activities. The corporate social responsibility performed well, and the focus of brand building and promotion.

Drilling holes into printed circuit boards (PCBs) is a critical part of the PCB manufacturing process. These holes are used for mounting electronic components and for creating electrical connections between different layers of the board. There are two main methods for drilling holes into a PCB – mechanical drilling and laser drilling. Mechanical drilling involves using a high speed drill bit to physically drill through the board, while laser drilling uses a high-powered laser to vaporize the material and create the holes. Both methods have their own advantages and are often used in combination to achieve the desired hole sizes and precision. Regardless of the method, the holes are carefully planned and executed to ensure the successful production of a high-quality PCB.

13.What is the role of a data sheet in a56-001 z60 pcb layout design?

A data sheet is an essential tool for PCB design, providing vital information and specifications for all of the components used in the design process. It contains detailed technical data, such as dimensions, electrical ratings, and performance characteristics, that allow designers to make informed decisions when selecting and placing components on a PCB. By referencing the data sheet, designers can ensure that each component is properly integrated into the overall design, following any necessary guidelines or restrictions. Additionally, data sheets also provide necessary information for the layout and routing of traces on the PCB, ensuring that the design can meet required performance specifications.

14.What types of a56-001 z60 pcb layouts are there?

As one of the a56-001 z60 pcb layout market leaders, we are known for innovation and reliability.

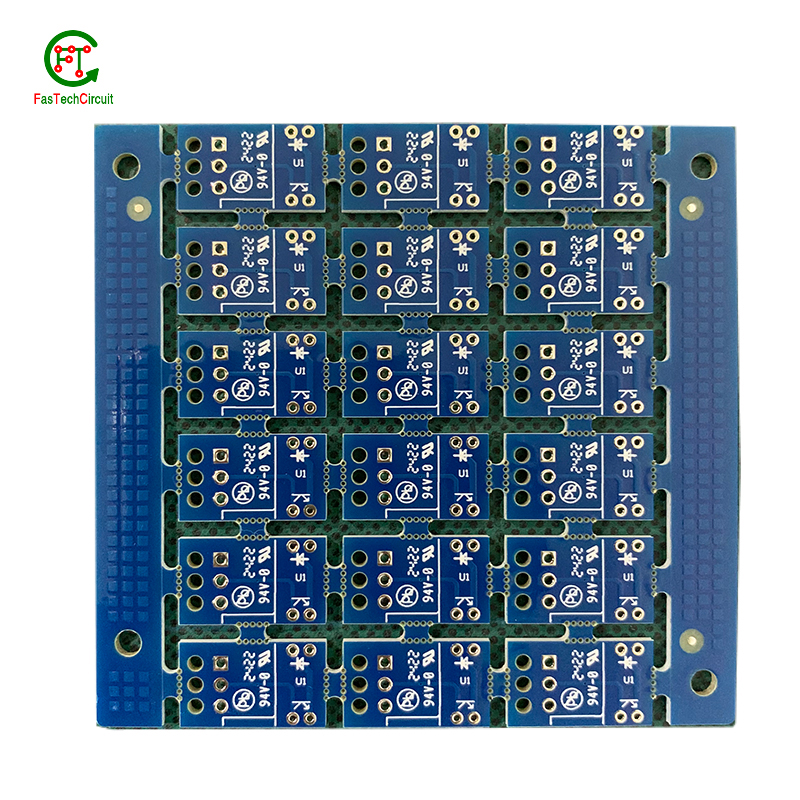

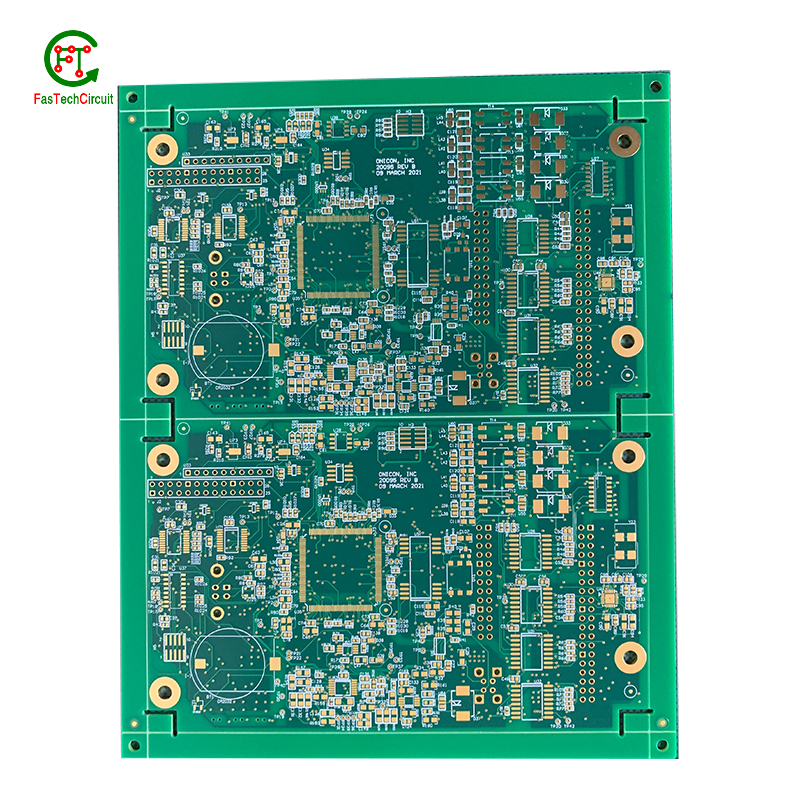

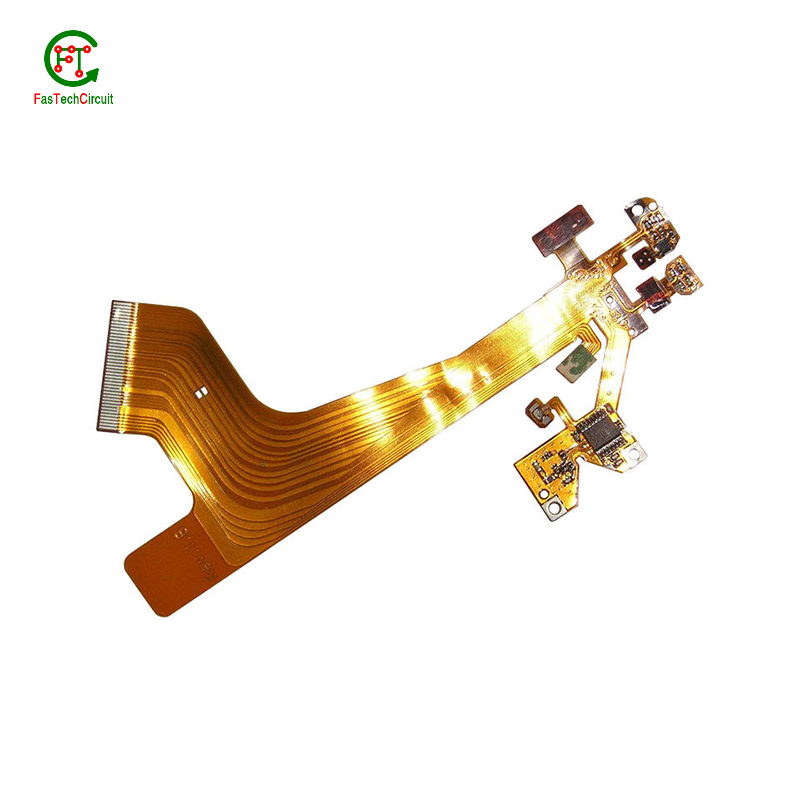

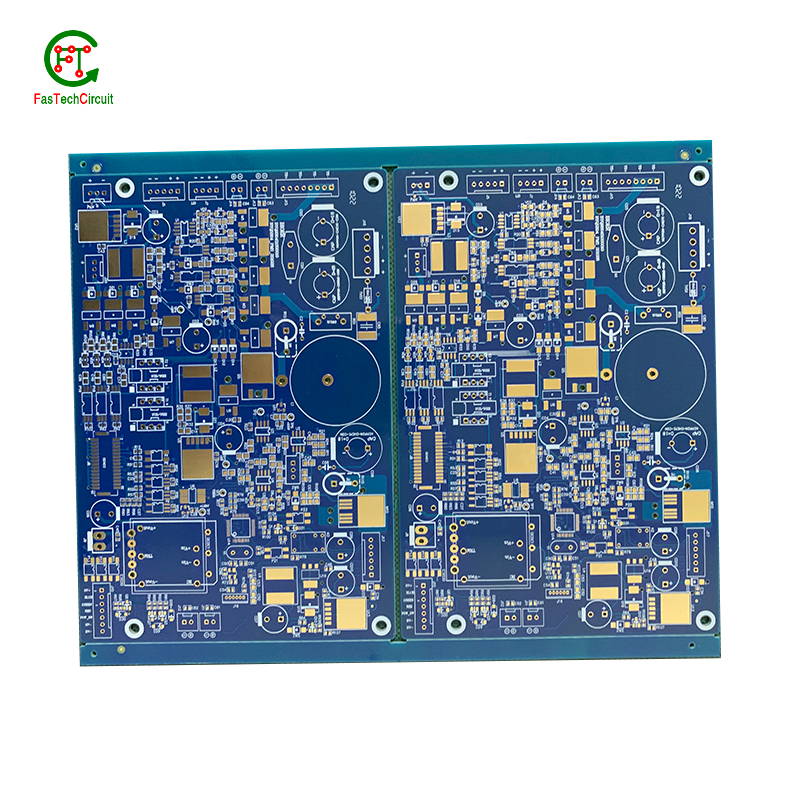

There are several types of PCBs, including single-sided, double-sided, multi-layer, and flexible PCBs. Single-sided PCBs have components mounted on one side and conductive traces on the other. Double-sided PCBs have components mounted on both sides with conductive traces connecting them. Multi-layer PCBs have several layers of conductive traces and insulating material sandwiched together. Flexible PCBs are made from a flexible plastic material, allowing them to bend and twist for use in applications where traditional rigid PCBs are not suitable. Each type of PCB serves a different purpose and can be used in a variety of electronic devices and applications.

15.What materials are used to make a a56-001 z60 pcb layout?

We have advanced production equipment and technology to meet the needs of customers, and can provide customers with high quality, low priced a56-001 z60 pcb layout products.

A PCB, or printed circuit board, is typically made of a non-conductive material such as fiberglass or composite epoxy resin. This material acts as a base for a thin layer of copper foil, which is then etched to create the desired circuit pattern. Other common materials used in the production of PCBs include solder mask, a polymer layer used to insulate and protect the copper traces, and silkscreen, which is used to label and identify the different components on the PCB. In addition, various electronic components such as resistors, capacitors, and diodes are also mounted onto the PCB to form a functional electronic circuit. Other potential materials used in the production of PCBs include metal core, ceramics, and conductive ink, depending on the specific design and requirements of the circuit.

16.What is the function of a decoupling capacitor on a a56-001 z60 pcb layout?

We have rich industry experience and professional knowledge, and have strong competitiveness in the market.

A decoupling capacitor is a type of capacitor that is used to reduce or eliminate noise and interference in electronic circuits. It is typically placed on a PCB (printed circuit board) near the power supply pins of an integrated circuit (IC) or other active component.

The main function of a decoupling capacitor is to provide a stable and clean power supply to the IC or other active component. This is achieved by filtering out high-frequency noise and voltage fluctuations that can be caused by other components on the PCB or external sources.

In addition, a decoupling capacitor also helps to prevent voltage drops and spikes that can occur when the IC or other component suddenly draws a large amount of current. This is especially important for sensitive components that require a stable power supply to function properly.

17.What is the purpose of a solder mask on a a56-001 z60 pcb layout?

We have a good reputation and image in the industry. The quality and price advantage of a56-001 z60 pcb layout products is an important factor in our hard overseas market.

A solder mask is a thin layer of protective material applied to a printed circuit board (PCB) to prevent solder from bridging between conductive traces, pads, or vias during the soldering process. It also helps to protect the PCB from environmental factors such as moisture, dust, and corrosion. Additionally, the solder mask can provide insulation between conductive traces, reducing the risk of short circuits. It also helps to improve the overall appearance of the PCB by providing a uniform and professional finish.

18.What is the role of vias on a a56-001 z60 pcb layout?

Our company has many years of a56-001 z60 pcb layout experience and expertise.

Vias play a crucial role in connecting different layers of a printed circuit board (PCB). These small, plated holes act as conductive paths, allowing signals and power to pass through the board and reach various components. Vias are also essential for routing traces from one layer to another, optimizing the layout and reducing the size and complexity of the board. Additionally, vias provide structural support and improve thermal management by facilitating heat dissipation.

RELATED PRODUCTS & SERVICE

pcb board manufacturing How To Contact US

PCB from 1 to 30 layers, HDI, Heavy Copper, Rigid-flex board with "pcb board manufacturing One-Stop" service.