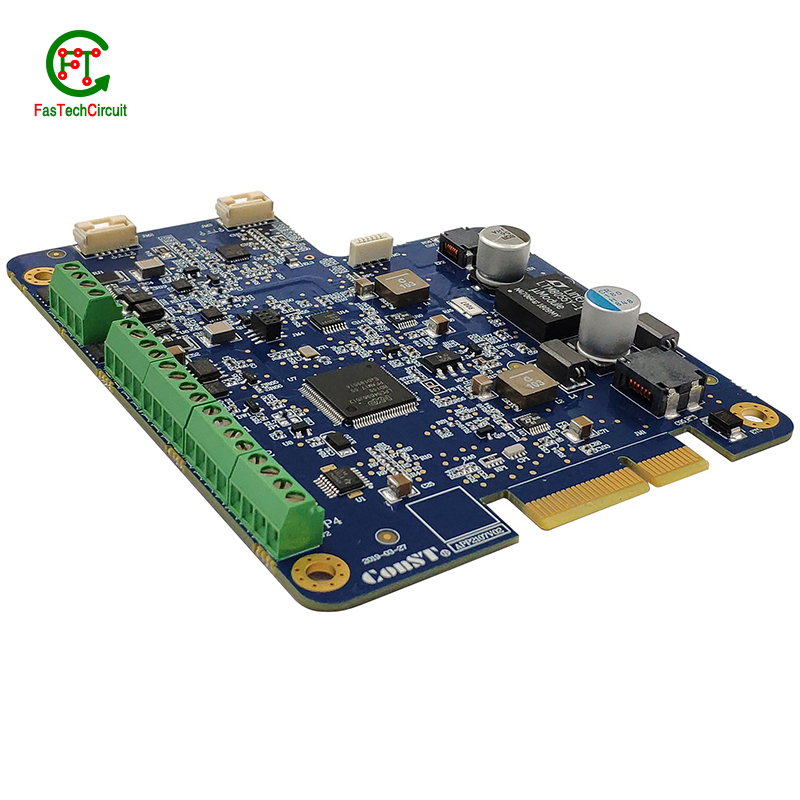

about pcb circuit

We can provide one-stop OEM service, and we constantly improve ourselves to keep up with international development levels. Since its establishment, we have passed ISO9001:2000, UL, TS16949:2002, ISO14001:2004 and other certifications. The purpose of our company is that quality and integrity are the lifeline! We strictly control quality to meet customers' needs, and our products are exported to more than 40 countries including North America, Europe, and Estonia,Holy See (Vatican City),Montserrat.

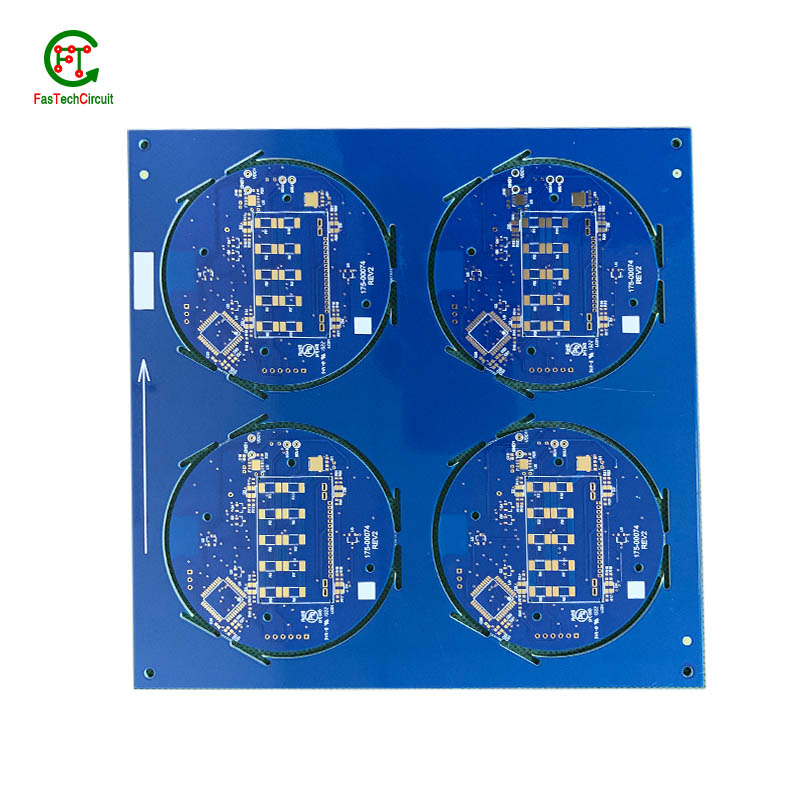

| Base Material | FR-4/CEM-1/CEM-3/Polyimild/PTFE/Rogers |

| Board Thickness | 0.2-9mm |

| Model Number | Custom PCB & PCB Assembly |

| Type | Aluminum PCB |

| Brand Name | FC |

| Copper Thickness | 0.3-2mil(15-54um) |

| Min. Hole Size | 0.1mm(4mil)for HDI / 0.15mm(6mil) |

| Min. Line Width | 0.075mm/0.075mm(3mil/3mil) |

| Min. Line Spacing | 0.003'' |

| Surface Finishing | HASL/OSP/Ag/ENIG/ENEPIG/Immersion silver/Tin |

| Board Size | Custom |

| Model Number | Customized |

| Base Material | FR4 Aluminum CEM-1 94V0 |

| Surface Finishing | HASLENIG OSP |

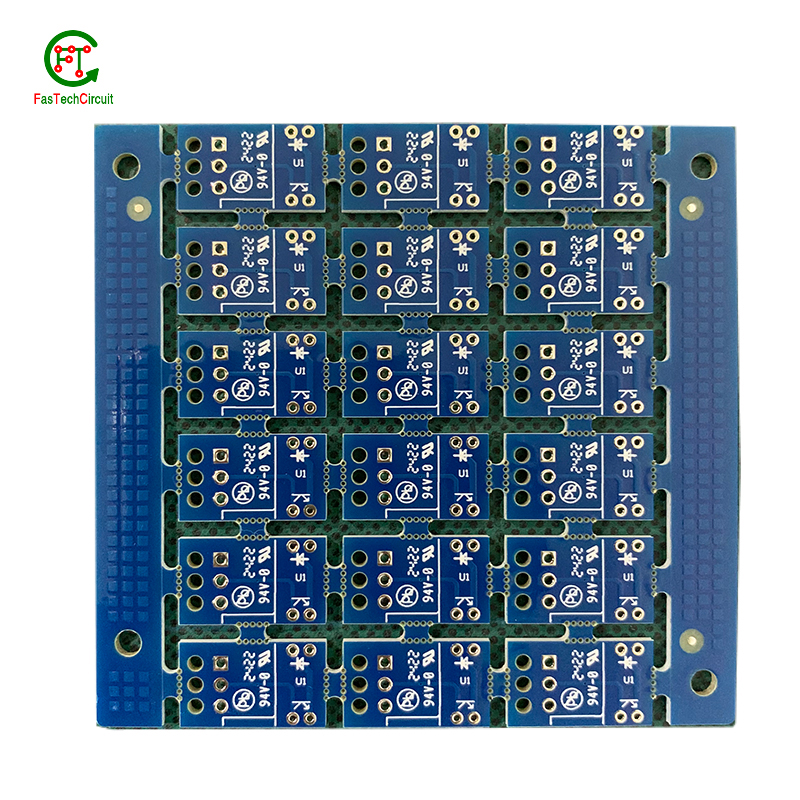

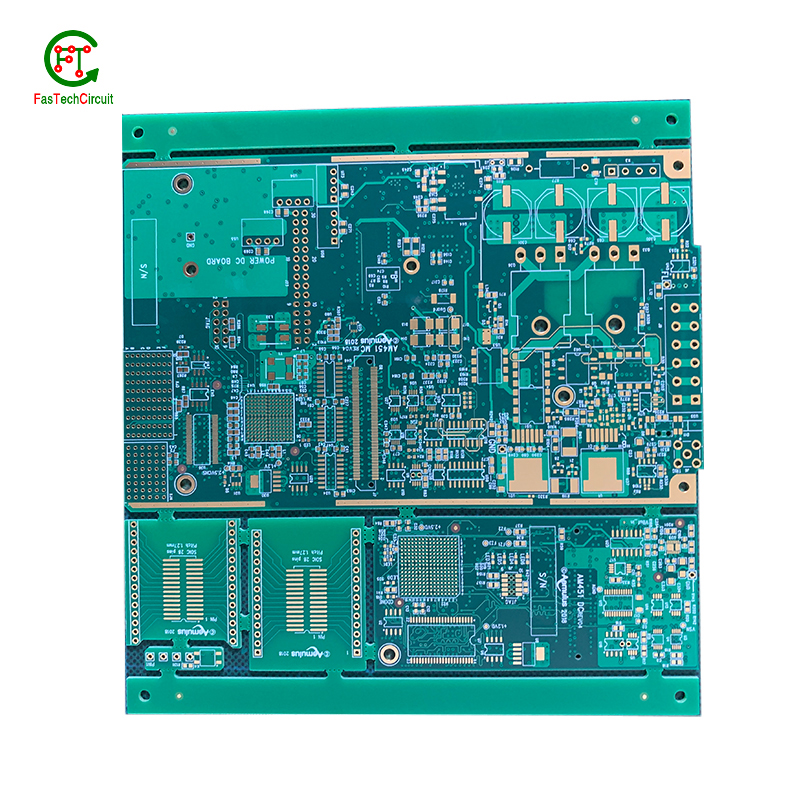

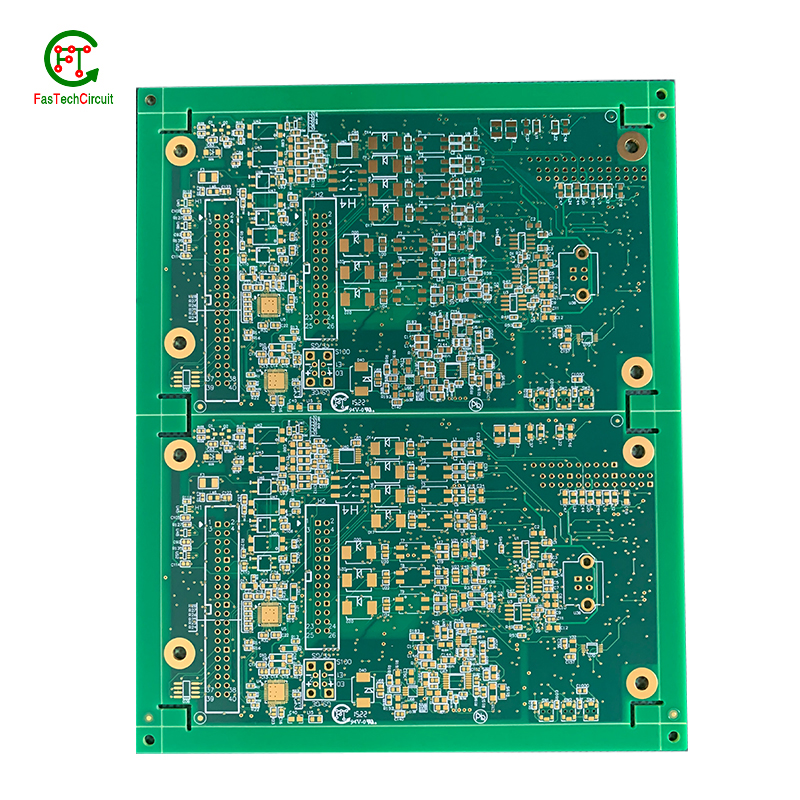

| Number of layer | 1-18layer |

| Other service | Components purchasing and assem |

| ly Solder mask | White Black Green Blue,Red,etc. |

| Dsign service | Available |

| Testing | Function testing |

| Certificate | RoHS, ISO/TS16949, ISO9001 |

| Name | High Quality led light aluminum pcb printed circuit board |

| Packaging Details | Vaccum package and standard carton outside High Quality led light aluminum pcb printed circuit board |

| Supply Ability | 44730 Square Meter/Square Meters per Month |

| Quantity (pieces) | > 24157 |

| Lead time (days) | 7 |

about pcb circuit bearings FAQs Guide Welcome to our state-of-the-art PCB (Printed Circuit Board) products. We are proud to offer a comprehensive range of high-quality and versatile PCB solutions to meet the constantly evolving needs of the modern electronics industry.Our PCBs are expertly designed and manufactured using the latest technology and advanced techniques, ensuring reliability, durability, and exceptional performance for a wide range of applications. We understand the importance of precision and attention to detail in the production of PCBs and we are committed to meeting stringent quality standards.

2.What is noise coupling and how can it be prevented on a about pcb circuit?

3.How are thermal considerations taken into account during about pcb circuit design?

4.What types of about pcb circuits are there?

5.What are some common problems that can occur with about pcb circuit?

6.How are about pcb circuit used in medical devices?

7.What is the function of a decoupling capacitor on a about pcb circuit?

8.What is the difference between single-sided, double-sided, and multi-layer about pcb circuit?

9.What is the function of a resistor on a about pcb circuit?

10.What type of material is used for the silkscreen on a about pcb circuit?

11.What are the advantages of using a about pcb circuit?

12.What is the difference between a diode and a capacitor?

13.What is the standard thickness for copper used in about pcb circuits?

14.How are components attached to a about pcb circuit?

15.What is embedded about pcb circuit technology?

16.What is the role of vias on a about pcb circuit?

17.How are signal traces routed on a about pcb circuit?

18.How are high-speed/high-frequency about pcb circuit tested and validated?

1.Can about pcb circuits be used in high-frequency applications?

Our mission is to provide customers with the best solutions for about pcb circuit.

Yes, PCBs (printed circuit boards) can be used in high-frequency applications. However, the design and construction of the PCB must be carefully considered to ensure optimal performance at high frequencies. This includes using specialized materials, such as high-frequency laminates, and implementing proper grounding and shielding techniques. Additionally, the layout and routing of the PCB must be optimized to minimize signal loss and interference.

2.What is noise coupling and how can it be prevented on a about pcb circuit?

We are a professional about pcb circuit company dedicated to providing high quality products and services.

Signal traces on a PCB (printed circuit board) are routes created to connect electronic components and allow for the transfer of electrical signals. These traces are typically made from copper and are carefully routed and designed to ensure efficient and reliable signal flow. The routing of signal traces is a critical aspect of PCB design and involves determining the best paths for the traces to minimize interference and optimize signal integrity. This is achieved through techniques such as controlled impedance routing, differential pair routing, and length-matching. Properly routing signal traces on a PCB is crucial for ensuring a functional and high-performance electronic circuit.

3.How are thermal considerations taken into account during about pcb circuit design?

As one of the top about pcb circuit manufacturers in China, we take this very seriously.

Thermal considerations are crucial in the design of printed circuit boards (PCB), as excessive heat can greatly affect the performance and lifespan of electronic components. PCB design engineers must carefully consider thermal management strategies, such as proper placement of heat-generating components, effective heat dissipation techniques, and optimal selection of materials. Thermal simulations and analysis are also commonly used to evaluate and optimize the PCB design to ensure that the temperature of the PCB and its components are within safe limits. By taking into account these thermal considerations, the finished PCB can perform reliably and efficiently, ensuring the overall quality and function of electronic devices.

4.What types of about pcb circuits are there?

As one of the about pcb circuit market leaders, we are known for innovation and reliability.

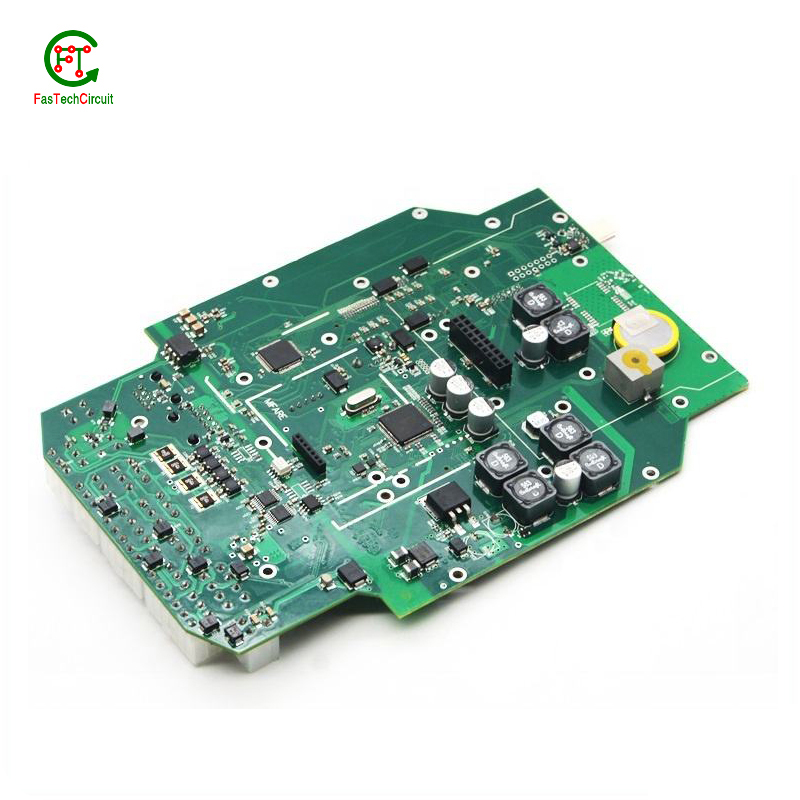

There are several types of PCBs, including single-sided, double-sided, multi-layer, and flexible PCBs. Single-sided PCBs have components mounted on one side and conductive traces on the other. Double-sided PCBs have components mounted on both sides with conductive traces connecting them. Multi-layer PCBs have several layers of conductive traces and insulating material sandwiched together. Flexible PCBs are made from a flexible plastic material, allowing them to bend and twist for use in applications where traditional rigid PCBs are not suitable. Each type of PCB serves a different purpose and can be used in a variety of electronic devices and applications.

5.What are some common problems that can occur with about pcb circuit?

Our about pcb circuit products undergo strict quality control to ensure customer satisfaction.

PCB (printed circuit boards) are an integral part of electronic devices, serving as the foundation for electrical connections and components. However, like any other technology, there are certain issues that may arise with PCB. One common problem is damage to the board due to excessive heat, as electronic components generate heat and if the PCB is not properly designed or ventilated, it can lead to malfunctions or even permanent damage. Another issue is poor soldering, which can result in weak connections or no connection at all. This can be caused by inadequate equipment or inexperience in the assembly process. Additionally, PCB can also suffer from corrosion over time, especially in high humidity environments, affecting its performance and reliability. It is important to address these problems early on to prevent further damage and ensure the functionality of electronic devices. Regular maintenance, proper design and assembly techniques, and use of quality materials can help prevent these common issues with PCB.

6.How are about pcb circuit used in medical devices?

Printed Circuit Boards (PCBs) are essential components used in a wide range of medical devices, playing a crucial role in both diagnostic and treatment equipment. These devices require reliable and precise circuitry to accurately collect and process data, deliver therapies, and regulate medical procedures. PCBs are used in equipment such as MRI machines, pacemakers, defibrillators, and monitors, where their small size and high density make them ideal for compact and portable designs. In addition, PCBs are also used in medical implants, enabling a safe and secure connection between the device and the body. With their advanced technology, PCBs continue to be an integral part of the medical industry, ensuring the effectiveness and success of various medical procedures and treatments.

7.What is the function of a decoupling capacitor on a about pcb circuit?

We have rich industry experience and professional knowledge, and have strong competitiveness in the market.

A decoupling capacitor is a type of capacitor that is used to reduce or eliminate noise and interference in electronic circuits. It is typically placed on a PCB (printed circuit board) near the power supply pins of an integrated circuit (IC) or other active component.

The main function of a decoupling capacitor is to provide a stable and clean power supply to the IC or other active component. This is achieved by filtering out high-frequency noise and voltage fluctuations that can be caused by other components on the PCB or external sources.

In addition, a decoupling capacitor also helps to prevent voltage drops and spikes that can occur when the IC or other component suddenly draws a large amount of current. This is especially important for sensitive components that require a stable power supply to function properly.

8.What is the difference between single-sided, double-sided, and multi-layer about pcb circuit?

We have established a good reputation and reliable partnerships within the about pcb circuit industry.

Single-sided PCB (Printed Circuit Board) is a type of PCB that has components and traces on only one side of the board. The other side is usually used for soldering and mounting the board onto a larger circuit.

Double-sided PCB is a type of PCB that has components and traces on both sides of the board. The traces on both sides are connected through vias, which are small holes drilled through the board and plated with metal to create an electrical connection.

Multi-layer PCB is a type of PCB that has multiple layers of conductive material and insulating material sandwiched together. The layers are connected through vias, allowing for more complex and compact circuit designs. Multi-layer PCBs are used in more advanced and high-performance electronic devices.

9.What is the function of a resistor on a about pcb circuit?

We are a new about pcb circuit manufacturer.

The ground plane on a printed circuit board (PCB) serves as a reference point for the electrical signals that flow throughout the circuit. It is typically a large area of copper that is connected to the negative terminal of the power supply and serves as a low-impedance return path for current. Its main purpose is to provide a stable and uniform ground connection for the components on the PCB, helping to reduce electromagnetic interference and ensuring proper signal grounding. Without a ground plane, the circuit may experience noise and other unwanted effects, potentially causing malfunctions or disruptions in its functionality. Therefore, the ground plane plays a crucial role in ensuring the overall performance and reliability of a PCB.

10.What type of material is used for the silkscreen on a about pcb circuit?

We have a wide range of about pcb circuit customer groups and establishes long -term cooperative relationships with partners. The countries we provide services include .

The material used for the silkscreen on a PCB is typically a white or black ink made of epoxy or acrylic. It is applied using a screen printing process and is cured at high temperatures to ensure durability and resistance to chemicals and solvents.

11.What are the advantages of using a about pcb circuit?

We are centered on customers and always pay attention to customers' needs for about pcb circuit products.

There are several advantages of using a PCB (Printed Circuit Board). Firstly, a PCB provides a compact and organized layout for electronic components, which makes it easier for technicians to troubleshoot and repair any issues. Secondly, it reduces the chances of loose connections and short circuits, which can be a major safety concern. Thirdly, PCBs are cost-effective and can be easily mass-produced, making them a popular choice for large-scale production. Additionally, they offer durability and stability, ensuring long-lasting performance. Finally, PCBs also allow for easy integration of new components, making it easier to upgrade or modify the electronic devices.

12.What is the difference between a diode and a capacitor?

We have a first -class management team, and we pay attention to teamwork to achieve common goals.

A diode is an electronic component that allows current to flow in only one direction. It has two terminals, an anode and a cathode, and works by allowing current to flow from the anode to the cathode, but not in the reverse direction.

A capacitor, on the other hand, is an electronic component that stores electrical energy in an electric field. It has two conductive plates separated by an insulating material, and when a voltage is applied, one plate accumulates a positive charge and the other accumulates a negative charge. This allows the capacitor to store energy and release it when needed.

13.What is the standard thickness for copper used in about pcb circuits?

The standard thickness for copper used in PCBs is 1 ounce (oz) or 35 micrometers (µm). However, thicker copper layers such as 2 oz or 3 oz can also be used for higher current carrying capacity or better heat dissipation. The thickness of copper used in a PCB is determined by the design requirements and the intended use of the board.

14.How are components attached to a about pcb circuit?

We adhere to the principle of integrity and transparency, and establish long -term relationships with partners, and we attach great importance to this detail.

eads or pins of the component and melting solder onto them, whicComponents are attached to a PCB (printed circuit board) through a process called soldering. This involves heating the metal lh then solidifies and creates a strong electrical and mechanical connection between the component and the PCB. There are two main methods of soldering components onto a PCB:

1. Through-hole soldering: This method involves inserting the leads or pins of the component through pre-drilled holes on the PCB and soldering them on the opposite side of the board. This method is commonly used for larger components such as resistors, capacitors, and integrated circuits.

2. Surface mount soldering: This method involves soldering the component directly onto the surface of the PCB, without the need for pre-drilled holes. This is done using specialized equipment such as a soldering iron or a reflow oven. Surface mount components are smaller in size and are commonly used for more complex and compact electronic devices.

15.What is embedded about pcb circuit technology?

Our products & services cover a wide range of areas and meet the needs of different fields.

Embedded PCB technology refers to the integration of electronic components directly onto a printed circuit board (PCB) during the manufacturing process. This allows for a more compact and efficient design, as well as improved reliability and performance. The components are embedded within the layers of the PCB, rather than being mounted on the surface, resulting in a more streamlined and durable product. This technology is commonly used in applications such as smartphones, tablets, and other portable electronic devices.

16.What is the role of vias on a about pcb circuit?

Our company has many years of about pcb circuit experience and expertise.

Vias play a crucial role in connecting different layers of a printed circuit board (PCB). These small, plated holes act as conductive paths, allowing signals and power to pass through the board and reach various components. Vias are also essential for routing traces from one layer to another, optimizing the layout and reducing the size and complexity of the board. Additionally, vias provide structural support and improve thermal management by facilitating heat dissipation.

17.How are signal traces routed on a about pcb circuit?

Signal traces are an essential element of a PCB, responsible for carrying electronic signals between components and ensuring proper communication and functionality of the circuit. To route these traces, designers use specialized software to determine the most efficient and optimal path for each signal, taking into account factors such as signal integrity, trace length, and potential interference. This process involves careful planning, as well as techniques such as vias, ground and power planes, and differential pairs to minimize noise and maintain signal integrity.

18.How are high-speed/high-frequency about pcb circuit tested and validated?

Testing and validation are essential steps in the production process of high-speed and high-frequency printed circuit boards (PCBs). These specialized types of PCBs are used in a wide range of industries, including telecommunications, aerospace, and automotive, and require precision and reliability in their performance.

The testing and validation process for high-speed/high-frequency PCBs involves several steps to ensure that the final product meets the required specifications. This starts with design simulation and analysis using specialized software to verify the layout and electrical characteristics of the PCB.

Once the design is confirmed, prototype PCBs are manufactured and subjected to various tests, including signal integrity and power integrity tests. These tests evaluate the electrical performance of the PCB, such as its ability to transmit signals at high speeds and maintain signal integrity.

In addition to electrical tests, environmental and mechanical tests are also performed to assess the durability and reliability of the PCB under different conditions, such as temperature changes and mechanical stress.

The final step in the testing and validation process is the inspection and analysis of the tested PCBs. This involves a detailed review of the test results and any necessary modifications to meet the required specifications.

RELATED PRODUCTS & SERVICE

pcb board manufacturing How To Contact US

PCB from 1 to 30 layers, HDI, Heavy Copper, Rigid-flex board with "pcb board manufacturing One-Stop" service.