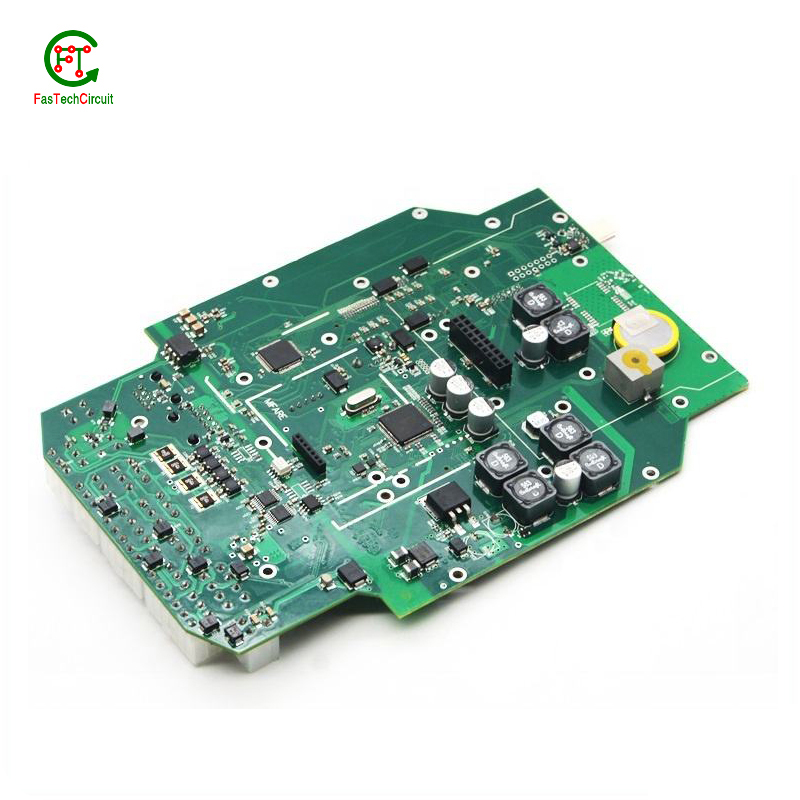

18650 pcb bms protection board

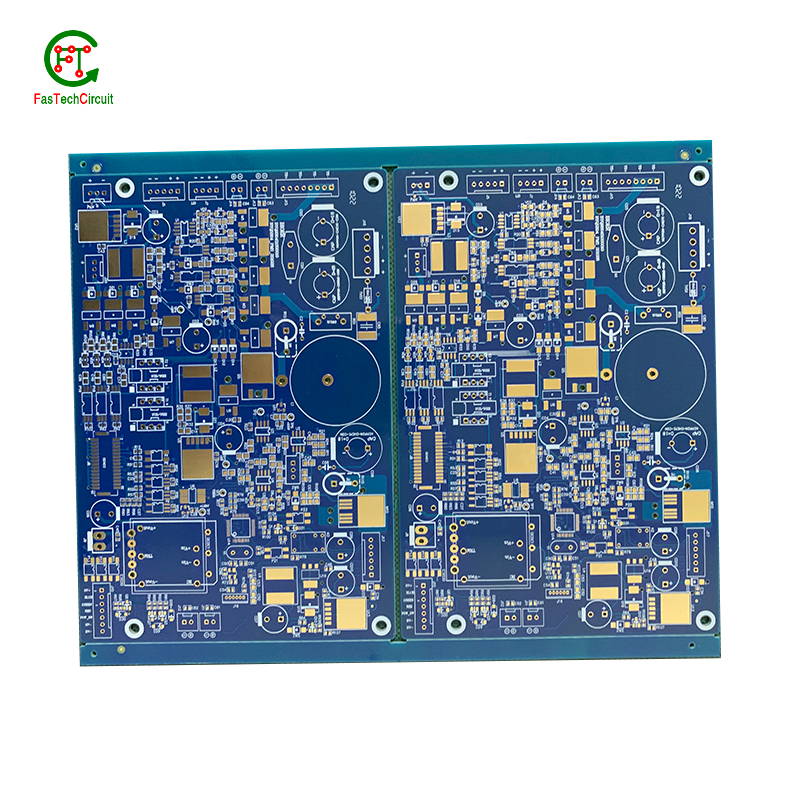

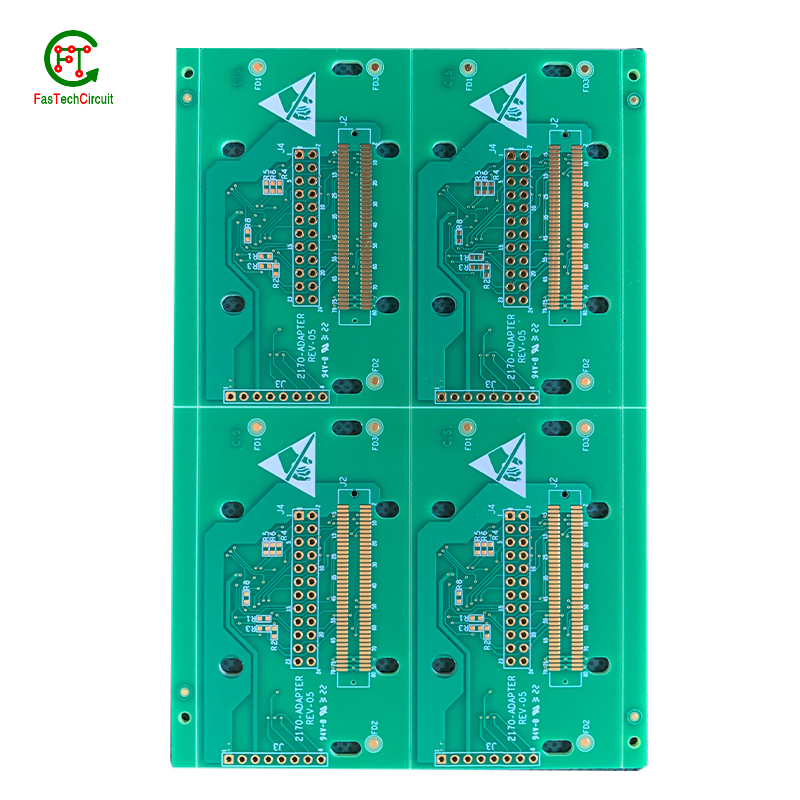

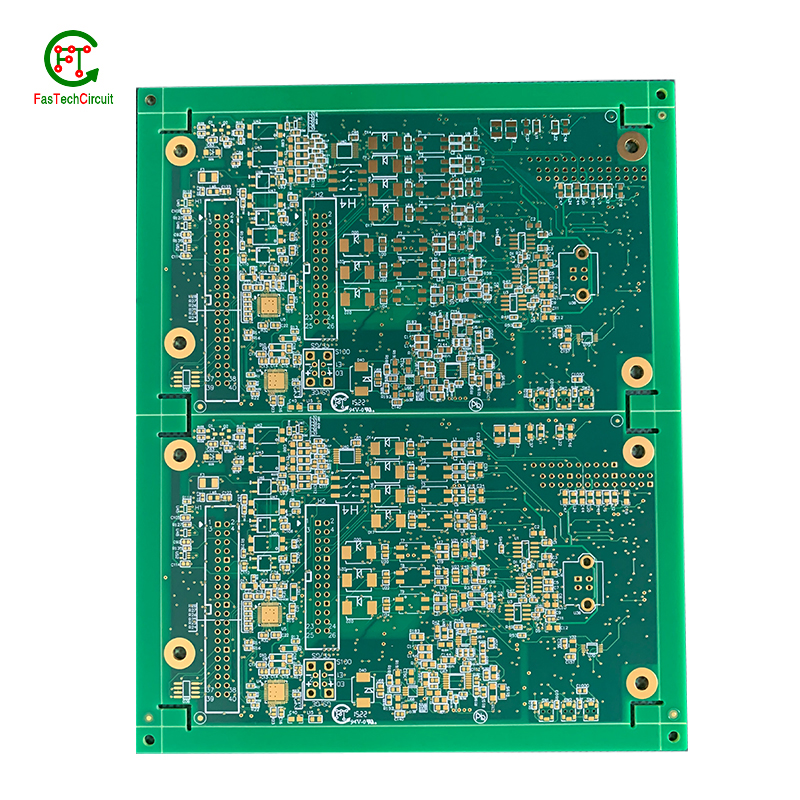

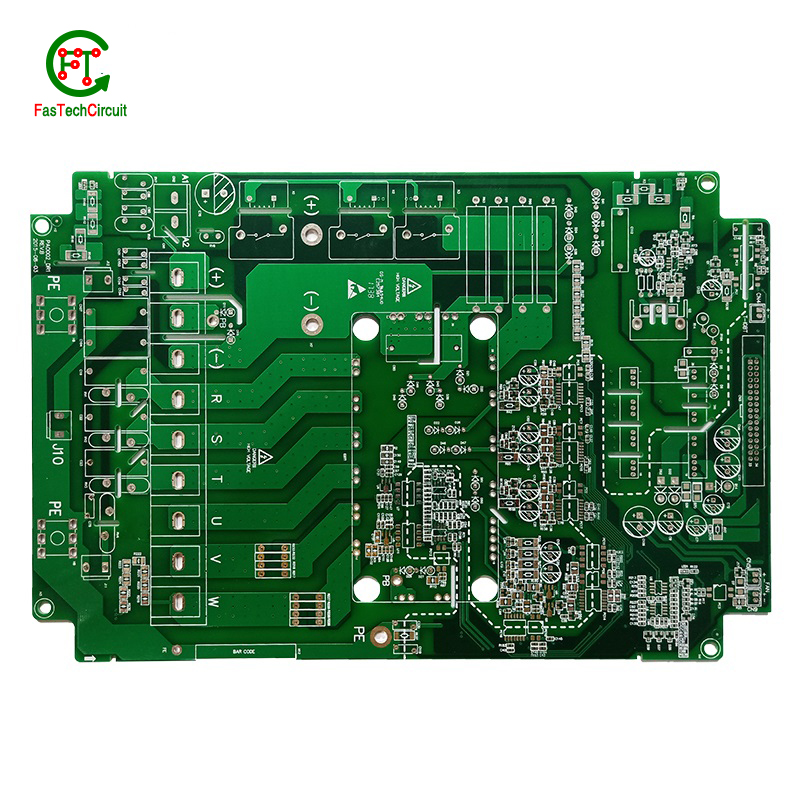

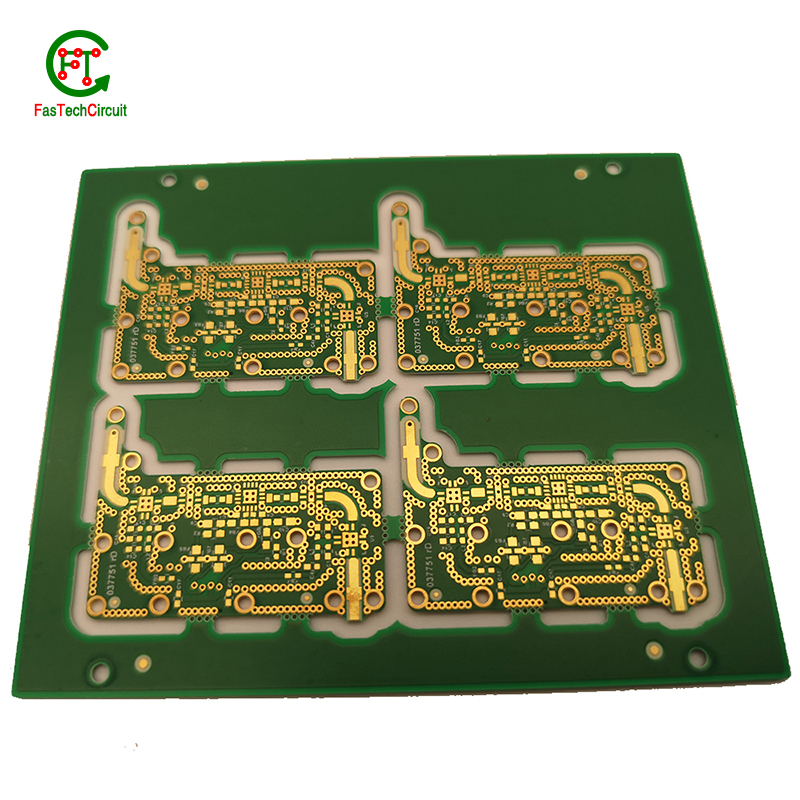

FasTechCircuit's products cover single-panel, double-panel, multi-layer boards, rigid boards, flexible boards, hybrid (rigid-soft) boards and other types. According to customer needs and application fields, we can provide PCB products of different materials and processes, such as FR-4, aluminum substrates, ceramic substrates, etc. At the same time, we can also provide a variety of surface treatment processes according to customer needs, such as OSP, HASL, ENIG, etc., to ensure the reliability and stability of the circuit board. We also provide non-standard customization services and can customize production according to the special requirements provided by customers to meet their personalized needs.

FasTechCircuit's printed circuit board products are widely used in communication equipment, industrial control, consumer electronics, computers and peripheral equipment, medical equipment, aerospace and other fields. Our products undergo strict quality control, have high precision, high reliability and stability, and can meet customers' high requirements for electronic products. Our products are very popular in Jan Mayen,Greenland,Belgium,Isle of Man,Greece, the United States and Japan. Won high praise from customers.

| Number of Layers | 4 layer |

| Base Material | gold sinking |

| Board Thickness | 1.4MM |

| Board Size | 251M*561MM |

| Model Number | 4 layer pcb |

| Type | pcb |

| Place of Origin | Original |

| Brand Name | Original |

| Copper Thickness | 3OZ |

| Min. Hole Size | custom made |

| Min. Line Width | custom made |

| Min. Line Spacing | custom made |

| Surface Finishing | custom made |

| Impedance control | +/- 4% |

| Warpage | less than 1% |

| Packaging Details | New and Original, factory sealed packing, it will be pack in one of these packing type: Tube, Tray, Tape and Reel, Tape and Box, Bulk packing, Bag and etc. Please kindly contact us for more details. |

| Supply Ability | 9058 Piece/Pieces per Week |

| Quantity (pieces) | > 19448 |

| Lead time (days) | 12 |

18650 pcb bms protection board bearings FAQs Guide Welcome to our state-of-the-art PCB (Printed Circuit Board) products. We are proud to offer a comprehensive range of high-quality and versatile PCB solutions to meet the constantly evolving needs of the modern electronics industry.Our PCBs are expertly designed and manufactured using the latest technology and advanced techniques, ensuring reliability, durability, and exceptional performance for a wide range of applications. We understand the importance of precision and attention to detail in the production of PCBs and we are committed to meeting stringent quality standards.

2.What are the advantages of using a 18650 pcb bms protection board?

3.What are the benefits of using surface mount technology (SMT) for 18650 pcb bms protection board?

4.How are 18650 pcb bms protection boards designed?

5.How are through-hole components soldered onto a 18650 pcb bms protection board?

6.What software is used for 18650 pcb bms protection board design?

7.What is the maximum size of a 18650 pcb bms protection board?

8.What is the process of etching a 18650 pcb bms protection board?

9.How are holes drilled into a 18650 pcb bms protection board?

10.What types of 18650 pcb bms protection boards are there?

11.What is the role of automated optical inspection (AOI) in 18650 pcb bms protection board production?

12.Can 18650 pcb bms protection boards be used in automotive applications?

13.What is the purpose of a solder mask on a 18650 pcb bms protection board?

14.What is the role of a data sheet in 18650 pcb bms protection board design?

15.How are 18650 pcb bms protection board used in medical devices?

1.What is the maximum operating temperature of a 18650 pcb bms protection board?

We have a professional team that is committed to the innovation and development of 18650 pcb bms protection board.

The maximum operating temperature of a PCB (printed circuit board) can vary depending on the materials and components used in its construction. Generally, the maximum operating temperature for a standard FR4 PCB is around 130-140 degrees Celsius. However, specialized materials such as high-temperature laminates or ceramic substrates can withstand higher temperatures up to 200-250 degrees Celsius. The maximum operating temperature of a PCB should always be determined by the manufacturer's specifications and guidelines.

2.What are the advantages of using a 18650 pcb bms protection board?

We are centered on customers and always pay attention to customers' needs for 18650 pcb bms protection board products.

There are several advantages of using a PCB (Printed Circuit Board). Firstly, a PCB provides a compact and organized layout for electronic components, which makes it easier for technicians to troubleshoot and repair any issues. Secondly, it reduces the chances of loose connections and short circuits, which can be a major safety concern. Thirdly, PCBs are cost-effective and can be easily mass-produced, making them a popular choice for large-scale production. Additionally, they offer durability and stability, ensuring long-lasting performance. Finally, PCBs also allow for easy integration of new components, making it easier to upgrade or modify the electronic devices.

3.What are the benefits of using surface mount technology (SMT) for 18650 pcb bms protection board?

We focus on innovation and continuous improvement to maintain a competitive advantage.

Surface mount technology (SMT) is a popular method for assembling printed circuit boards (PCBs) that offers numerous benefits over traditional through-hole components. Firstly, SMT components are smaller and more compact, allowing for greater PCB density and reducing the overall size of the board. This makes SMT ideal for increasingly miniaturized electronics, such as smartphones and wearables. Additionally, SMT components are typically cheaper and easier to manufacture, leading to cost savings in both materials and labor. SMT also allows for automated assembly, resulting in faster and more efficient production processes. Furthermore, the smaller size of SMT components leads to improved electrical performance due to decreased parasitic effects and shorter signal paths. This makes SMT ideal for high-frequency applications.

4.How are 18650 pcb bms protection boards designed?

We should perform well in market competition, and the prices of 18650 pcb bms protection board products have a great competitive advantage.

Printed Circuit Boards, commonly known as PCBs, are an essential part of modern-day technology. They serve as the foundation for electronic devices and are crucial to their functionality. The process of designing a PCB involves several stages, starting with creating a schematic diagram that outlines the connections between various electronic components. This is followed by placement and routing, where the physical layout of the board is determined and traces are added to connect the components. PCB designers use advanced software to optimize the layout and ensure that it meets the necessary electrical and mechanical requirements. Once the design is finalized, manufacturers can use the design files to produce the PCB. Designing a PCB requires a combination of technical knowledge, creativity, and attention to detail to create a functional and efficient circuit board for a specific application.

5.How are through-hole components soldered onto a 18650 pcb bms protection board?

Through-hole components are soldered onto a printed circuit board (PCB) using a process called wave soldering. First, the PCB is fitted with all the necessary through-hole components, such as resistors, capacitors, and diodes. Then, the board is passed over a wave of molten solder, which flows through the holes in the PCB and creates a secure connection between the component and the board. The excess solder is removed and the board is inspected to ensure all components are properly soldered. This method of soldering provides a strong and reliable connection for through-hole components, making it a popular choice for electronic assembly.

6.What software is used for 18650 pcb bms protection board design?

Our 18650 pcb bms protection board products have competitive and differentiated advantages, and actively promote digital transformation and innovation.

Some popular software used for PCB design include:

1. Altium Designer

2. Eagle PCB

3. KiCad

4. OrCAD

5. PADS

6. Proteus

7. DipTrace

8. EasyEDA

9. CircuitMaker

10. DesignSpark PCB

7.What is the maximum size of a 18650 pcb bms protection board?

We pay attention to the introduction and training of talents, scientifically regulate the management system, and focus on cultural construction and team cohesion.

The maximum size of a PCB (printed circuit board) can vary depending on the manufacturer and theircapabilities. However, the industry standard maximum size for a single PCB panel is typically around 18 inches by 24 inches (457 mm by 610 mm). Larger PCBs can be created by combining multiple panels together. Some manufacturers may also have the capability to create custom-sized PCBs that exceed the industry standard maximum size.

8.What is the process of etching a 18650 pcb bms protection board?

We have flexible production capacity. Whether you are large orders or small orders, you can produce and release goods in a timely manner to meet customer needs.

PCB (Printed Circuit Board) etching is the process of creating a circuit pattern on a copper-clad board by using chemical etchants to selectively remove the unwanted copper. The process begins by transferring the circuit design onto a copper-clad board using various methods such as printing or photolithography. Next, the board is coated with a resist material, which protects the areas of copper that will eventually become the circuit traces. The board is then placed in an etching solution, typically a mixture of acid and water, which dissolves the unprotected copper. Once the desired circuit pattern is etched into the board, the resist material is removed, and the board is cleaned and inspected for any imperfections. PCB etching is a crucial step in the manufacturing of PCBs, as it creates the necessary conductive pathways for electronic components to be mounted and interconnected, making it an essential process in the production of electronic devices.

9.How are holes drilled into a 18650 pcb bms protection board?

We actively participate in the 18650 pcb bms protection board industry associations and organization activities. The corporate social responsibility performed well, and the focus of brand building and promotion.

Drilling holes into printed circuit boards (PCBs) is a critical part of the PCB manufacturing process. These holes are used for mounting electronic components and for creating electrical connections between different layers of the board. There are two main methods for drilling holes into a PCB – mechanical drilling and laser drilling. Mechanical drilling involves using a high speed drill bit to physically drill through the board, while laser drilling uses a high-powered laser to vaporize the material and create the holes. Both methods have their own advantages and are often used in combination to achieve the desired hole sizes and precision. Regardless of the method, the holes are carefully planned and executed to ensure the successful production of a high-quality PCB.

10.What types of 18650 pcb bms protection boards are there?

As one of the 18650 pcb bms protection board market leaders, we are known for innovation and reliability.

There are several types of PCBs, including single-sided, double-sided, multi-layer, and flexible PCBs. Single-sided PCBs have components mounted on one side and conductive traces on the other. Double-sided PCBs have components mounted on both sides with conductive traces connecting them. Multi-layer PCBs have several layers of conductive traces and insulating material sandwiched together. Flexible PCBs are made from a flexible plastic material, allowing them to bend and twist for use in applications where traditional rigid PCBs are not suitable. Each type of PCB serves a different purpose and can be used in a variety of electronic devices and applications.

11.What is the role of automated optical inspection (AOI) in 18650 pcb bms protection board production?

Automated optical inspection (AOI) plays a crucial role in the production of printed circuit boards (PCBs). It is a technology that uses advanced imaging techniques to detect and identify defects or errors on a PCB, such as missing components, incorrect placement, and faulty soldering. AOI has become an essential step in the production process as it helps manufacturers ensure the quality and reliability of their PCBs. By detecting and identifying defects at an early stage, AOI can significantly reduce the number of defects and increase the efficiency of the production process. Furthermore, AOI is able to perform inspections at a much faster rate and with higher accuracy compared to manual inspection, making it an indispensable tool for PCB production.

12.Can 18650 pcb bms protection boards be used in automotive applications?

Yes, PCBs (printed circuit boards) can be used in automotive applications. They are commonly used in various electronic systems in vehicles, such as engine control units, infotainment systems, and safety systems. PCBs offer a compact and reliable way to connect and control electronic components in vehicles. They are also designed to withstand harsh environmental conditions, such as temperature fluctuations, vibrations, and moisture, making them suitable for use in automotive applications.

13.What is the purpose of a solder mask on a 18650 pcb bms protection board?

We have a good reputation and image in the industry. The quality and price advantage of 18650 pcb bms protection board products is an important factor in our hard overseas market.

A solder mask is a thin layer of protective material applied to a printed circuit board (PCB) to prevent solder from bridging between conductive traces, pads, or vias during the soldering process. It also helps to protect the PCB from environmental factors such as moisture, dust, and corrosion. Additionally, the solder mask can provide insulation between conductive traces, reducing the risk of short circuits. It also helps to improve the overall appearance of the PCB by providing a uniform and professional finish.

14.What is the role of a data sheet in 18650 pcb bms protection board design?

A data sheet is an essential tool for PCB design, providing vital information and specifications for all of the components used in the design process. It contains detailed technical data, such as dimensions, electrical ratings, and performance characteristics, that allow designers to make informed decisions when selecting and placing components on a PCB. By referencing the data sheet, designers can ensure that each component is properly integrated into the overall design, following any necessary guidelines or restrictions. Additionally, data sheets also provide necessary information for the layout and routing of traces on the PCB, ensuring that the design can meet required performance specifications.

15.How are 18650 pcb bms protection board used in medical devices?

Printed Circuit Boards (PCBs) are essential components used in a wide range of medical devices, playing a crucial role in both diagnostic and treatment equipment. These devices require reliable and precise circuitry to accurately collect and process data, deliver therapies, and regulate medical procedures. PCBs are used in equipment such as MRI machines, pacemakers, defibrillators, and monitors, where their small size and high density make them ideal for compact and portable designs. In addition, PCBs are also used in medical implants, enabling a safe and secure connection between the device and the body. With their advanced technology, PCBs continue to be an integral part of the medical industry, ensuring the effectiveness and success of various medical procedures and treatments.

RELATED PRODUCTS & SERVICE

pcb board manufacturing How To Contact US

PCB from 1 to 30 layers, HDI, Heavy Copper, Rigid-flex board with "pcb board manufacturing One-Stop" service.