20w led pcb board module

Our customers mainly come from 50 regions around the world including Hungary,Norfolk Island,Virgin Islands,Algeria,Christmas Island,Lebanon. As an ISO9001 certified electronics assembly manufacturer, all projects we undertake are fully compliant with ROHS standards and quality assurance. Based on our engineering excellence and production capabilities in technology areas such as material analysis and storage, advanced equipment, reliability testing (AOI, X-RAY, ICT testing and functional testing), efficient SMT and THT assembly, we are recognized as a global leader in A PCBA supplier that more and more customers have trusted for a long time. Welcome to visit us for inspection at any time.

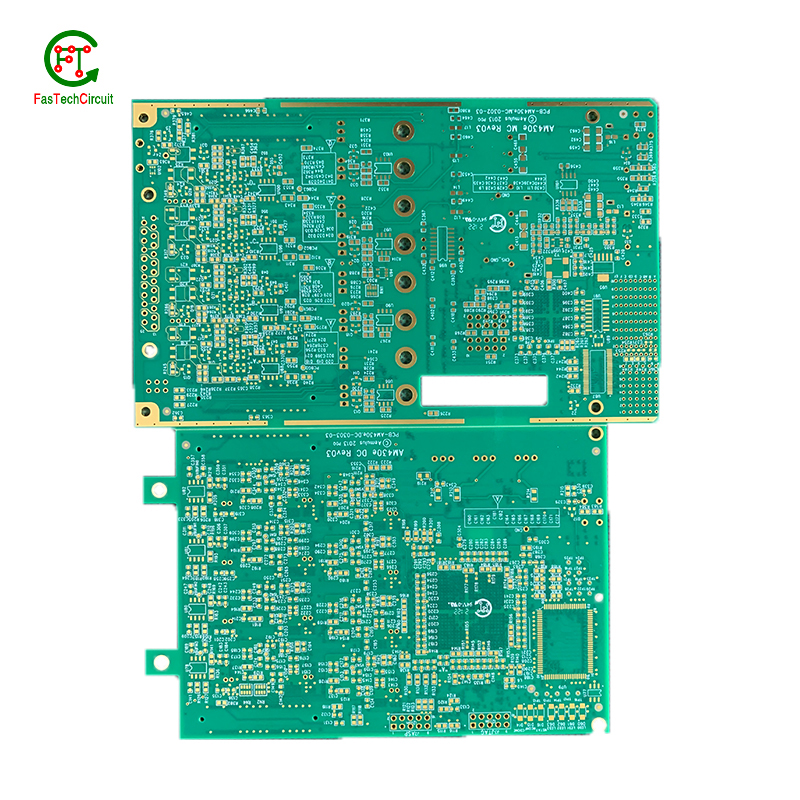

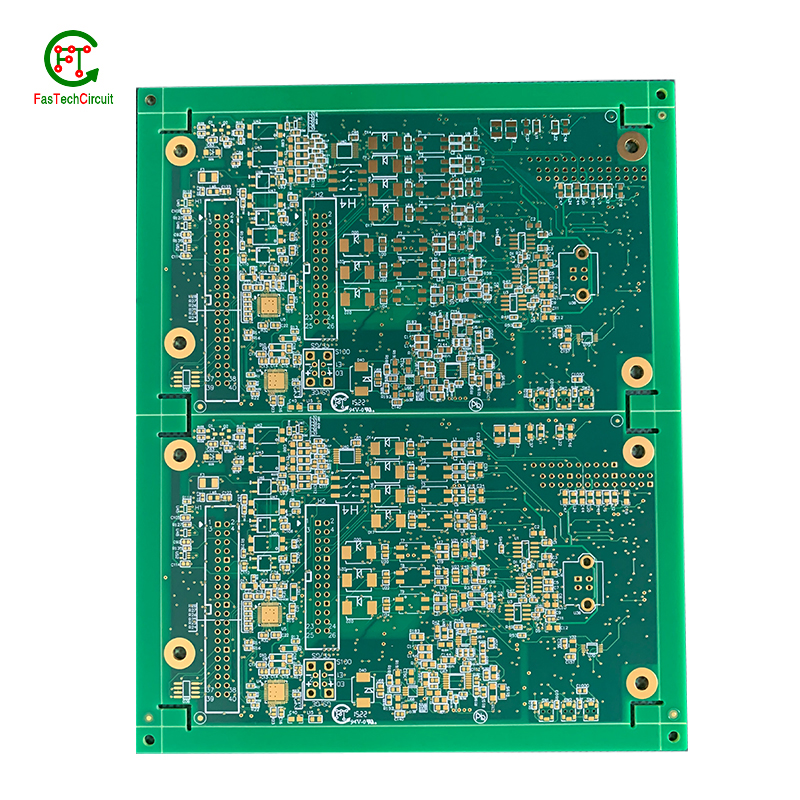

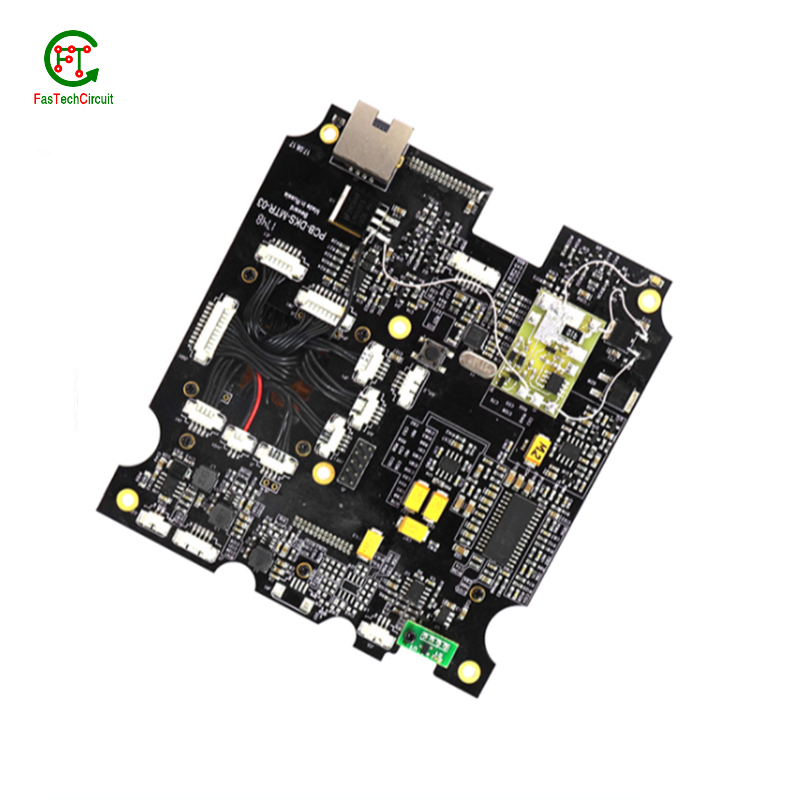

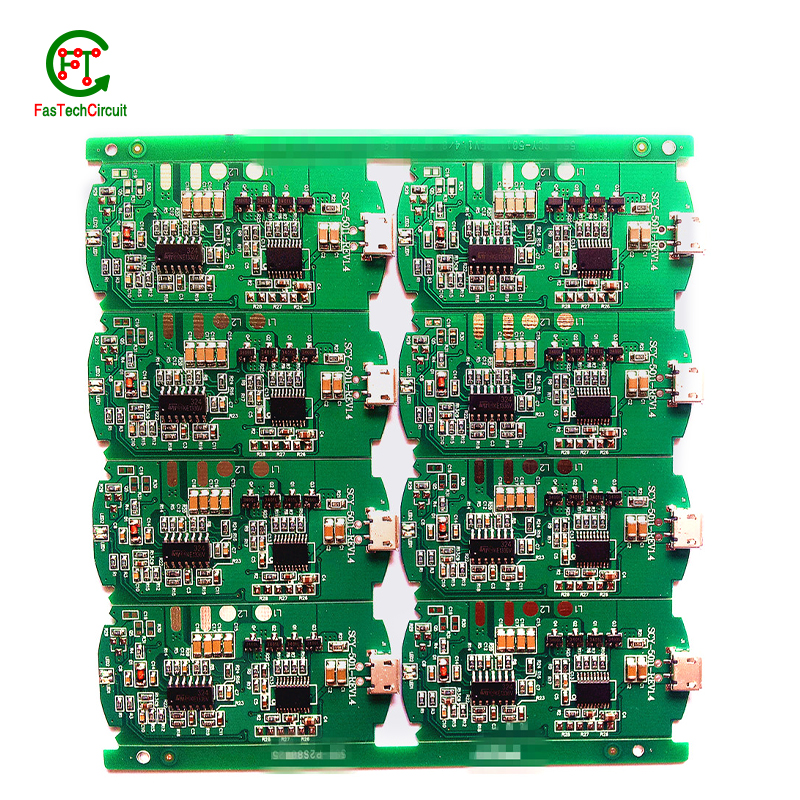

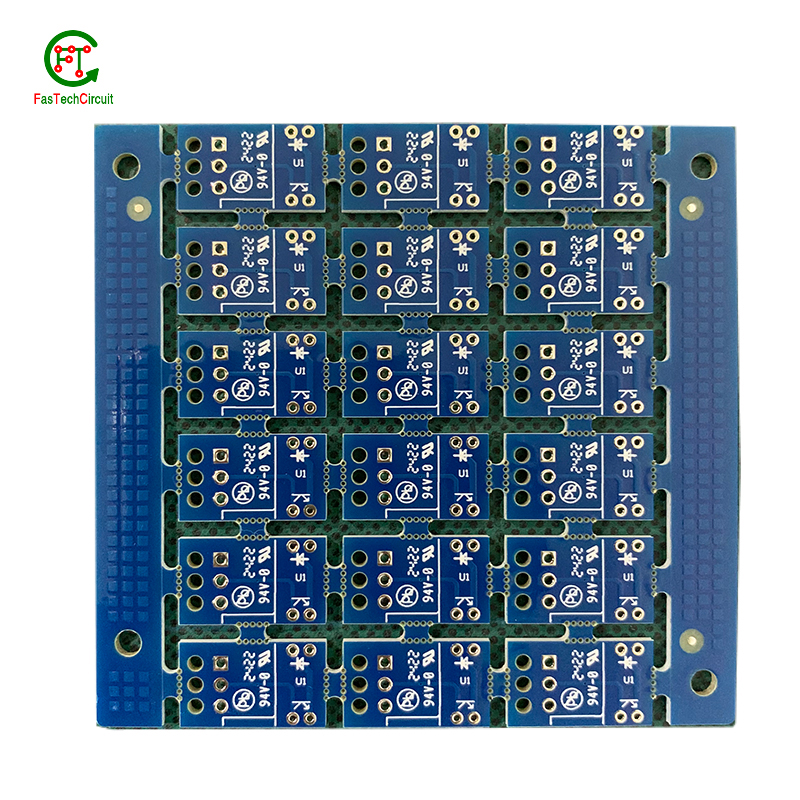

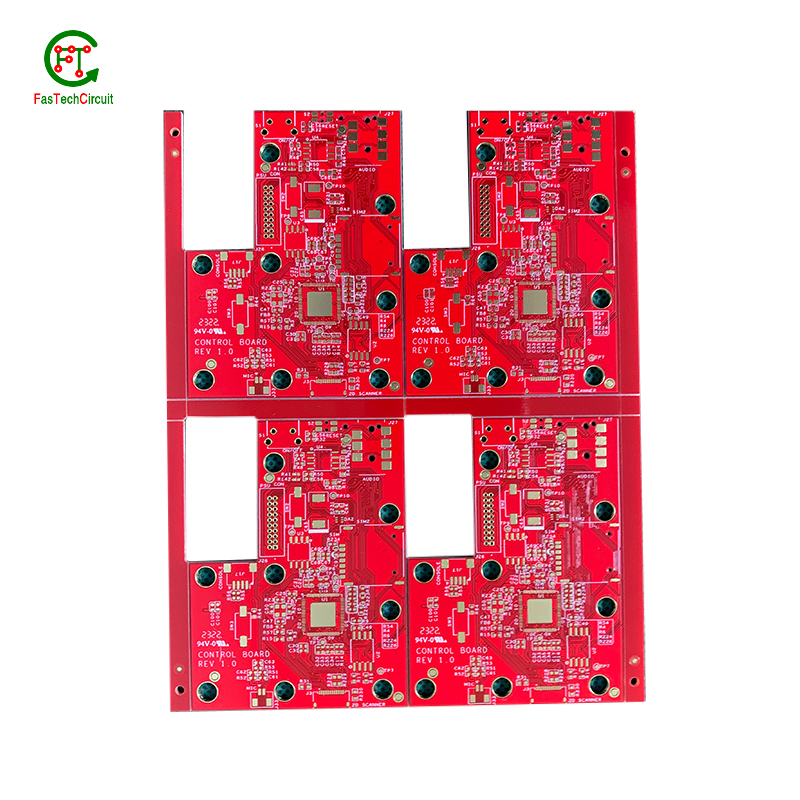

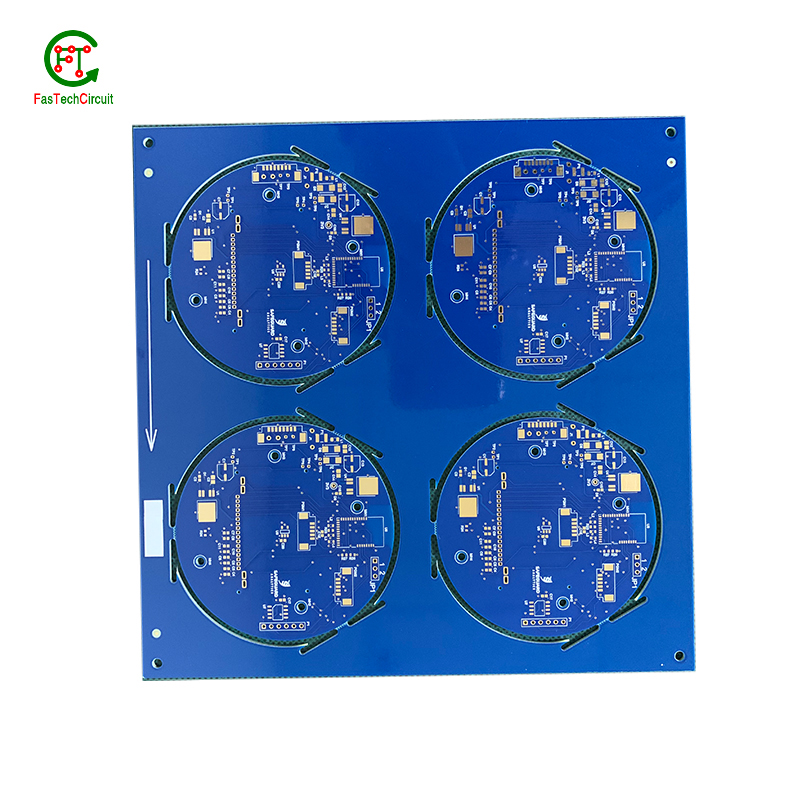

| Number of Layers | 4 layer |

| Base Material | gold sinking |

| Board Thickness | 3.3MM |

| Board Size | 320M*623MM |

| Model Number | 4 layer pcb |

| Type | pcb |

| Place of Origin | Original |

| Brand Name | Original |

| Copper Thickness | 3OZ |

| Min. Hole Size | custom made |

| Min. Line Width | custom made |

| Min. Line Spacing | custom made |

| Surface Finishing | custom made |

| Impedance control | +/- 3% |

| Warpage | less than 1% |

| Packaging Details | New and Original, factory sealed packing, it will be pack in one of these packing type: Tube, Tray, Tape and Reel, Tape and Box, Bulk packing, Bag and etc. Please kindly contact us for more details. |

| Supply Ability | 8326 Piece/Pieces per Week |

| Quantity (pieces) | > 11575 |

| Lead time (days) | 6 |

20w led pcb board module bearings FAQs Guide Welcome to our state-of-the-art PCB (Printed Circuit Board) products. We are proud to offer a comprehensive range of high-quality and versatile PCB solutions to meet the constantly evolving needs of the modern electronics industry.Our PCBs are expertly designed and manufactured using the latest technology and advanced techniques, ensuring reliability, durability, and exceptional performance for a wide range of applications. We understand the importance of precision and attention to detail in the production of PCBs and we are committed to meeting stringent quality standards.

2.Can a 20w led pcb board module be used with both through-hole and surface mount components?

3.What is noise coupling and how can it be prevented on a 20w led pcb board module?

4.What does 20w led pcb board module stand for?

5.What materials are used to make a 20w led pcb board module?

6.What are the advantages of using a 20w led pcb board module?

7.What is the role of automated optical inspection (AOI) in 20w led pcb board module production?

8.What type of solder is used for 20w led pcb board module assembly?

9.What is the difference between a gold-plated and a tin-plated 20w led pcb board module?

10.How are components attached to a 20w led pcb board module?

11.What is the lifespan of a 20w led pcb board module under harsh environmental conditions?

12.What is the function of a decoupling capacitor on a 20w led pcb board module?

13.What are the main components of a 20w led pcb board module?

14.What is the typical lifespan of a 20w led pcb board module?

15.How are components selected for a 20w led pcb board module design?

1.What is the difference between an analog and a digital signal on a 20w led pcb board module?

An analog signal is a continuous signal that varies in amplitude and frequency over time. It can take on any value within a given range and is typically represented by a smooth, continuous waveform. Analog signals are used to transmit information such as audio, video, and sensor data.

A digital signal, on the other hand, is a discrete signal that can only take on a limited number of values. It is represented by a series of binary digits (0s and 1s) and can only have two states: on or off. Digital signals are used to transmit information in the form of data and are commonly used in digital electronics such as computers and smartphones.

On a PCB, the main difference between analog and digital signals lies in the way they are processed and transmitted. Analog signals require specialized components such as amplifiers and filters to maintain their integrity, while digital signals can be processed and transmitted using digital logic circuits. Additionally, analog signals are more susceptible to noise and interference, while digital signals are more immune to these factors.

2.Can a 20w led pcb board module be used with both through-hole and surface mount components?

We continue to improve 20w led pcb board module products and processes to improve efficiency.

Yes, a PCB (printed circuit board) can be designed to accommodate both through-hole and surface mount components. This is known as a mixed-technology PCB. The PCB will have both through-hole and surface mount pads and traces, allowing for the placement and soldering of both types of components. This type of PCB is commonly used in electronic devices that require a combination of through-hole and surface mount components for functionality.

3.What is noise coupling and how can it be prevented on a 20w led pcb board module?

We are a professional 20w led pcb board module company dedicated to providing high quality products and services.

Signal traces on a PCB (printed circuit board) are routes created to connect electronic components and allow for the transfer of electrical signals. These traces are typically made from copper and are carefully routed and designed to ensure efficient and reliable signal flow. The routing of signal traces is a critical aspect of PCB design and involves determining the best paths for the traces to minimize interference and optimize signal integrity. This is achieved through techniques such as controlled impedance routing, differential pair routing, and length-matching. Properly routing signal traces on a PCB is crucial for ensuring a functional and high-performance electronic circuit.

4.What does 20w led pcb board module stand for?

We attach importance to the innovation ability and team spirit of employees, have advanced R & D facilities and laboratories, and have a good quality management system.

PCB stands for Printed Circuit Board.

5.What materials are used to make a 20w led pcb board module?

We have advanced production equipment and technology to meet the needs of customers, and can provide customers with high quality, low priced 20w led pcb board module products.

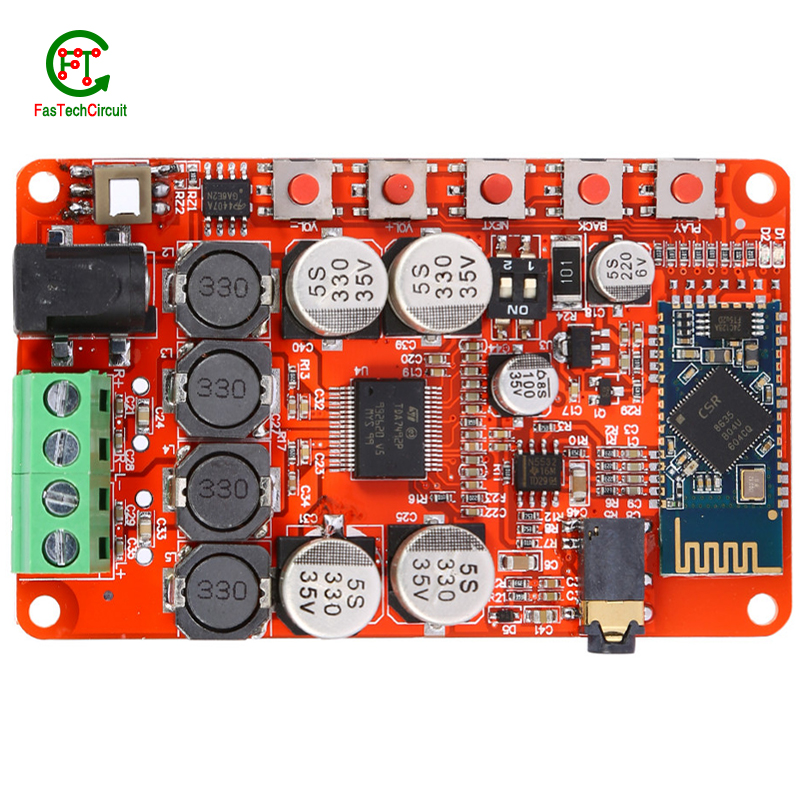

A PCB, or printed circuit board, is typically made of a non-conductive material such as fiberglass or composite epoxy resin. This material acts as a base for a thin layer of copper foil, which is then etched to create the desired circuit pattern. Other common materials used in the production of PCBs include solder mask, a polymer layer used to insulate and protect the copper traces, and silkscreen, which is used to label and identify the different components on the PCB. In addition, various electronic components such as resistors, capacitors, and diodes are also mounted onto the PCB to form a functional electronic circuit. Other potential materials used in the production of PCBs include metal core, ceramics, and conductive ink, depending on the specific design and requirements of the circuit.

6.What are the advantages of using a 20w led pcb board module?

We are centered on customers and always pay attention to customers' needs for 20w led pcb board module products.

There are several advantages of using a PCB (Printed Circuit Board). Firstly, a PCB provides a compact and organized layout for electronic components, which makes it easier for technicians to troubleshoot and repair any issues. Secondly, it reduces the chances of loose connections and short circuits, which can be a major safety concern. Thirdly, PCBs are cost-effective and can be easily mass-produced, making them a popular choice for large-scale production. Additionally, they offer durability and stability, ensuring long-lasting performance. Finally, PCBs also allow for easy integration of new components, making it easier to upgrade or modify the electronic devices.

7.What is the role of automated optical inspection (AOI) in 20w led pcb board module production?

Automated optical inspection (AOI) plays a crucial role in the production of printed circuit boards (PCBs). It is a technology that uses advanced imaging techniques to detect and identify defects or errors on a PCB, such as missing components, incorrect placement, and faulty soldering. AOI has become an essential step in the production process as it helps manufacturers ensure the quality and reliability of their PCBs. By detecting and identifying defects at an early stage, AOI can significantly reduce the number of defects and increase the efficiency of the production process. Furthermore, AOI is able to perform inspections at a much faster rate and with higher accuracy compared to manual inspection, making it an indispensable tool for PCB production.

8.What type of solder is used for 20w led pcb board module assembly?

The most commonly used solder for PCB assembly is a lead-free solder, specifically a tin-silver-copper (SnAgCu) alloy. This type of solder is preferred due to its high melting point, good wetting properties, and compatibility with surface mount technology (SMT) components. Other types of solder that may be used include tin-lead (SnPb) solder and lead-free alternatives such as tin-copper (SnCu) and tin-bismuth (SnBi) alloys. The specific type of solder used may vary depending on the application and industry standards.

9.What is the difference between a gold-plated and a tin-plated 20w led pcb board module?

A gold-plated PCB (Printed Circuit Board) is a type of PCB that has a thin layer of gold coating on its surface. This layer is added through a process called electroplating and is commonly used to protect the PCB components from corrosion and increase the conductivity. On the other hand, a tin-plated PCB has a layer of tin coating on its surface, which is also applied through electroplating. Unlike gold plating, tin plating is mainly used to prevent oxidization and improve solderability.

10.How are components attached to a 20w led pcb board module?

We adhere to the principle of integrity and transparency, and establish long -term relationships with partners, and we attach great importance to this detail.

eads or pins of the component and melting solder onto them, whicComponents are attached to a PCB (printed circuit board) through a process called soldering. This involves heating the metal lh then solidifies and creates a strong electrical and mechanical connection between the component and the PCB. There are two main methods of soldering components onto a PCB:

1. Through-hole soldering: This method involves inserting the leads or pins of the component through pre-drilled holes on the PCB and soldering them on the opposite side of the board. This method is commonly used for larger components such as resistors, capacitors, and integrated circuits.

2. Surface mount soldering: This method involves soldering the component directly onto the surface of the PCB, without the need for pre-drilled holes. This is done using specialized equipment such as a soldering iron or a reflow oven. Surface mount components are smaller in size and are commonly used for more complex and compact electronic devices.

11.What is the lifespan of a 20w led pcb board module under harsh environmental conditions?

The lifespan of a PCB (printed circuit board) under harsh environmental conditions can vary greatly depending on the specific conditions and the quality of the PCB. In general, a well-designed and high-quality PCB can last for 10-20 years under harsh conditions such as extreme temperatures, humidity, and exposure to chemicals or vibrations. However, if the PCB is not properly designed or manufactured, its lifespan can be significantly shorter, potentially lasting only a few years or even months. Factors such as the type of materials used, the thickness of the copper traces, and the quality of the solder joints can also affect the lifespan of a PCB under harsh environmental conditions. Regular maintenance and proper handling can also help extend the lifespan of a PCB.

12.What is the function of a decoupling capacitor on a 20w led pcb board module?

We have rich industry experience and professional knowledge, and have strong competitiveness in the market.

A decoupling capacitor is a type of capacitor that is used to reduce or eliminate noise and interference in electronic circuits. It is typically placed on a PCB (printed circuit board) near the power supply pins of an integrated circuit (IC) or other active component.

The main function of a decoupling capacitor is to provide a stable and clean power supply to the IC or other active component. This is achieved by filtering out high-frequency noise and voltage fluctuations that can be caused by other components on the PCB or external sources.

In addition, a decoupling capacitor also helps to prevent voltage drops and spikes that can occur when the IC or other component suddenly draws a large amount of current. This is especially important for sensitive components that require a stable power supply to function properly.

13.What are the main components of a 20w led pcb board module?

We continuously upgrade our skills and knowledge to adapt to changing 20w led pcb board module market needs.

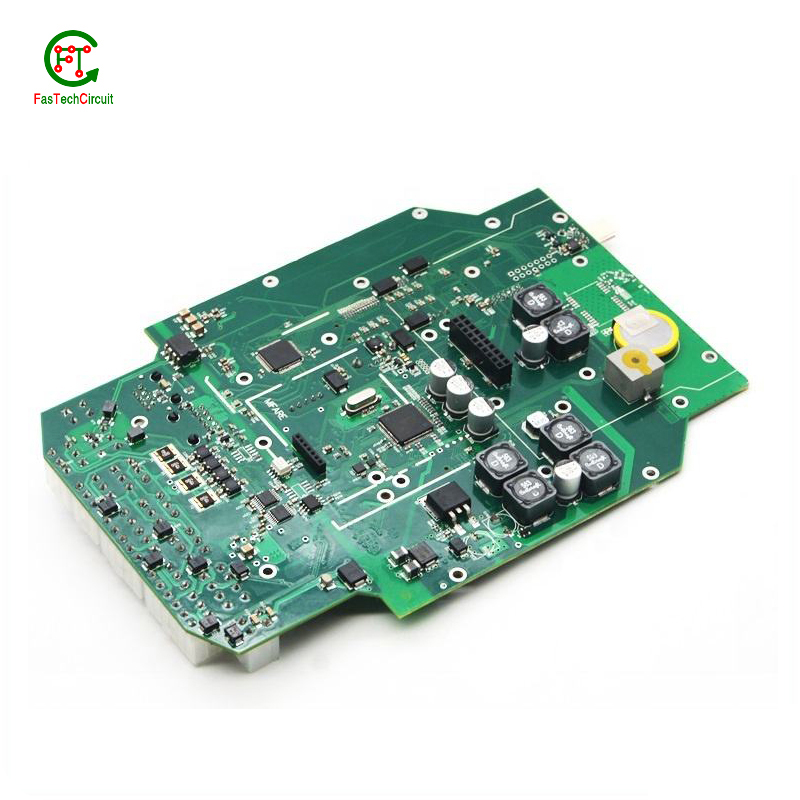

A typical PCB consists of several vital components, including a substrate material, copper traces, solder mask, silk screen, and plated through-holes. The substrate material acts as the base and provides mechanical support for the board. Copper traces, usually made of thin lines of copper foil, serve as the conductive paths for transmitting electrical signals. The solder mask, applied as a protective layer, prevents accidental short circuits and corrosion. Silk screen, a layer of ink-based labeling, aids in component identification. Lastly, plated through-holes enable electrical connection between different layers of the PCB board. These components work together to form a fully functioning PCB.

14.What is the typical lifespan of a 20w led pcb board module?

20w led pcb board module is not a product only, but also can help you comes to money-making.

The typical lifespan of a PCB (printed circuit board) can vary greatly depending on various factors such as the quality of materials used, environmental conditions, and usage. In general, a well-designed and properly manufactured PCB can last for 10-20 years or more. However, some PCBs may fail prematurely due to factors such as corrosion, thermal stress, or mechanical damage. Regular maintenance and proper handling can also extend the lifespan of a PCB.

15.How are components selected for a 20w led pcb board module design?

We pay attention to employee development and benefits, and provide a good working environment in order to improve the efficiency of employees and improve the quality management of 20w led pcb board module products.

A power rating for a PCB, or Printed Circuit Board, is a measure of the maximum amount of power the board is able to safely handle. This rating takes into account the overall design and materials used in the creation of the PCB, as well as the environment in which it will be used. It is an important consideration in electronics and circuit design as exceeding the power rating can lead to overheating and potential damage to the board and connected components. Properly understanding and adhering to the power rating of a PCB is crucial for ensuring safe and efficient operation of electronic devices.

RELATED PRODUCTS & SERVICE

pcb board manufacturing How To Contact US

PCB from 1 to 30 layers, HDI, Heavy Copper, Rigid-flex board with "pcb board manufacturing One-Stop" service.